High-efficiency ozone water treatment system and continuous ozone preparation and water treatment method

A treatment system and ozone water technology, applied in ozone preparation, oxidized water/sewage treatment, etc., can solve the problem of high water content in gas, and achieve the effects of high ozone output, improved efficiency and good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

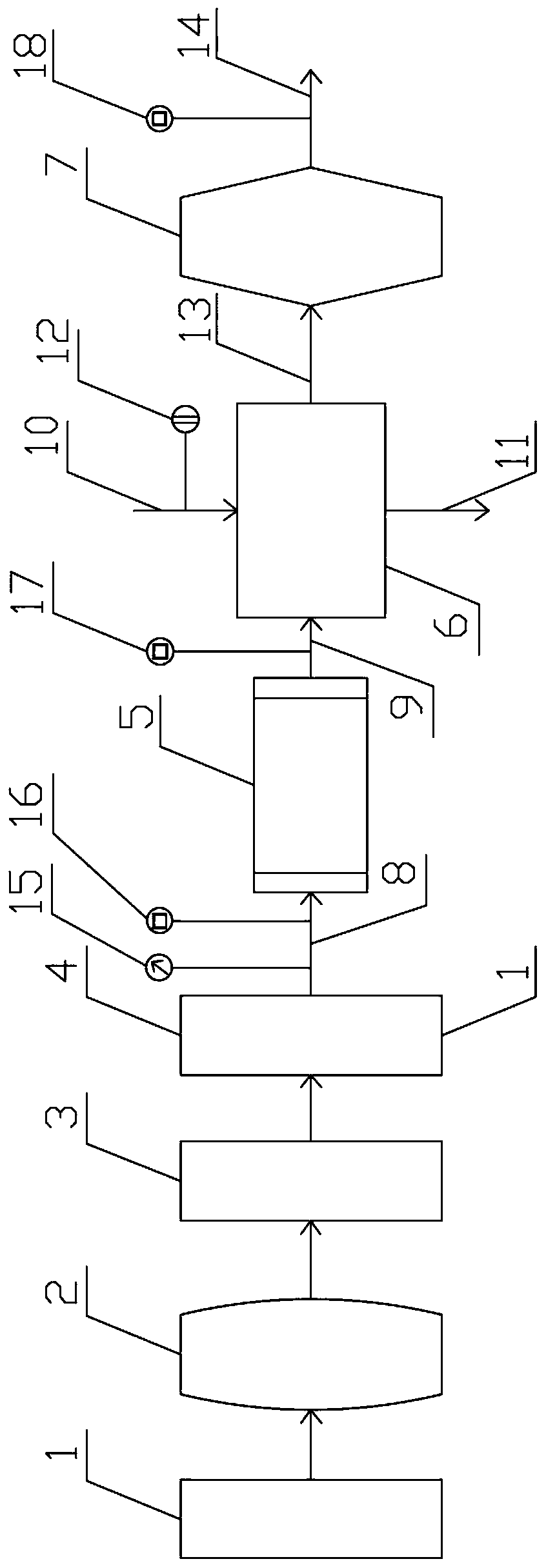

[0049] Embodiment 1: refer to figure 1 , a high-efficiency ozone water treatment system, characterized in that it includes a gas source preparation system, an ozone generator 5, an ozone contact tank 6 and an exhaust gas destroyer 7, and the gas source preparation system includes air compressors connected in sequence through pipelines 1, gas storage tank 2, refrigerated dryer 3 and adsorption dryer 4; Air intake pipeline 8 is connected between the adsorption dryer 4 and the inlet end of ozone generator 5, the gas outlet end of ozone generator 5 and Ozone outlet pipeline 9 is connected between the ozone contact tanks 6; said ozone contact tank 6 is provided with contact tank water inlet pipeline 10 and contact tank water outlet pipeline 11 respectively, and said contact tank water inlet pipeline 10 is equipped with liquid The level meter 12; the ozone contact pool 6 and the exhaust gas destroyer 7 are connected through the exhaust gas discharge pipeline 13, and the exhaust gas ...

