Novel heavy cutter ring and production process thereof

A production process and knife ring technology, applied in the field of new heavy-duty knife ring and its production process, can solve the problems of high maintenance cost, difficult adjustment of the knife head, wear of the knife ring, etc., to achieve convenient disassembly, reduce impact, and reduce maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

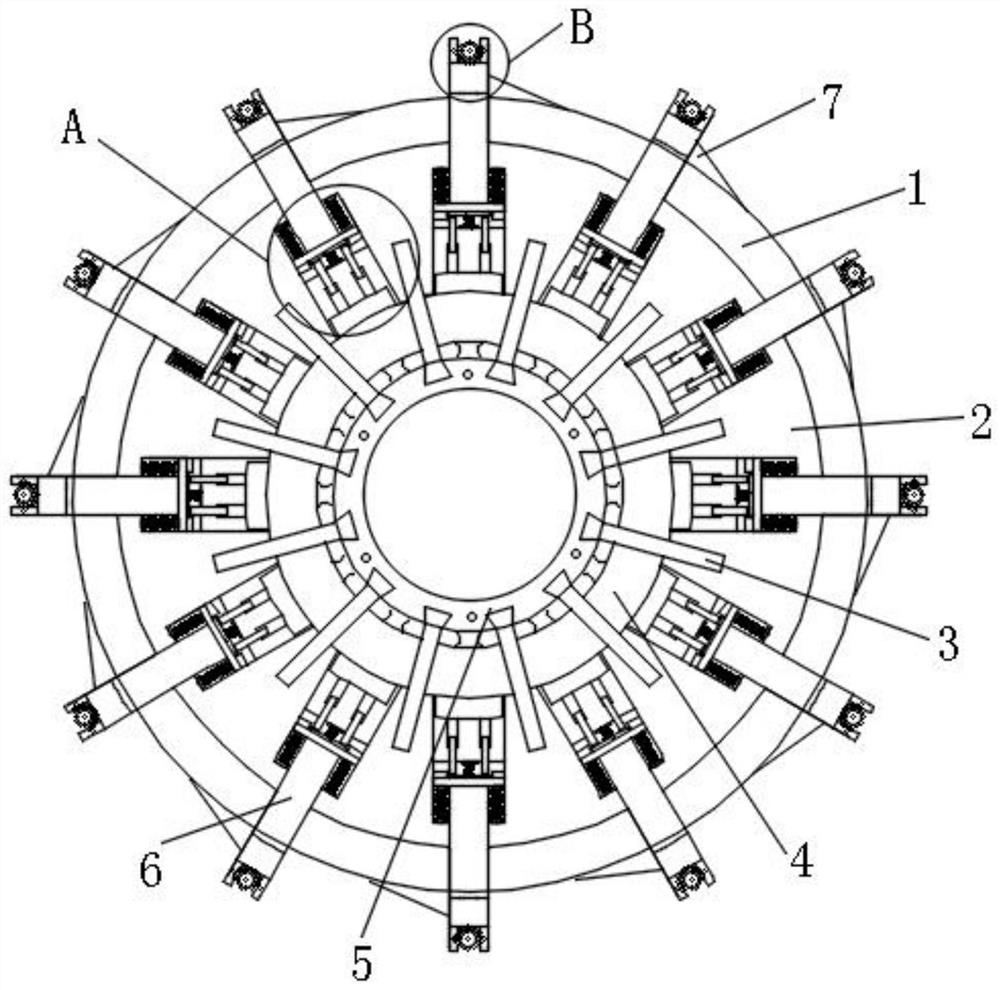

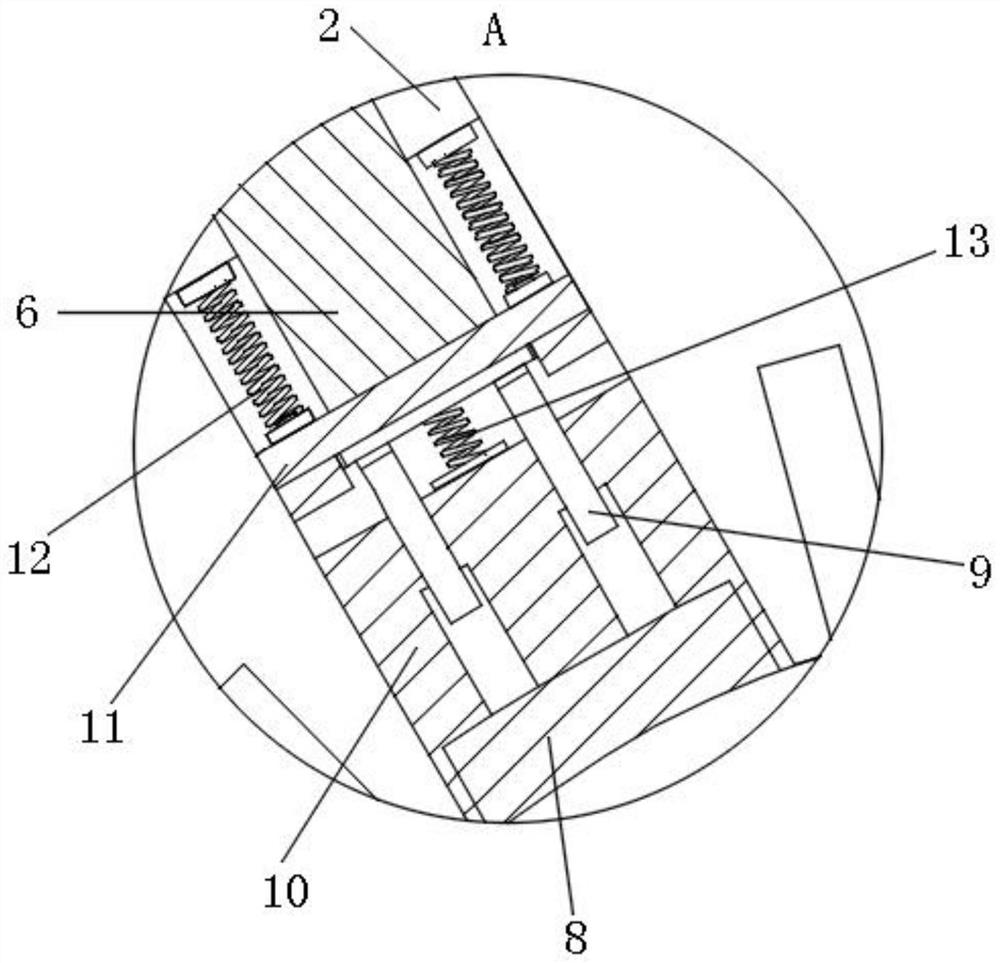

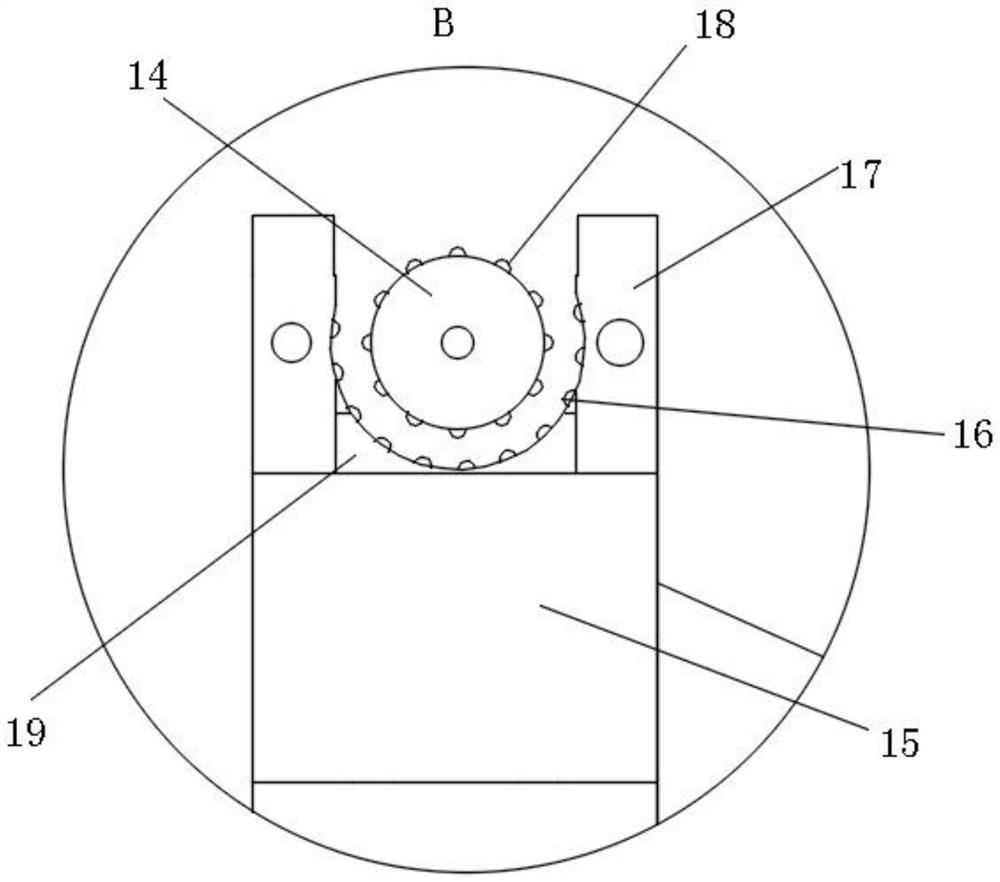

[0027] like Figure 1-3 As shown, the embodiment of the present invention provides a new type of heavy-duty knife ring and its production process, including a protective ring 1, a splicing plate 2, a fixed column 3, a fixed ring 4 and a reinforcement ring 5, the protective ring 1 is made of wear-resistant materials, and the protective ring The outer wall of 1 is provided with mounting grooves equidistantly distributed on the central axis of the protective ring 1, and the outer wall of the protective ring 1 is fixedly connected with a triangular block 7 near the installation groove, and the curvature of the outer wall of one end of the splicing plate 2 is consistent with the inner wall of the protective ring 1. Compatible, one end of the splicing plate 2 is fixedly connected to the inner wall of the protective ring 1, and a plurality of annularly distributed splicing plates 2 constitute the middle part of the knife ring, the section of the splicing plate 2 is approximately an is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com