Continuous strip spraying device

A technology of spraying belts and strips, which is applied in the field of strip spraying devices, can solve problems such as inability to guarantee cleanliness, and achieve the effects of being conducive to calmness, reducing impurities, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0011] The continuous tape spraying device of the present invention is mainly used for continuous production of amorphous strips.

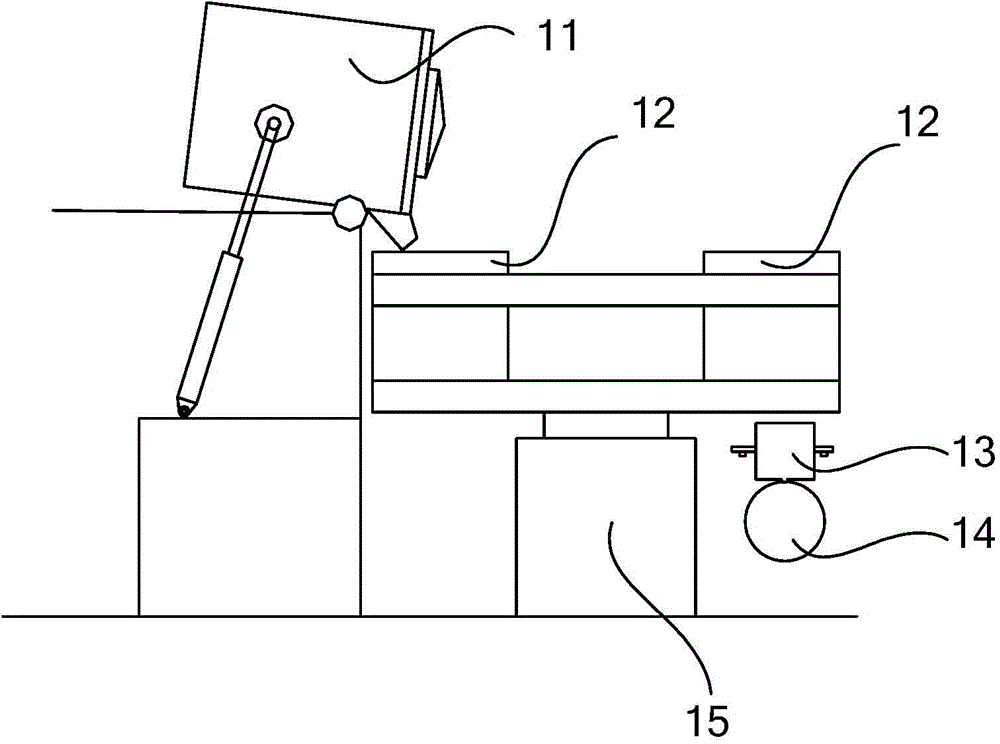

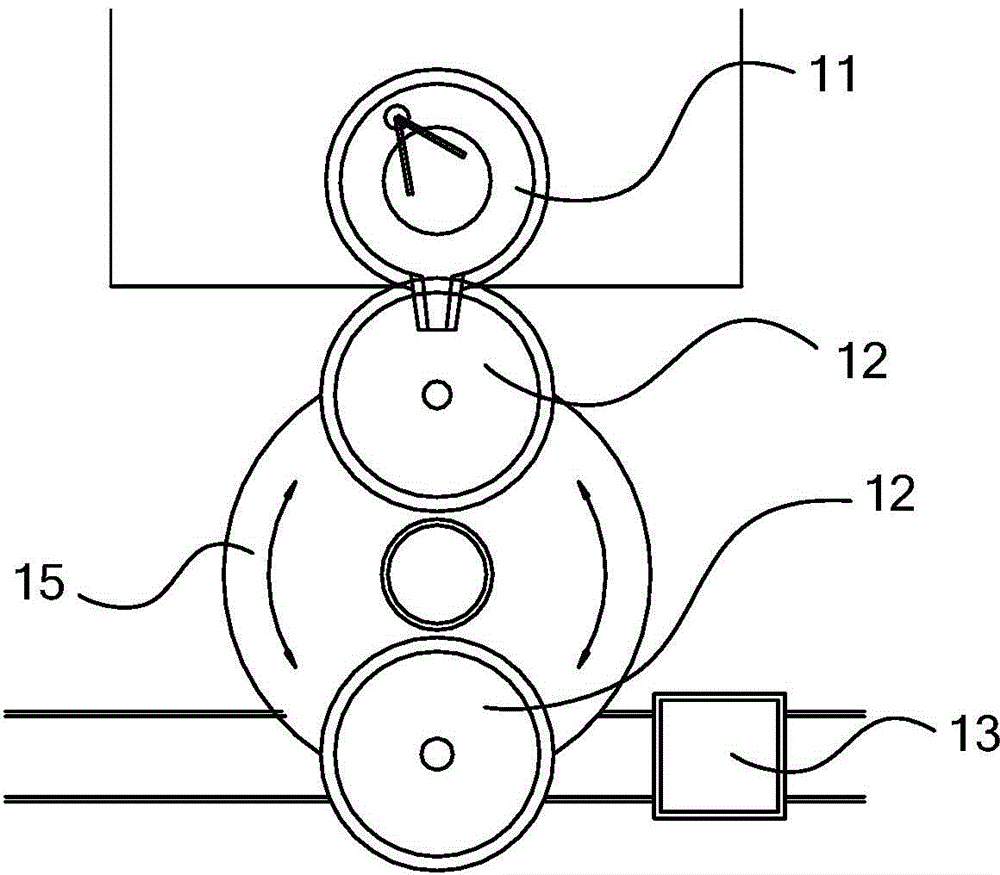

[0012] figure 1 It is a side view of the structural schematic diagram of the continuous spraying belt device of the present invention, figure 2 It is the top view of the structural representation of the continuous spray belt device of the present invention, combined with figure 1 and figure 2 As shown, the device includes a melting furnace 11 , a bottom injection furnace 12 , a spray bag 13 , and a crystallizer 14 .

[0013] The smelting furnace 11 is located at the top of the continuous belt spraying device and is used for melting molten steel. A bottom injection furnace 12 is provided below the smelting furnace 11, and the continuous belt spraying device has two identical bottom in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com