Electrostatic composite intelligent cleaning type waste gas purification device

An exhaust gas purification device and intelligent cleaning technology, applied in electrostatic separation, electrostatic effect separation, external electrostatic separator, etc., can solve problems such as affecting electrostatic dust removal effect and dust particles, reducing exhaust gas escape, prolonging service life, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

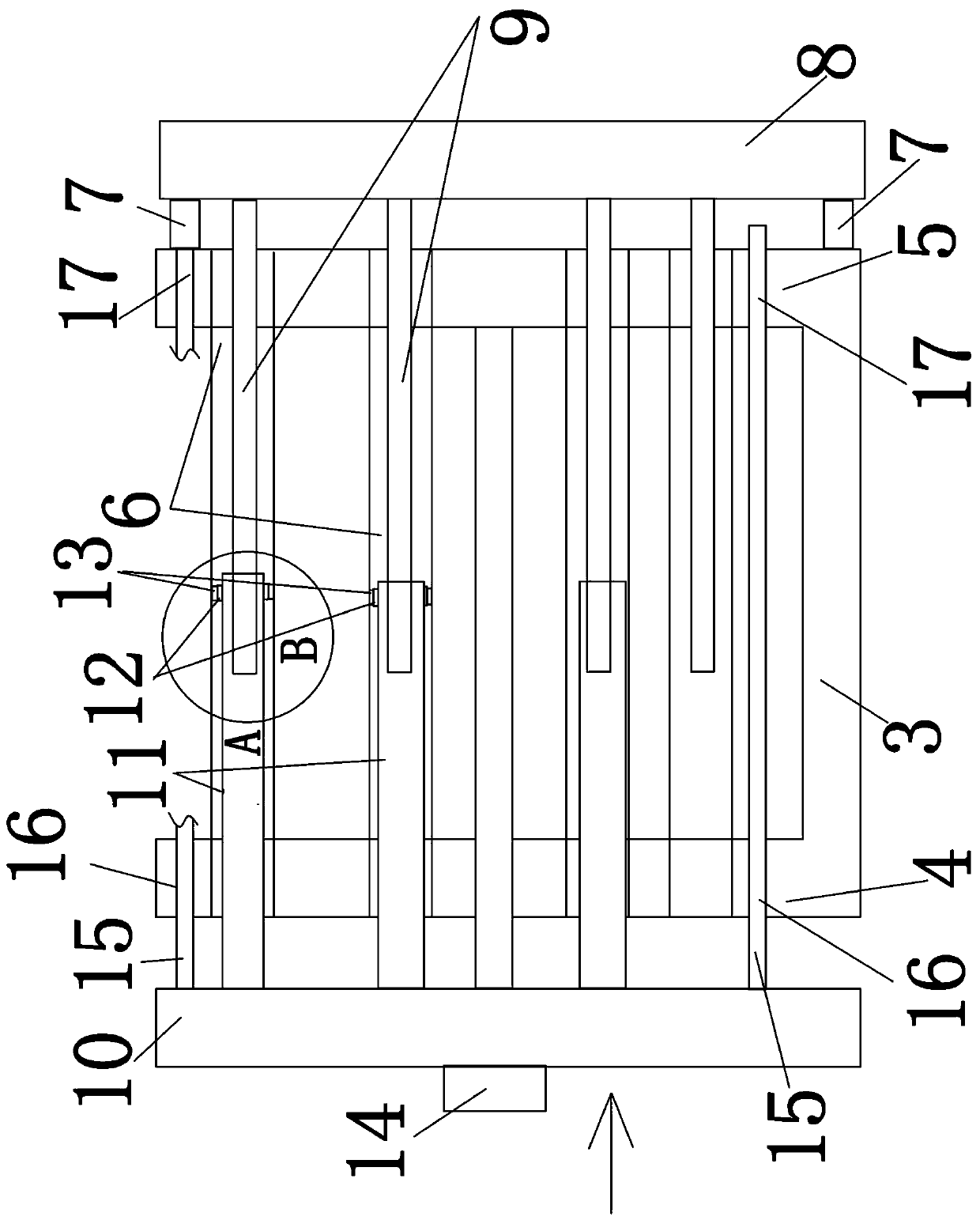

[0032] An electrostatic composite intelligent cleaning waste gas purification device has a bracket 3 .

[0033] The support 3 has a front flower board 4 and a rear flower board 5 arranged in parallel.

