Patents

Literature

217results about "Candle preparation apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

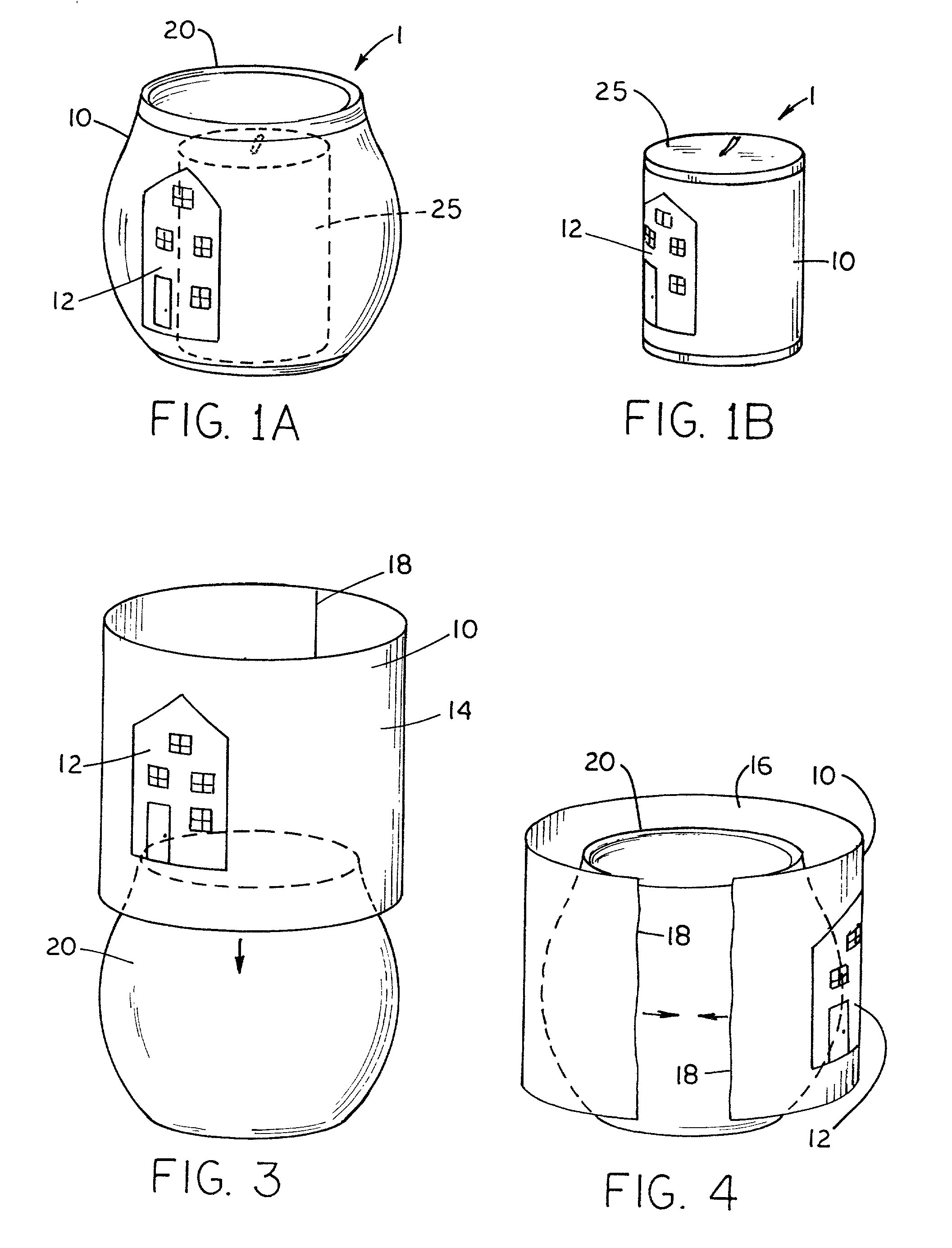

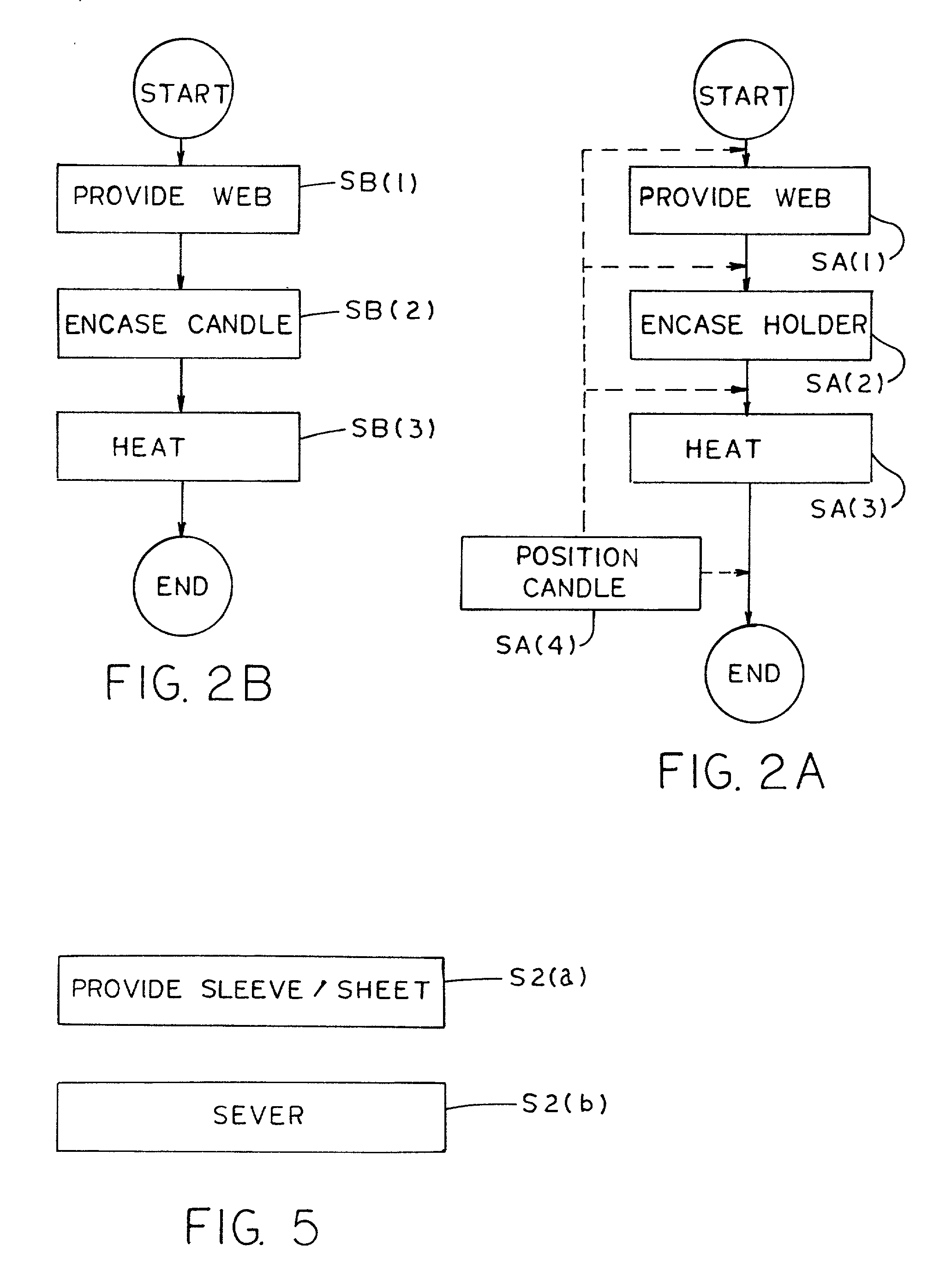

Luminary device with thermochromatic label

A decorated luminary product includes either a candle or a candle holder containing the candle. A decorative web of a heat-shrinkable polymer web is heat shrunk to conform to a shape of the one of the candle and the candle holder. The web is decorated with a thermochromic ink or pigmentation to cooperate with heat emitted by burning the candle to provide a visible change in the ink or pigmentation, so as to provide a pleasing visual effect when the candle is burned.

