Organic waste gas multifunctional integral processing device

A technology of organic waste gas and treatment device, which is applied in incinerators, combustion methods, combustion types, etc., can solve the problems that catalytic combustion method is not suitable for organic waste gas, secondary pollution, increase treatment costs, etc., and achieve short desorption preheating time. , the effect of reducing operating costs and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

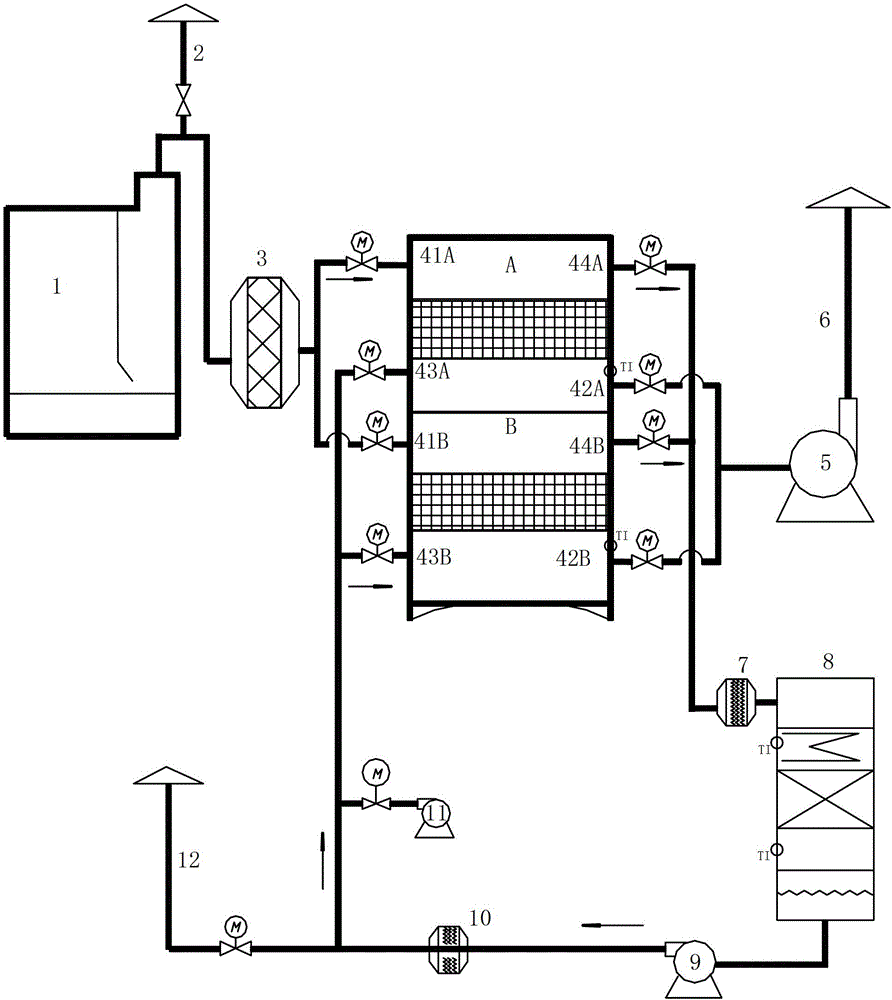

[0021] Embodiment: Take the organic waste gas that the water curtain spray booth produces as an example to illustrate the working process of the present invention:

[0022] In the present invention, two activated carbon adsorption beds A and B work alternately. When one is performing adsorption operation, the other is performing desorption operation. The operation time of adsorption and desorption depends on the concentration of organic substances contained in the waste gas.

[0023] The working process of the adsorption operation is that the valves at the inlet and outlet of the adsorption gas of the activated carbon adsorption bed A or B are opened, and the desorption inlet and outlet valves are closed; The organic waste gas is sucked into the dust filter device 3, and the dust and paint mist in the waste gas are filtered out to prevent them from blocking the gaps of the adsorbent in the activated carbon adsorption bed and affecting the adsorption effect; then, the waste gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com