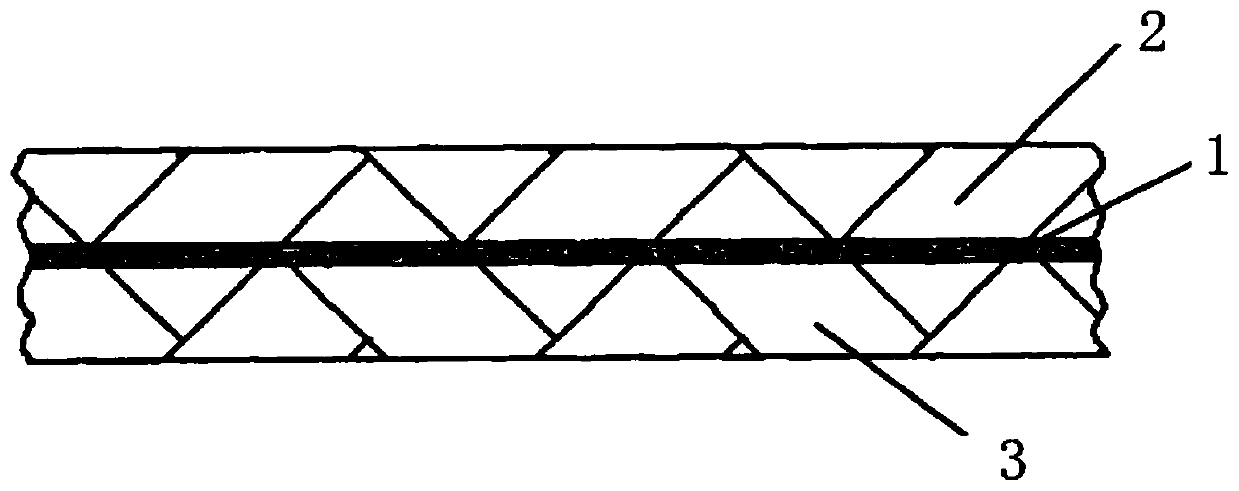

Nanofiber filtering material and preparation method thereof

A filter material and nanofiber technology, which is applied in the field of nanofiber filter material and its preparation, can solve the problems that threaten the survival and development of all human beings, high resistance to filtration, ecological damage, etc., and achieve excellent air permeability, high filtration efficiency, and low The effect of filter resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

