Bulk-phase doped nano-photocatalysis material, preparation method thereof and application of material

A photocatalytic material and a technology for catalytic materials are applied in the field of bulk doped nano-photocatalytic materials and their preparation, and can solve the problems of increasing the difficulty of photocatalytic materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

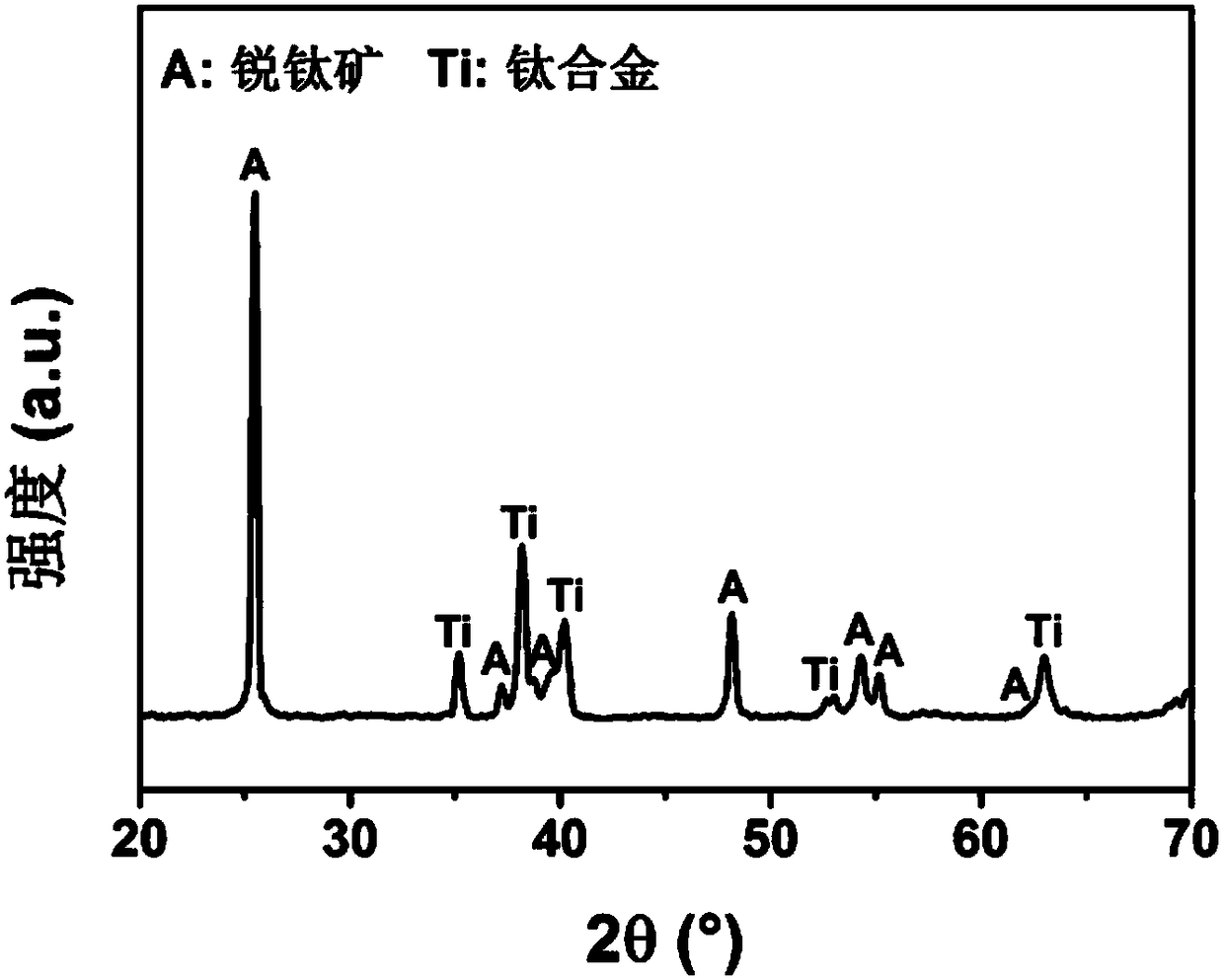

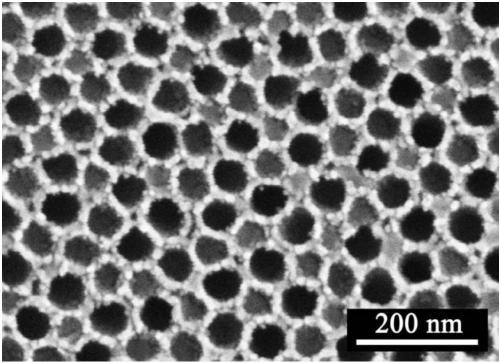

[0030] The bulk phase-doped nano-photocatalytic material prepared in this example is a titanium dioxide nanotube material doped with molybdenum element in the bulk phase, and the specific process is as follows:

[0031] 1. Mix titanium sponge and molybdenum powder evenly according to the atomic ratio of 95:5, put them into a non-consumable vacuum electric arc furnace and repeatedly smelt them at 3000°C for more than three times to make them evenly mixed to obtain Ti-5Mo alloy. The Ti-5Mo alloy ingot was subjected to homogenization annealing in a tubular heat treatment furnace, the heating rate was 5 °C / min, the annealing temperature was 1000 °C, the holding time was 4 h, and then directly quenched to room temperature in 15 wt.% NaCl aqueous solution, A single-phase Ti-5Mo alloy is obtained.

[0032] 2. Put the single-phase alloy in the fluorine-containing electrolyte, and use the electrochemical anodic oxidation method for oxidation treatment; wherein: the fluorine-containing ...

Embodiment 2

[0035] The bulk phase-doped nano-photocatalytic material prepared in this example is a titanium dioxide nanotube material doped with tungsten element bulk phase, and the specific process is as follows:

