Hot nozzle assembly and hot runner system

A component and hot nozzle technology, applied in the field of hot nozzle components, can solve the problems of yellowing and product quality discount, achieve the effect of reasonable internal structure, avoid wire drawing phenomenon, and speed up cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

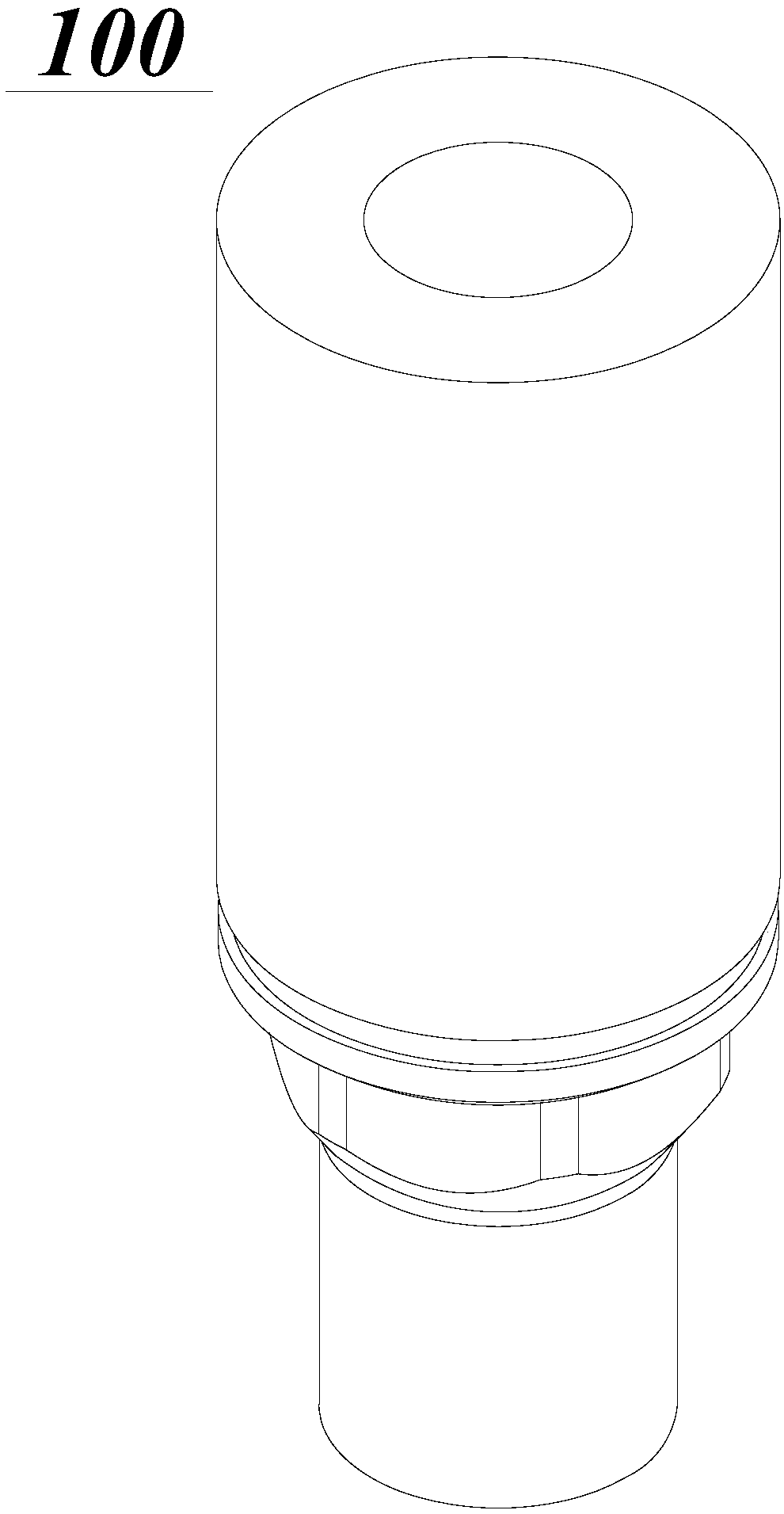

