State monitoring device and method for fiber strands in cans

A state monitoring device and can technology, which is applied to fiber processing safety devices, textiles and papermaking, fiber processing, etc. The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

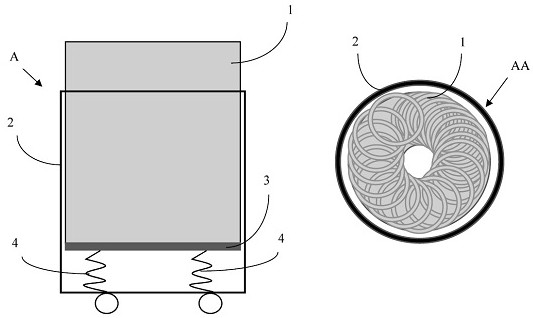

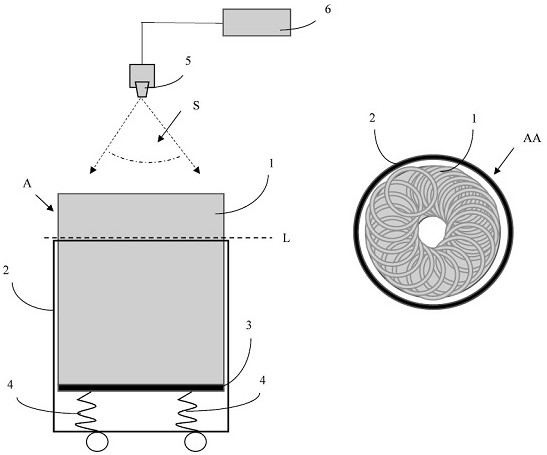

[0024] First, use figure 1 A side view A and a top view AA of a full can are shown. In side view A, this is a normal can filled with sliver, 1 is the sliver column composed of sliver rings, 2 is the usual can, 3 is the tray for the can, 4 is the support tray The two ends of the spring are respectively fixed on the bottom of the tray and the can, and the spring will stretch or compress with the weight of the can; AA is a schematic view of a full can from the top, and 1 is a column composed of a can. , 2 is a can. Because the whisker 1 circle is placed on the tray 3, the circles are placed layer by layer to form the whisker column, and when viewed from above, the tray 3 is covered by the whisker 1.

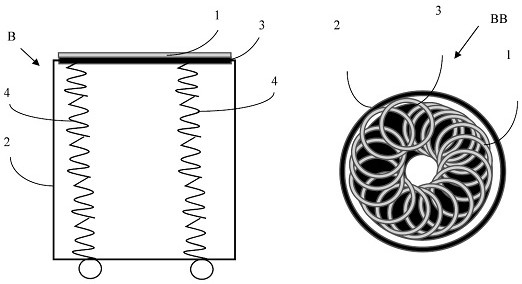

[0025] figure 2 A side view B and a top view BB of an almost empty can are shown. In the side view B, due to the reduction of the strands 1, the weight borne by the spring 4 and the tray 3 is reduced, and the spring 4 is stretched, pushing the tray 3 to the top of the can 2. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com