Anti-drawing and quick-break device at the glue inlet point of the mold

A technology of glue feeding and wire drawing prevention, applied in the field of plastic molds, can solve problems such as affecting product production efficiency, and achieve the effect of avoiding wire drawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

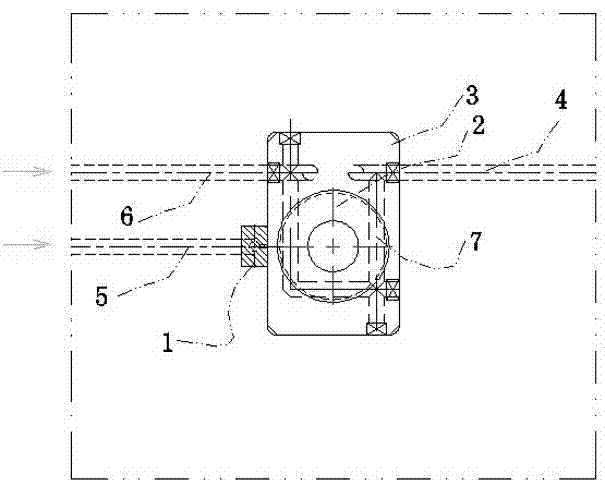

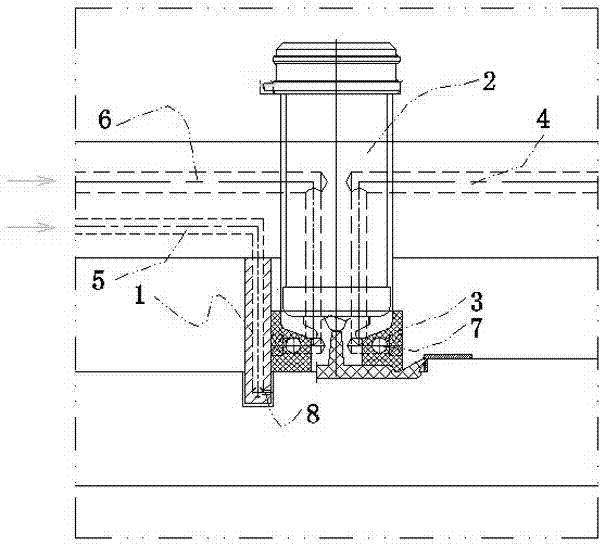

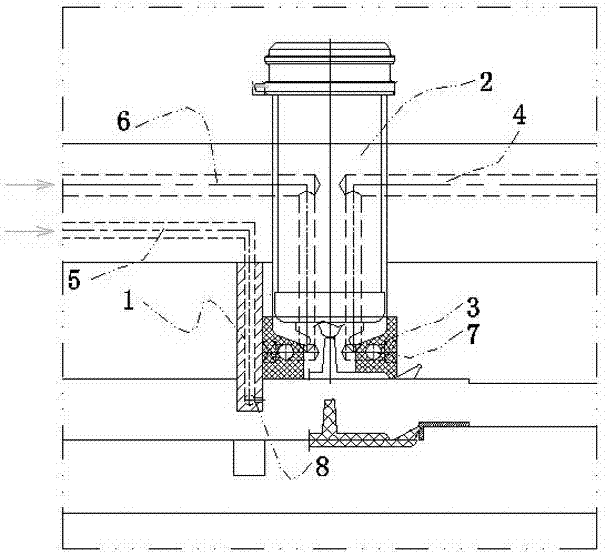

[0017] It includes a cooling insert 3 near the hot nozzle 2. The cooling insert 3 is provided with a water delivery pipe 7. One end of the water delivery pipe 7 communicates with the water inlet pipe 6 in the mould, and the other end communicates with the water outlet pipe in the mould. 4 communicated, and the water delivery pipe 7 is set near the outlet of the hot nozzle 2.

[0018] The cooling insert 3 is provided with a blowing block 1, or is connected with the blowing block 1, and one end of the blowing block 1 communicates with the air intake pipe 5 in the mould, and the blowing direction of the blowing hole 8 of the blowing block 1 It corresponds to the exit of hot nozzle 2, that is, the position of the gate of the product;

[0019] The blowing hole 8 of the blowing block 1 is below the cooling insert 3, the blowing direction of the blowing hole 8 is facing the gate part of the product after the mold is opened, and the bottom end surface of the cooling insert 3 is in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com