Degradable bubble protective film and processing method thereof

A processing method and protective film technology, applied in the field of degradable bubble protective film and its processing, can solve the problems of poor environmental protection, non-degradable bubble protective film, white pollution, etc., and achieve the effects of good environmental protection, convenient observation and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

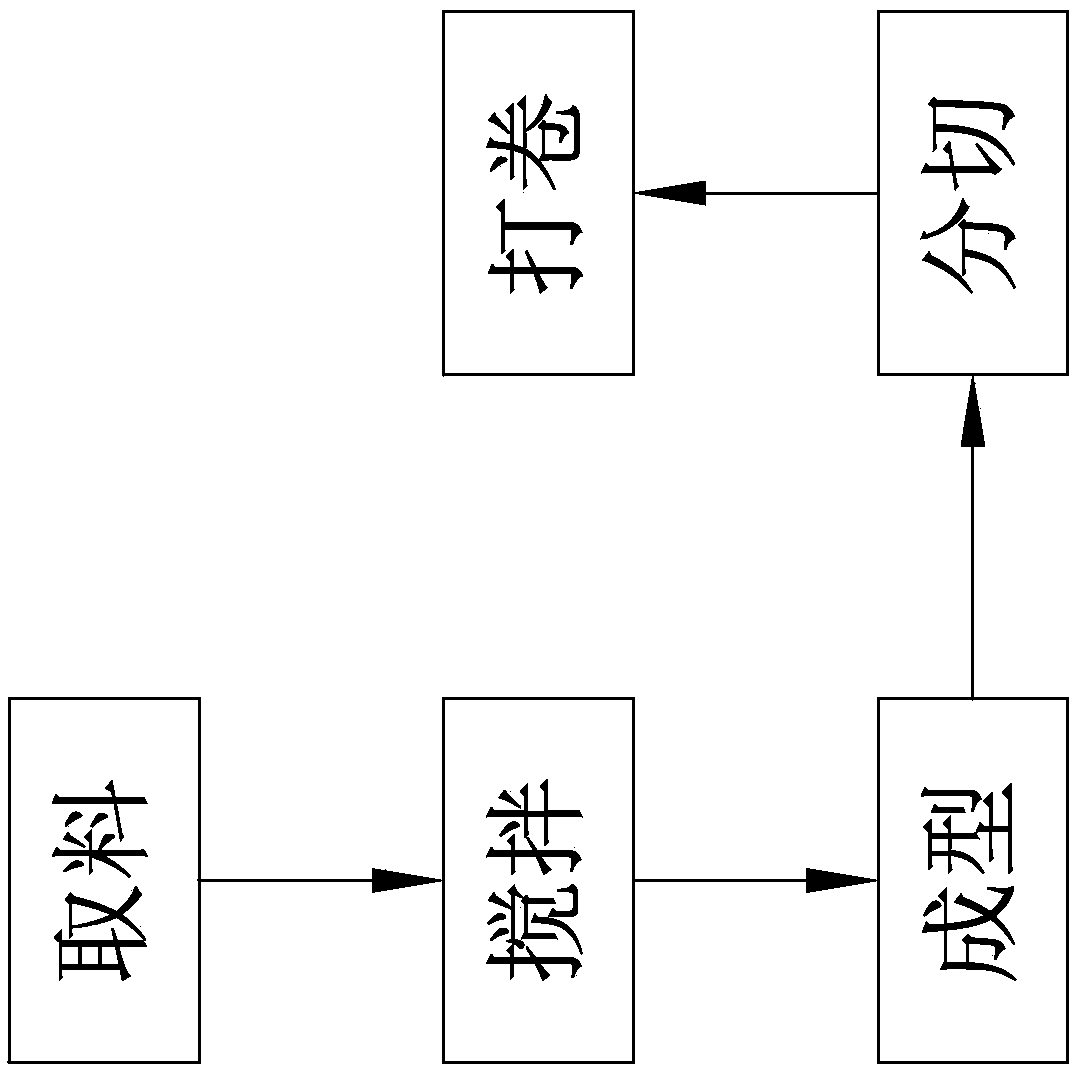

[0070] The processing method of the degradable air bubble protective film comprises the following steps:

[0071] a, taking material: by weight, take by weight 65 parts of low-density polyethylene, 3.5 parts of antioxidant, 1.8 parts of plasticizer and 2.8 parts of biodegradable additives;

[0072] b. Stirring: put the low-density polyethylene, antioxidant and plasticizer into the stirring device, and after stirring for 20 minutes, put the biodegradable additive into the stirring device, and stir for 15 minutes to prepare the mixture;