Owner:SC JOHNSON & SON INC

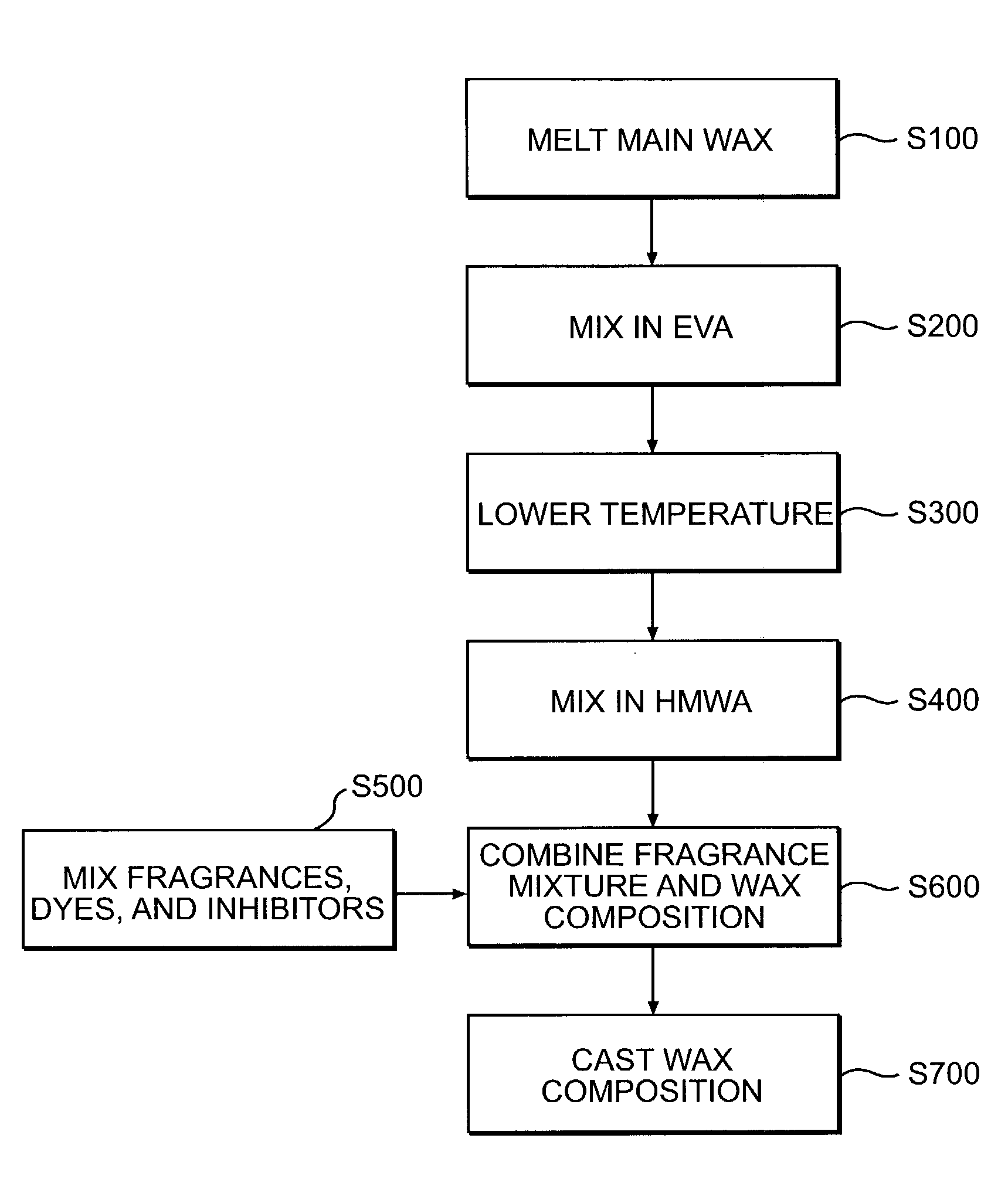

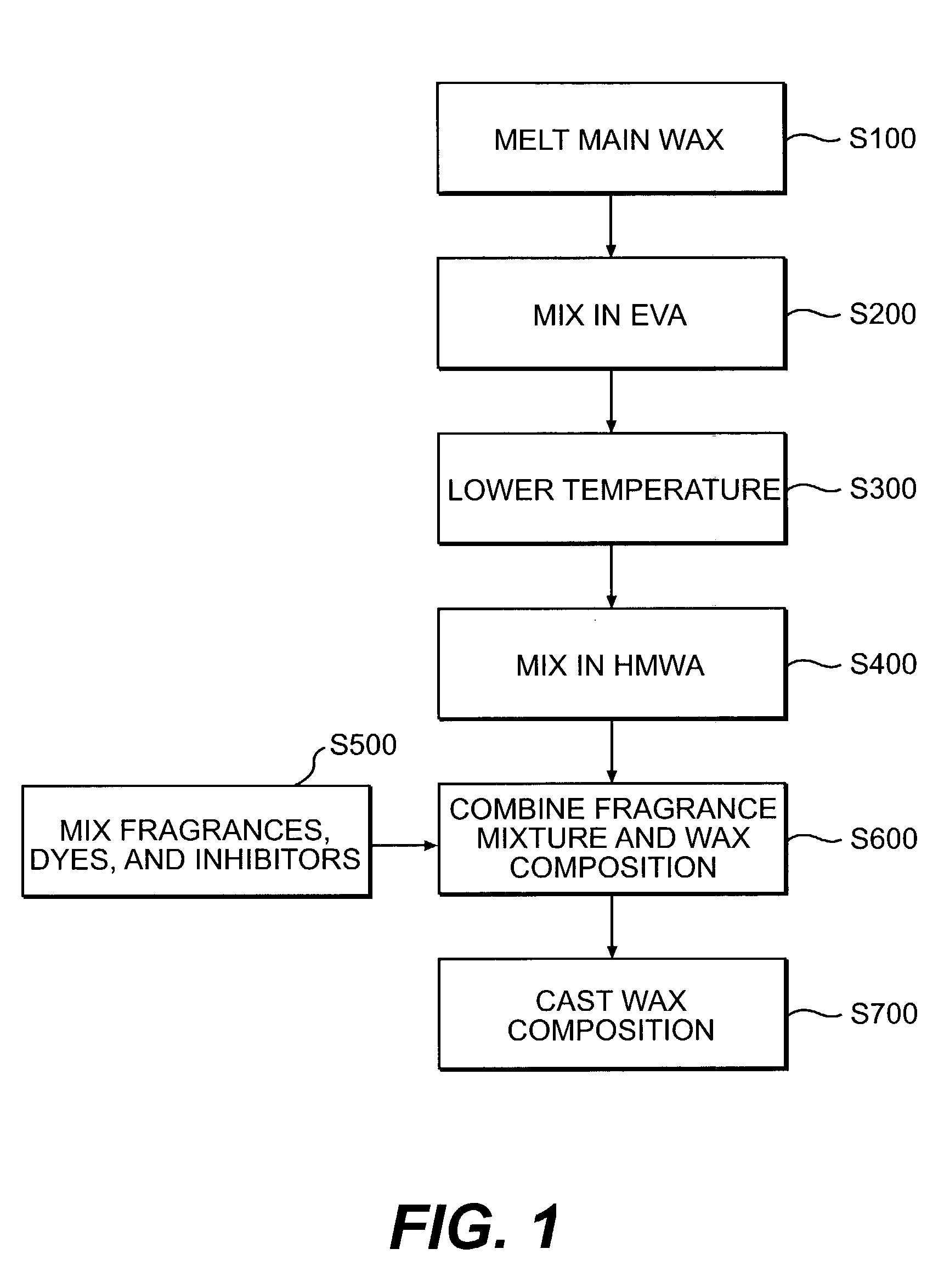

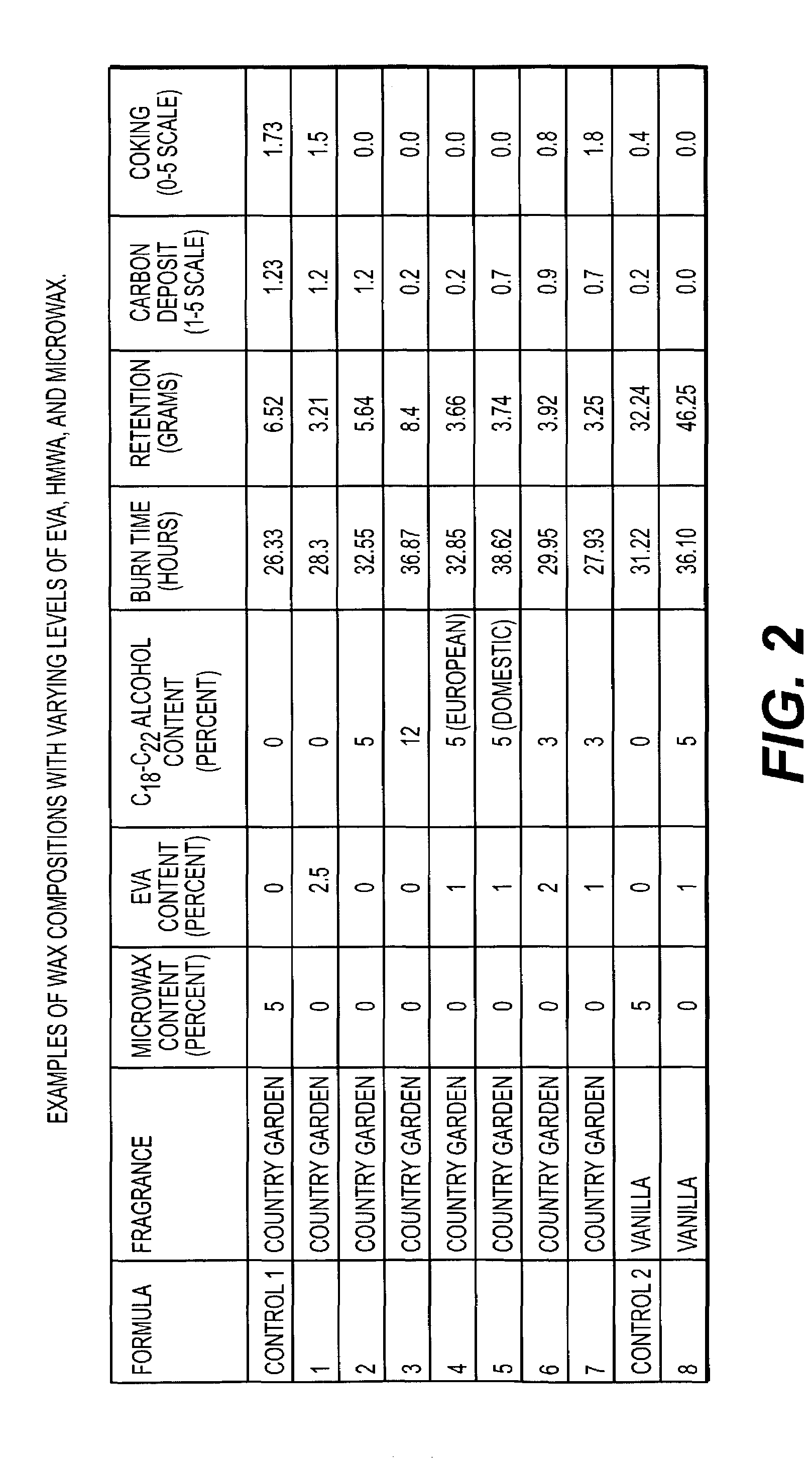

Clean-burning fragrance candle with consistent flame size and burn rate

InactiveUS7410513B2Alleviate cokingReduce smokeCandle preparation apparatusSolid fuelsWaxAcetic acid

A wax composition comprising a high molecular weight aliphatic alcohol, a low molecular weight ethylene vinyl acetate copolymer, at least one odorant, and a wax. The odorant is substantially retained in the wax composition when the wax composition is exposed to temperatures below a melting point of the wax composition. Furthermore, the odorant is emitted from the wax composition when the wax composition is exposed to temperatures at or above the melting point of the wax composition.