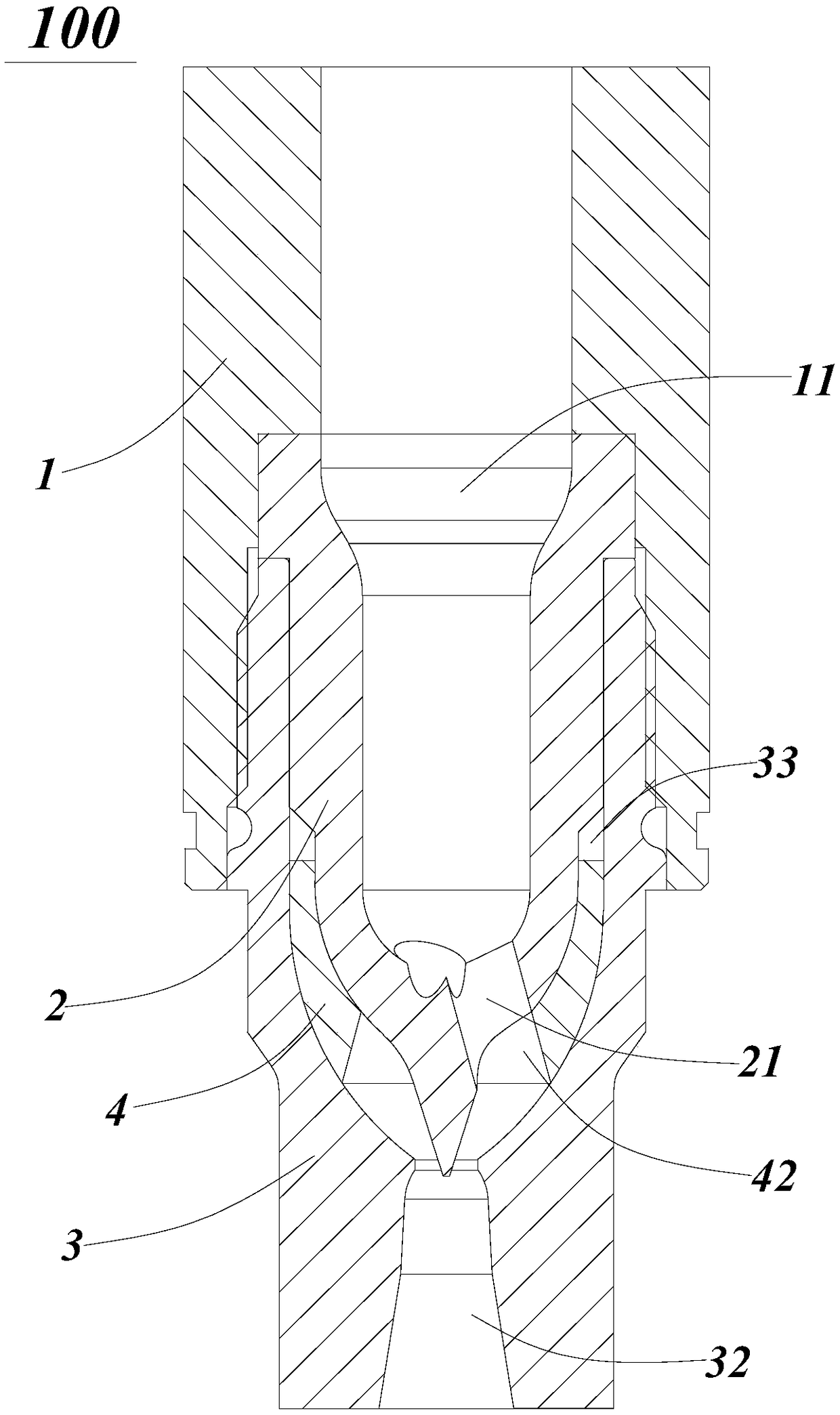

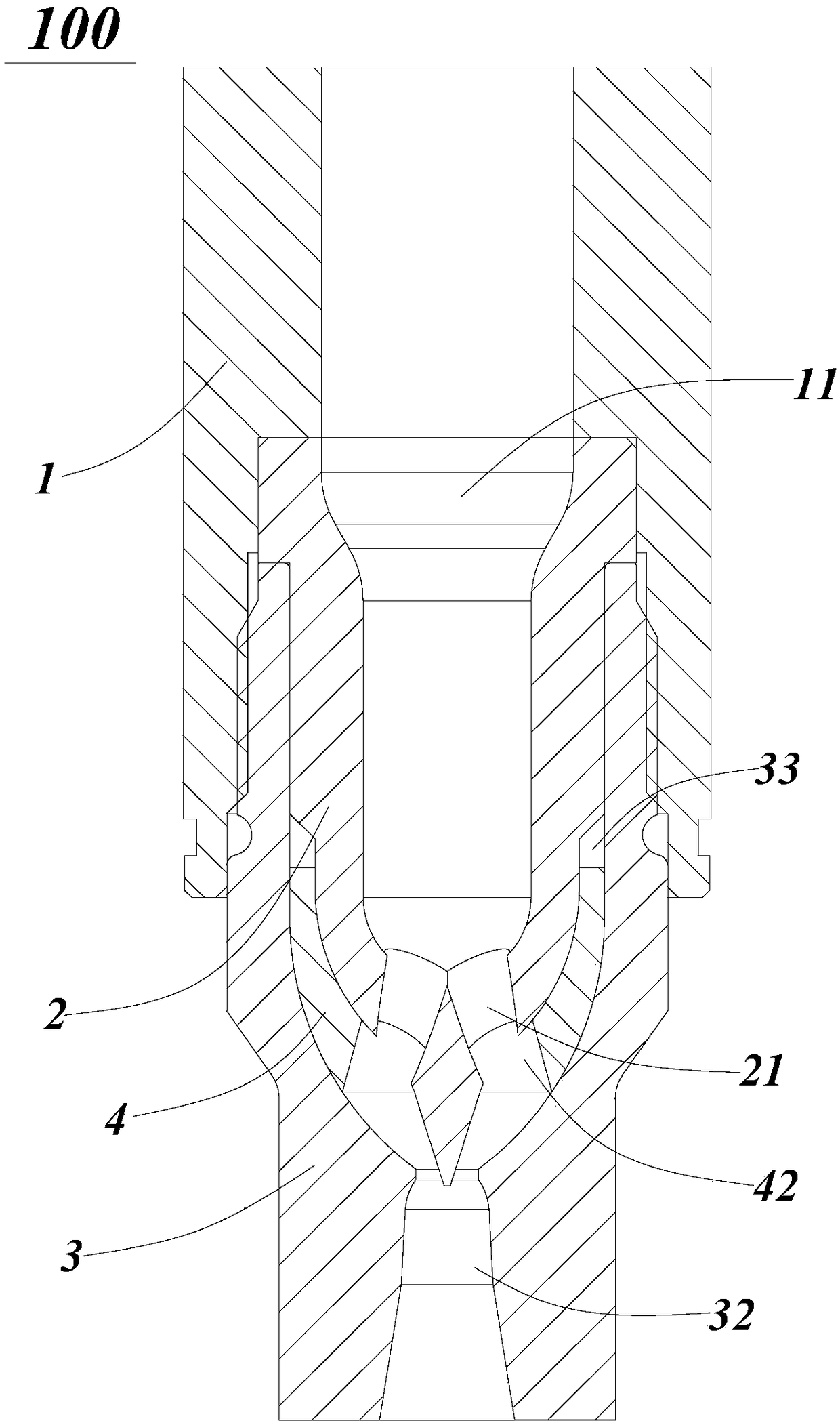

[0026] An embodiment of the present invention provides a hot nozzle assembly 100, such as figure 1 As shown, the hot nozzle assembly 100 includes a hot nozzle 1 and a nozzle tip 2 arranged at the end of the hot nozzle 1. A flow channel 11 runs through the inside of the hot nozzle 1 and the nozzle tip 2, and the end of the nozzle tip 2 is sleeved with a pressing member 3; The liquid material flows from the hot nozzle 1 through the flow channel 11 to the nozzle tip 2, and then flows into the pressing part 3 from the end of the nozzle tip 2, and the pressing part 3 cooperates with the mold and flows into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com