[0036] 1. Mix titanium sponge and tungsten powder evenly according to the atomic ratio of 90:10, put them into a non-consumable vacuum electric arc furnace and repeatedly smelt them at 3500°C for more than three times to make them evenly mixed to obtain Ti-10W alloy. The Ti-10W alloy ingot was subjected to homogenization annealing in a tubular heat treatment furnace, the heating rate was 10°C / min, the annealing temperature was 1400°C, the holding time was 6h, and then directly quenched to room temperature in 15wt.% NaCl aqueous solution, A single-phase Ti-10W alloy was obtained.

[0037] 2. Put the single-phase alloy in the fluorine-containing electrolyte, and use the electrochemical anodic oxidation method for oxidation treatment; wherein: the fluorine-containing electrolyte ...

Embodiment 3

[0040] 1. With a wavelength of 254nm and a light intensity of 6mW / cm 2 The ultraviolet lamp tube was used as the light source, and the Ti-5Mo-O nanotube material prepared in Example 1 was pre-irradiated for 8 hours at a temperature of 20° C. and a relative humidity of 50%.

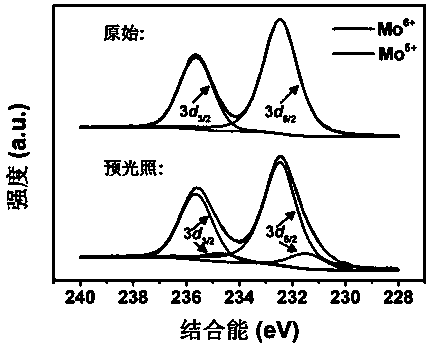

[0041] 2. After the irradiation, put the Ti-5Mo-O nanotube material into the X-ray photoelectron spectrometer to test the XPS spectrum, and compare it with the XPS spectrum of the original sample without UV pre-irradiation. From image 3 It can be seen that after UV irradiation, some molybdenum elements in Ti-5Mo-O change from +6 valence to +5 valence, realizing the capture and storage of photogenerated electrons under light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com