Robotic greasing system

A robot and grease injection technology, which is applied in the direction of mechanical equipment, engine components, engine lubrication, etc., can solve the problems of large deviation of grease injection amount and grease injection position, uneven bearing lubrication, poor appearance quality, etc., and achieve improvement Production efficiency, reducing waste of raw materials, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

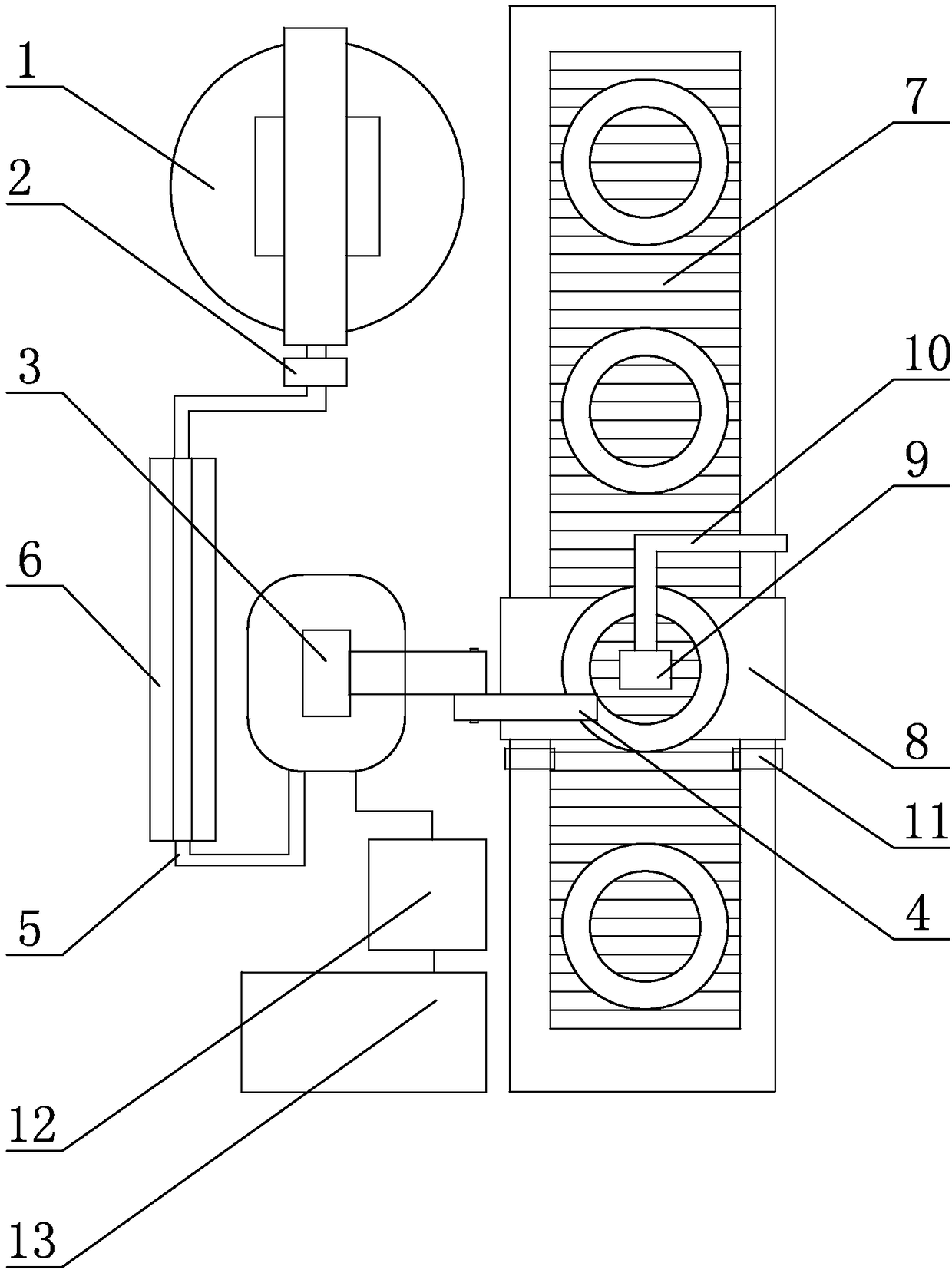

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment, a robotic grease injection system of this embodiment, which includes a grease injection machine 1, a suction device 2, a grease injection robot 3, a grease injection working head 4, an oil pipeline 5, a gantry frame 6, a belt conveyor machine 7 and bearing fixture 8, the grease injection robot 3 is set on one side of the belt conveyor 7, the bearing fixture 8 is set on the belt conveyor 7, and the grease injection working head 4 is installed at the execution end of the grease injection robot 3, so The bearing fixture 8 is arranged opposite to the grease injection working head 4. The upper beam of the gantry 6 is provided with an oil delivery pipe installation groove along its length direction. The oil delivery pipeline 5 is installed on the upper beam of the gantry 6. One end of the oil delivery pipeline 5 is connected to the grease injection The oil outlet of the grease tank of the machine 1 i...

