Bag-making machine loading device

A bag making machine and receiving table technology, applied in bag making operation, packaging, transportation and packaging, etc., can solve problems such as low production efficiency, and achieve the effect of improving production efficiency, strong practicability and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

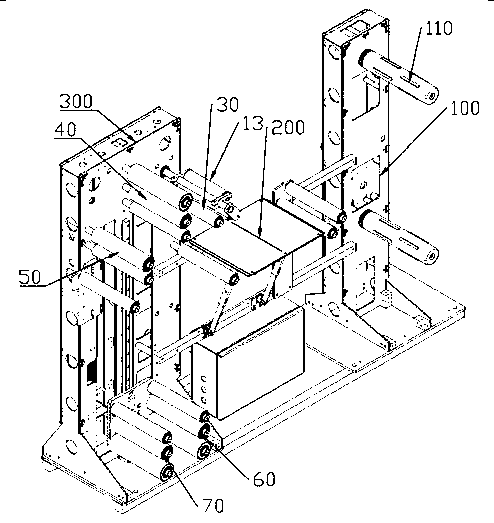

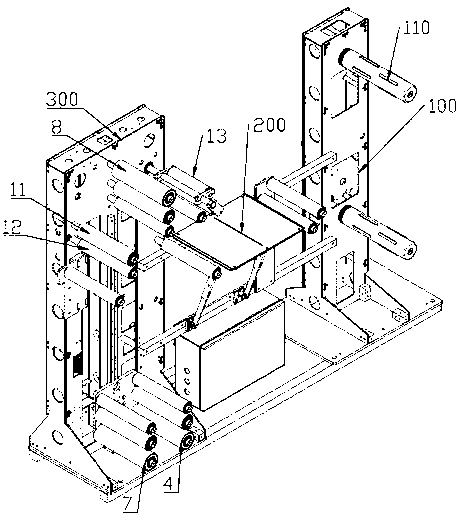

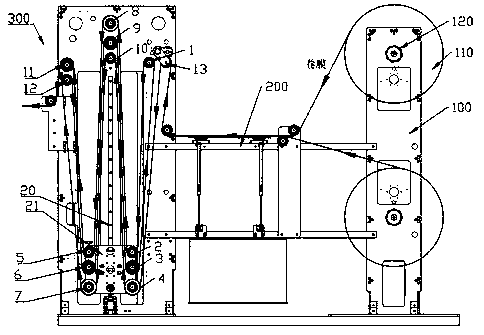

[0023] Such as Figure 1-3 As shown, the feeding device of the bag making machine is sequentially provided with a double film roll support frame 100, a first guide roller, a material receiving platform 200 and a roll film storage rack 300, and the roll film storage rack 300 is provided with a one-way 13 sets of bearing rollers and some roll material rollers, the one-way bearing roll set 13 includes a one-way bearing roll and a pressure roller, and the roll material rollers include fixed rollers and movable rolls that cooperate with each other to realize three-layer winding storage. Rollers, the movable rollers are installed and fixed together on a slide block 21 of a rodless cylinder 20 arranged in a vertical direction, and can move as the slide block 21 moves up and down.

[0024] The dual-mode roll support frame 100 is provided with two pneumatic tension rollers 120, each of which can be mounted with a film roll.

[0025] The material receiving platform 200 is a retractable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com