Owner:SC JOHNSON & SON INC

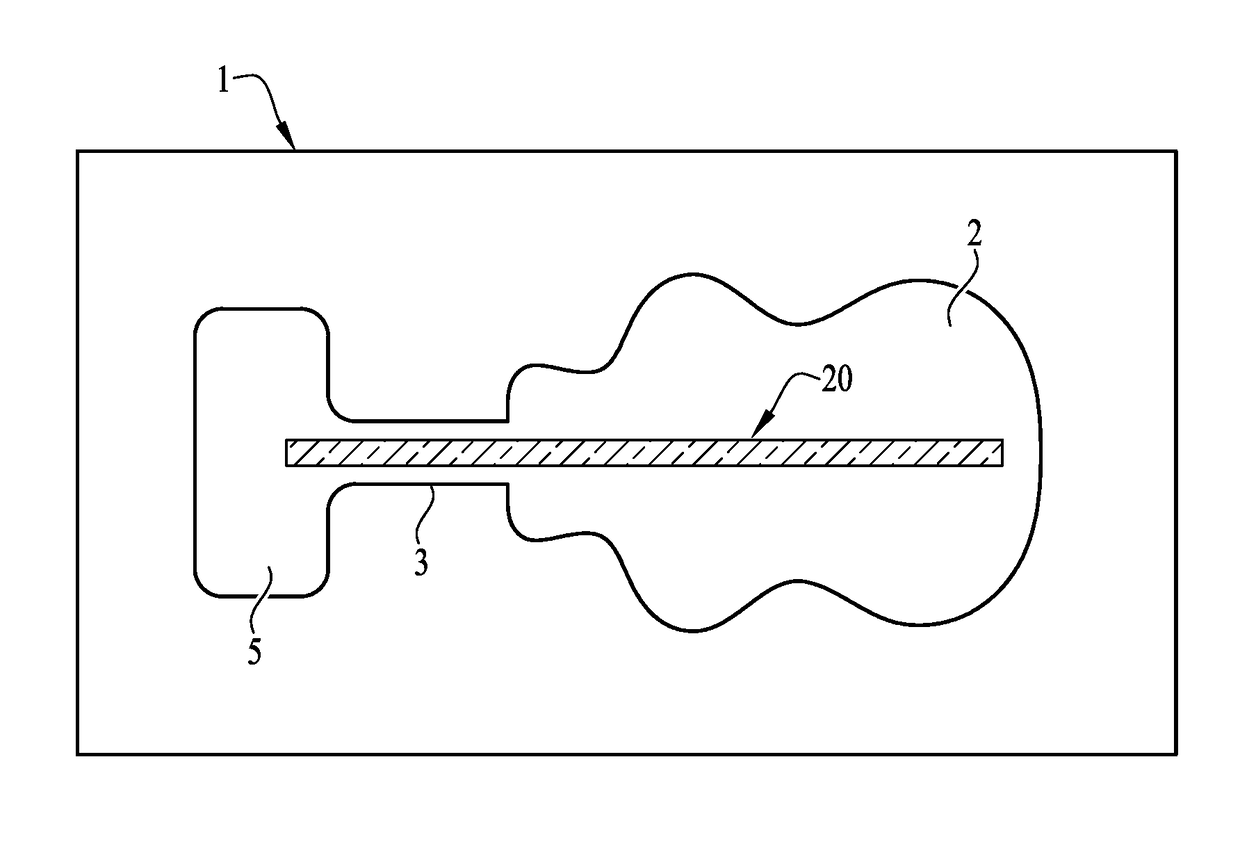

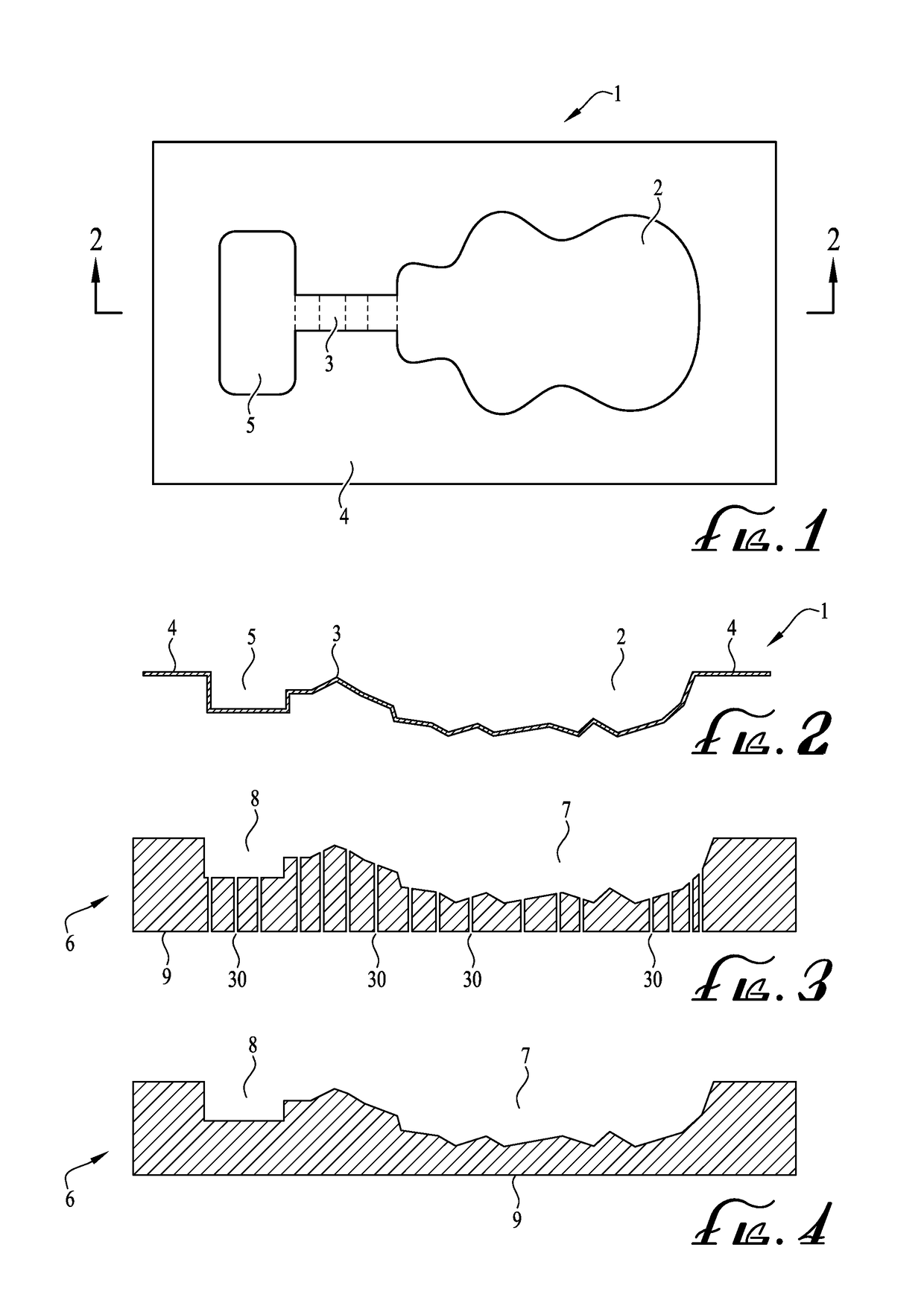

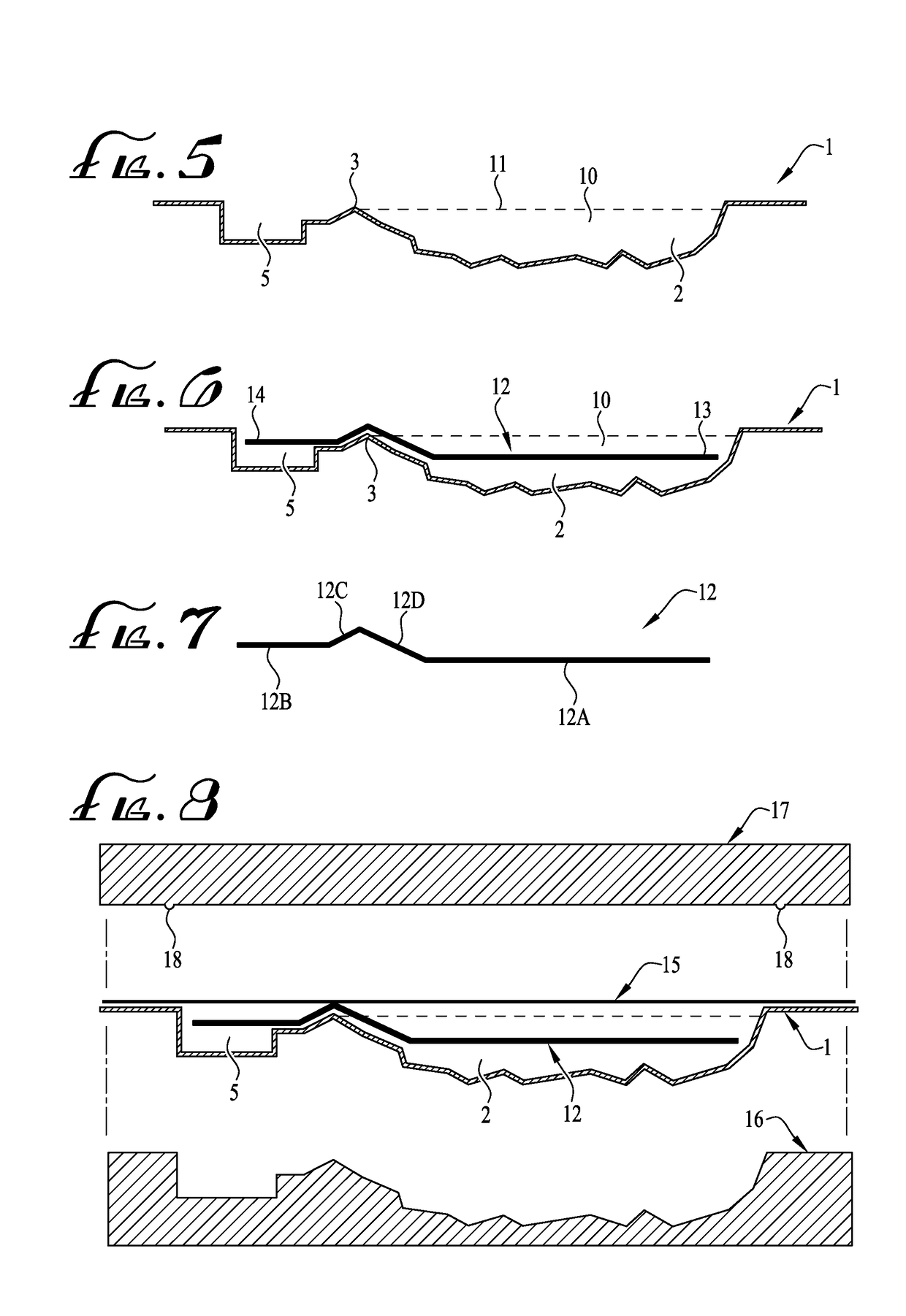

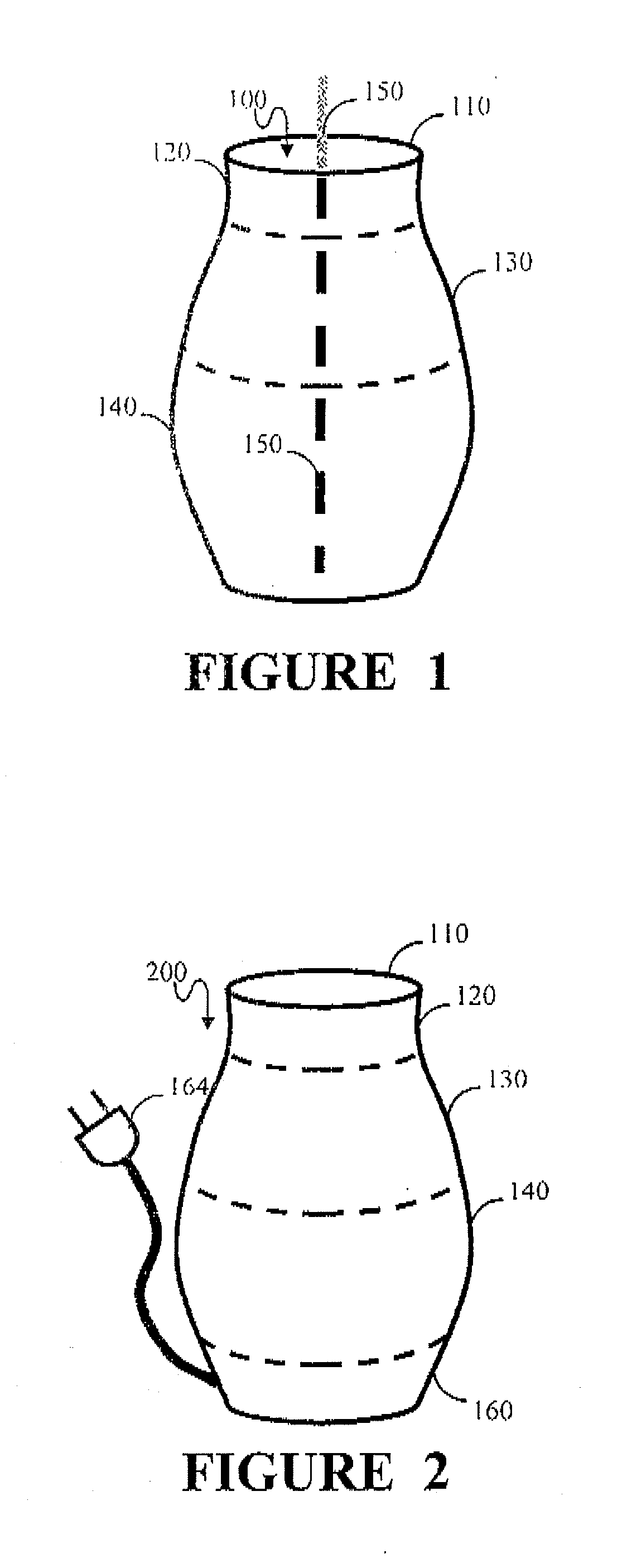

Wooden wicks including a booster for a candle and method of making

ActiveUS20120064467A1Improve flammabilityImprove combustion qualityCandle preparation apparatusCapillary burnersWaxEngineering

A wooden wick for use in a wax candle comprising a strip of predetermined wood having each of a first predetermined length, a first predetermined width and a first predetermined thickness. Such wick further includes a wood booster member having each of a second predetermined length, a second predetermined width and a second predetermined thickness adhered to the strip of wood.

Owner:DELCOTTO IP

Method utilizing waste vegetable and animal fat to manufacture candle

InactiveCN101747998ALow costMake up for wasteFatty acid hydrogenationCandle preparation apparatusFood industryParaffin wax

The invention provides a method utilizing waste vegetable and animal fat to manufacture a candle. The waste vegetable and animal fat is refined and hydrogenated to obtain a selective hydride or an extreme hydride; the selective hydride or the extreme hydride and paraffin are put into a stainless steel or porcelain container according to the weight proportion of 51-100:0-49, are uniformly mixed together, are heated to the temperature of 65 to 75 DEG C after candle essence (the total weight of micro auxiliary dyestuff and raw materials is within 0 to 5%) is added, and are completely stirred to be completely melted, so as to obtain the candle through mould forming. The candle can also be formed through pressing after the powdered extreme hydride and the paraffin are mixed together. The method makes full use of (recycles) the waste vegetable and animal fat in catering and food industries, so as to turn waste into wealth, thereby reducing the production and raw material costs of the candle; moreover, the method avoids resources waste due to that the paraffin, vegetable wax and animal wax are simply adopted as raw materials for manufacturing the candle, and leads the utilizing of human resources to be more complete and reasonable.

Owner:DALIAN TALENT GIFT CO LTD

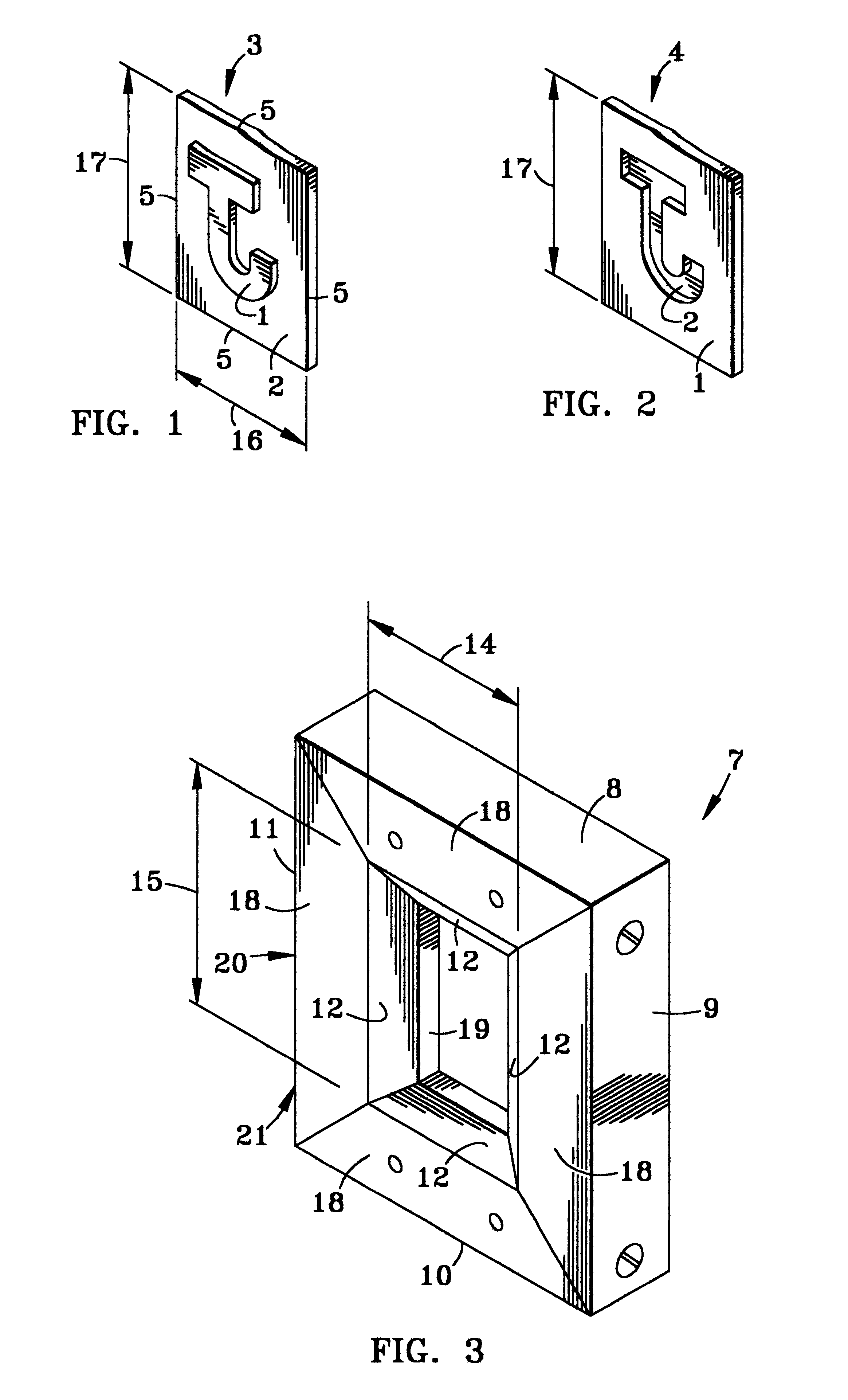

Method for producing candles having three dimensional surface designs

