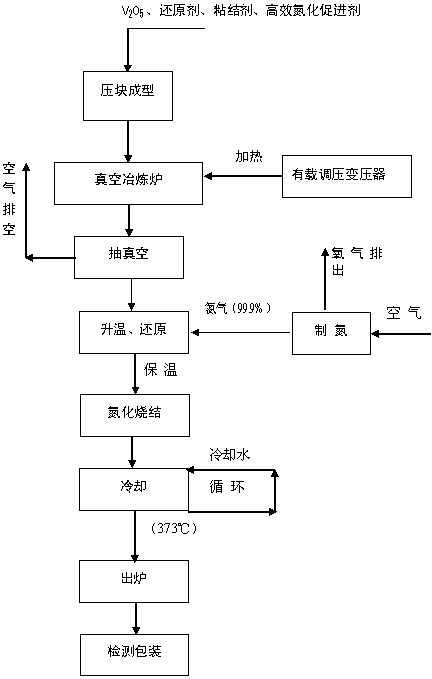

Production process for preparing high-nitrogen vanadium nitride by using vacuum furnace method

A production process and vacuum furnace technology, which is applied in the production process field of vanadium nitride production, can solve the problems of low equipment reliability, complex process, long production cycle, etc., and achieve stable production efficiency, accurate process control, and no environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Put 2.72 tons of high-purity vanadium pentoxide (V2O5 content ≥ 99.5%), 0.64 tons of reducing agent graphite powder, 0.48 tons of binder polyvinyl alcohol aqueous solution, and 0.2 tons of high-efficiency nitriding accelerator urea into the mixing equipment for Mixing, the total weight of the four materials is 4 tons, and the uniformly mixed materials are put into a four-column hydraulic press for compression molding. The shape of the pressed materials is a cylindrical cake of Φ50*30, and the materials are loaded into the conveying material trolley, each Put 1 ton on the car, put 4 cars for a total of 4 tons, push the 4 cars into the vacuum smelting furnace and seal it;

[0026] 2. Vacuumize the vacuum furnace to 50-100Pa, heat up to 800°C and keep it at this temperature for 3.5 hours to pre-reduce vanadium pentoxide and carbon, and then continue to heat up to 1300°C for 4 hours of deep reduction and carbonization, continuously filling nitrogen with a purity of more ...

Embodiment 2

[0031] 1. Put 4.08 tons of high-purity vanadium pentoxide (V2O5 content ≥ 99.5%), 0.96 tons of reducing agent graphite powder, 0.72 tons of binder polyvinyl alcohol aqueous solution, and 0.9 tons of high-efficiency nitriding accelerator urea into the stirring equipment for Mixing, the total weight of the four materials is 6 tons, and the uniformly mixed materials are put into the double-roller hydraulic forming machine for compression molding. The shape of the pressed materials is a 50*35*25 spherical shape, and the materials are loaded into the conveying materials Carts, each car puts 1.5 tons, puts 4 cars for a total of 6 tons, pushes 4 cars into the vacuum smelting furnace and seals them;

[0032]2. Vacuumize the vacuum furnace to 120Pa, heat up to 850°C and keep it at this temperature for 4 hours to pre-reduce vanadium pentoxide and carbon, and then continue to heat up to 1350°C for 6 hours of deep reduction and carbonization. During the process, nitrogen gas with a pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com