High temperature resistant honeycomb core strip adhesive, preparation method and application thereof

A honeycomb core, high temperature resistant technology, applied in the directions of adhesives, non-polymer adhesive additives, adhesive types, etc. and other problems, to achieve the effect of improving the strength of the honeycomb node, improving the preparation efficiency, and improving the penetration phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

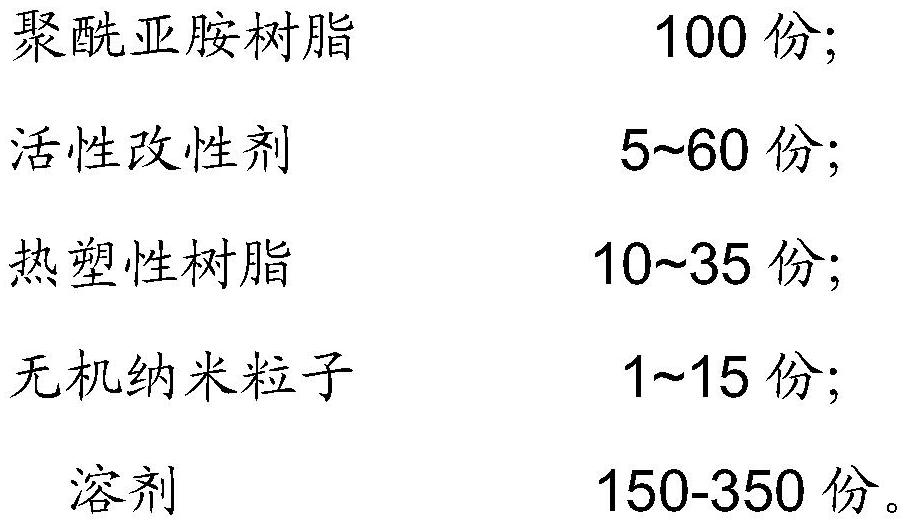

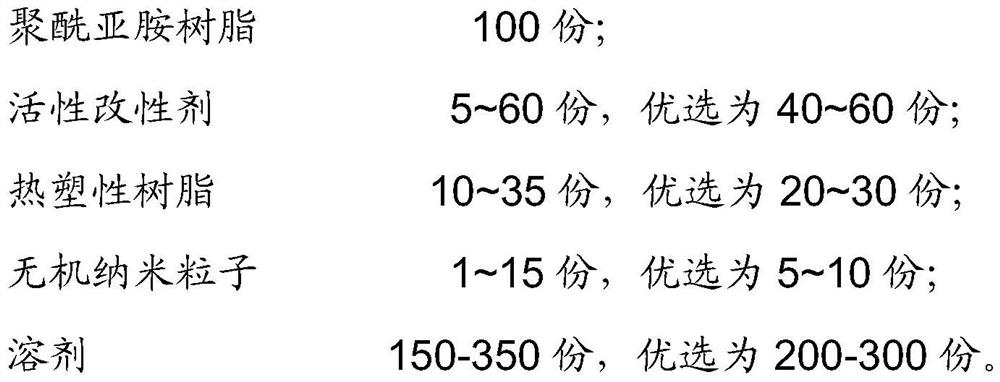

Method used

Image

Examples

preparation example Construction

[0034] According to a second aspect of the present invention, there is provided a method for preparing a high-temperature-resistant honeycomb core strip, which is used to prepare the honeycomb core strip described in the first aspect above, comprising the following steps:

[0035] Step 1: Add 1 / 4 to 1 / 3 of the thermoplastic resin to the active modifier, dissolve it in the range of 100 to 150°C, then lower the temperature to below 80°C, and add the remaining thermoplastic resin and inorganic nanoparticles to the active modifier Among modifiers, stir and disperse to obtain component A;

[0036]Step 2, under the condition of stirring at room temperature, adding the polyimide resin and component A into the solvent for dissolving and dispersing to obtain a uniform and stable honeycomb core strip adhesive.

[0037] In the present invention, 1 / 4 to 1 / 3 of the thermoplastic resin is pre-dissolved in the active modifier, which makes the prepared core strip glue have a certain viscosity...

Embodiment 1

[0043] The high-temperature-resistant honeycomb core strip adhesive is prepared from the components of the mass ratio in Table 1 below:

[0044] Table 1

[0045] ingredient name content Remark factory thermosetting polyimide 100g phenynyl capped Institute of Chemistry, Chinese Academy of Sciences Alkynyl benzoxazine resin 40g Sichuan University thermoplastic polyimide resin 25g Particle size 18μm Evonik Nano silica 10g 200nm Evonik acetone 300g chemically pure Sinopharm Chemical Reagent

[0046] The high temperature resistant honeycomb core strip adhesive is prepared by the following method:

[0047] Preparation of component A: Weigh 7g of thermoplastic polyimide resin and add it to 40g of alkynyl benzoxazine resin, heat to 120°C and keep it warm until the thermoplastic polyimide resin is dissolved and transparent, then add 18g of thermoplastic polyimide resin under the condition of cooling to 50°C Polyimid...

Embodiment 2

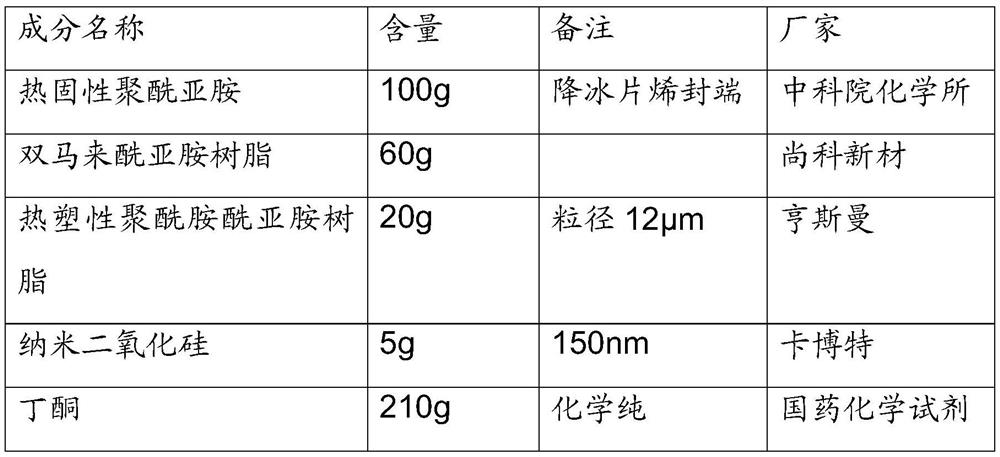

[0053] The high-temperature-resistant honeycomb core strip adhesive is prepared from the components of the mass ratio in Table 2 below:

[0054] Table 2

[0055]

[0056] The high temperature resistant honeycomb core strip adhesive is prepared by the following method:

[0057] 1. Preparation of component A: Weigh 5g of thermoplastic polyamide-imide resin and add it to 60g of bismaleimide resin, heat to 120°C and keep it warm until the thermoplastic polyamide-imide resin is dissolved and transparent, then cool down to below 80°C , Add 15g of thermoplastic polyamideimide resin and 5g of nano-silica at 70°C, and disperse evenly at high speed.

[0058] 2. Preparation of high-temperature-resistant core strip glue: under the condition of high-speed stirring at room temperature, add 85g of component A and 100g of thermosetting polyimide resin into 210g of butanone, dissolve, mix and disperse evenly.

[0059] The room temperature tensile shear strength (GB / T7124-2008) of the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com