Correction device for winebottle posture

A technology for correcting devices and postures, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of uneven quality of flower paper forming, increase of cost investment of production and processing enterprises, and the inability to absolutely unify wine bottles, etc., to achieve Effects of improving stability, reducing vibration amplitude, and preventing sideways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

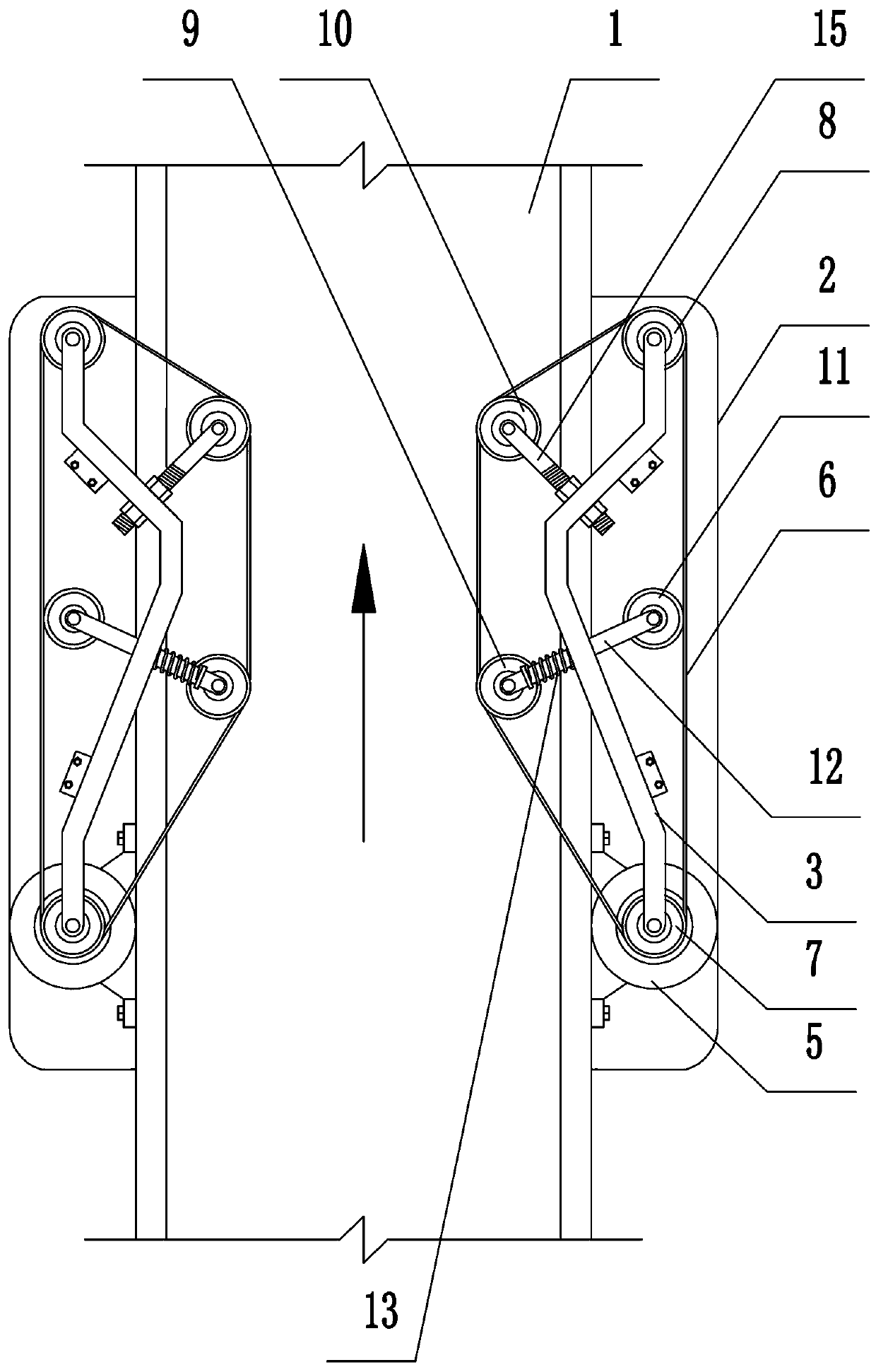

[0028] Such as figure 1 As shown, a wine bottle posture correction device of the present invention is provided with a correction mechanism on both sides of the conveying mechanism 1 between the decals and decals. The conveying mechanism 1 adopts the current belt conveyor, and the two correction mechanisms are arranged symmetrically. , each correction mechanism includes a support plate 2 fixedly connected with the conveying mechanism 1 and a correction assembly arranged on the support plate 2 .

