A kind of fluorenyl cardo type polyimide thinner and its preparation method and application

A polyimide diluent, polyimide technology, used in the field of high-performance polymer materials, can solve the problem of increased glass transition temperature and melt viscosity, narrowed prepolymer processing window, and difficulty in meeting resin requirements. Transfer molding process and other issues, to achieve the effect of low glass transition temperature, improved operating temperature range, high solubility and solution stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

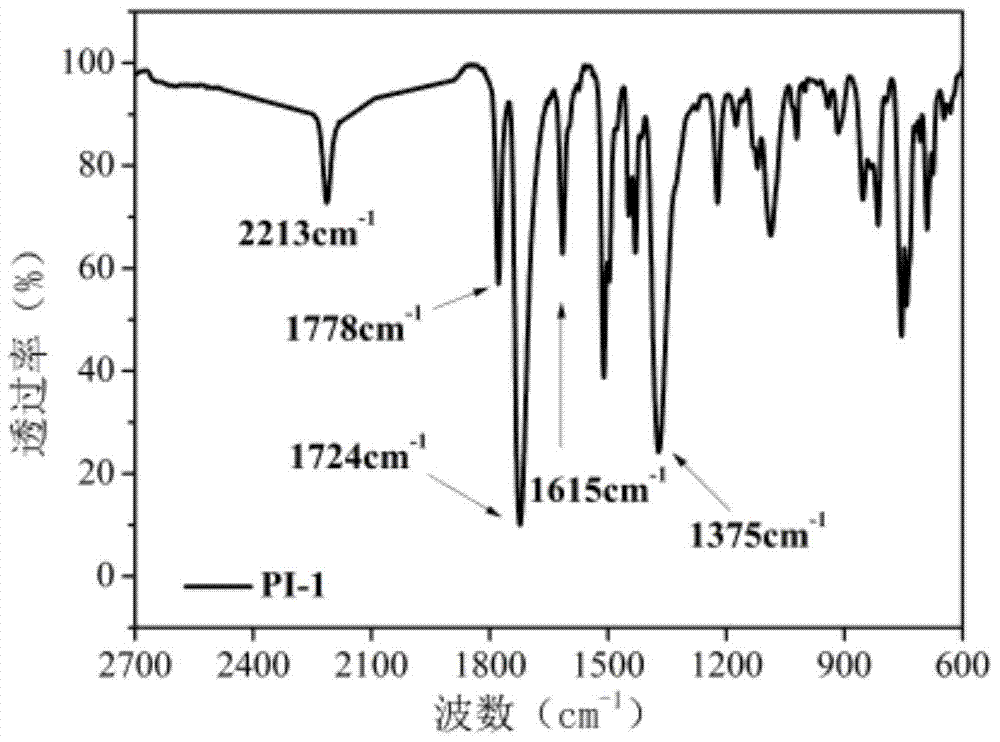

Embodiment 1

[0035] Under the protection of mechanical stirring and inert gas, weigh 3.48 g (0.01 mol) of diamine 9,9-bis(4-aminophenyl) fluorene (BAFL) and 4.96 g of end-capping agent 4-phenylethynylphthalic anhydride (PEPA). g (0.02mol) in the there-necked flask, dropwise add 32.32g organic solvent DMAc after vacuum distillation, after reacting at room temperature for 8 hours, add triethylamine (0.03mol, 3.04g) and acetic anhydride (0.03mol, 3.06g), reacted at 40°C for 5 hours, finally the solution obtained was washed 4 times with excess distilled water until the pH value of the filtered water was equal to 5, and the product obtained was placed in Fully dried and pulverized in a vacuum oven at 120° C., finally obtained a powdered polyimide prepolymer diluent, namely 7.76 g of a fluorenyl-containing reactive diluent, with a yield of 96%.

[0036] Under nitrogen protection, in a three-neck round bottom flask with mechanical stirring, add N,N-dimethylacetamide (DMAc, 20g) after vacuum disti...