A method for producing candles having surface designs comprising creating a rubber stamp, building a frame atop the rubber stamp, the frame and rubber stamp forming a reservoir, filling the reservoir with casting material, allowing the casting material to harden, removing the hardened casting material, creating as many casting materials as the candle to be produced has sides, connecting the casting materials together in the form of a box with an open top and bottom, constructing a dam around the box, the space between the box and the dam defining a reservoir, filling the box with filler, filling the reservoir with sufficient mold material so that the box is submerged, allowing the mold material to set, disassembling the dam, removing the set mold material from around the box, the set mold material having an open end, inverting the mold material so the open end faces upwardly, rebuilding the dam about the mold material, pouring liquefied candle wax into the mold material open end until the mold material is completely filled by the liquefied candle wax, allowing the liquefied candle wax to set into a final candle, disassembling the dam, removing the final candle from the mold material.

Owner:SILBERGELD JOSEPH I

Method for recovering animal and plant oil for manufacturing candles of sacred vessels

InactiveCN101831359ASimple production processReduce manufacturing costCandle preparation apparatusFatty-oils/fats refiningAdditive ingredientCandle

The invention relates to a method for recovering animal and plant oil for manufacturing candles of sacred vessels, comprising the following steps: pretreating and refining raw oil before obtaining refined raw oil; heating minor ingredients to 44-75 DEG C, stirring until the minor ingredients are completely melted; mixing the refined raw oil and the minor ingredients according to the parts by weight ratio of 40-95:5-60, stirring the mixture to obtain semisolid porridge-like substance with bubbles; pouring the semisolid porridge-like substance with bubbles into a container and then cooling and solidifying the substance to obtain the container candle; or heating the minor ingredients to 44-75 DEG C, stirring until the minor ingredients are completely melted; pouring the raw oil directly into the container and pouring the melted minor ingredients at the upper part of the raw oil in the container according to the party by weight ratio of 40-95:5-60 between the raw oil and the minor ingredients; finally cooling and crusting to obtain the container candle. In the invention, the step of 'hydrogenation' in the process of refining waste oil is omitted, the production technology is simplified and the cost is reduced; in addition, with the selection and processing of the minor ingredients and matching of the minor ingredients with the refined raw oil according to a certain proportion, the candles of sacred vessels of the invention can be on a par with hydrogenated candle products in terms of performance.

