Micro-interface reinforced combined alkali production device and production method

A combined alkali production and interface technology, applied in products, carbonate preparations, reagents, etc., can solve the problems of limited absorption intensity, high equipment investment and power consumption, and low level of automation control, so as to improve the space-time yield and save raw materials. , the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

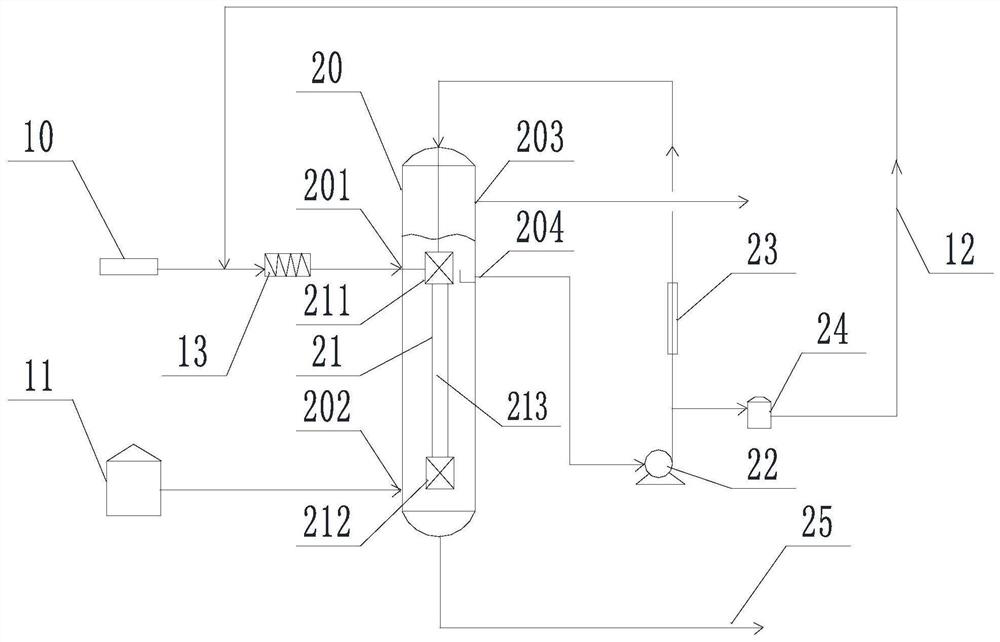

[0062] refer to figure 1 As shown, it is a schematic structural diagram of a device for micro-interface strengthening combined alkali production provided in this embodiment, and the device mainly includes: CO 2Air intake pipeline 10, AII liquid storage tank 11 and carbonization tower 20. A liquid inlet 202 is provided at the bottom of the carbonization tower 20 , and the AII liquid storage tank 11 is communicated with the liquid inlet 202 to send the AII liquid into the carbonization tower 20 . CO 2 The gas inlet pipeline 10 and the exhaust gas pipeline 12 of the crystallizer 24 are connected in parallel, and the mixed gas is delivered to the gas pressurizer 13, and the gas pressurizer 13 sends the gas from the gas inlet 201 of the carbonization tower 20 to the liquid of the composite microinterface generator 21. In the dynamic micro-interface generator 211, the hydraulic micro-interface generator 211 now disperses and breaks gas into gas microbubbles.

[0063] The gas micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com