Method for extracting lithium carbonate from carbonate brine

A carbonate-type, lithium carbonate technology, applied in the direction of lithium carbonate;/acid carbonate, solar collectors using working fluids, lighting and heating equipment, etc., can solve the problem of high consumption of fossil fuels, brine Slow heating rate, high freight and energy consumption, etc., to improve production efficiency and product quality, improve production efficiency and product yield, and save construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

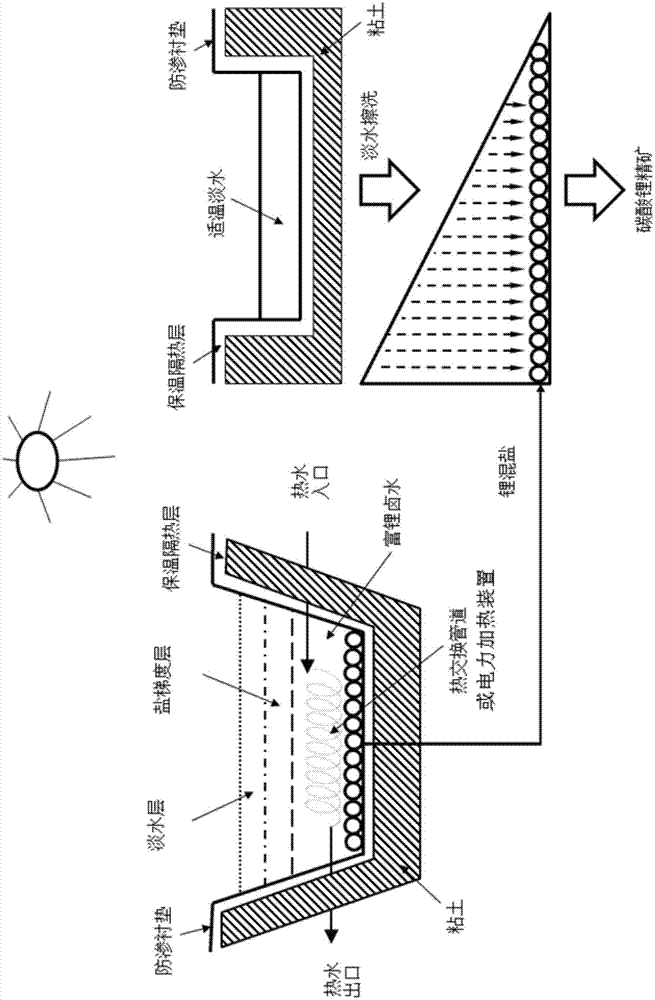

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] refer to figure 1 , the method for extracting lithium carbonate disclosed by the present invention uses the salt gradient thermal insulation solar pool equipped with heat exchange pipes or electric heating devices as the crystallization pool, and crystallizes lithium carbonate from carbonate type brine. The so-called salt gradient thermal insulation solar pool is directly built of clay, with a lighting area of 1000~10000m2 2, the depth of the pool is 3~4m, the bottom of the pool and the inner wall of the pool are made of plastic film and thermal insulation materials to form a sandwich structure of thermal insulation layer, the inner surface of the pool can be laid with black EPDM waterproof membrane, geomembrane or high-density polyethylene spray Plastic canvas, etc. are used as liners to prevent brine penetration; heat exchange pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com