Construction method of wall body provided with distribution box body

A construction method and box technology, applied in the direction of walls, molds, electrical components, etc., can solve the problems of high cost and difficulty of blocking, increased working hours of masonry workers, and large loosening and knocking off debris, etc., to achieve firmness and construction. Delicacy guarantee, high utilization rate of materials, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0040] like Figure 1-Figure 5 Shown, a kind of wall construction method with power distribution box is characterized in that, comprises the following steps:

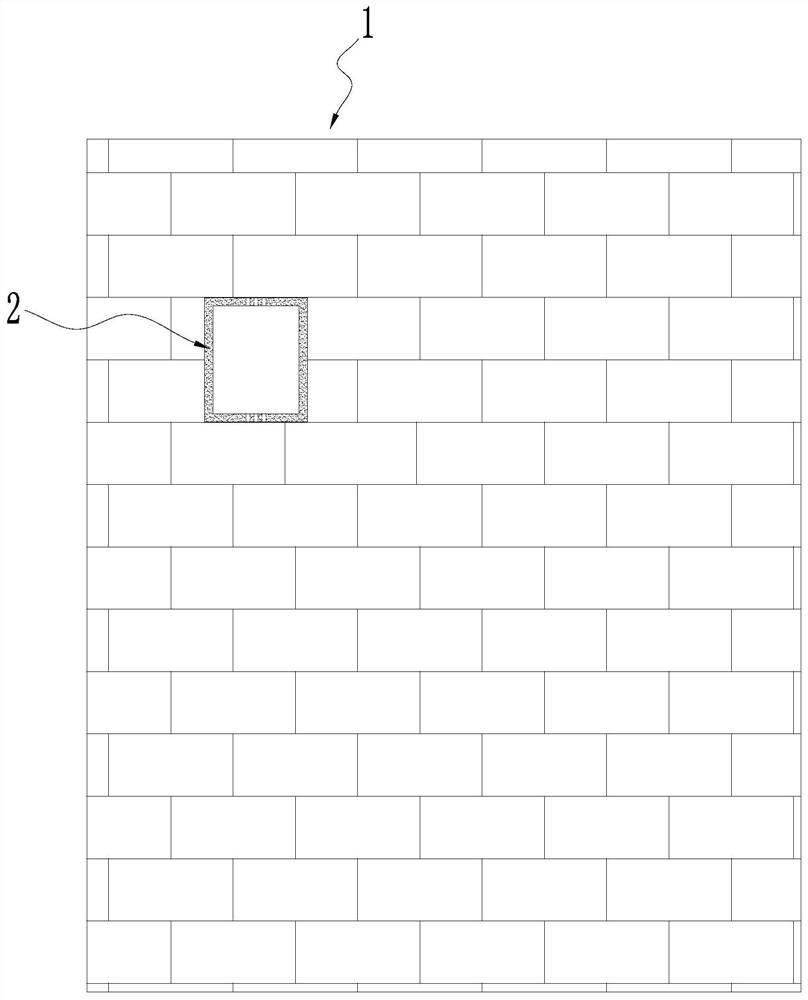

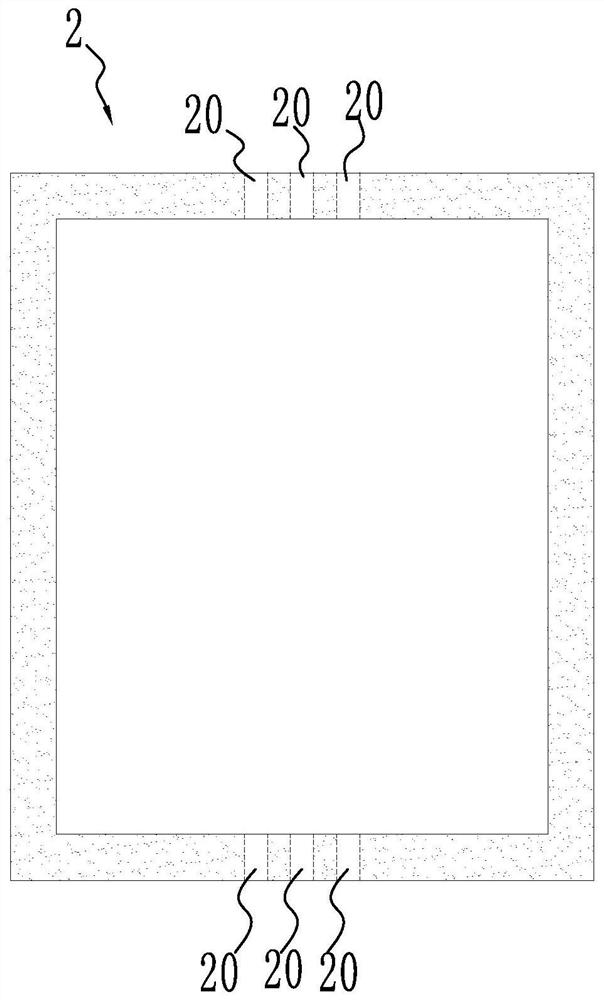

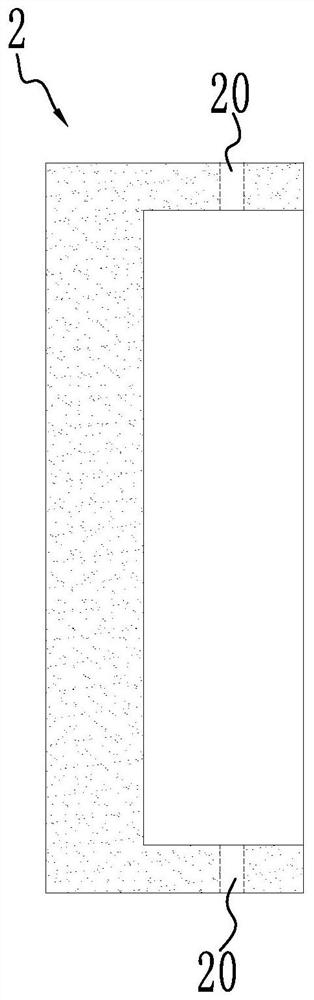

[0041] S1. According to the size of the preset power distribution box 2 and the installation position of the power distribution box 2, design a row of bricks on the wall, and generate a corresponding brick arrangement diagram; and determine standard bricks and non-standard bricks on the brick arrangement diagram The number and arrangement of bricks. Since the position and required size of the general power distribution box 2 have been determined in the early stage of design, planning it in the early stage will help improve construction efficiency. The brick arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com