Preparation method of CoV2O6 sheets

A lamellar, V2O5 technology, applied in chemical instruments and methods, inorganic chemistry, nanotechnology, etc., can solve the problems of difficult large-scale production, complex process, low efficiency, etc., achieve short reaction cycle, simple process, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Weigh 0.364 g of vanadium pentoxide powder, disperse it in 30 mL of deionized water, add 5 mL of hydrogen peroxide, and ultrasonically disperse for 30 minutes; , hydrothermal reaction for 72 hours; the hydrothermal product was centrifuged, washed and dried to obtain one-dimensional V 2 o 5 nanoribbons;

[0018] (2) Weigh 0.16 g of cobalt nitrate hexahydrate and 0.1 g of prepared V 2 o 5 The sample was controlled at a molar ratio of 1:1, dispersed in 10 mL of deionized water; dried after immersion for 12 hours, to obtain a brown powder sample;

[0019] (3) Put the product obtained in (2) into a box-type resistance furnace, heat-treat at 500°C for 2 hours, and obtain the composite powder after cooling.

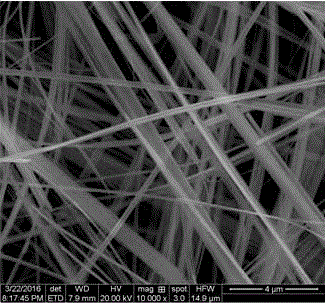

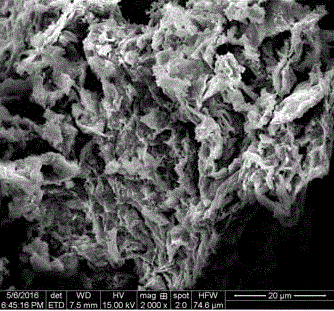

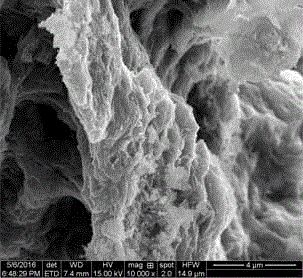

[0020] With the strip-shaped V prepared in Example 1 2 o 5 FESEM spectra of nanomaterials such as figure 1 As shown, it can be seen that the obtained product is a strip-like structure with uniform morphology; sheet-like CoV 2 o 6 The SEM pattern such as fig...

Embodiment 2

[0023] (1) Weigh 0.364 g of vanadium pentoxide powder, disperse it in 30 mL of deionized water, add 5 mL of hydrogen peroxide, and ultrasonically disperse for 30 minutes; , hydrothermal reaction for 72 hours; the hydrothermal product was centrifuged, washed and dried to obtain one-dimensional V 2 o 5 nanoribbons;

[0024] (2) Weigh 0.2 g of cobalt nitrate hexahydrate and 0.32 g of prepared V 2 o 5 The sample was controlled at a molar ratio of 1:1, dispersed in 15 mL of deionized water; dried after immersion for 12 hours, to obtain a brown powder sample;

[0025] (3) Put the product obtained in (2) into a box-type resistance furnace, heat-treat at 300 °C for 2 hours, and obtain the composite powder after cooling.

Embodiment 3

[0027] (1) Weigh 0.364 g of vanadium pentoxide powder, disperse it in 30 mL of deionized water, add 5 mL of hydrogen peroxide, and ultrasonically disperse for 30 minutes; , hydrothermal reaction for 72 hours; the hydrothermal product was centrifuged, washed and dried to obtain one-dimensional V 2 o 5 nanoribbons;

[0028] (2) Weigh 0.3 g of cobalt nitrate hexahydrate and 0.48 g of prepared V 2 o 5 The sample was controlled at a molar ratio of 1:1, dispersed in 20 mL of deionized water; dried after immersion for 12 hours, to obtain a brown powder sample;

[0029] (3) Put the product obtained in (2) into a box-type resistance furnace, heat-treat at 400 °C for 2 hours, and obtain the composite powder after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com