Horizontal stretch coating film transfer tool

A technology for coating film and printing tool, which is applied in the directions of printing, thin material processing, eraser, etc., can solve the problem of not being able to form a horizontal drawing type coating film transfer tool, etc., and achieves the effect of good cutting and preventing wire drawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Hereinafter, the present invention will be described based on representative embodiments. First, the first embodiment will be described.

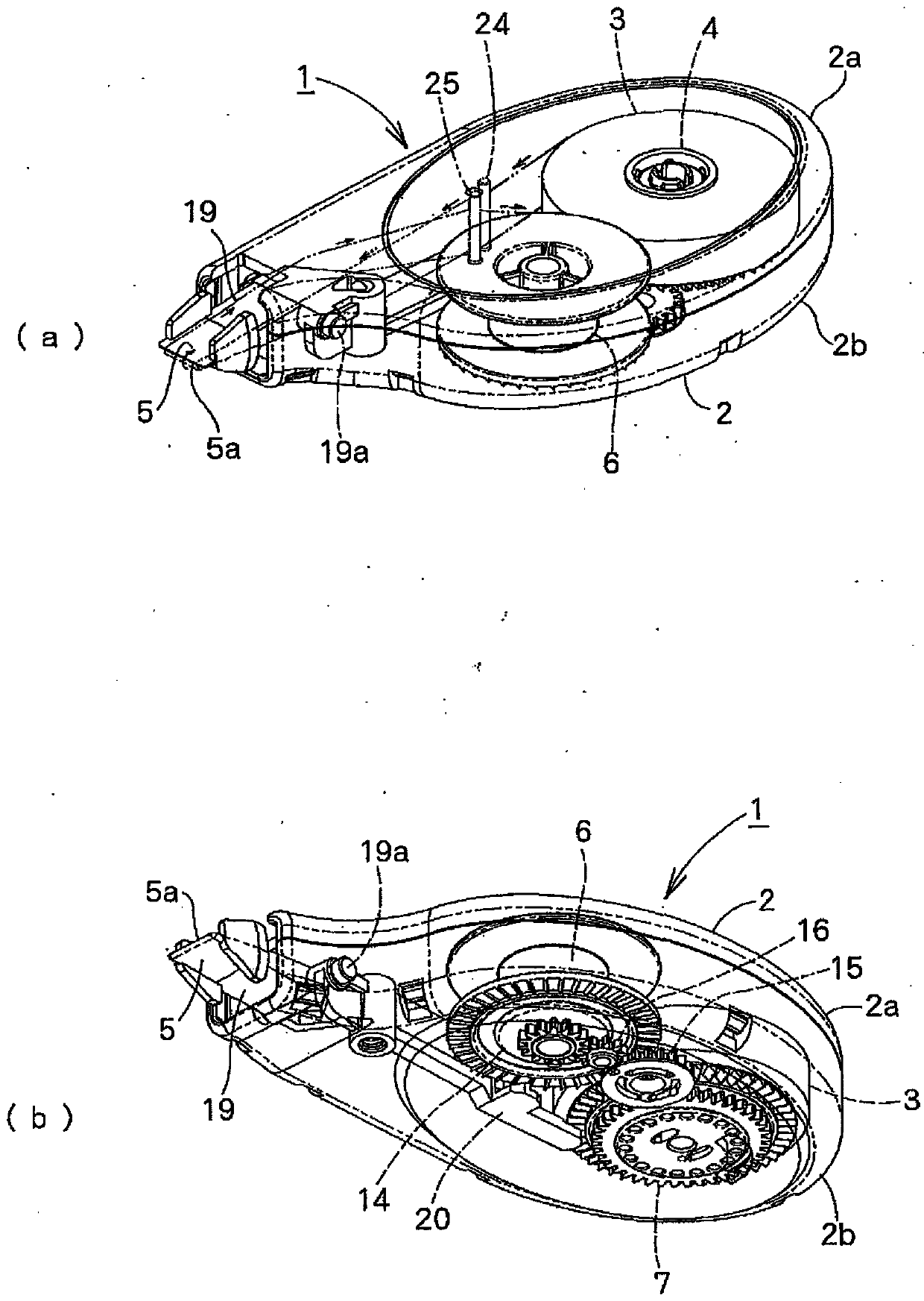

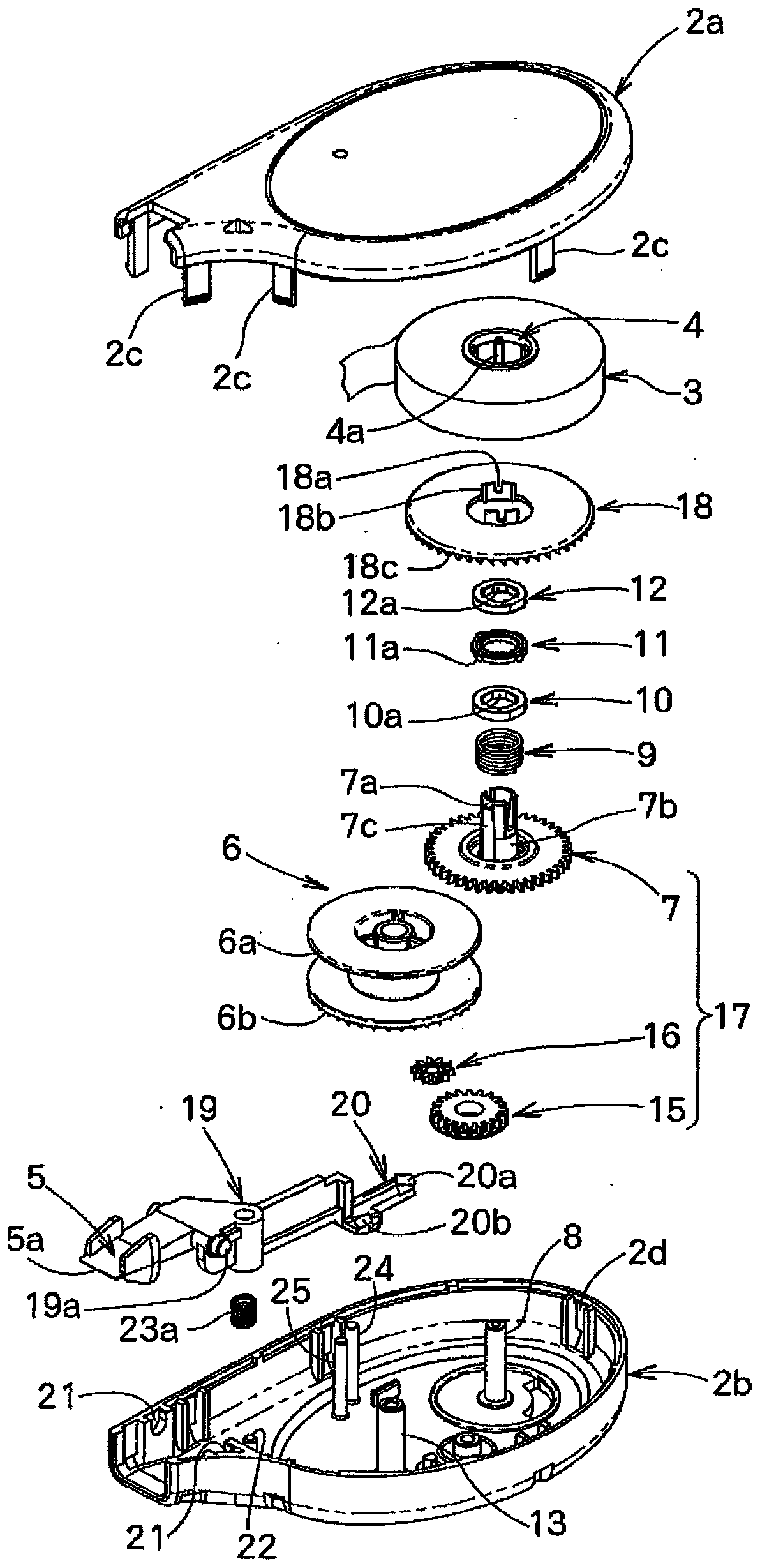

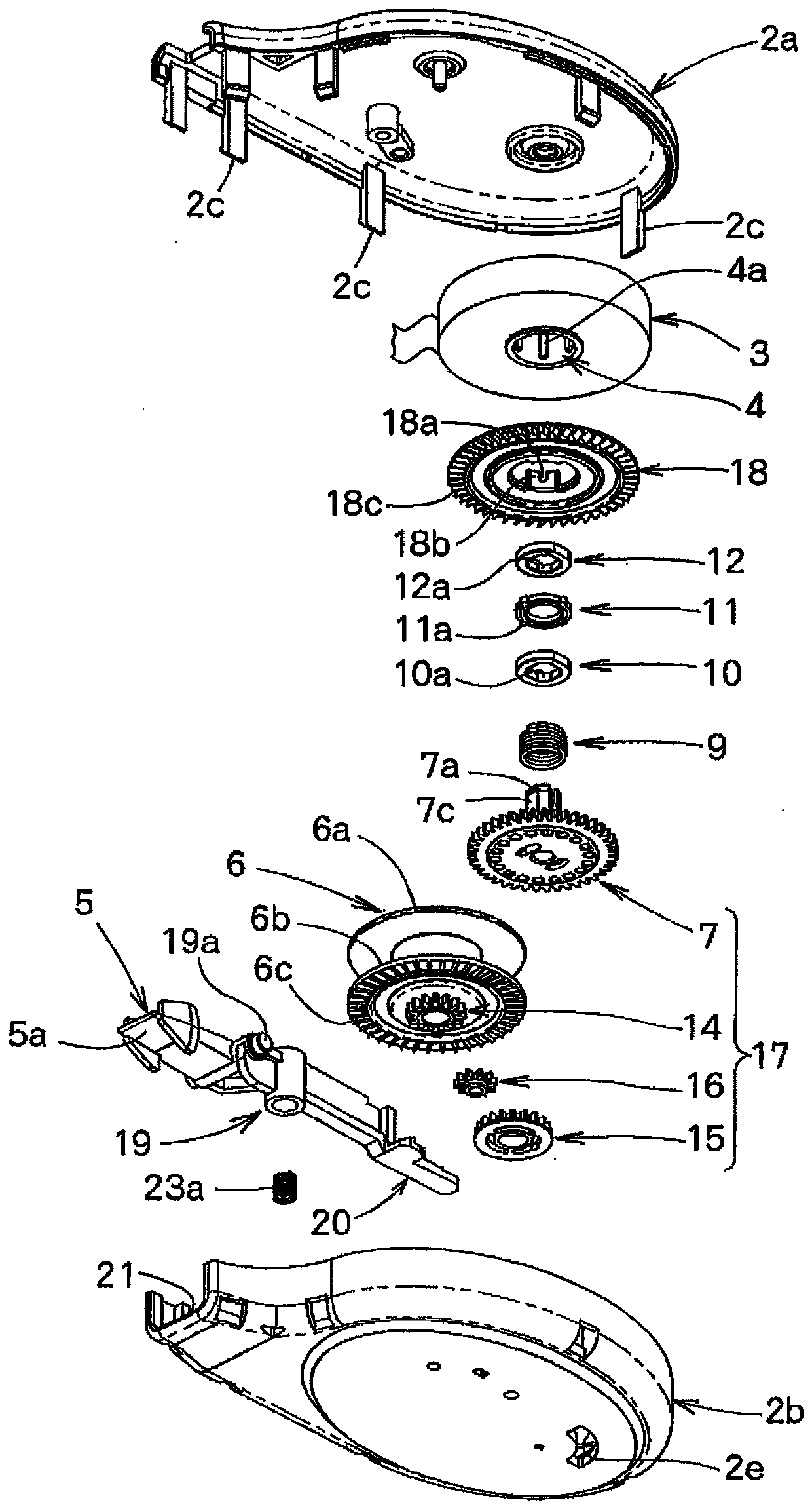

[0068] figure 1 (a) is a top perspective view, and (b) is a bottom perspective view which shows the perspective view of 1st Example of the horizontal pull type coating film transfer tool 1 of this invention. figure 2 ,Yes figure 1 The upper perspective exploded view of the shown horizontal pull type coating film transfer tool 1, image 3 same for figure 1 The lower perspective exploded view of the horizontal pull-type coating film transfer tool 1 shown. In addition, the drawing except for a part of the transfer belt pressed by the transfer head to the surface to be transferred is omitted.

[0069] figure 1 Indicates the horizontal pull type coating film transfer tool 1, such as Figure 1 ~ Figure 3 As shown, in the front-end opening frame body 2 formed by a pair of frame members 2a and 2b up and down, there are at least: a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com