Multi-spray-head three-dimensional printer

A 3D printer and multi-nozzle technology, applied in additive manufacturing, coating devices, 3D object support structures, etc., can solve the problems of not being able to change the nozzle radius and inconvenient use, achieve fine and smooth contours, increase printing speed, and avoid Brushed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

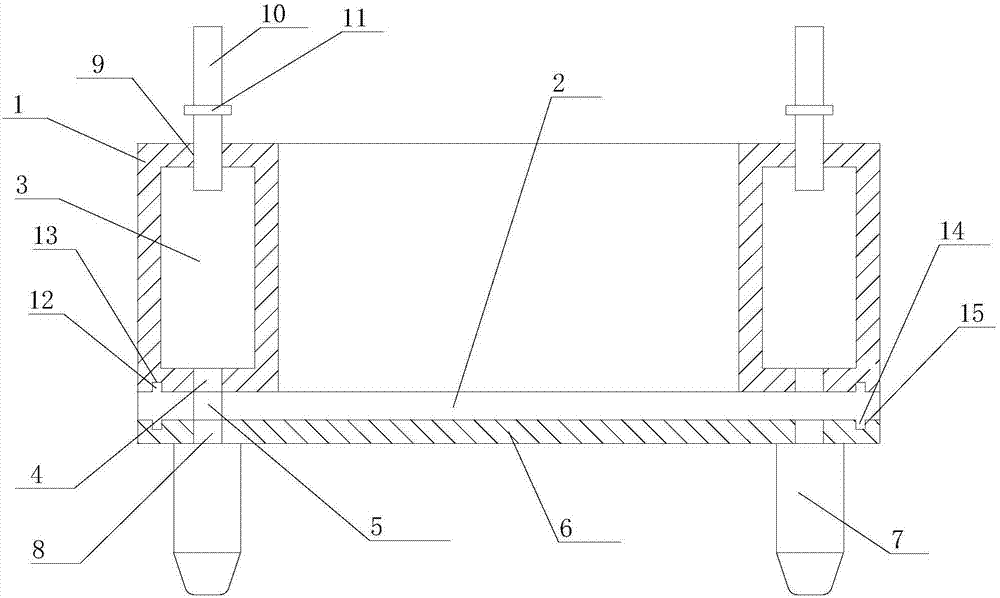

[0016] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a multi-nozzle 3D printer proposed by the present invention.

[0017] refer to figure 1 , the present invention proposes a multi-nozzle three-dimensional printer, including a material distribution plate 1, a plurality of feed pipes 10, a baffle plate 2, a first drive mechanism and a nozzle assembly, wherein:

[0018] The material distribution plate 1 is ring-shaped, and the interior of the material distribution plate 1 is provided with a plurality of material distribution chambers 3, and the multiple material distribution chambers 3 are circumferentially distributed around the central axis of the material distribution plate 1, and the bottom ends of each material distribution chamber 3 are A discharge hole 4 is provided.

[0019] The baffle plate 2 is located below the material distribution plate 1 and is rotatably connected with the material distribution plate 1. The baffle plate 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com