Embodiment 2

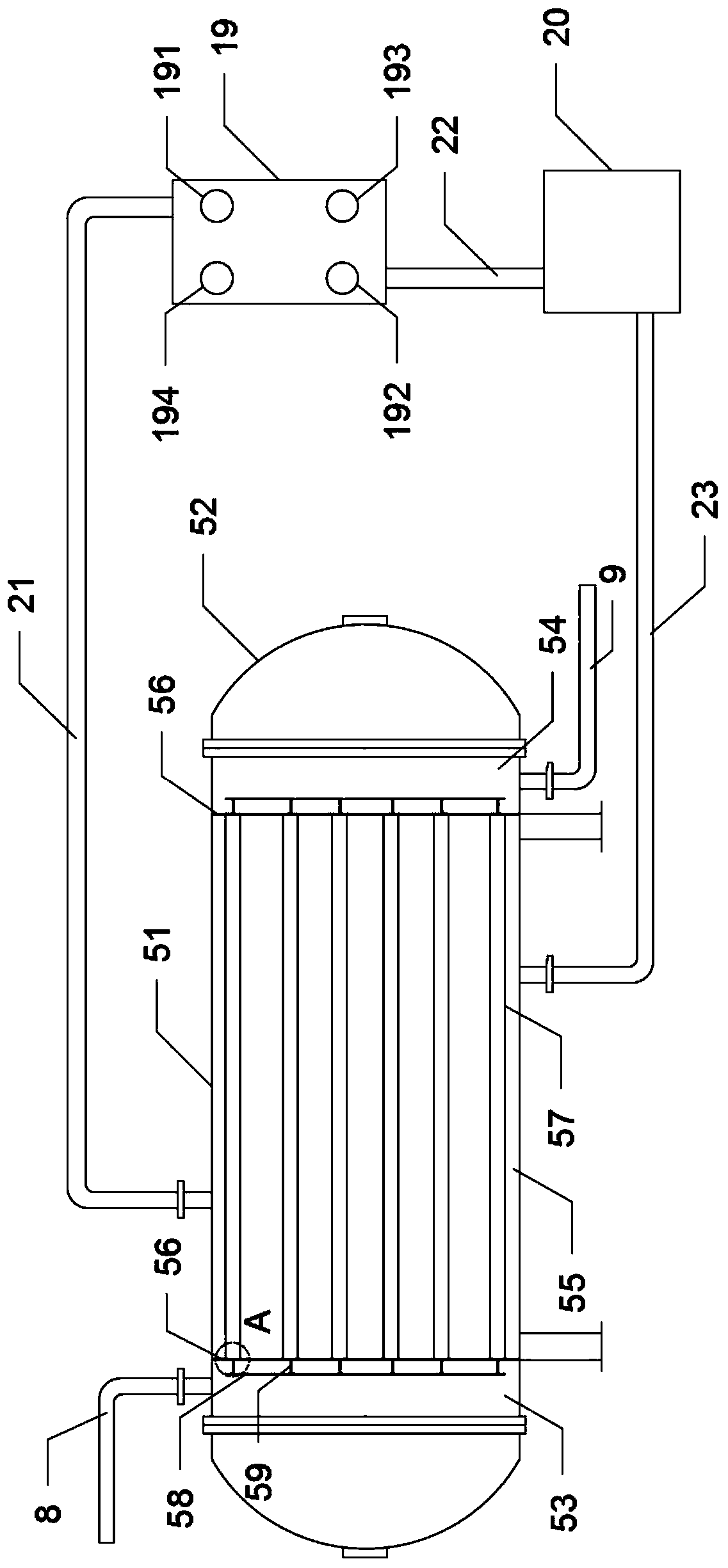

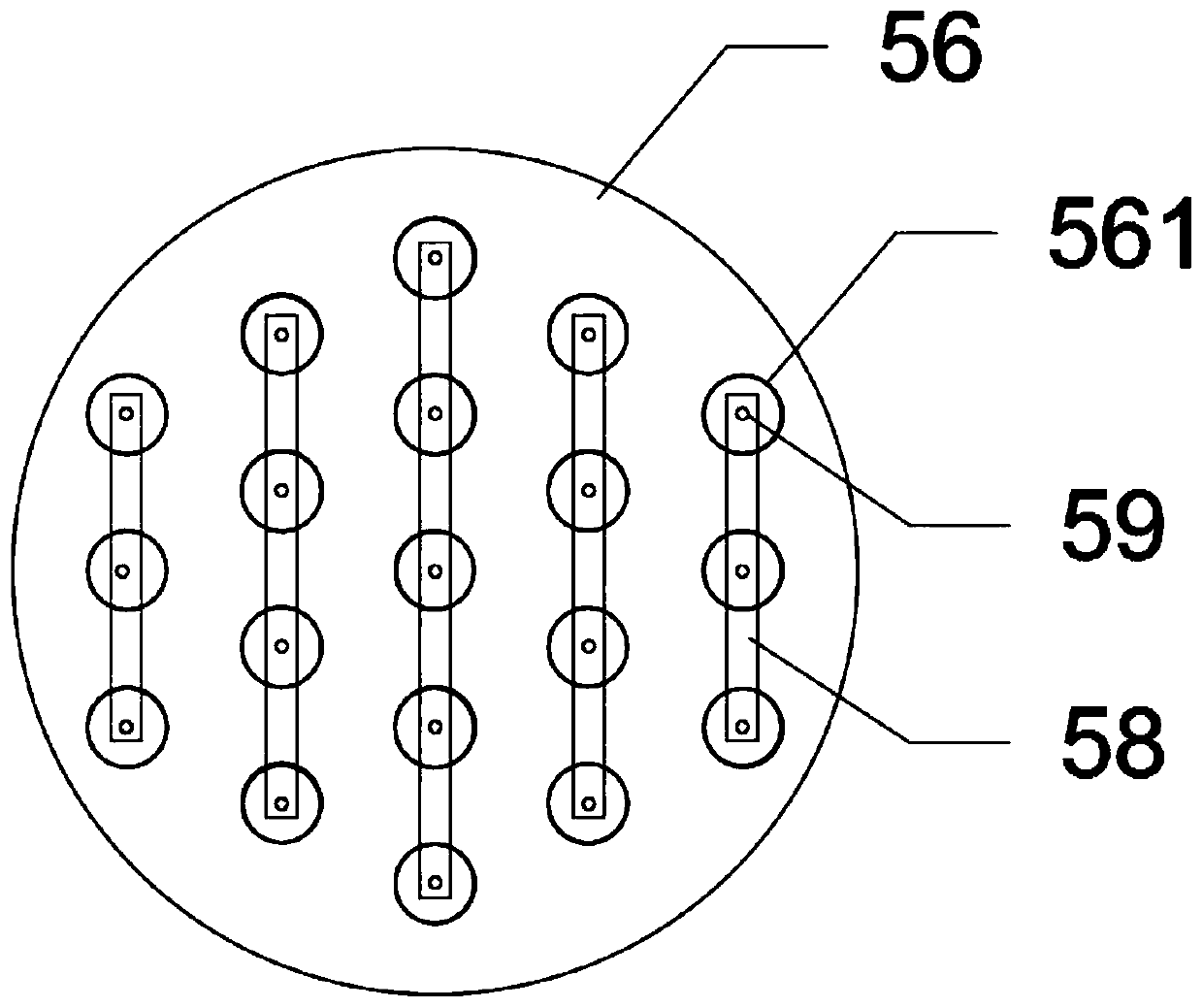

[0054] Embodiment 2: refer to figure 2 , image 3 , Figure 4 , in a kind of efficient ozone water treatment system described in embodiment 1, described ozone generator 5 comprises horizontal main tank body 51, and the two ends of main tank body 51 are connected with end cover 52 by flange; Ozone generator 5 The air inlet end of the inner cavity is provided with an air inlet chamber 53, the air outlet end is provided with an air outlet chamber 54, and a discharge chamber 55 is arranged between the air inlet chamber 53 and the air outlet chamber 54; plate-shaped ports 56 are installed at both ends of the discharge chamber 55, A number of discharge units 57 are arranged between the plate-shaped ports 56; the discharge units 57 include a stainless steel tube 571 and a discharge tube 572, the outer layer of the discharge tube 572 is coated with an insulating layer 573, and the stainless steel tube 571 is sleeved outside the discharge tube 572 and Set concentrically with the dis...

Embodiment 3

[0057] Embodiment 3: refer to figure 2 , Figure 4 , in a kind of high-efficiency ozone water treatment system described in embodiment 2, the material of described insulating layer 573 is ceramics, also is connected with fuse 59 between described high-voltage distribution bar 58 and discharge tube 572, and described cooling device 19 is In the plate heat exchanger, the heat medium inlet 191 of the plate heat exchanger is connected to the water inlet pipe 21 of the cooling device, and the heat medium outlet 192 of the plate heat exchanger is connected to the water outlet pipe 22 of the cooling device.

[0058] As a common insulating material, ceramics have a good insulating effect; the discharge tubes 572 are connected in parallel. When a discharge tube 572 fails, the corresponding fuse 59 is disconnected to disconnect the discharge tube 572 from the entire circuit. , to avoid affecting other discharge tubes 572; hot water enters the plate heat exchanger through the heat medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com