Rotary filling machine for filling containers with liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

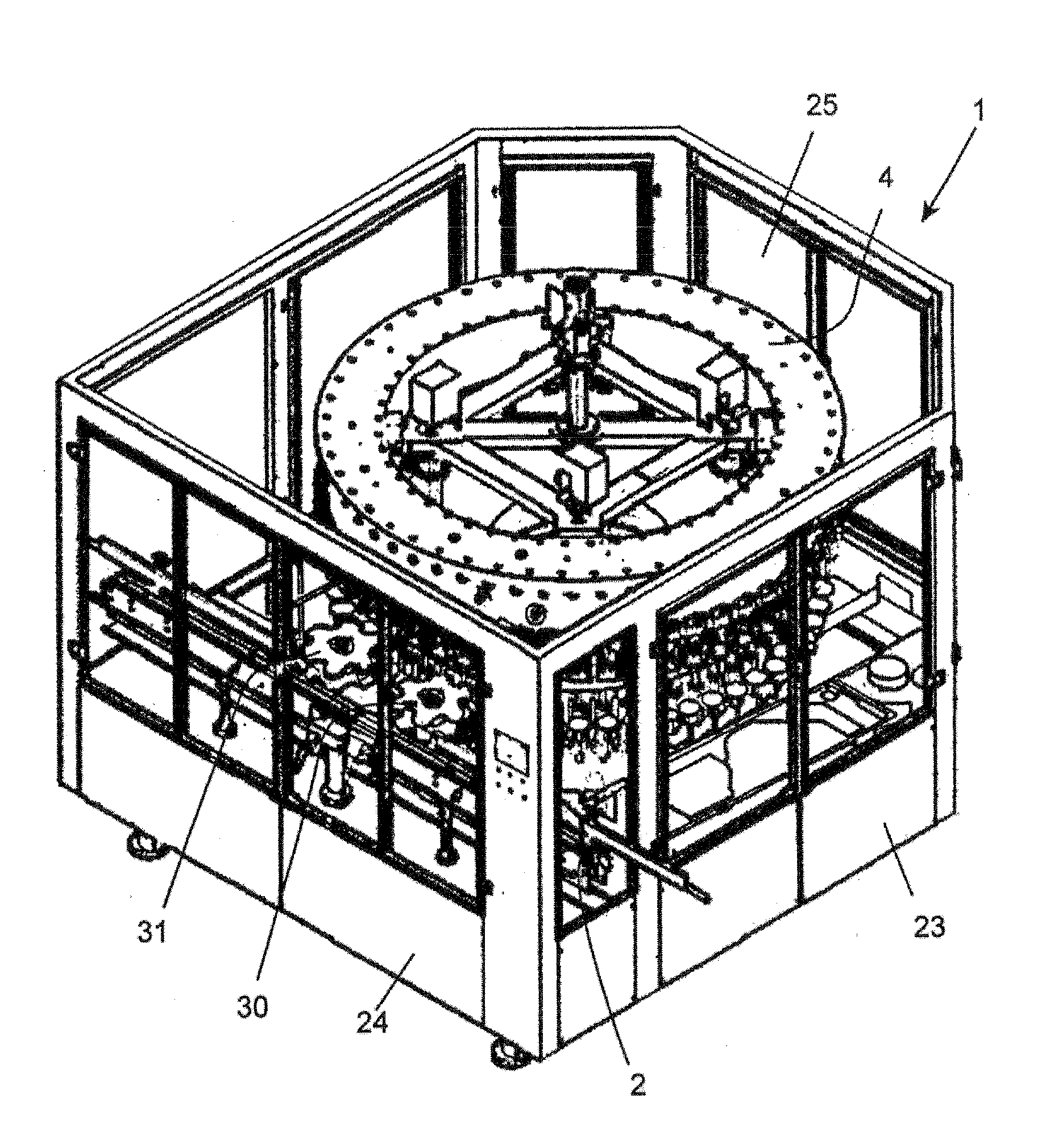

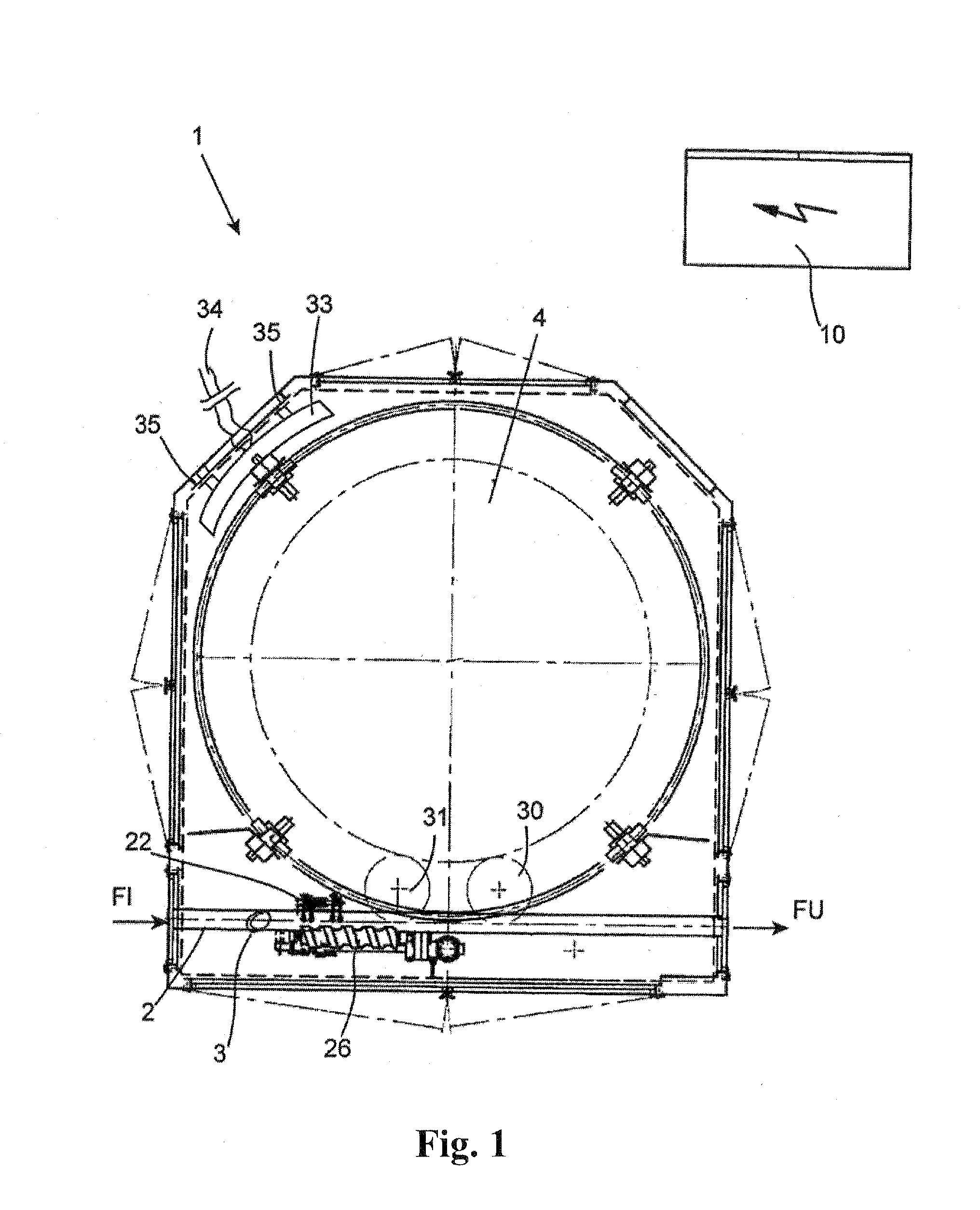

[0039]With reference to the accompanying drawings, 1 denotes in its entirety the rotary filling machine for filling containers with liquids, according to the present invention.

[0040]The abovementioned machine 1 may be arranged, in a per se entirely conventional manner, inside a bottling plant, for example downstream of a rinsing machine and upstream of a capping machine to which it is operationally connected by means of conveying means.