Owner:DALIAN TALENT GIFT CO LTD

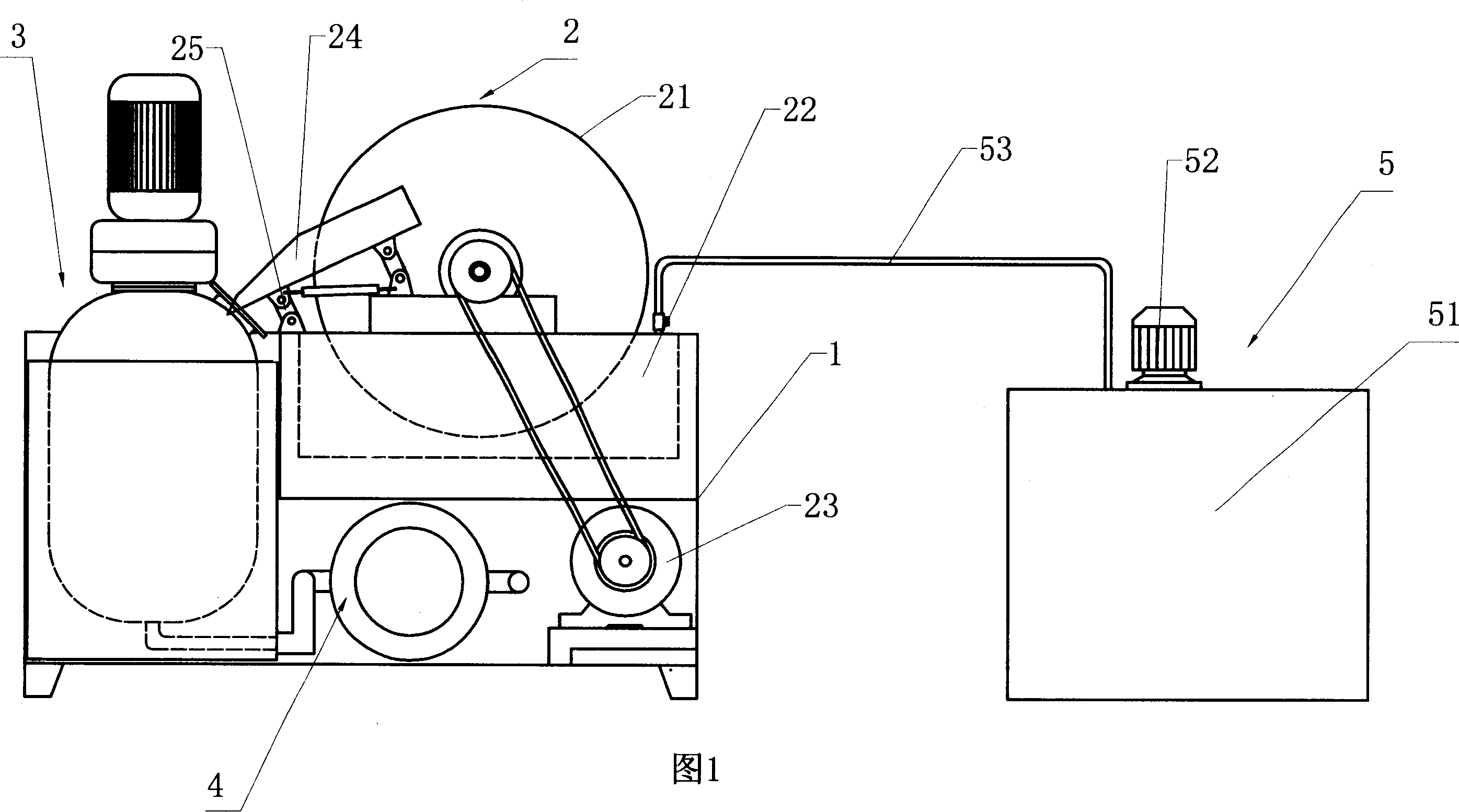

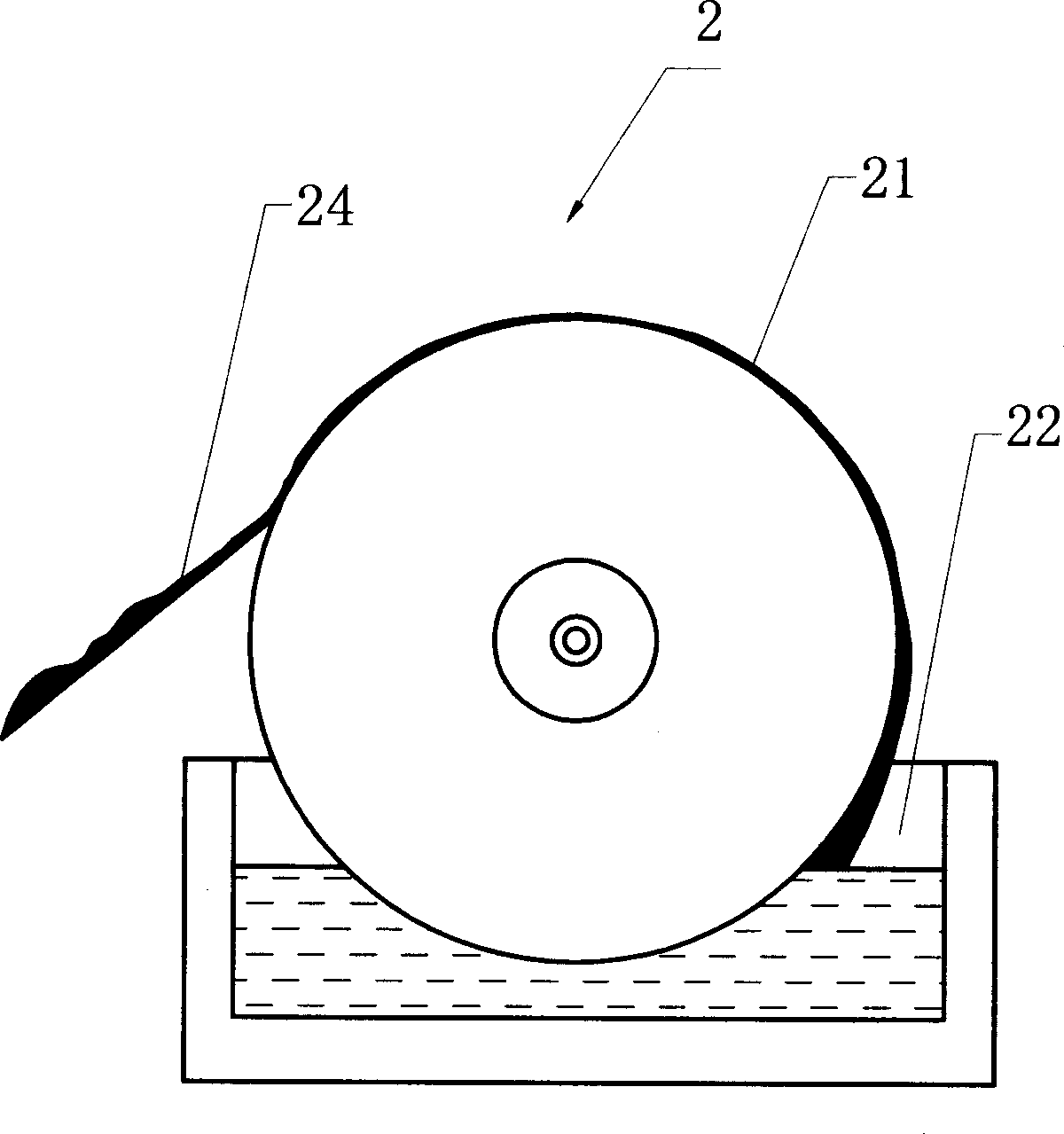

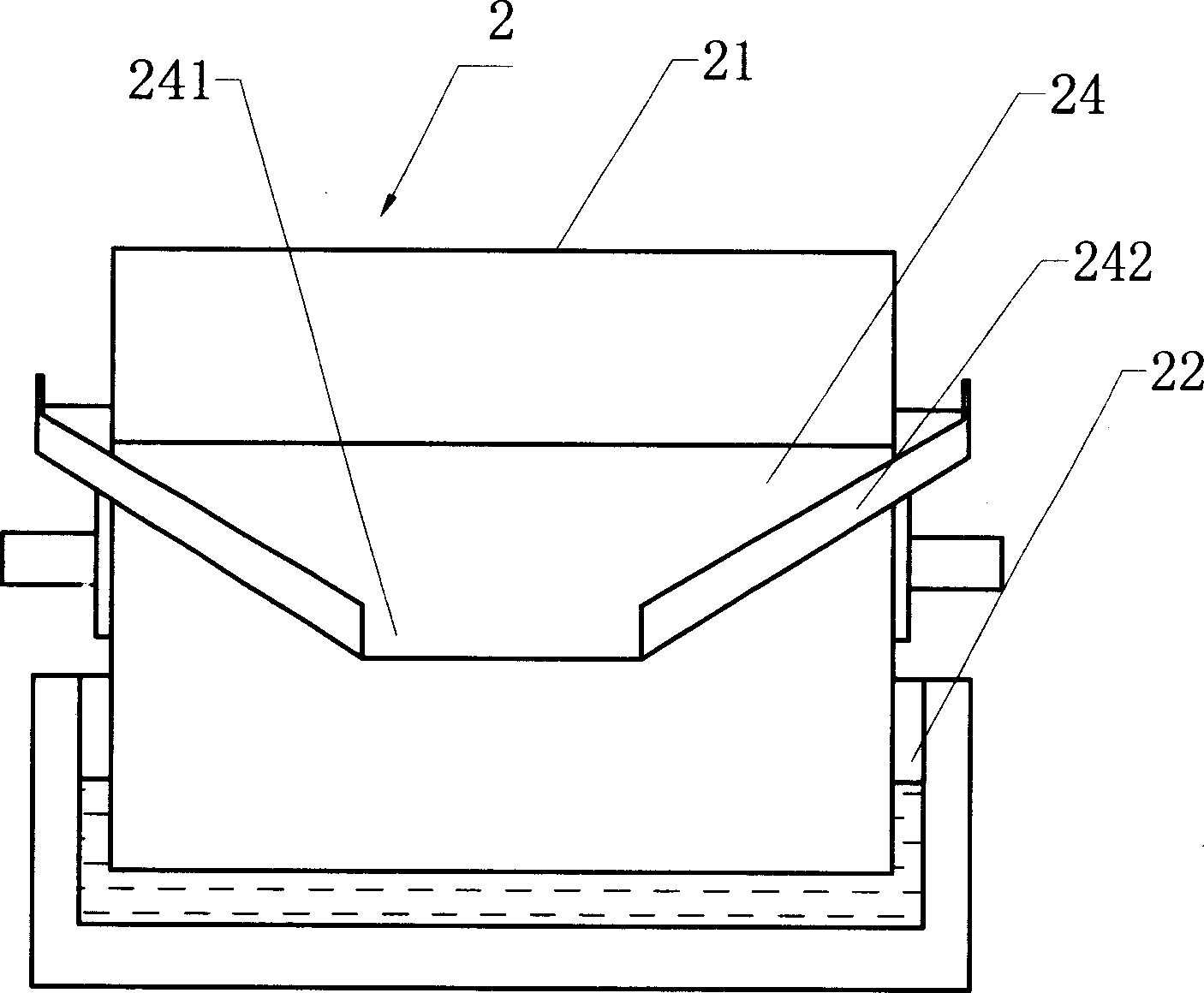

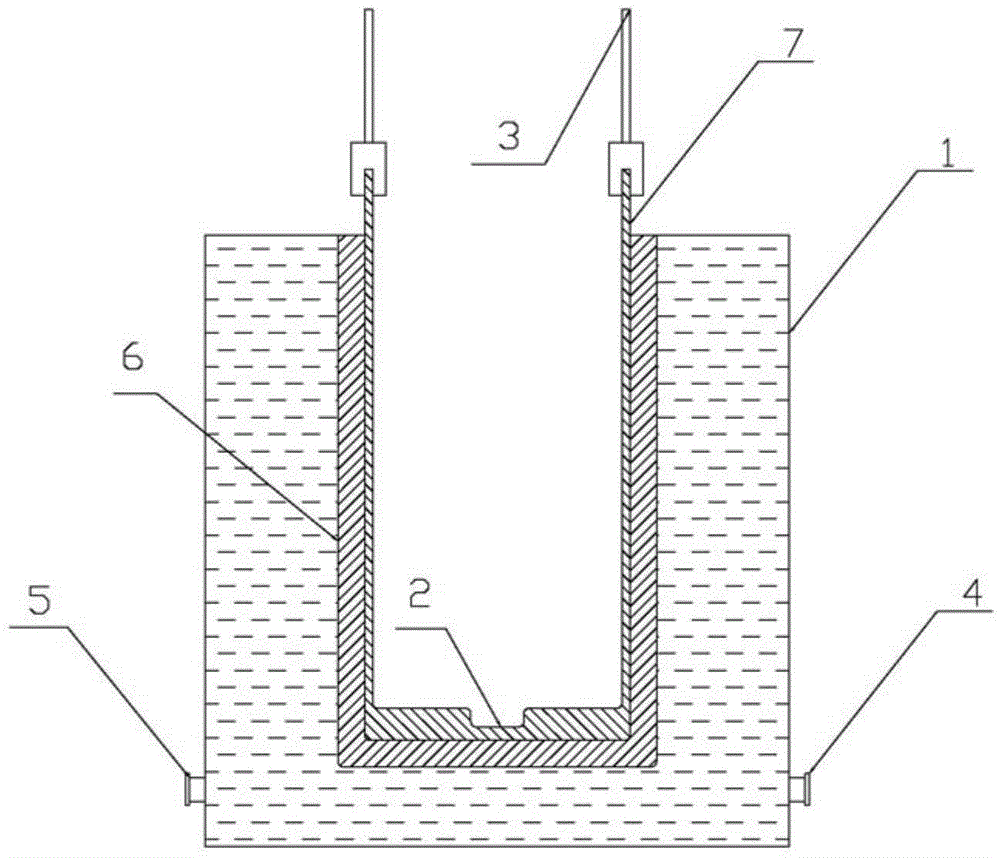

Integrated wax preparing and injecting machine

ActiveCN1810411AImprove efficiencyImprove product qualityFoundry moulding apparatusCandle preparation apparatusWaxMaterials science

The integrated wax preparing and injecting machine as one kind of wax preparing and injecting apparatus includes a frame, and molten wax condensating and scraping unit, wax paste stirring unit and wax paste extruding unit connected successively on the frame. Molten wax is first condensated into paste and planed into wax flakes in the wax condensating and scraping unit, then stirred into homogeneous wax paste in the wax paste stirring unit, and finally injected into mold with the wax paste extruding unit. All the steps are completed automatically and continuously in the same machine in high production efficiency and stable product quality.