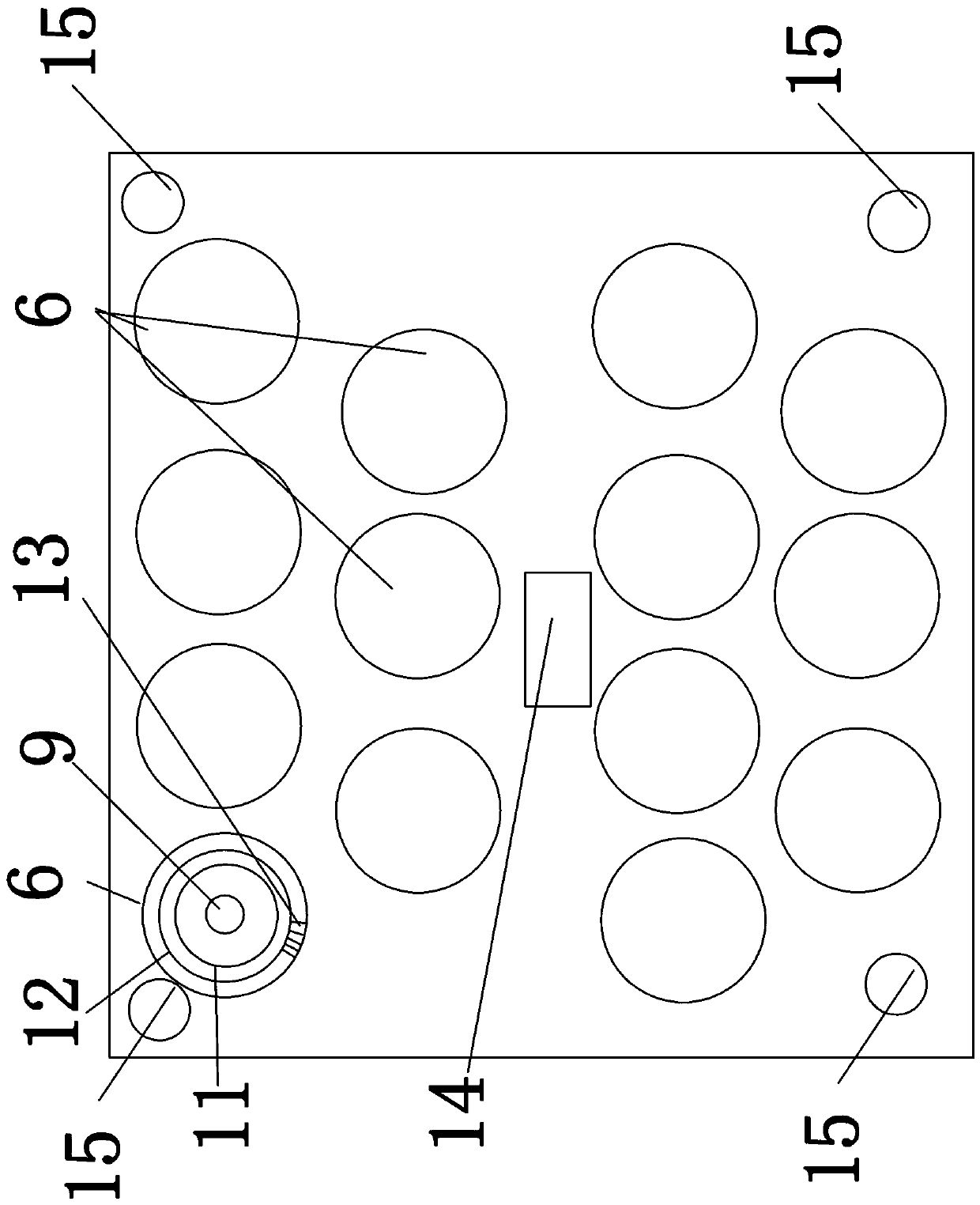

[0034] A plurality of anode tubes 6 are fixedly arranged between the front flower panel 4 and the rear flower panel 5, and the plurality of anode tubes 6 are arranged in a honeycomb pattern.

[0035] The rear side of the rear flower plate 5 is fixed with a cathode frame 8 through a plurality of insulators 7 .

[0036] A plurality of cathode rods 9 are fixed in front of the cathode frame 8 , and each cathode rod 9 extends forward into the corresponding anode cylinder 6 and is arranged along the central axis of the anode cylinder 6 .

