Treatment equipment for solid waste pollution

A technology for treating equipment and solid waste, which is applied in the fields of solid waste removal, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as large engineering volume, poor filtration, and low drainage efficiency of solid waste. Achieve strong functionality and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

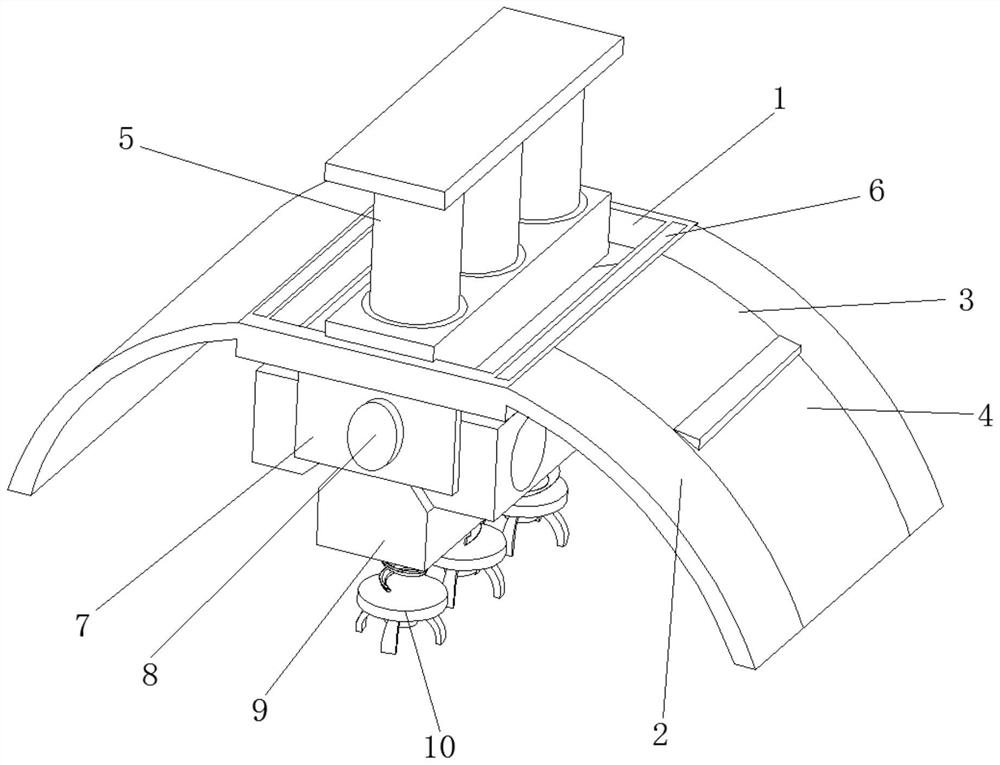

[0033] see Figure 1-3 , the present invention provides a technical solution: a treatment equipment for solid waste pollution, including a fixed frame 1, the left and right sides of the fixed frame 1 are fixedly connected with arc-shaped support plates 2, and the outer surface of the arc-shaped support plate 2 is provided with Fixed groove 3, the inner surface of fixed groove 3 is fixedly connected with water storage mechanism 4, the inner surface of fixed frame 1 is slidably connected with compacting column 5, and the movable connection of fixed frame 1 is provided with stabilizing mechanism 6, and the front and rear sides of fixed frame 1 bottom The sides are fixedly connected with side plates 7, and the opposite sides of the two side plates 7 are rotatably connected with a rotating shaft 8, and the outer surface of the rotating shaft 8 is uniformly and fixedly connected with a compacting chamber 9, and the outer surface of the compacting column 5 is connected with the compac...

