Angle-adjustable laser cutting device

A laser cutting and adjustable technology, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of tool breakage, easily damaged cutter head, and barbs at the cutting edge, etc., and achieve the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

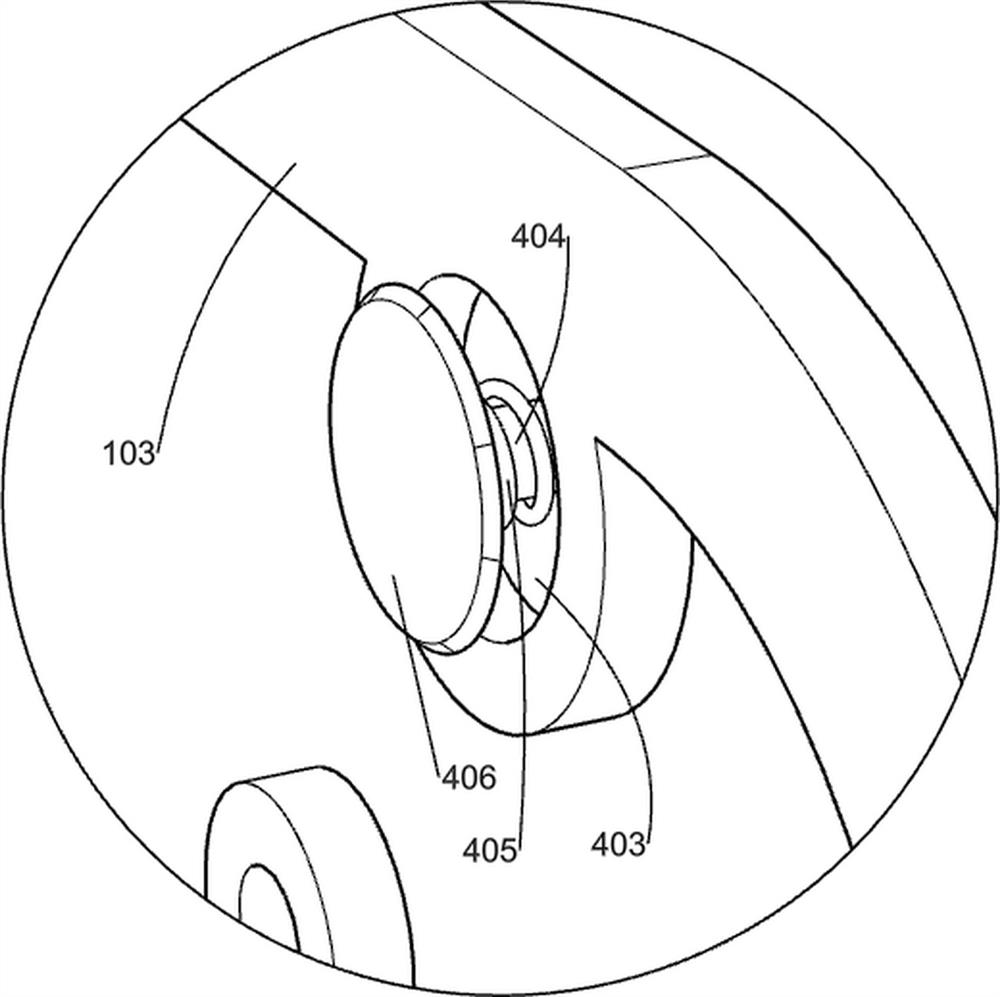

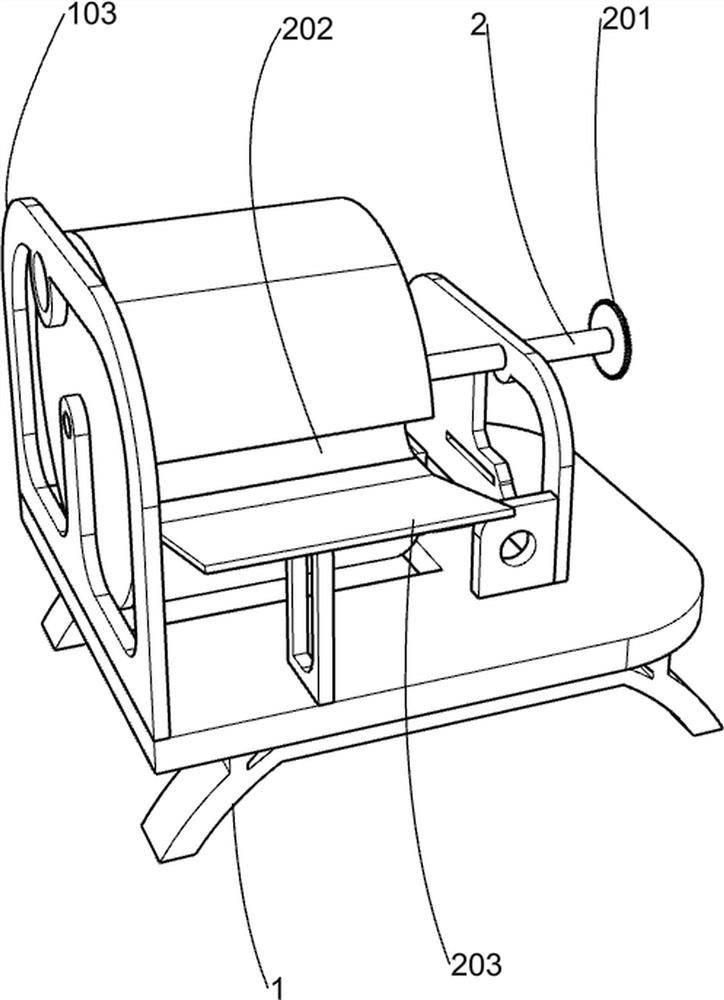

[0029] Such as Figure 1-2As shown, an angle-adjustable laser cutting device includes a base 1, a frame 101, a motor 1011, a missing gear 1012, a first bracket 102, a support plate 103, a bucket cover 104, a second bracket 105, and a third bracket 106, the fourth bracket 107, the intermittent rotation assembly, the cutting assembly and the limit assembly, the upper side of the base 1 is fixedly installed with the frame 101, the first bracket 102, the support plate 103, the second bracket 105, the third bracket 106 and the fourth bracket. Support 107, the frame 101 is located on the right side of the base 1, the support plate 103 is located on the left side of the base 1, the first support 102 is located on the right front side of the support plate 103, the second support 105 is located on the left side of the frame 101, and the second support 105 There is a straight chute 1051 in the middle part below, the third support 106 is positioned at the left side of the second support ...

Embodiment 2

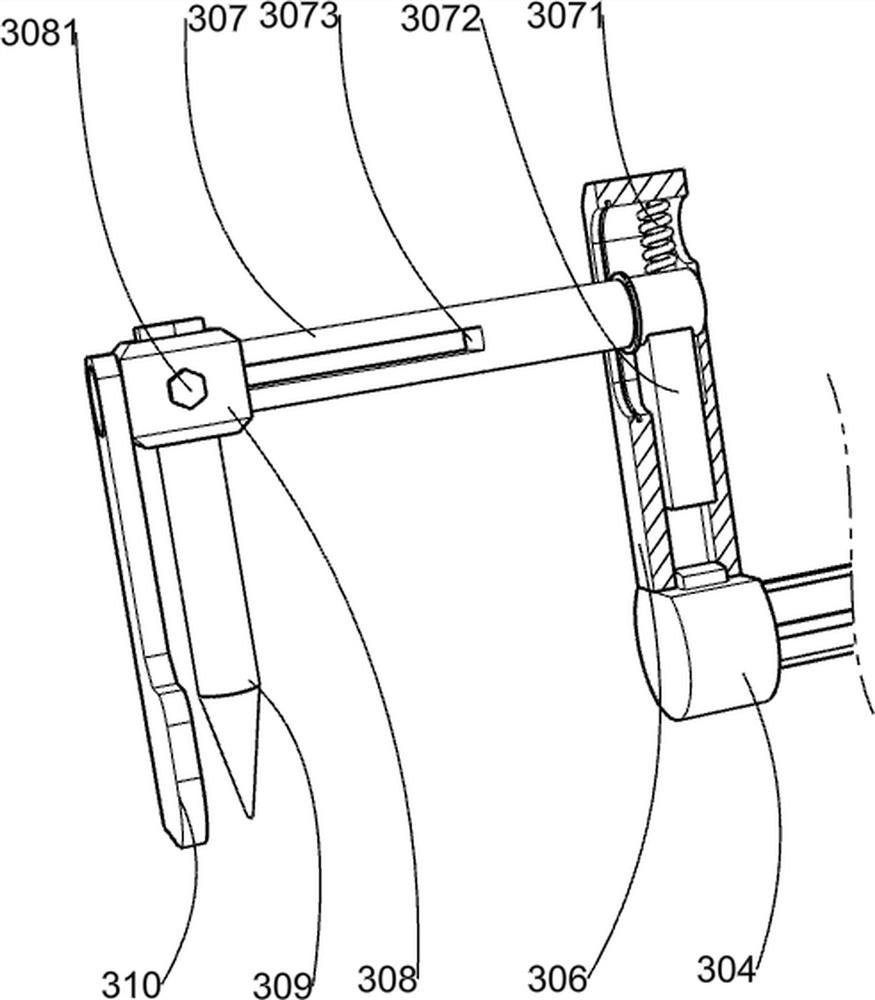

[0032] Specific reference Figure 3-7 , on the basis of Embodiment 1, the intermittent rotating assembly includes a long rotating shaft 2, a first gear 201, a three-station drum 202 and a feeding swash plate 203, and the long rotating shaft 2 rotates through the center of the support plate 103, the bucket The upper