Box forming machine

A forming machine and box body technology, applied in container manufacturing machinery, box making operations, paper/cardboard containers, etc., can solve the problems of increased labor costs, high cost, and inconsistent quality of packaging boxes, and achieve labor cost savings, High degree of automation and good box quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

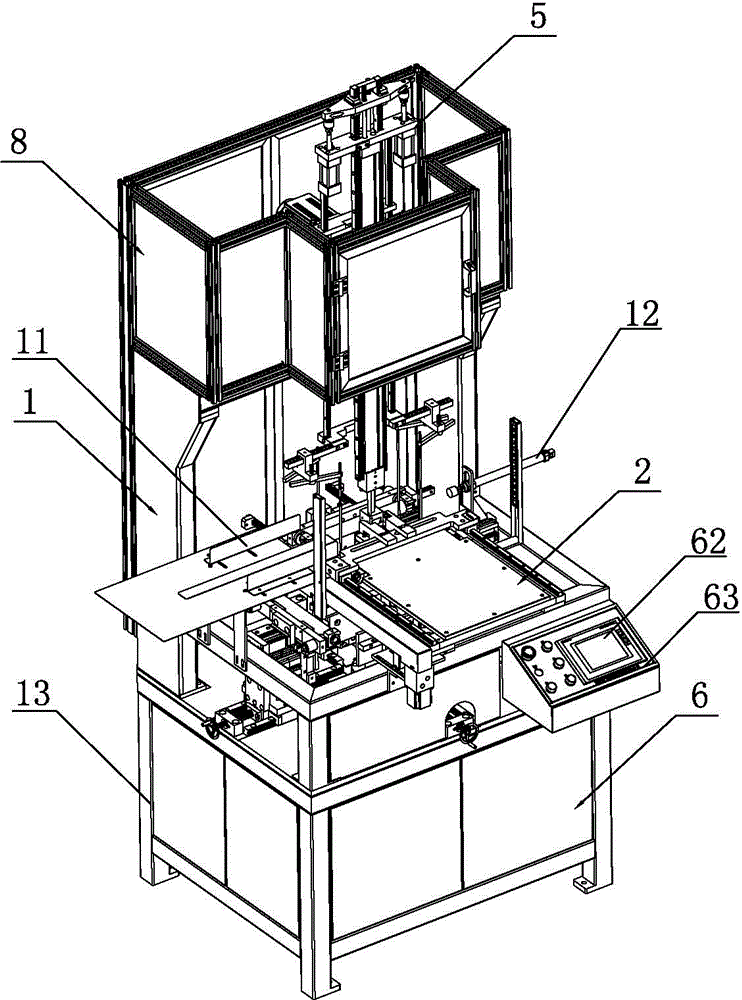

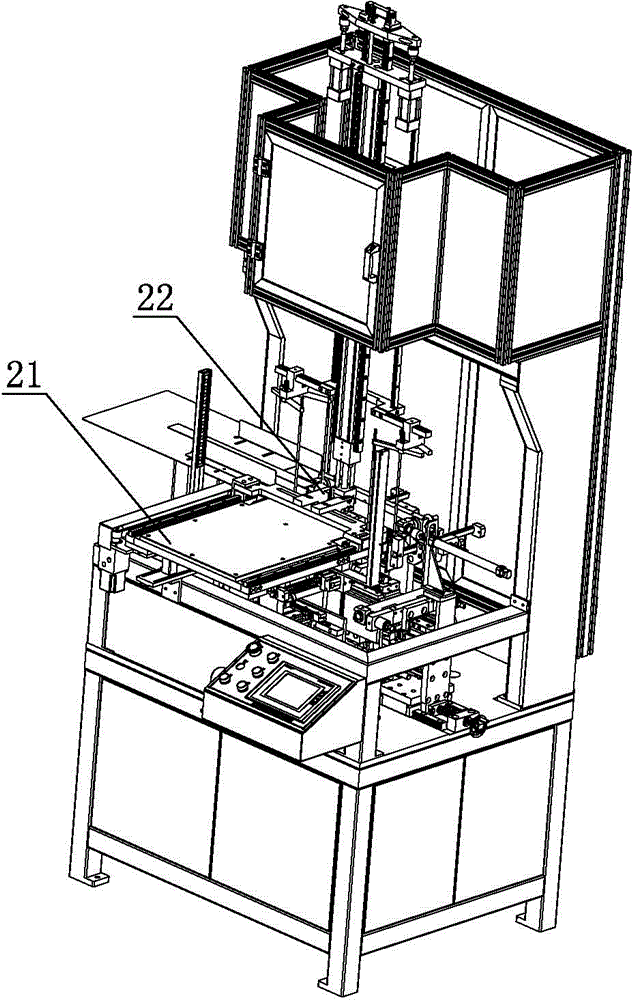

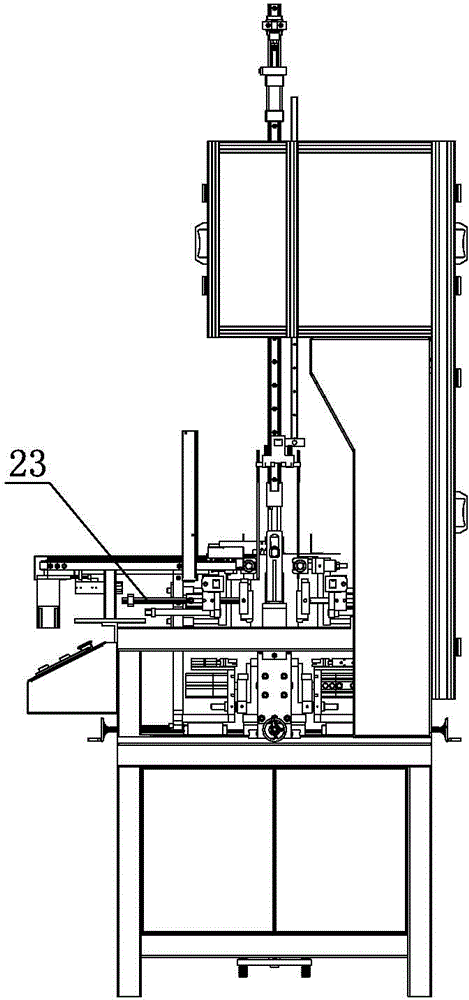

[0024] see Figure 1 to Figure 9 , a box body forming machine, comprising a frame 1, the frame 1 is connected with an electric control cabinet 13, the frame 1 is provided with a box feeding mechanism 2 for sending the box body into the drawing die position, and the box feeding mechanism 2 The bottom of the mechanism 2 is respectively provided with a first combination device 3 for fitting the first pair of sides of the box body and a second combination device 4 for fitting the second pair of sides of the box body, and also includes a combination device arranged above the frame 1 The drawing mechanism 5 used for the downward or upward transmission of the adsorption box body, one side of the drawing mechanism 5 is provided with a discharge channel 11, and the other side of the drawing mechanism 5 is provided with a discharge cylinder 12, so The electric control cabinet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com