Continuous operation type anti-wiredrawing dispensing robot complete machine

A robot and anti-drawing technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of low error tolerance rate of position deviation, affecting dispensing quality, efficiency ratio, etc., and achieve high error tolerance rate of position deviation and reduce Effects of production cost and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

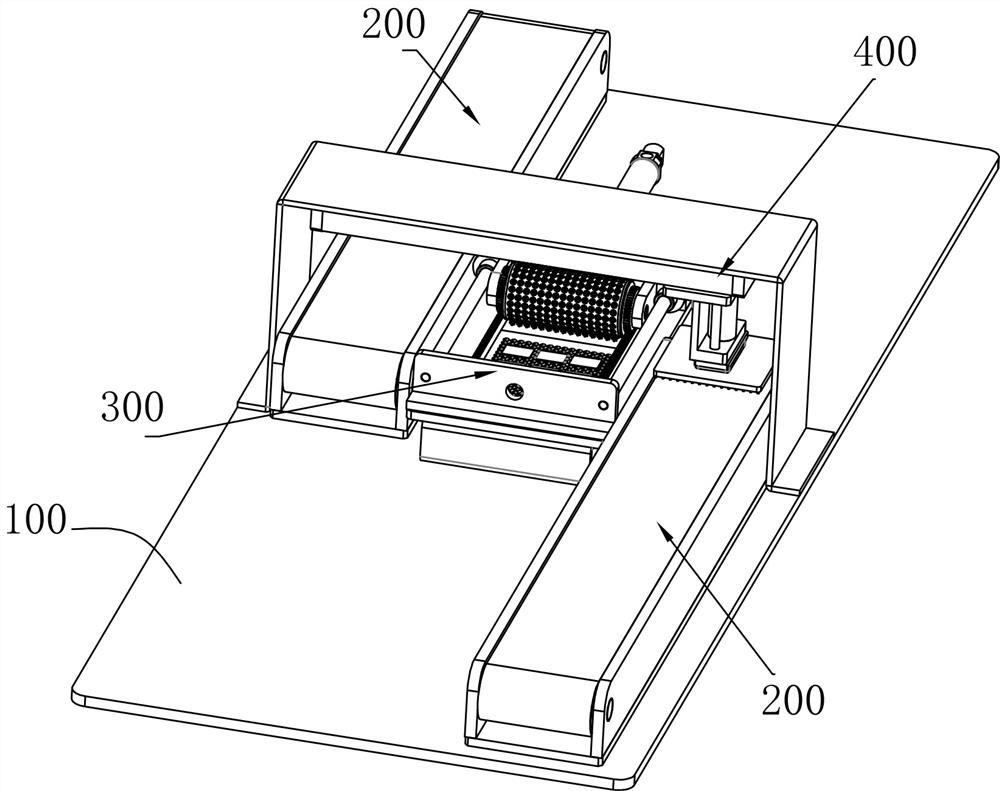

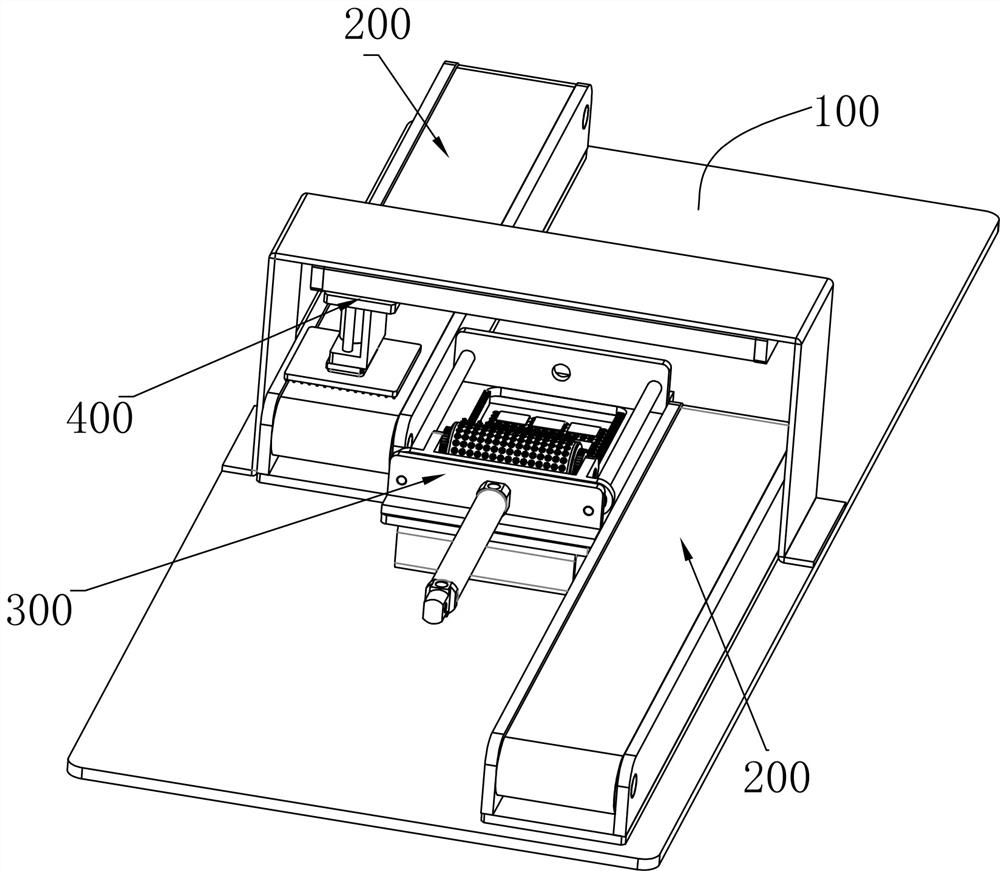

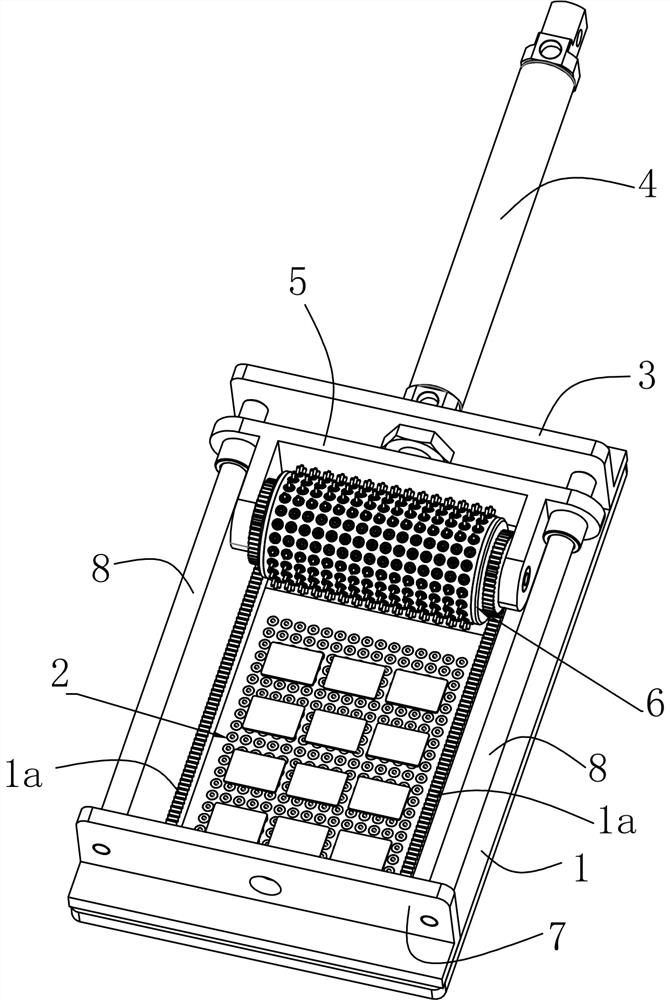

[0027] Such as Figure 1 to Figure 9 As shown, a continuous operation type anti-drawing dispensing robot complete machine described in this embodiment includes a base 100, two transfer tables 200 arranged symmetrically on two diagonal positions of the base 100, A rolling dispensing robot 300 disposed in the middle of the base 100 and between the two transfer mechanisms 200 and a gantry-type material transfer robot arm 400 disposed on the base 100 .

[0028] In this embodiment, one of the transfer tables 200 is used to transfer the chips to be dispensed, and the other transfer table 200 is used to transfer the chips that have been dispensed; in actual use, the transfer table 200 transfers the chips to be dispensed to the Transfer the position, then the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com