Atmospheric pressure plasma particle polymer material processing equipment

A technology of atmospheric pressure plasma and polymer materials, which is applied in the field of plasma particle polymer material processing equipment, can solve the problems of small effective area of treatment and poor surface treatment effect, and achieve time saving, low equipment investment and increase of water cooling system Effect

Active Publication Date: 2019-04-09

长沙立兴环保科技有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It has the disadvantages of convenient use, low operating cost, but poor effect on surface treatment, small effective area of treatment, and certain timeliness.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

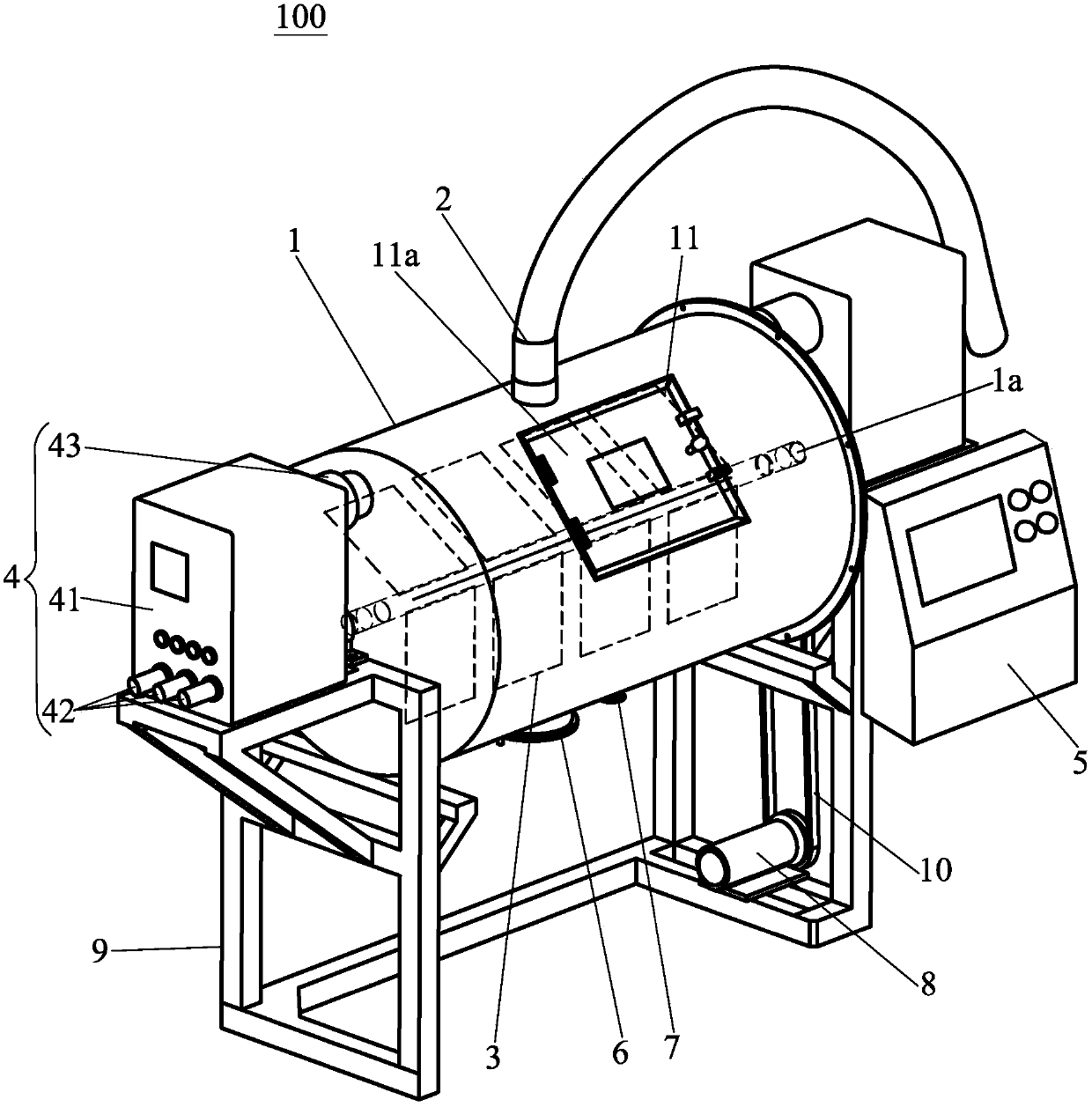

[0022] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 1 As shown, the present invention provides an atmospheric pressure plasma particle polymer material processing equipment 100, comprising:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an atmospheric pressure plasma particle polymer treatment device. The device comprises a tank, wherein an argon inlet is connected to the tank and a stainless steel stirring paddle is installed in the tank, an atmospheric pressure jet processor, wherein the atmospheric pressure jet processor comprises a power supply, an inlet and a spray gun, the power supply provides powder for the atmospheric pressure jet processor, plasma, water and gas fed through the inlet are treated and then are sprayed through the spray gun and the spray gun is seal-connected to the tank, and an automatic control and induction system, wherein the system comprises a temperature sensing unit, a data acquisition unit and a control unit, the temperature sensing unit is arranged in the tank and can detect a temperature in the tank, the detected data is transmitted to the control unit through the data acquisition unit and the control unit determines if the atmospheric pressure jet processor needs to be started to carry out plasma water cooling injection in the tank. The invention provides an atmospheric pressure plasma treatment method and device for a particle polymer.

Description

technical field [0001] The invention belongs to the field of plasma processing devices, and in particular relates to an atmospheric pressure plasma particle polymer material processing equipment. Background technique [0002] The surface modification of granular materials by low-temperature plasma, on the one hand, can generate polar groups, free radicals and other active groups on the surface of the material, such as hydroxyl, carboxyl, etc., to improve its hydrophilicity, wettability and surface activity. On the other hand, for natural degradable polymer materials, it is to increase the mechanical strength of the material, reduce the degradation rate of the material itself, and prolong its service life. Therefore, the performance of inorganic polymer particle materials such as water treatment fillers, plastic materials, activated carbon particles, and plastic fillers can be improved. with broadly application foreground. Domestic research in this field is still in the lab...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08J7/12C08L23/12C08L69/00C08L55/02C08L77/00C08L23/06C08L27/06

CPCC08J7/123C08J2323/06C08J2323/12C08J2327/06C08J2355/02C08J2369/00C08J2377/00

Inventor 叶仁锋叶友谦

Owner 长沙立兴环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com