An automatic forming machine for tofu string

An automatic forming and tofu technology, applied in metal processing and other directions, can solve the problems of difficult operation, low degree of mechanization, and cumbersome processing procedures in the processing process, and achieve the effect of avoiding contamination of tofu, high degree of automation, and improving the accuracy of guidance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

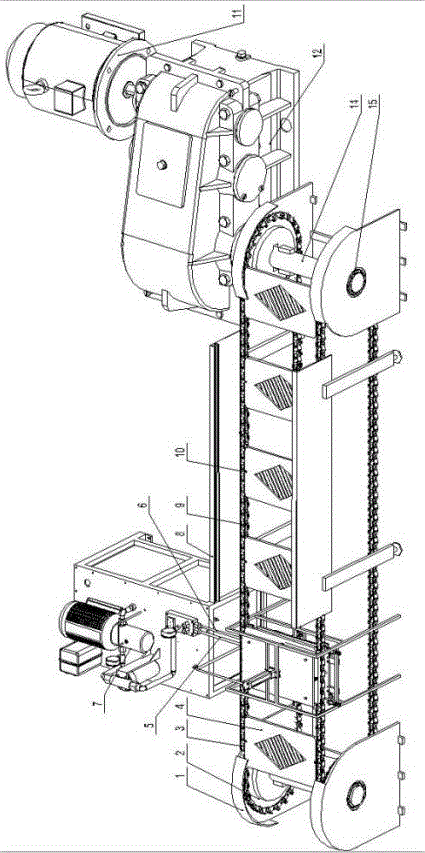

[0034] Such as figure 1 The shown tofu string automatic forming machine includes a chain plate transmission mechanism, a flower cutting mechanism and a power mechanism. The chain plate conveying mechanism comprises two sprocket bearings 1 arranged oppositely and a transverse shaft 14 installed on the sprocket bearing 1 through a bearing 15. A sprocket 2 is arranged at both ends of the transverse shaft 14, and a sprocket 2 is arranged on the sprocket 2. There are chains 3, two chains 3 are parallel to each other, and the ends of the transverse shaft 14 are sequentially connected with a reduction box 12 and a motor 11 through a shaft coupling. The outside of the chain 3 is provided with a protective plate 8, and the inboard of the chain 3 is provided with a fixed plate 9, and the fixed plate 9 is fixedly installed with a tofu tray 4 positioned between the two chains 3 by bolts 10, and the tofu tray 4 is fixed at equal intervals. On the outer circumference of the chain 3.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com