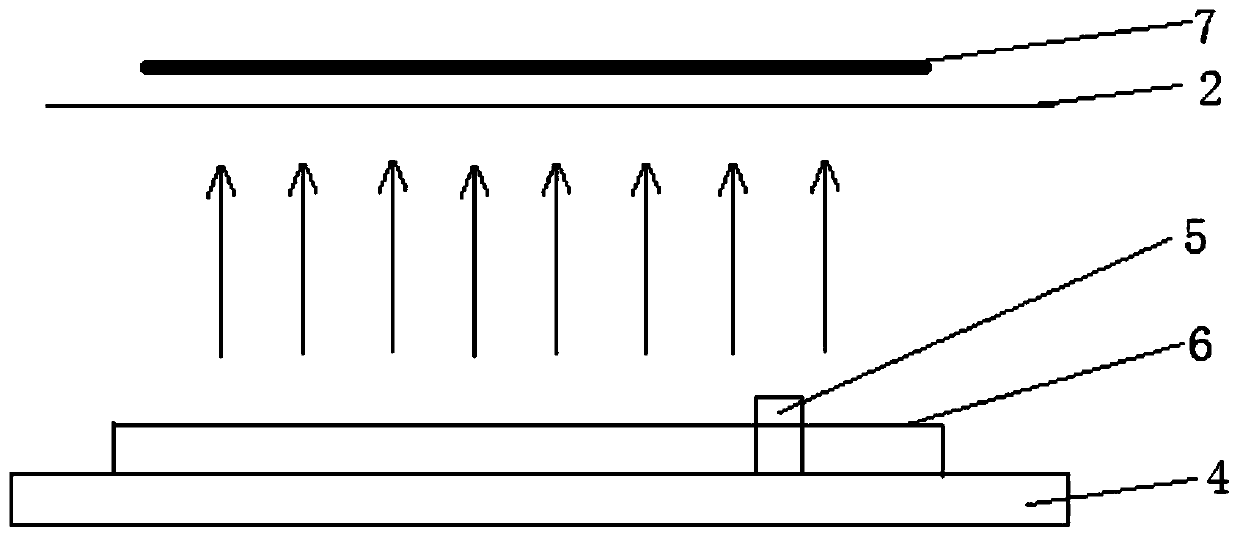

Method used

Image

Examples

Embodiment 1

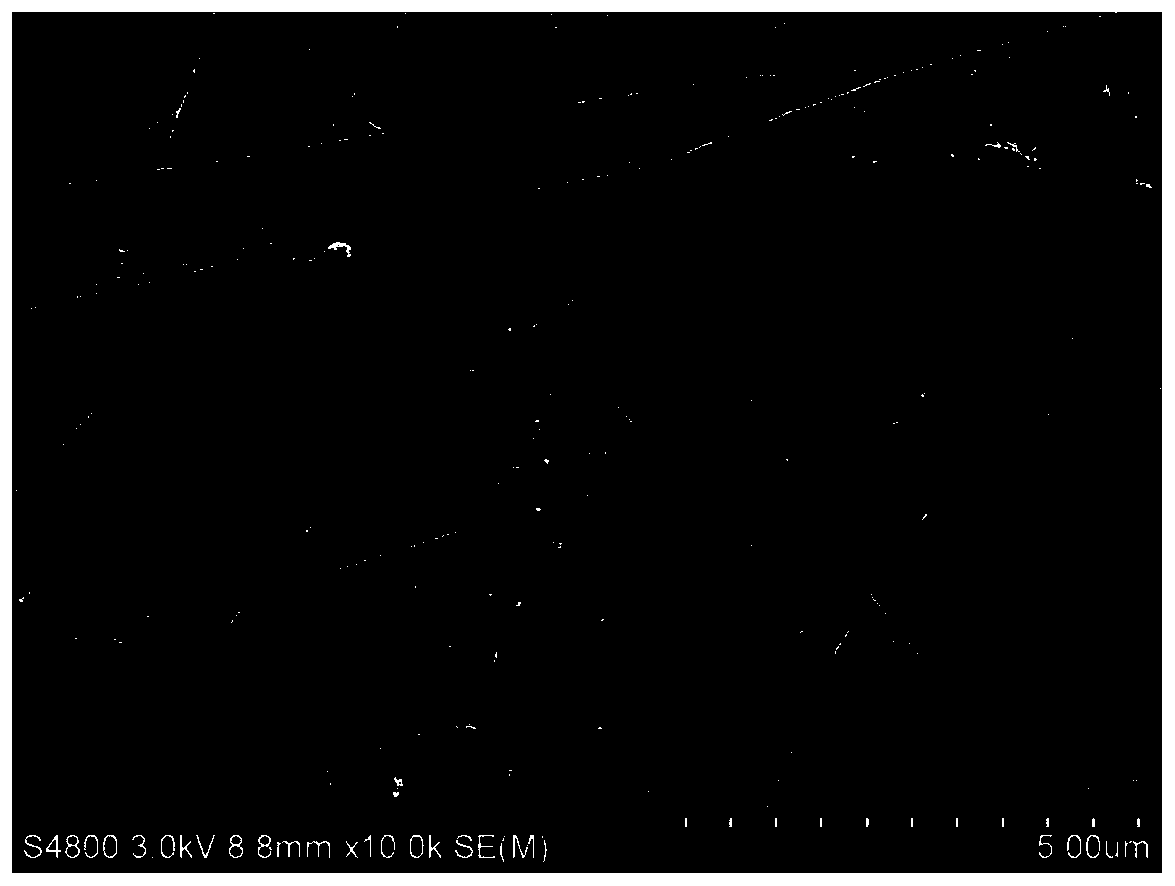

[0048] Mix 180g of nylon-66 with 820g of formic acid, stir at 50°C until completely dissolved to form a uniform spinning solution, and spin it on the polypropylene spunbonded nonwoven material substrate by a needle-free reciprocating electrospinning method, and then cover it with a After one layer of polypropylene spun-bonded non-woven material, hot roll pressing is carried out, and the grammage of the nanofiber filter material layer obtained by controlling the receiving time of the substrate is 2.0g, and the grammage of the two-layer polypropylene spun-bonded non-woven material is 20g. Wherein, the SEM electron micrograph of the nanofiber filter material layer that the present embodiment makes is as follows image 3 shown.

[0049] Among them, the specific parameters of the needle-free reciprocating electrospinning method are: the voltage of high-voltage static electricity is 80KV, the receiving distance between the spinning electrode and the first spunbonded filter material ...

Embodiment 2

[0052] Mix 180g of nylon-66 with 820g of formic acid, stir at 50°C until completely dissolved to form a homogeneous solution, and spin it on a polypropylene spunbonded nonwoven material substrate by a needle-free reciprocating electrospinning method, and then cover it with a layer of polypropylene After the propylene spunbonded nonwoven material is hot-rolled, the grammage of the nanofiber filter material layer obtained by controlling the receiving time of the substrate is 1.5g, and the grammage of the two layers of polypropylene spunbonded nonwoven material is 20g.

[0053] Among them, the specific parameters of the needle-free reciprocating electrospinning method are: the voltage of high-voltage static electricity is 70KV, the receiving distance between the spinning electrode and the first spunbond filter material substrate is 20cm, and the spinning temperature is 20°C. The relative humidity for spinning was 40%.

[0054] The filter material prepared in this embodiment was t...

Embodiment 3

[0056] Mix 140g of nylon-66 with 860g of formic acid, stir at 50°C until completely dissolved to form a homogeneous solution, and spin it on a polypropylene spunbonded nonwoven material substrate by a needle-free reciprocating electrospinning method, and then cover it with a layer of polypropylene After the propylene spunbonded nonwoven material is hot-rolled, the grammage of the nanofiber filter material layer obtained by controlling the receiving time of the substrate is 1.5g, and the grammage of the two layers of polypropylene spunbonded nonwoven material is 20g.

[0057] Among them, the specific parameters of the needle-free reciprocating electrospinning method are: the voltage of high-voltage static electricity is 75KV, the receiving distance between the spinning electrode and the first spunbond filter material substrate is 25cm, and the spinning temperature is 25°C. The relative humidity for spinning was 50%.

[0058] The filter material prepared in this embodiment was t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com