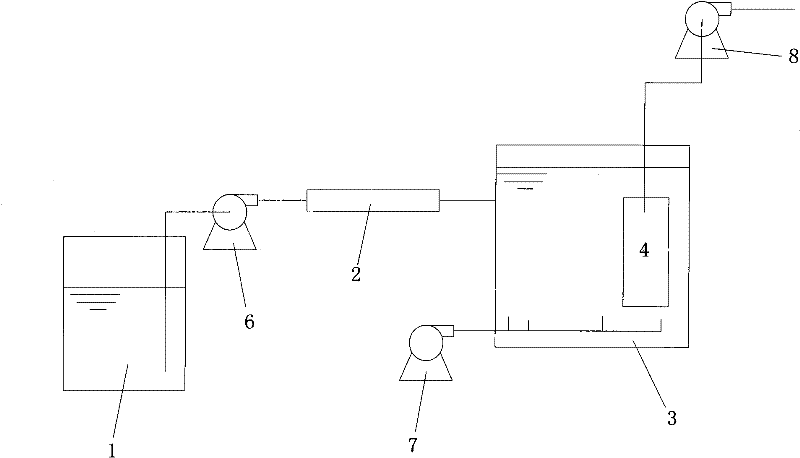

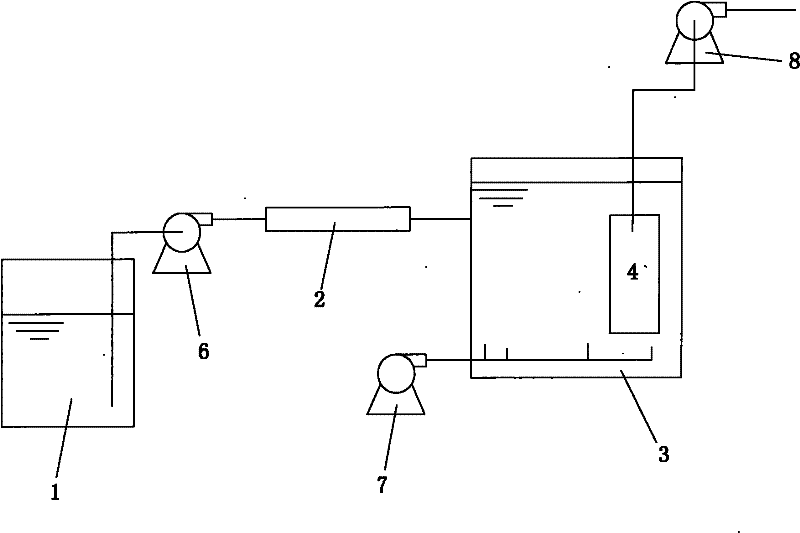

Method for treating paper-making wastewater by utilizing photocatalytic oxidation film coagulation reactor

A technology for photocatalytic oxidation and papermaking wastewater, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, energy wastewater treatment, etc. Low cost, low investment and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the water quality of papermaking wastewater is as follows: SS concentration is 256mg / L, COD concentration is 1378mg / L, BOD 5 The pH value is 326mg / L, the pH value is 3.0, the hydraulic retention time of the photocatalytic oxidation reactor is 2h, the hydraulic retention time of the membrane coagulation reactor is 3h, and the KRT-3 water treatment agent is added at a concentration of 8mg / L. Days later, the average value of effluent water quality is: SS concentration is 36mg / L, COD concentration is 88mg / L, BOD 5 It is 37mg / L, and the pH value is 7.1.

Embodiment 2

[0030] Embodiment 2: the water quality of papermaking wastewater is as follows: SS concentration is 423mg / L, COD concentration is 2120mg / L, BOD 5 The pH value is 435mg / L, the pH value is 3.8, the hydraulic retention time of the photocatalytic oxidation reactor is 2h, the hydraulic retention time of the membrane coagulation reactor is 3h, and the KRT-3 water treatment agent is added at a concentration of 15mg / L. Days later, the average value of effluent water quality is: SS concentration is 49mg / L, COD concentration is 102mg / L, BOD 5 It is 78mg / L, and the pH value is 7.4.

Embodiment 3

[0031] Embodiment 3: the water quality of papermaking wastewater is as follows: SS concentration is 510mg / L, COD concentration is 2570mg / L, BOD 5 The pH value is 513mg / L, the pH value is 4.1, the hydraulic retention time of the photocatalytic oxidation reactor is 2h, the hydraulic retention time of the membrane coagulation reactor is 3h, and the KRT-3 water treatment agent is added at a concentration of 18mg / L. Days later, the average value of effluent water quality is: SS concentration is 112mg / L, COD concentration is 126mg / L, BOD 5 It is 89mg / L, and the pH value is 7.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com