Embodiment 2

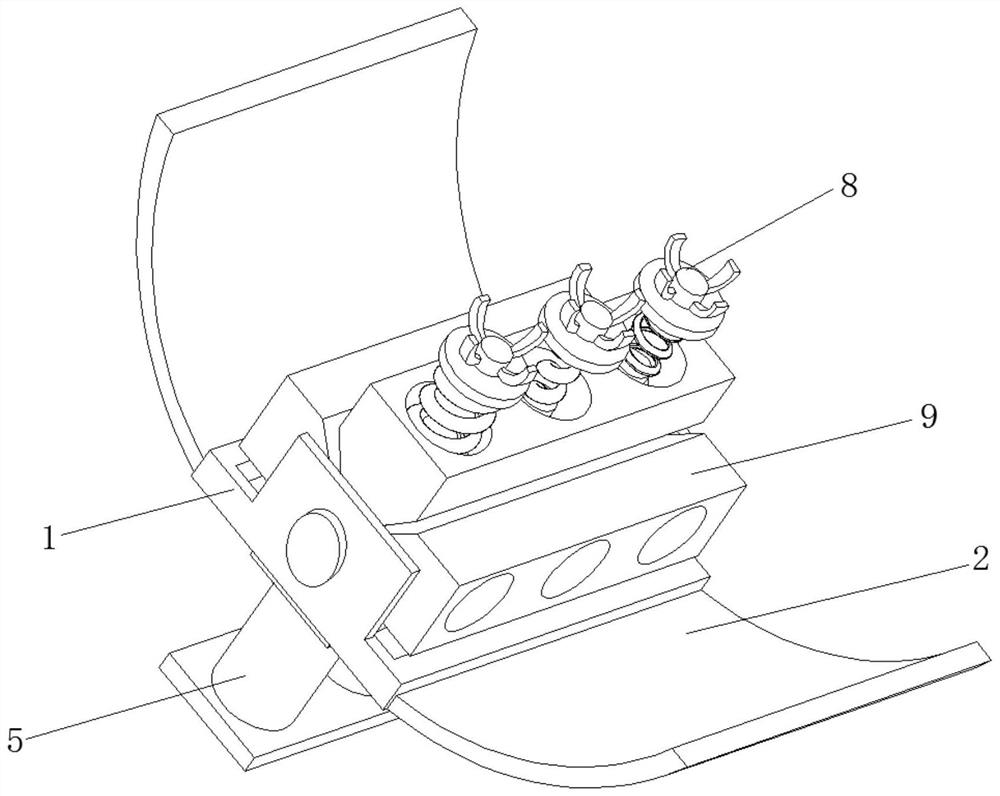

[0040] see Figure 4-5 , the present invention provides a technical solution: the reinforcing mechanism 10 includes a circular cylinder 101, the inner surface of each compacting bin 9 is fixedly connected with a circular cylinder 101, and the inner surface of the circular cylinder 101 is provided with a dark groove, and the dark groove A threaded shaft 102 is rotatably connected to the inner surface of the threaded shaft 102 , and a protective sheath 103 is sheathed on the outer surface of the threaded shaft 102 .

[0041] A disc 104 is fixedly connected to the bottom of the threaded shaft 102 , and a clamping handle 105 is rotatably connected to the bottom of the disc 104 . Solid waste can be granulated by extrusion, which is more functional, and a threaded shaft 102 is provided inside the circular cylinder 101. The threaded shaft 102 can be squeezed or released to make the disc 104 shake and slide left and right, which can Pulling the solid waste repeatedly in multiple dire...

Embodiment 3

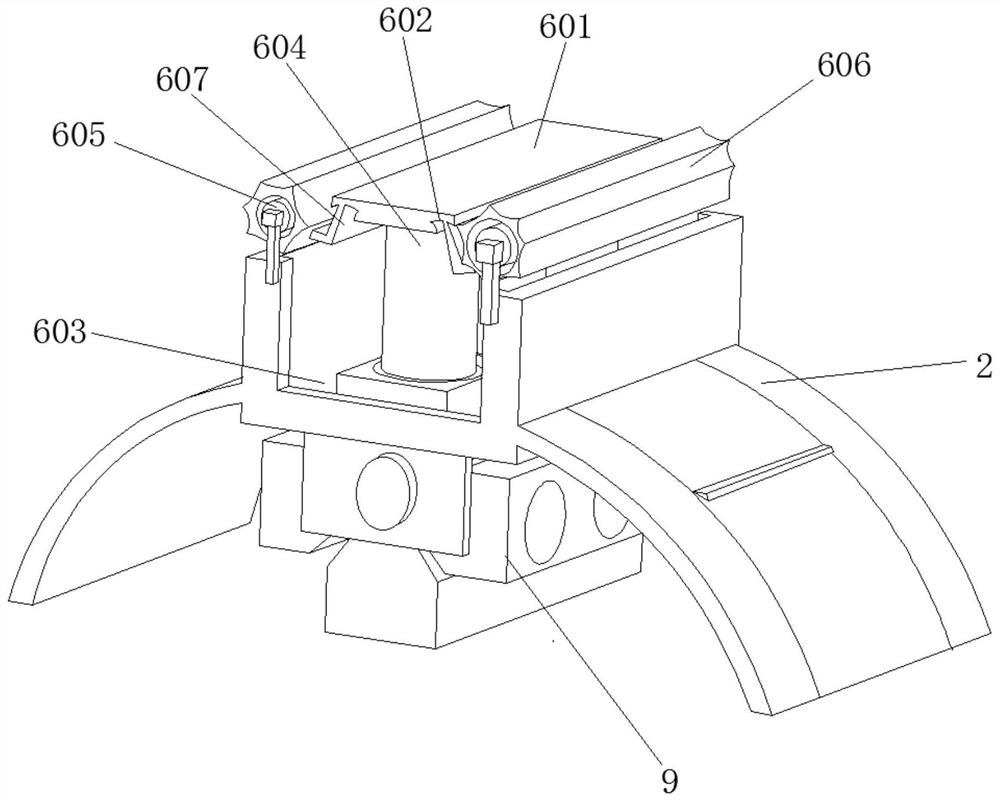

[0045] see Figure 6-7 The present invention provides a technical solution: the water storage mechanism 4 includes a water level plate 401, the outer surface of the water level plate 401 is slidably connected to the inner surface of the fixing groove 3, and the inner surface of the fixing groove 3 is slidably connected to an arc-shaped water storage bin 402.

[0046] The inner surface of the arc-shaped water storage bin 402 is provided with a connection assembly 403 , and the top of the arc-shaped water storage bin 402 is movably connected with the bottom of the water level plate 401 . A solvent assembly capable of mixing sewage is connected between each small arc-shaped water storage bin 402 , and the water flow rushes through and is actively mixed into the solvent, which acts as a filter and speeds up the treatment efficiency of sewage.

[0047] The connection assembly 403 includes a fixed ring a1, the outer surface of the fixed ring a1 is fixedly connected with the inner su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com