[0037] There is push tube holder 10 in the front of flower board 4 .

[0038] A plurality of push cylinders 11 are fixed behind the push cylinder frame 10, and the push cylinders 11 all extend backward into the corresponding anode cylinder 6, and...

Embodiment 2

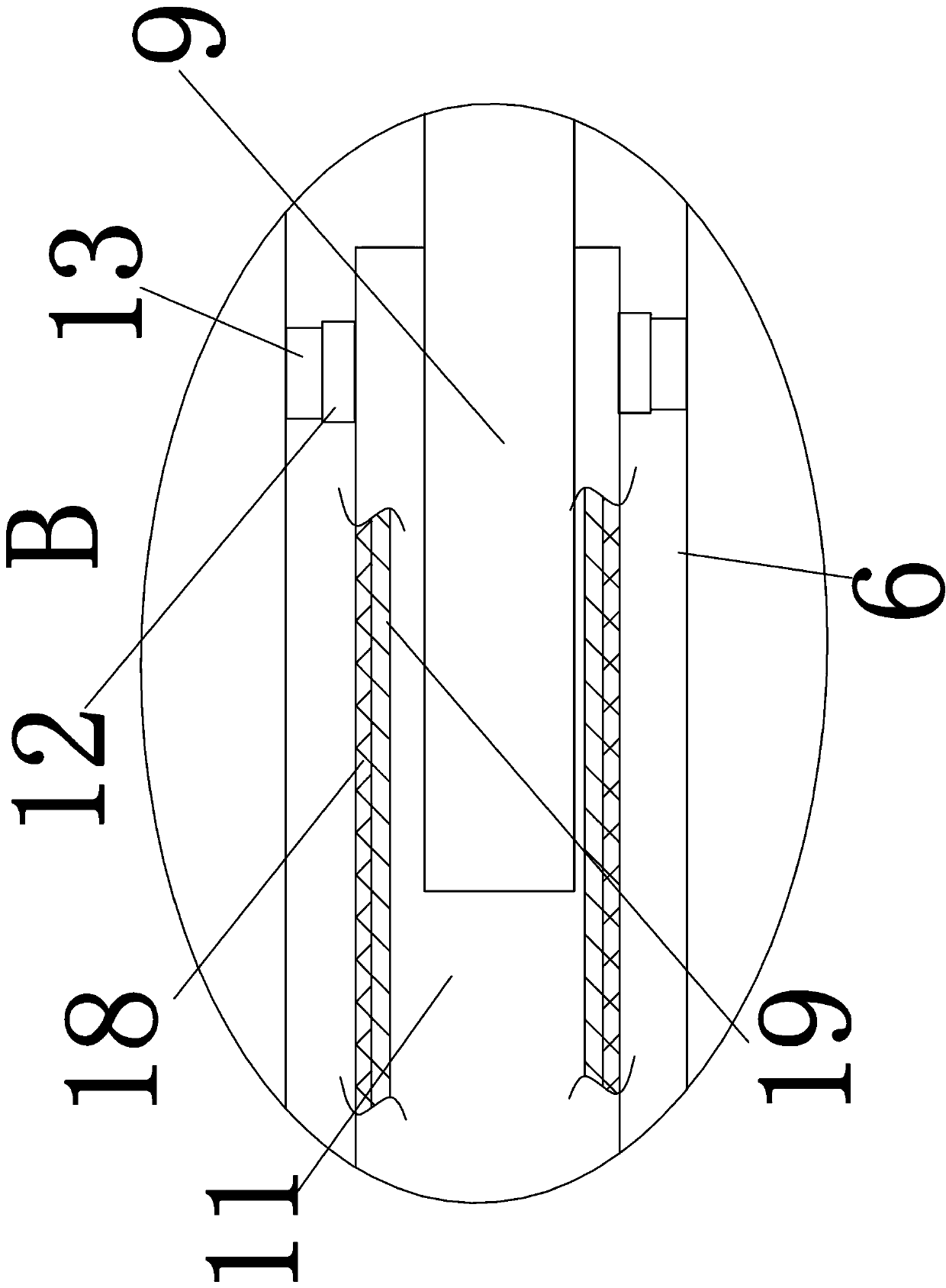

[0051] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

Embodiment 3

[0054] Embodiment 3 is basically the same as Embodiment 1, and its difference is:

[0055] The lining metal layer 19 is a metal plate, which is arranged in the interlayer of the insulating outer cylinder 18, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com