middle part of the cover 104 and the second bracket 105, the right end of the long rotating shaft 2 is fixedly connected with the first gear 201, the first gear 201 meshes with the missing gear 1012, and the three-station drum 202 is fixedly connected with the left end of the long rotating shaft 2, three The station drum 202 is completely placed in the barrel cover 104 , the rear end of the feeding ramp 203 is fixedly connected to the lower side of the feeding port 1042 , and the feeding ramp 203 is fixedly connected to the upper side of the first bracket 102 .

[0033] The missing gear 1012 will mesh with the first gear 201 during rotation. At this time, the missin...

Embodiment 3

[0041] Specific reference Figure 8 On the basis of Embodiment 2, it also includes a toggle lever 5, a sliding plate 501, a bump 5011, a triangular block 502, a sliding column 503 and a fifth spring 504, and the toggle lever 5 is fixedly connected to the long rotating shaft 2 , the toggle lever 5 is between the second bracket 105 and the first gear 201, the sliding plate 501 slides through the straight chute 1051, the triangular block 502 is slidably connected with the base 1, the second bracket 105 and the third bracket 106, and the triangular The right side of the block 502 is fixedly connected to the left side of the sliding plate 501, the lower side of the bump 5011 is fixedly connected to the upper right side of the sliding plate 501, the bump 5011 touches the toggle lever 5, and the sliding column 503 slides through the second bracket 105 , the rear end of the sliding post 503 is fixedly connected to the front side of the triangular block 502, the fifth spring 504 is sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com