Owner:CHAODA VALVE GRP

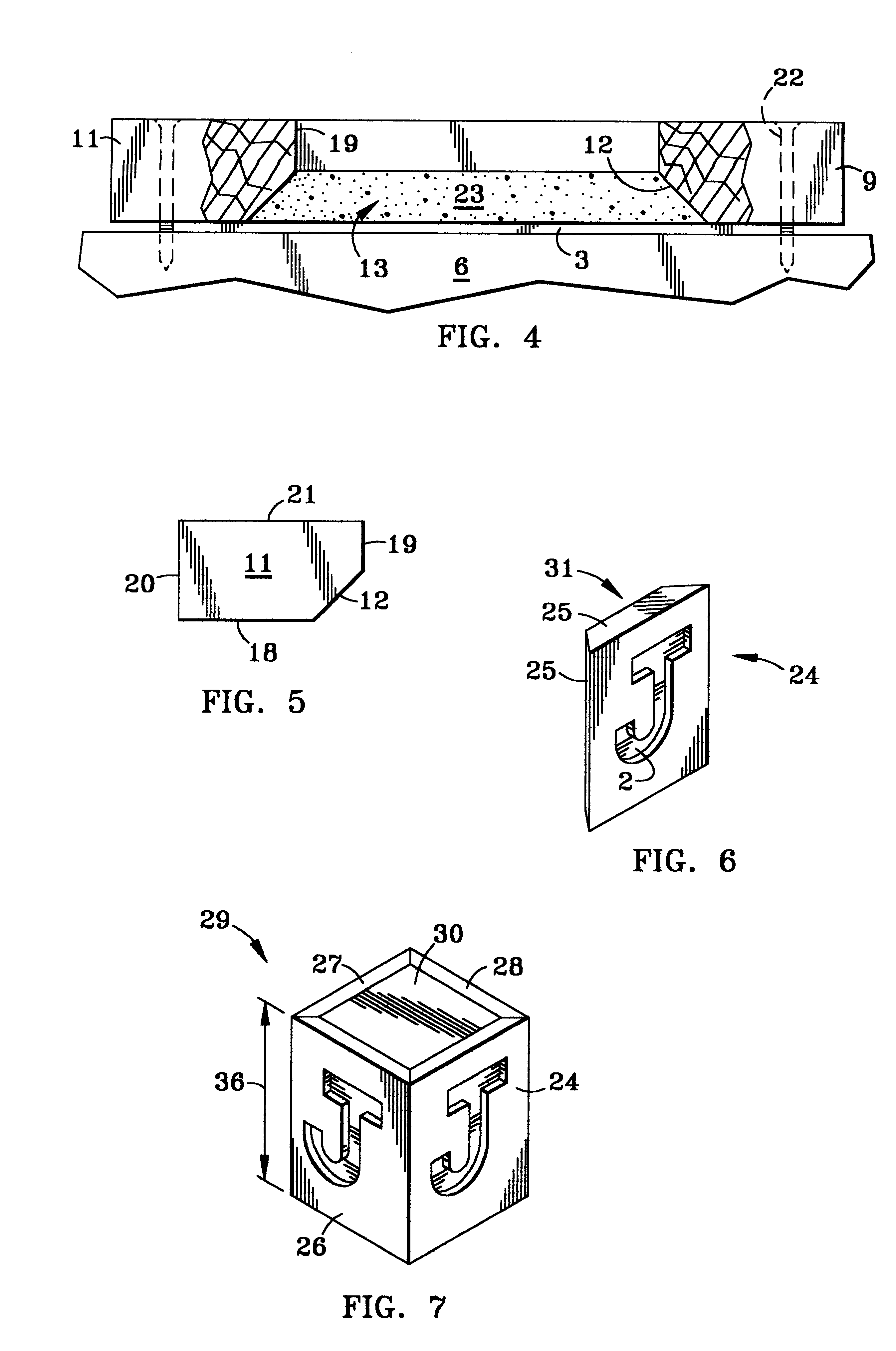

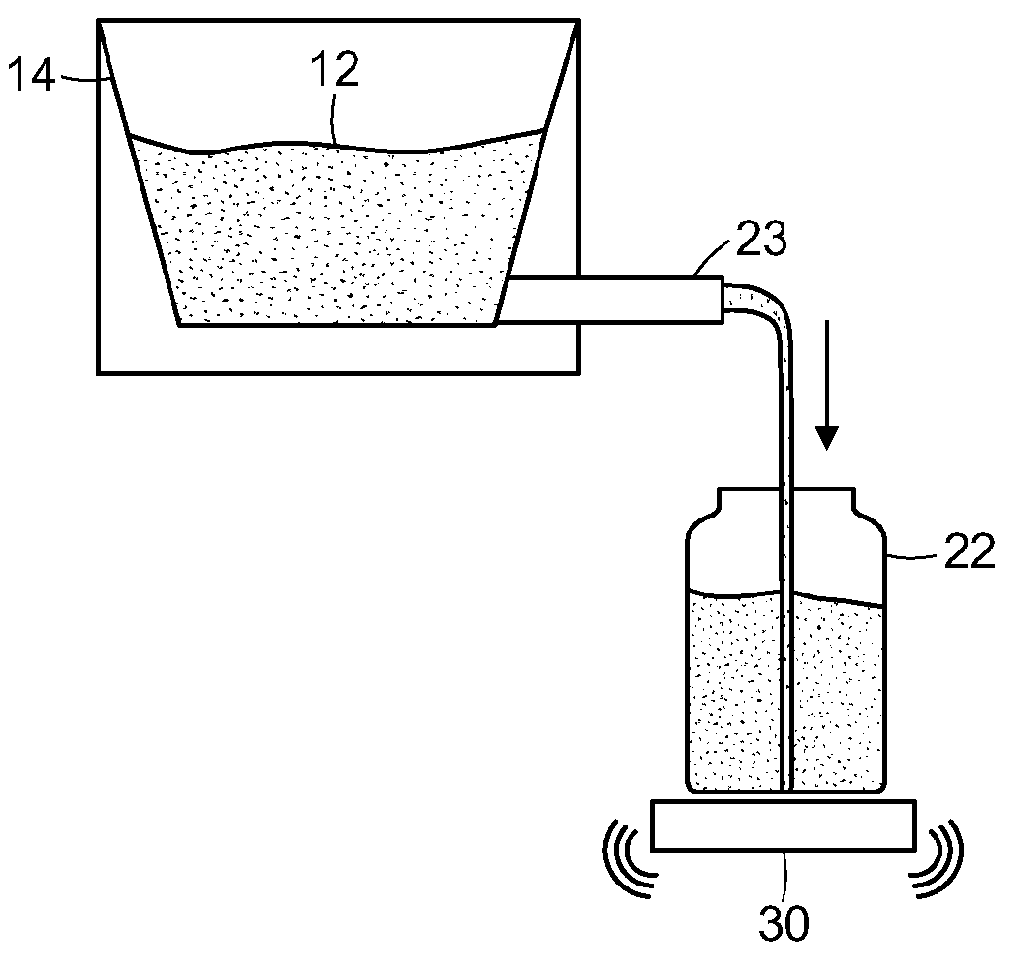

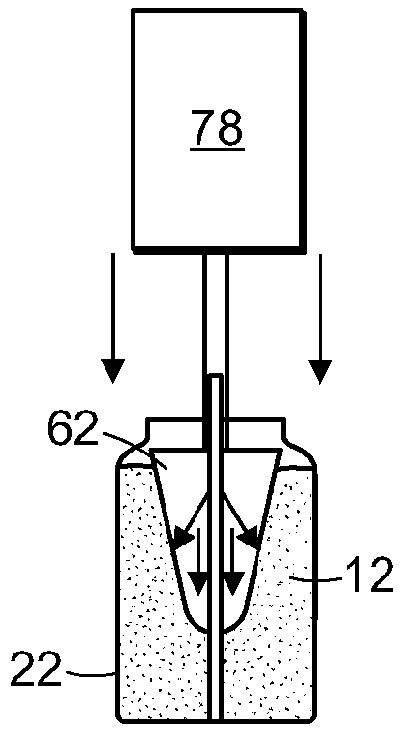

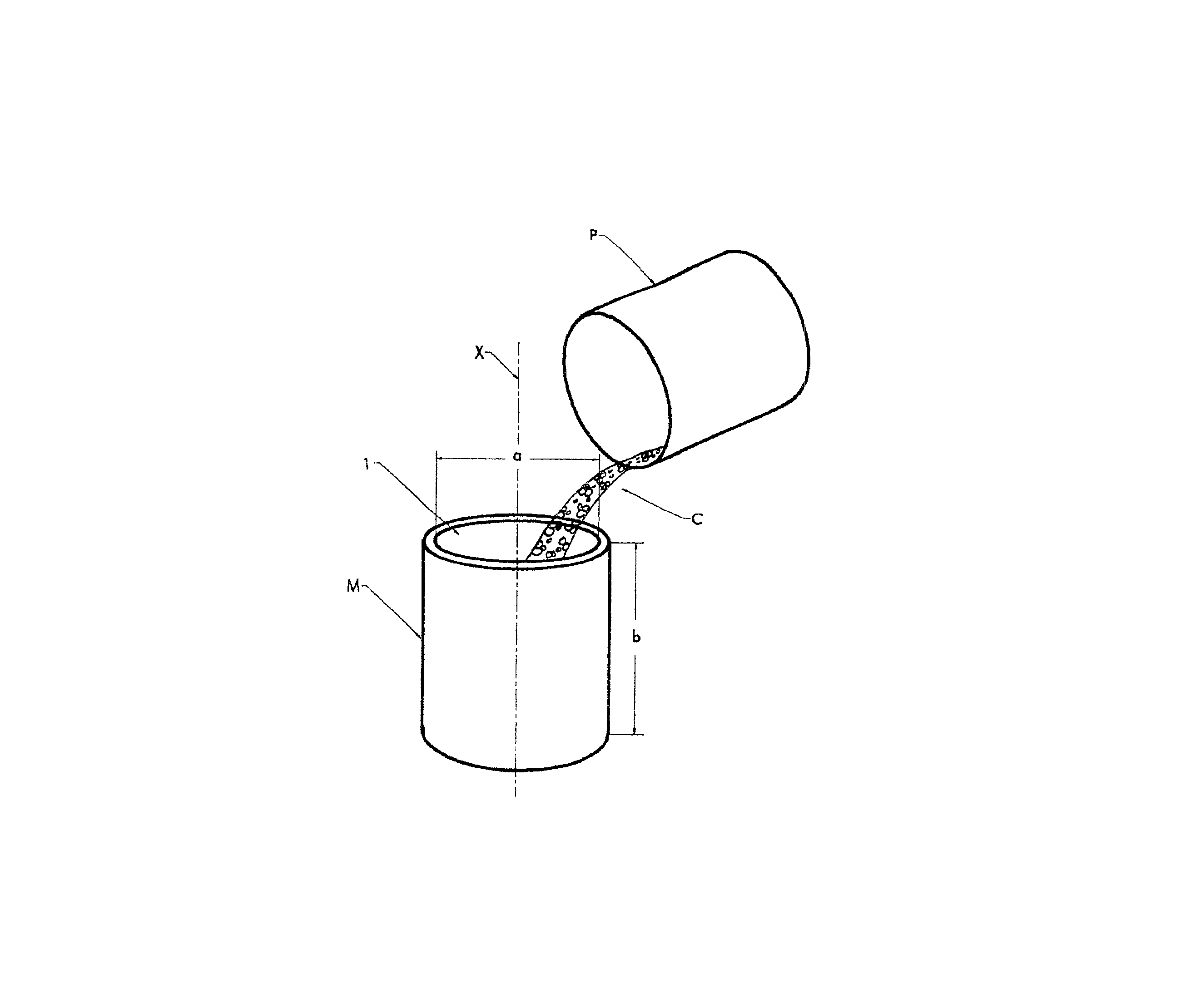

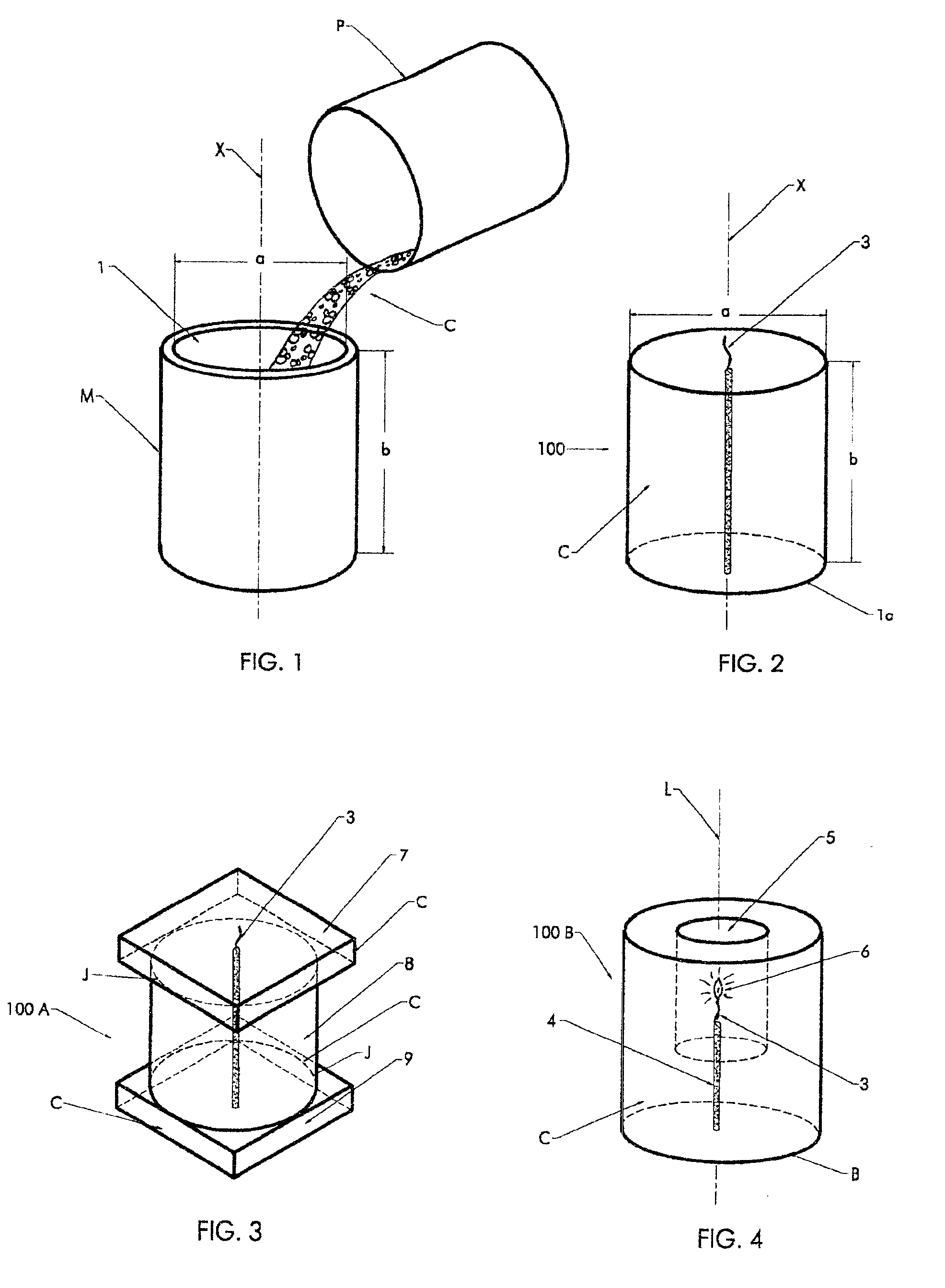

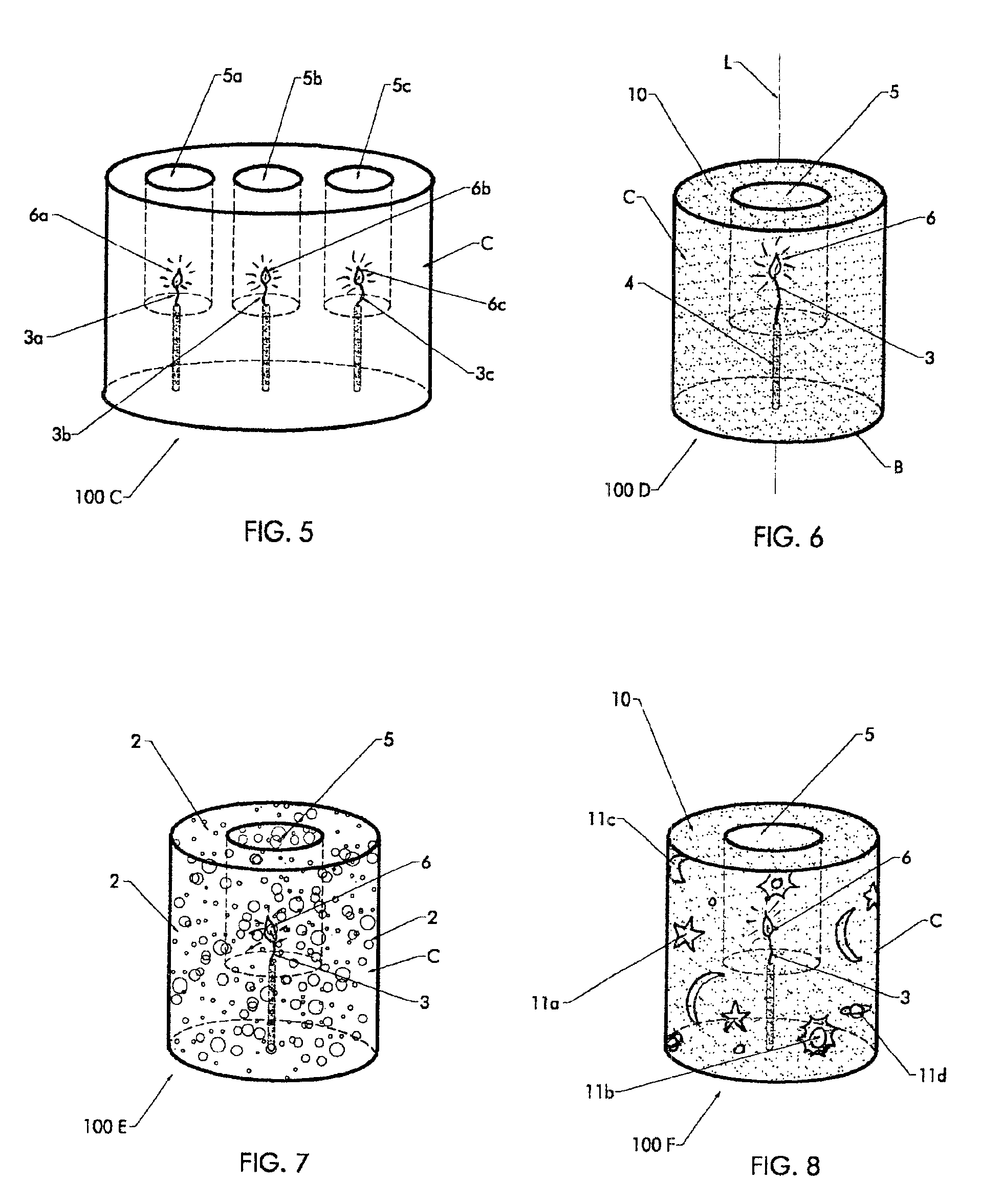

System And Method For Manufacturing A Candle With Wax Beads And Solid Wax Topping

ActiveUS20120137634A1Increased wax bead densityCandle preparation apparatusPackage sterilisationWaxCandle

The candle uses wax beads produced using existing equipment. The wax beads are transported to a bead hopper and the bead hopper deposits a volume of wax beads into jars prepared with a wick. Concurrently the jars are vibrated using a continuous vibratory motor to settle the wax beads for increased wax bead density. The filled jars are then transported to an in-container wax bead compression system where an automated plunging device compresses the wax beads. Jars are then transported by in-line conveyor to a wide conveyor. The jars are then filled at a liquid wax depositing station where the wax has been heated to its melting point and deposited into the jar to fill the void left by the in-container wax bead Compression system. The filled candle is then cooled to solidification. The finished candle is then ready for packing, distribution, sale, and use.

Owner:YANKEE CANDLE COMPANY

Special wax for candlelight and preparation method thereof

Owner:INNER MONGOLIA YITAI COAL BASED NEW MATERIALS RES INST CO LTD

LED (Light Emitting Diode) color glittery candle cup and production process thereof

The invention discloses an LED (Light Emitting Diode) color glittery candle cup and a production process thereof, wherein a traditional candle structure is modified, a light-triggered switch is taken as a switch of an electronic lightening component, the switching on and off of the electronic lightening component are controlled directly by candle lights, and the switching on and off of a lightening diode do not need to be manually operated, thus the use of the LED color glittery candle cup is convenient. An