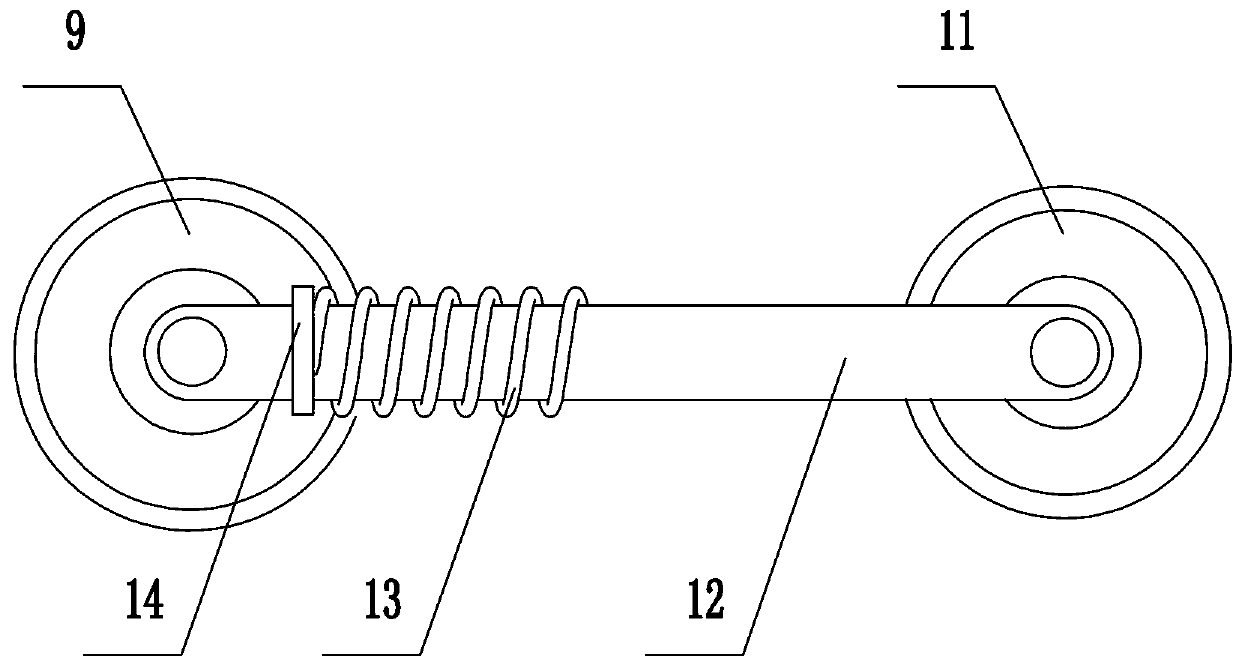

[0029] Such as figure 1 and figure 2 As shown, each correction assembly includes a fixed frame 3, a driving device arranged on the support plate 2, and a transmission wheel assembly arranged on the fixed frame 3, and the fixed frame 3 is fixed on one side of the conveying mechanism 1 by bolts, and the fixed frame 3. It is fixed on the upper end surface of the support plate 2 through the support rod. The driving device includes the motor 4 and the reducer 5 connected by transmission....