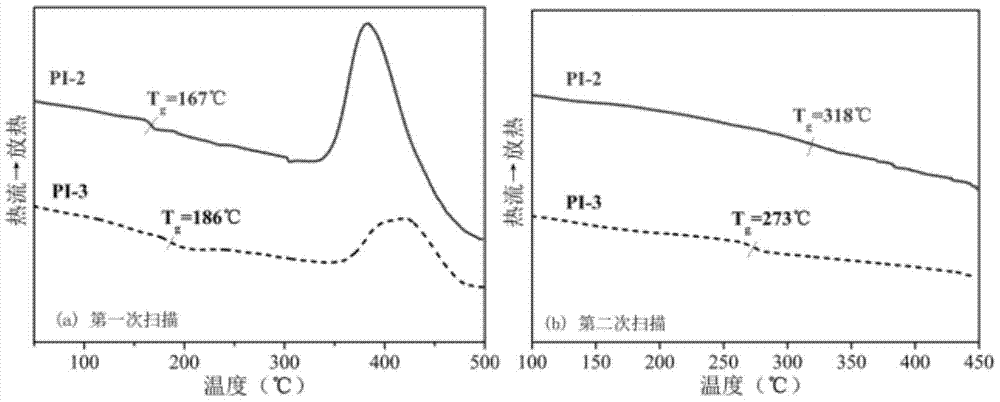

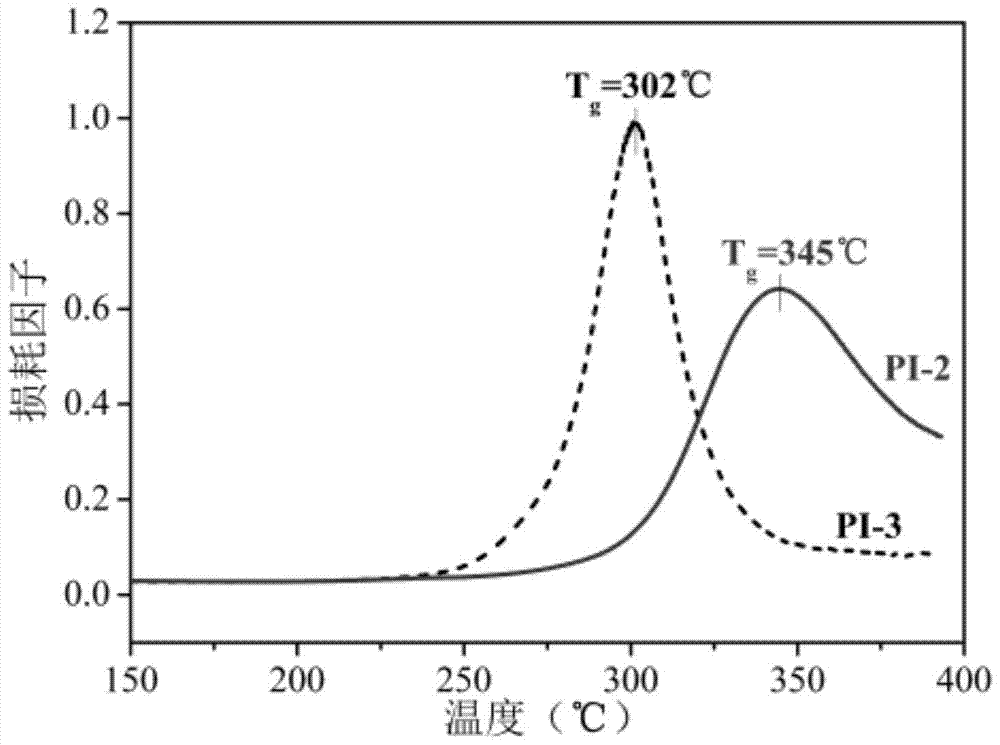

Embodiment 2

[0039] Under the protection of mechanical stirring and inert gas, weigh 3.48 g (0.01 mol) of diamine 9,9-bis(4-aminophenyl) fluorene (BAFL) and 4.96 g of end-capping agent 4-phenylethynylphthalic anhydride (PEPA). g (0.02mol) in a three-necked flask, dropwise add 32.32g of organic solvent DMAc after vacuum distillation, after reacting at room temperature for 8 hours, add pyridine (0.02mol, 1.582g) dropwise in the polyamic acid solution generated ) and acetic anhydride (0.03mol, 3.06g) were reacted at 40°C for 5 hours, and finally the solution obtained was washed 4 times with excess distilled water until the pH value of the filtered water was equal to 7, and the obtained product was placed at 150°C Fully dried in a vacuum oven and pulverized to finally obtain a powdered polyimide prepolymer diluent, namely 7.76 g of a fluorenyl-containing reactive diluent, with a yield of 96%.

[0040] Under nitrogen protection, in a three-neck round bottom flask with mechanical stirring, add N...

Embodiment 3

[0043] Under the protection of mechanical stirring and inert gas, weigh 3.48 g (0.01 mol) of diamine 9,9-bis(4-aminophenyl) fluorene (BAFL) and 4.96 g of end-capping agent 4-phenylethynylphthalic anhydride (PEPA). g (0.02mol) in the there-necked flask, dropwise add 32.32g organic solvent DMAc after vacuum distillation, after reacting at room temperature for 8 hours, add triethylamine (0.02mol, 2.02g) and acetic anhydride (0.04mol, 4.08g), reacted at 40 ℃ for 5 hours, finally the solution obtained was washed 4 times with excess distilled water until the pH value of the filtered water was equal to 7, and the product obtained was placed in Fully dried and pulverized in a vacuum oven at 150° C., finally obtained a powdered polyimide prepolymer diluent, namely 7.76 g of a fluorenyl-containing reactive diluent, with a yield of 96%.

[0044] Under nitrogen protection, in a three-neck round bottom flask with mechanical stirring, add N,N-dimethylacetamide (DMAc, 20g) after vacuum disti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com