optical fiber of the LED color glittery candle cup is combusted along with the combustion of a combustion core, is not left on a combustion end surface of the candle cup and does not influence the ornamental and the decorative. A coating outside the optical fiber prevents the optical fiber from being corroded, can reduce the sensitivity of the optical fiber to lights and prevents other natural lights from triggering and switching on the electronic lightening component. A cotton pad below a circuit board is used for preventing a welding point from being broken due to puncture. Anti-flaming sleeves of the optical fiber and the lower part of the combustion core have a fixing function and also have an anti-flaming function so as to prevent the damage caused by combustion and explosion of the electronic lightening component because the electronic lightening component at the bottom of a candle body is combusted when the combustion core of the candle cup is combusted to the end.

Owner:王德勋

Fatty acid candle and method for manufacturing same

The invention discloses a fatty acid candle and a method for manufacturing the same; the candle comprises a surface crystallization regulator and a fatty acid mixture consisting of hexadecanoic acid and octadecanoic acid; the weight percentages of hexadecanoic acid and octadecanoic acid in the fatty acid mixture can be divided into two ratio zones: 65-80% of hexadecanoic acid and 20-35% of octadecanoic acid are contained in one ratio zone; and 30-50% of hexadecanoic acid and 50-70% of octadecanoic acid are contained in the other ratio zone. The method for manufacturing the fatty acid candle comprises the following steps: after heating the object to the temperature of 120 DEG C, pouring into a mould and naturally cooling to form a hard husk; and adding the solid crushed blocks that are the same as the poured liquid mixture in components, or pouring into the stainless steel candle machine mould cylinder at the temperature of 30-35 DEG C; and after fully cooling, de-molding to obtain a fatty acid candle with a smooth and uniform surface. The fatty acid candle has the advantages of being reproducible, biologically degradable, nontoxic and low-cost; and the manufacturing method enables the surface of the candle to be smooth and free from cracking.

