A welding device for crimping rings of end caps with a stripper plate

A technology of welding equipment and crimping rings, which is applied in the field of welding equipment for crimping rings of end caps with strippers, can solve the problem of inconvenient access to finished end caps, the inability to weld two crimping rings, and reduce the cost of the enterprise Efficiency and other issues, to avoid wire drawing, easy to take, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

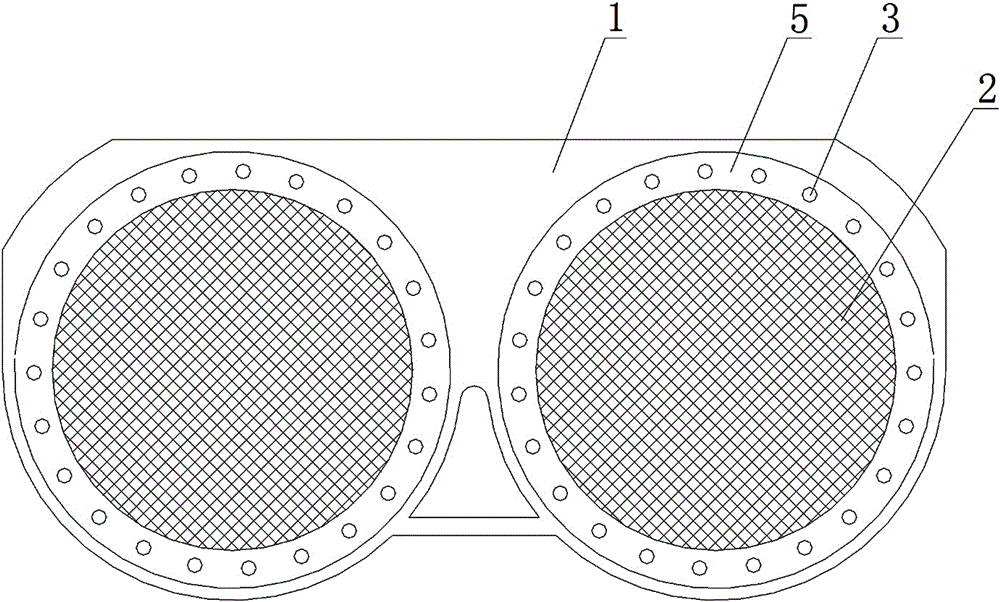

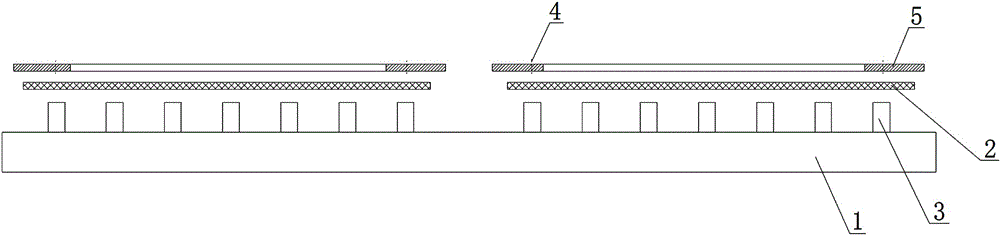

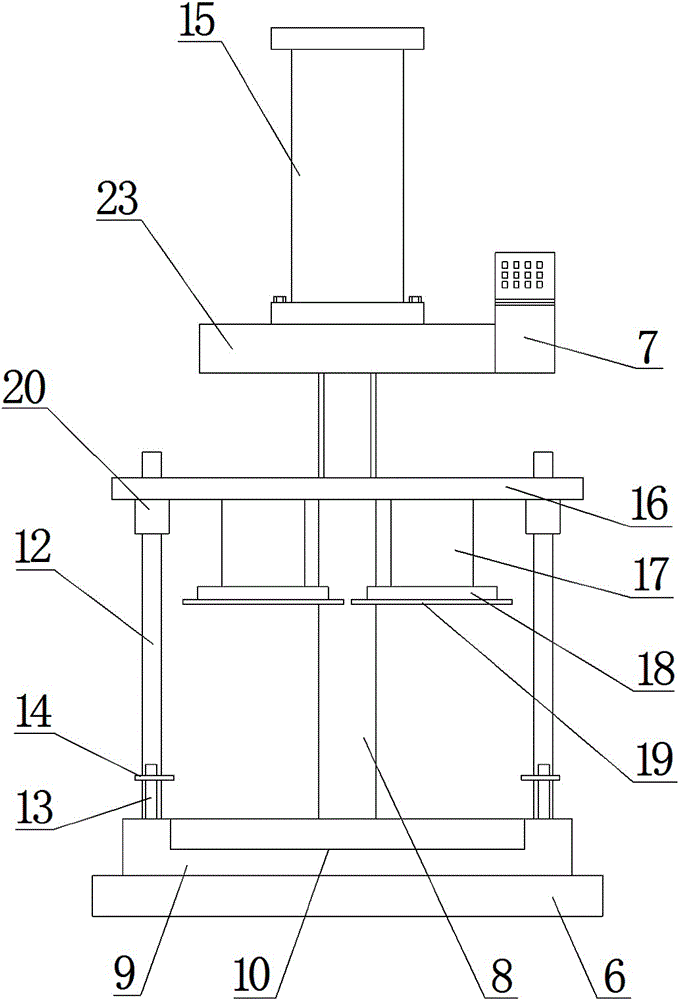

[0018] Such as Figure 3-5 Shown, a kind of welding equipment with the end cover crimping ring of stripping plate, it comprises workbench 6, heating coil 17, controller 7 and the column 8 that is arranged on workbench 6 and die 9, described The front end of the die 9 is provided with a groove 10, the bottom of the groove 10 is provided with a cavity 11, the outer contour of the cavity 11 is the same as that of the end cap, and the bottom of the cavity 11 is provided with two pits 22. Such as image 3 with Figure 4 As shown, on the top surface of the die 9 and on both sides of the groove 10, guide rails 12 and fixed columns 13 are arranged, and a stripper plate 14 is arranged between the fixed column 13 and the guide rails 12, and the stripper plate 14 is arranged in the cavity Above 11, the colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com