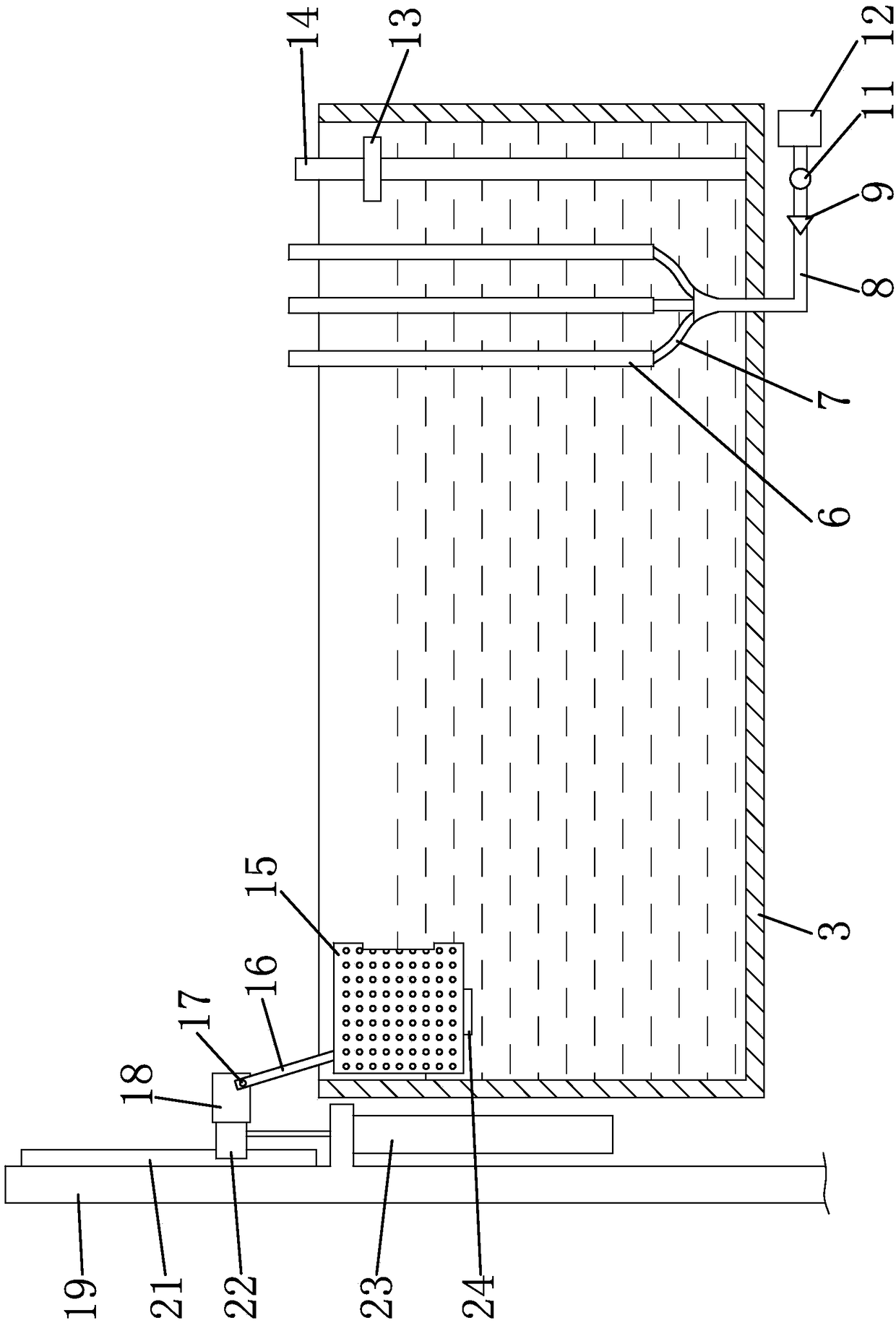

[0073] c. Forming: put the mixture into the air bubble film machine to extrude and form it to obtain a semi-finished degradable air bubble protective film; the process temperature of each section of extrusion in step c is: feeding section 150°C, plasticizing section 190°C °C, the homogenization section is 220 °C; the molding temperature in step c is 175 °C; the bubble diameter of the degradable bubble protective film in step c is 13 mm, and the...

Embodiment 2

[0077] The processing method of the degradable air bubble protective film comprises the following steps:

[0078] a, taking material: by weight, take by weight 60 parts of low-density polyethylene, 3 parts of antioxidant, 1.5 parts of plasticizer and 2.4 parts of biodegradable additives;

[0079] b. Stirring: put the low-density polyethylene, antioxidant and plasticizer into the stirring device, and after stirring for 15 minutes, put the biodegradable additive into the stirring device, and stir for 10 minutes to prepare the mixture;

[0080] c. Forming: put the mixture into the air bubble film machine for extrusion and molding to obtain a semi-finished degradable air bubble protective film; the process temperature of each section of extrusion in step c is: feeding section 140°C, plasticizing section 180°C °C, the homogenization section is 210 °C; the molding temperature in step c is 170 °C; the bubble diameter of the degradable bubble protection film in step c is 8mm, and the ...

Embodiment 3

[0084] The processing method of the degradable air bubble protective film comprises the following steps:

[0085] a, taking material: by weight, take by weight 80 parts of low-density polyethylene, 5 parts of antioxidants, 2.5 parts of plasticizers and 4.6 parts of biodegradable additives;

[0086] b. Stirring: put the low-density polyethylene, antioxidant and plasticizer into the stirring device, and after stirring for 35 minutes, put the biodegradable additive into the stirring device, and stir for 20 minutes to prepare the mixture;

[0087] c. Forming: put the mixture into the air bubble film machine for extrusion and molding to obtain a semi-finished degradable air bubble protective film; the process temperature of each section of extrusion in step c is: feeding section 160 ° C, plasticizing section 200 °C, the homogenization section is 230 °C; the molding temperature in step c is 180 °C; the bubble diameter of the degradable bubble protective film in step c is 20 mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com