Embodiment 2

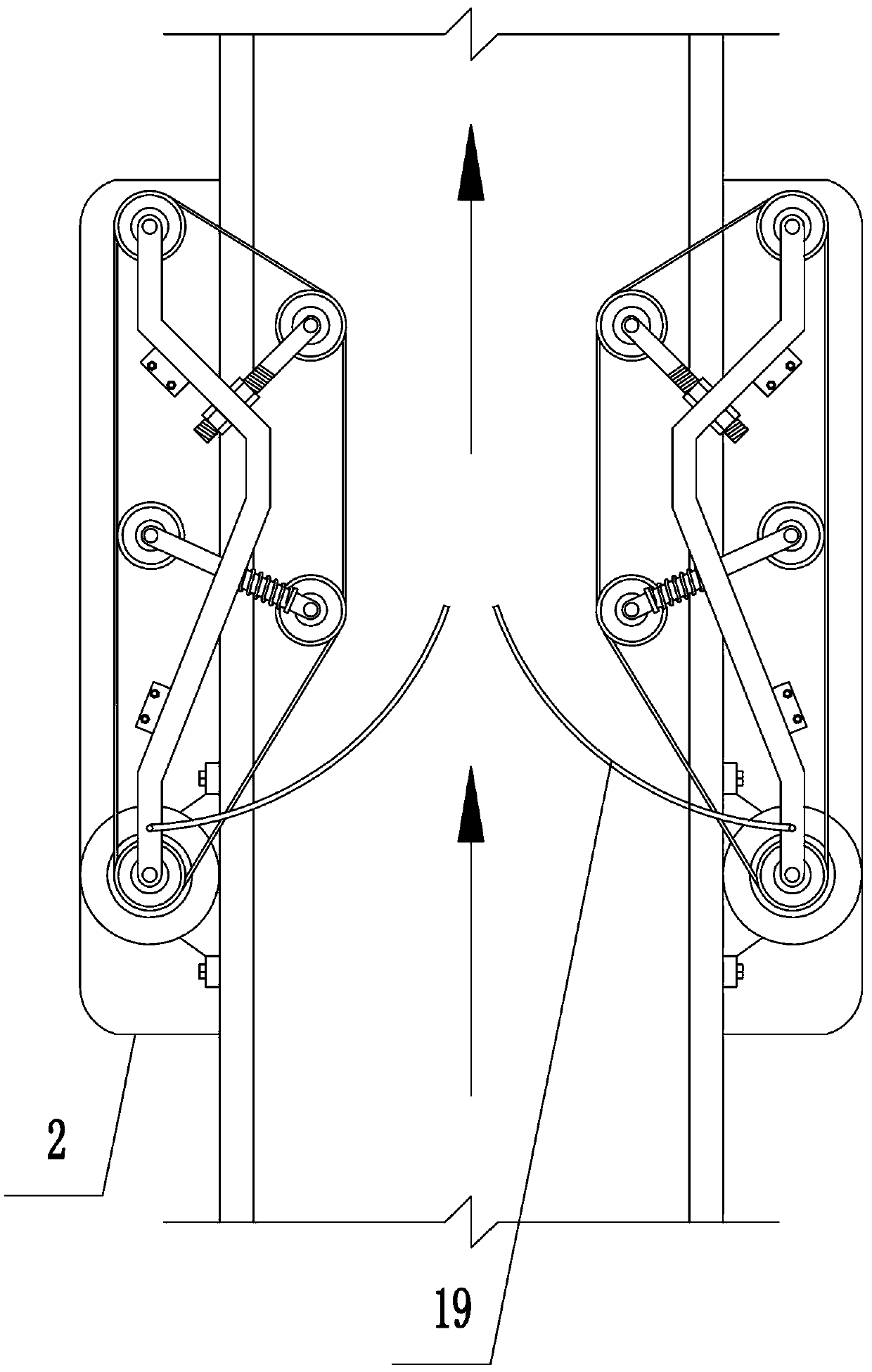

[0033] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 4 and Figure 5 As shown, the lower end of the support plate 2 is provided with a U-shaped hanger 16, the motor 4 is located in the U-shaped hanger 16, and a plurality of disc springs 17 are set between the motor 4 and the bottom of the U-shaped hanger 16, and each fixed mount 3 Bottleneck righting mechanisms are arranged on the top, the bottleneck righting mechanism is located in front of the correction mechanism, the height of the bottleneck righting mechanism is higher than the height of the transmission wheel assembly, the bottleneck righting mechanism includes a fixedly connected vertical rod 18 and an arc rod 19, the vertical rod One end of 18 is fixed with fixed mount 3 welders, and the minimum distance of two arc bar 19 ends matches the external diameter of wine bottle bottleneck.

[0034] In this embodiment, the stability of the wine bottle during the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com