specific Embodiment approach 2

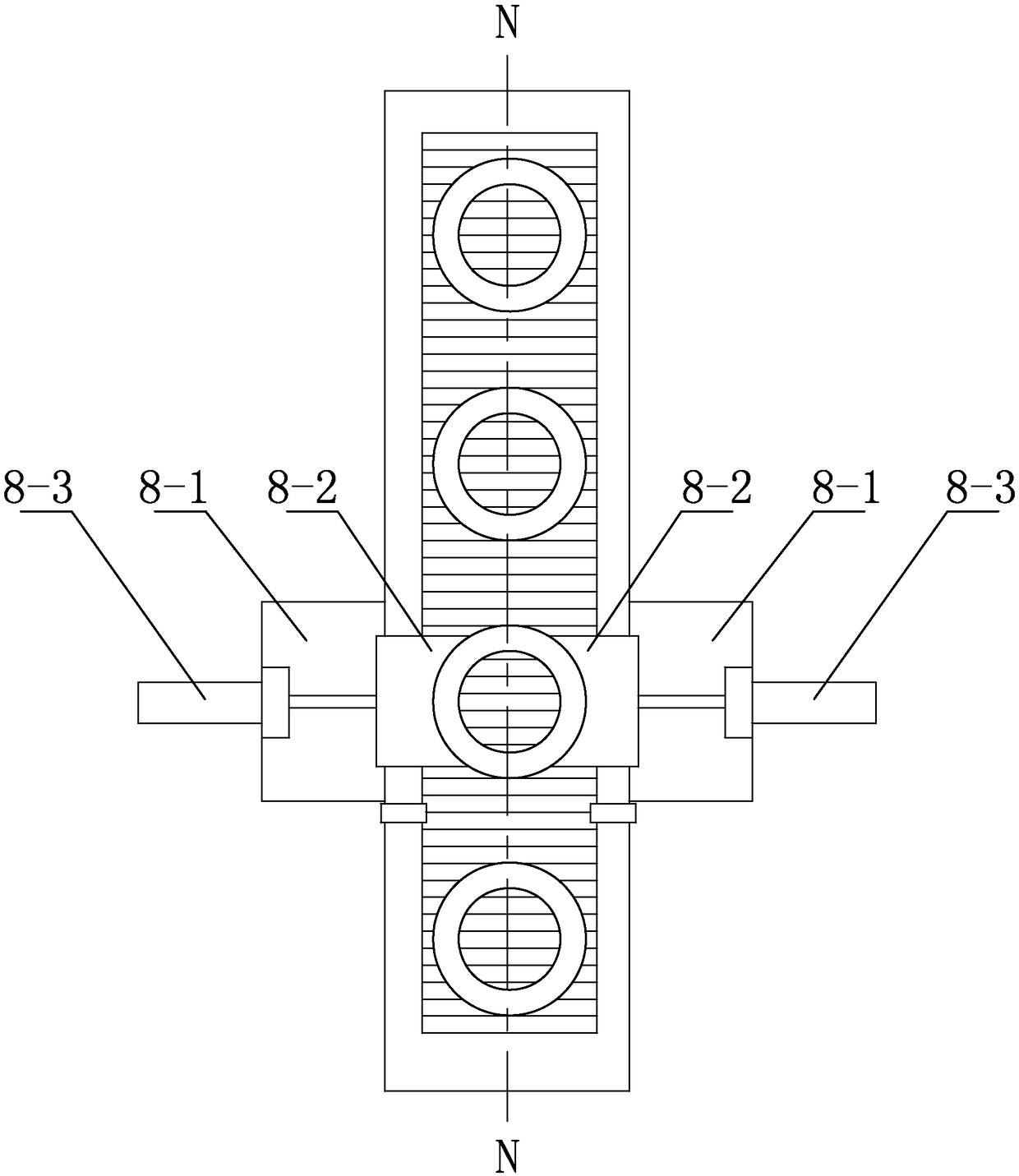

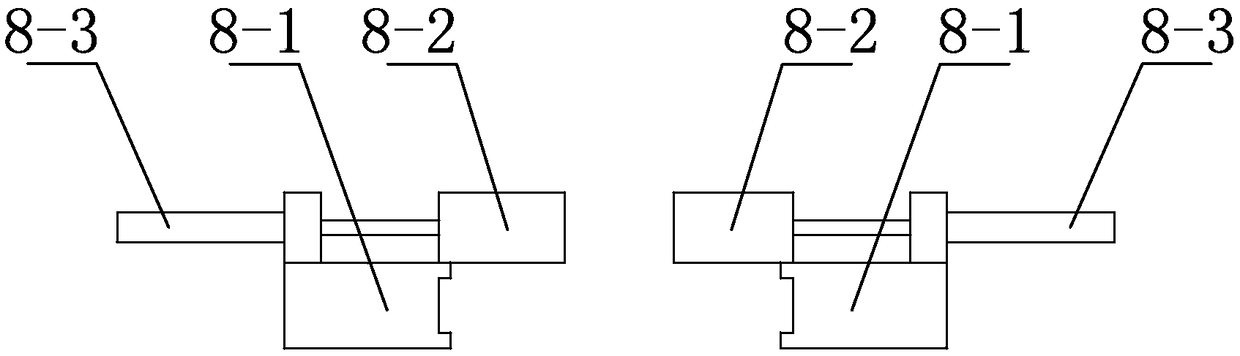

[0023] Specific implementation mode two: combination Figure 2 to Figure 4 To illustrate this embodiment, the bearing fixture 8 of this embodiment includes two clamping assemblies, and the two clamping assemblies are symmetrically arranged on both sides of the belt conveyor 7 along the centerline N-N of the belt conveyor 7, and each clamping assembly Including base 8-1, jaw 8-2, cylinder 8-3, base 8-1 is fixed on the frame side wall of belt conveyor 7, cylinder 8-3 is horizontally arranged on the upper end surface of base 8-1 , the piston rod of the cylinder 8-3 is affixed to the jaw 8-2. In this way, the bearing fixture 8 can accurately position the bearing, and the two clamping assemblies are arranged symmetrically on both sides of the belt conveyor 7. When the bearing is transported by the belt conveyor 7 to the station 3 of the grease injection robot, the two Cylinder 8-3 starts, and drives two jaws 8-2 to move to the middle and clamps and fixes the bearing. Other compos...

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 2 to Figure 4 To illustrate this embodiment, the end of the jaw 8-2 of this embodiment is processed with an arc-shaped groove matching the outer ring of the bearing. In this way, the jaw 8-2 adopts a conformal design to precisely position the bearing. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com