[0041]The filling machine 1 (FIG. 4) is provided with an external frame 23, protective walls 24, 25 on the perimeter of the machine 1 and an external cabin la containing the electric and electronic operating devices (FIG. 1).

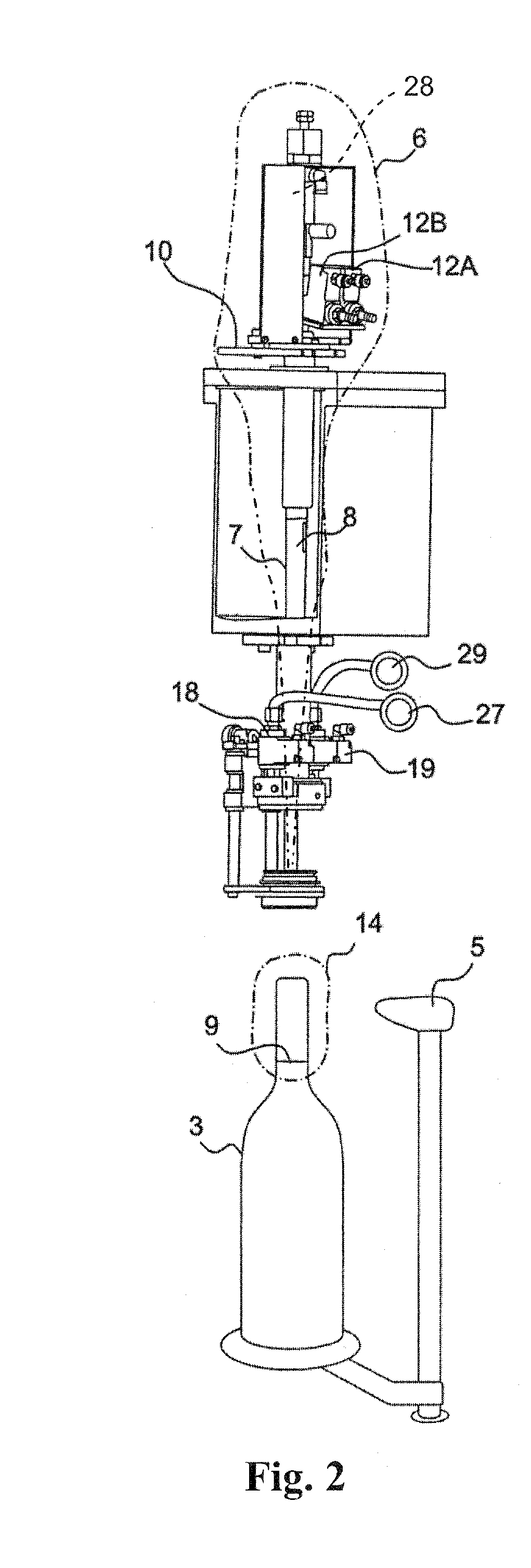

[0042]The machine is also provided, in a manner known per se, with a rotating carousel or turret 4 arranged inside the frame 23 and having, mounted along its periphery, a plurality of filling valves 6.

[0043]The containers 3, in particular bottles, to be filled are inserted inside the frame 23 and loaded onto the guide or conveyor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current | aaaaa | aaaaa |

| Digital information | aaaaa | aaaaa |

| Transmission | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com