Wet type electrostatic dust collector

A wet electrostatic and precipitator technology, used in external electrostatic separators, electrostatic separation, electrode cleaning, etc., can solve the problems of interval, poor effect and low efficiency of dust removal, and achieve the effect of improving dust collection effect and improving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] In order to more clearly and clearly illustrate the specific implementation objectives and implementation modes of the present invention, the technical solution of the present invention will be fully described below, and the described embodiments are part of the embodiments of the present invention, rather than all embodiments. On the premise of no creative work, all other embodiments based on the described embodiments of the present invention belong to the protection scope of the present invention.

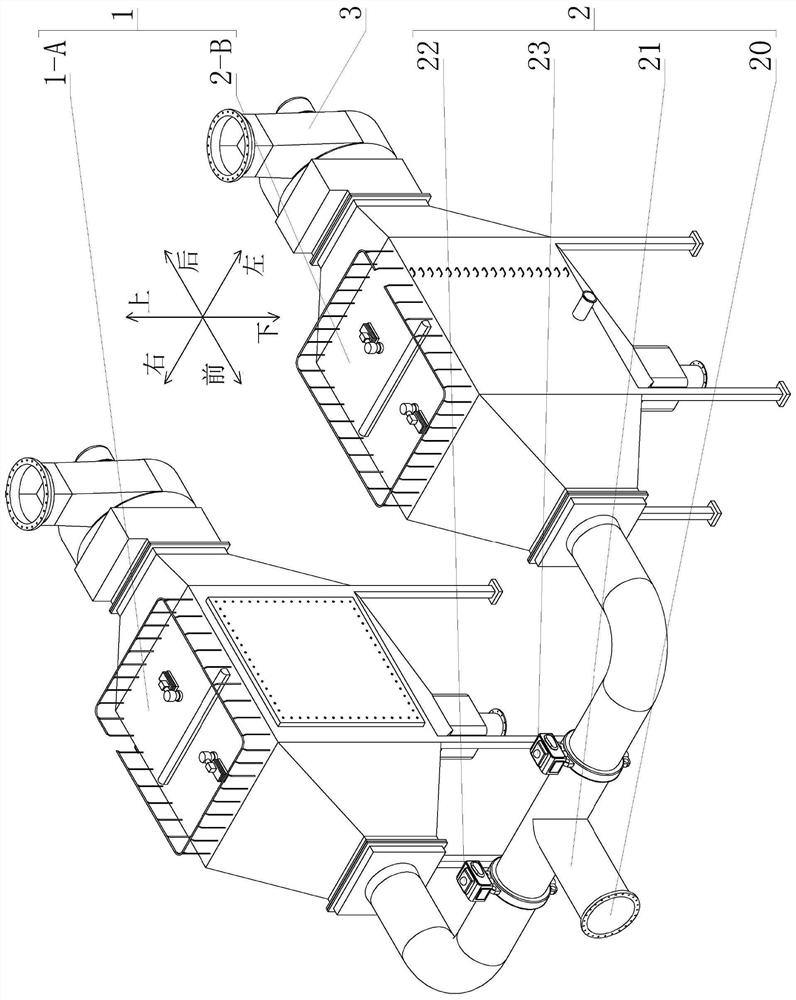

[0105] Wet electrostatic precipitator of the present invention, as figure 1 shown, including:

[0106] Dust collector body 1. Control mechanism.

