Metal-plastic double-layer mobile phone shell and manufacturing method thereof

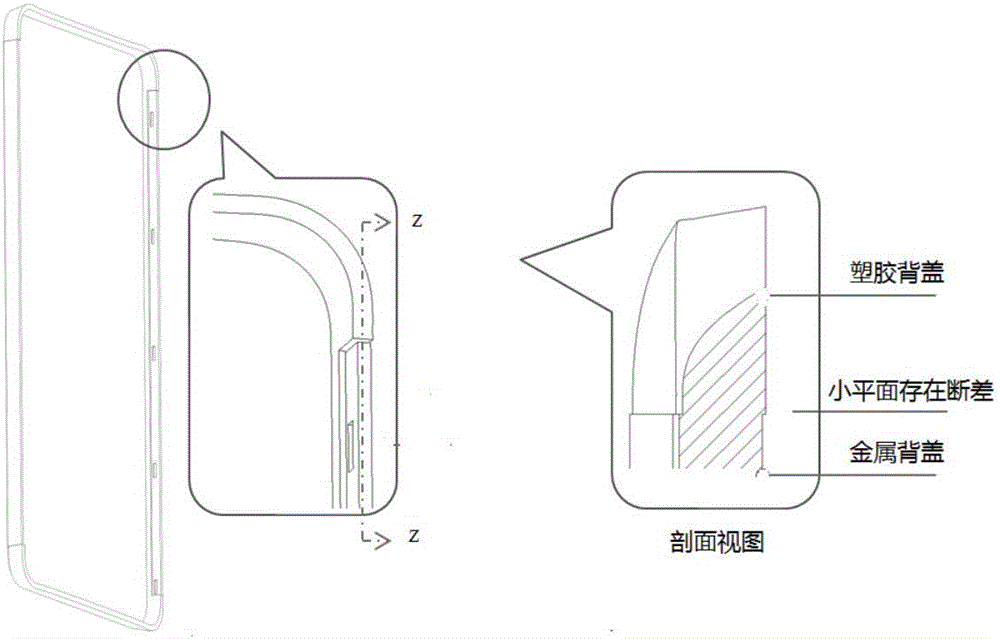

A manufacturing method and mobile phone shell technology, applied in the direction of the phone structure, can solve the problems of inaccurate positioning, easy deformation, unstable position and size in the Z direction of the buckle, etc., to achieve the effect of ensuring precision and user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

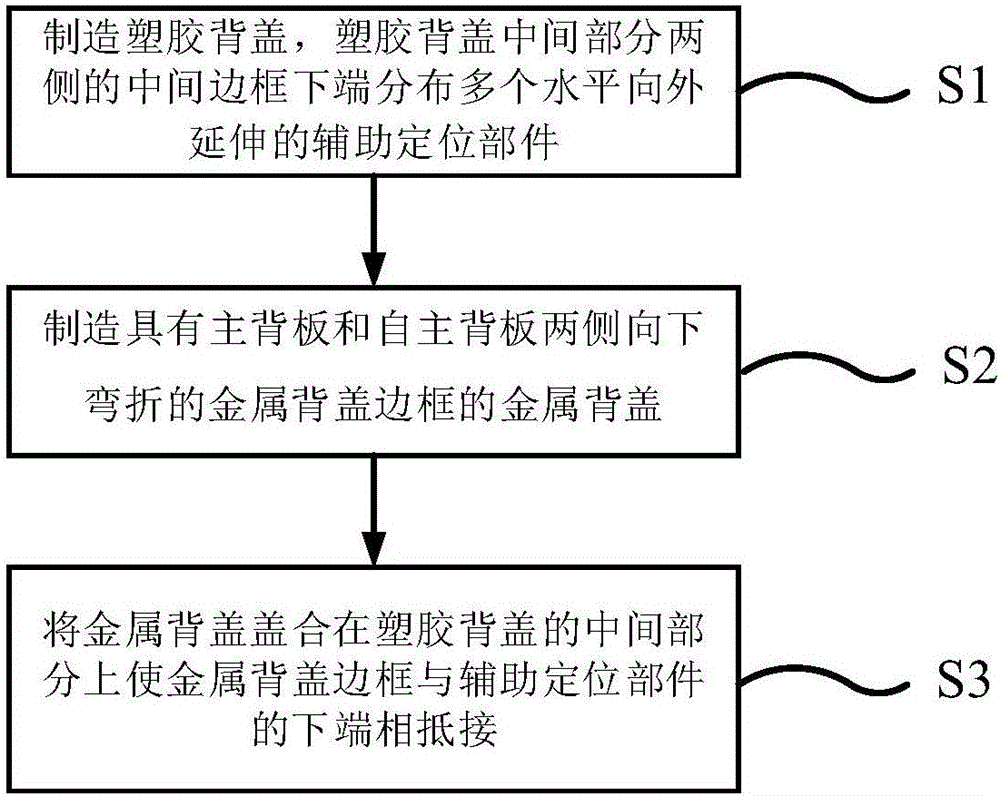

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below in conjunction with the accompanying drawings. Of course, the present invention is not limited to this specific embodiment, and general replacements known to those skilled in the art are also covered within the protection scope of the present invention.

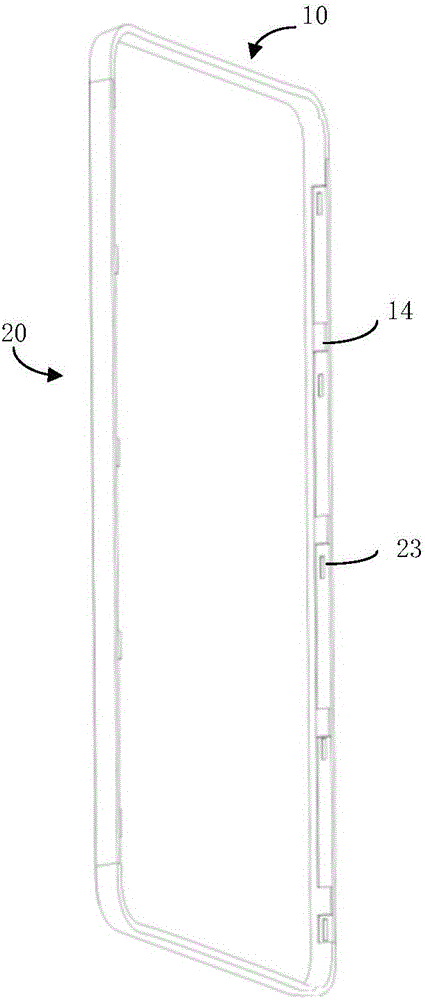

[0026] figure 2 Shown is a schematic diagram of a metal-plastic double-layer mobile phone case according to an embodiment of the present invention, as figure 2 As shown, the double-layer mobile phone case includes a plastic back cover 10 and a metal back cover 20 . The plastic back cover 10 has an upper part, a lower part and a middle part. Wherein the upper part and the lower part have plastic back cover frames bent downwards, which are used for fastening on the mobile phone body. The upper surfaces of the upper part and the lower part are to protrude from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com