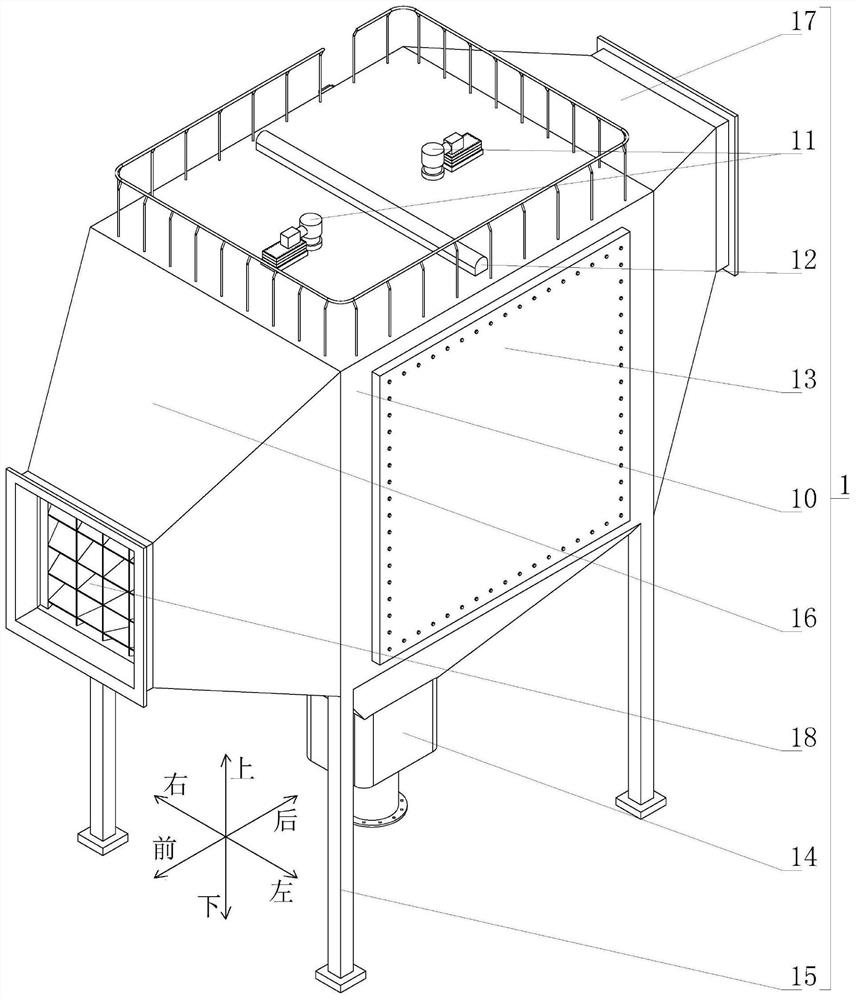

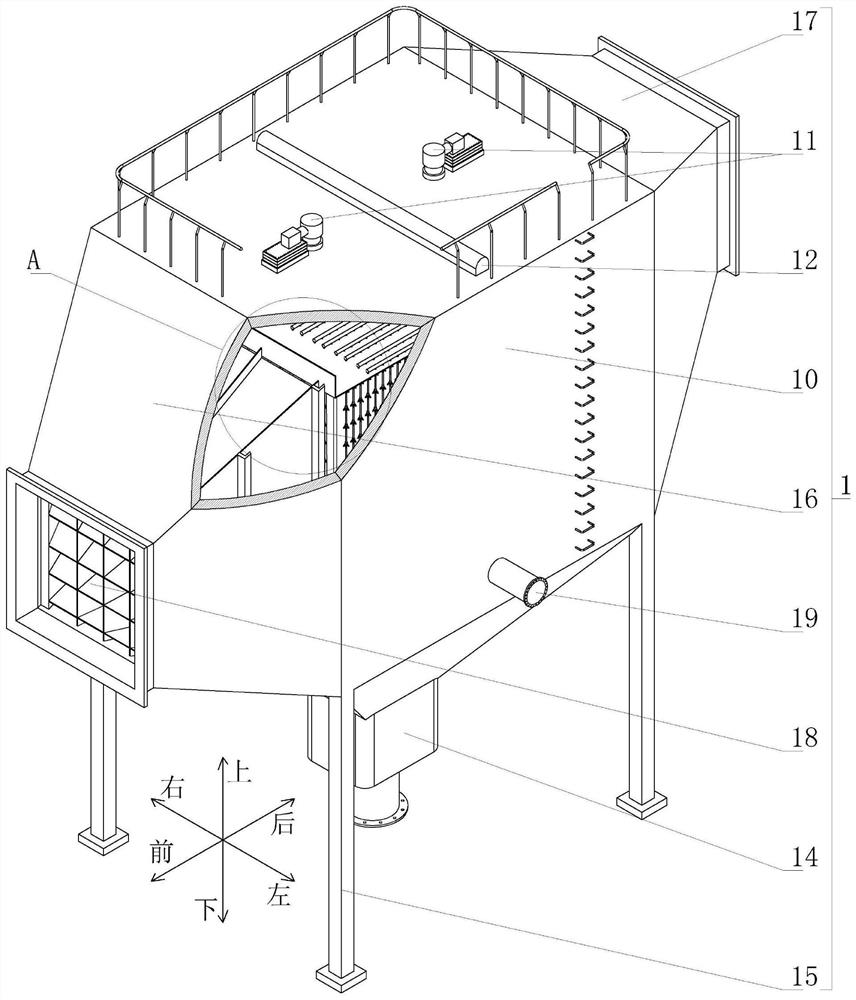

[0107] The dust collector body 1 is composed of a first dust collector 1-A and a second dust collector 1-B arranged side by side and having the same structure, as figure 1 , figure 2 , image 3 shown, including:

[0108] A "Π" shaped cavity 10 that runs through and is hollow in the front and rear direction, the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com