Owner:NINGBO KWUNGS HOME INTERIOR & GIFT

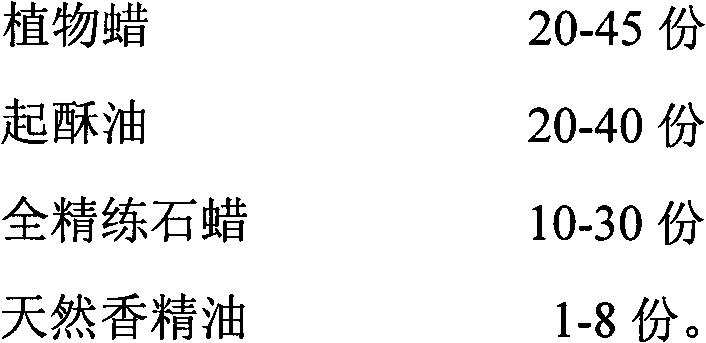

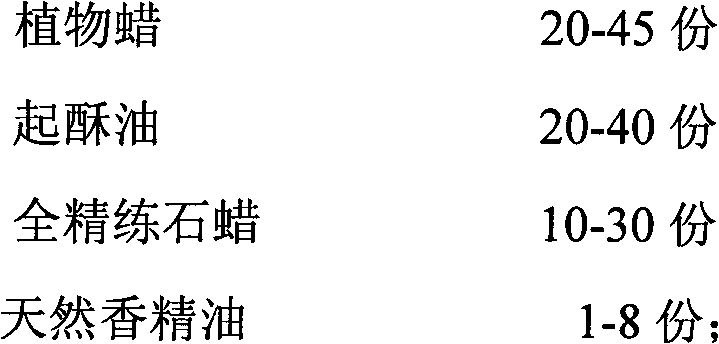

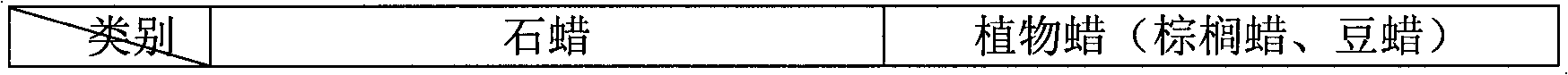

Cheese candle and preparation method thereof

InactiveCN102876467AAvoid high temperature operating conditionsReduce energy consumptionCandle preparation apparatusParaffin waxDissolution

The invention relates to a cheese candle and its preparation method. The cheese candle is prepared from the following raw materials by weight: 20-45 parts of plant wax, 20-40 parts of shortening, 10-30 parts of fully refined paraffin wax, and 1-8 parts of natural essence. The preparation method consists of: dissolving 52DEG C fully refined paraffin wax with steam, maintaining a constant temperature at 90-100DEG C, adding plant wax and Jinyan shortening to perform emulsification, stirring them uniformly, then adding natural essential oil, and after complete dissolution, pouring the emulsion into a well preheated constant temperature trough; and finally, by means of mechanical equipment and infrared control, filling liquid wax, and performing cooling as well as shaping, thus obtaining a finished candle product. Compared with traditional candles, the cheese candle provided in the invention employs plant wax and shortening as well as a small amount of paraffin wax as the main raw materials, has good intermiscibility with essential oil, and is renewable and cheap. During production, the energy consumption is low, and during actual use, the fragrance is lasting. With the advantages of clean and smokeless combustion, low wax pool temperature and good safety, the cheese candle can better improve the air environment effectively through combustion, thus being in line with the requirements of low carbon and environmental protection.

Owner:NINGBO KWUNGS WISDOM ART & DESIGN

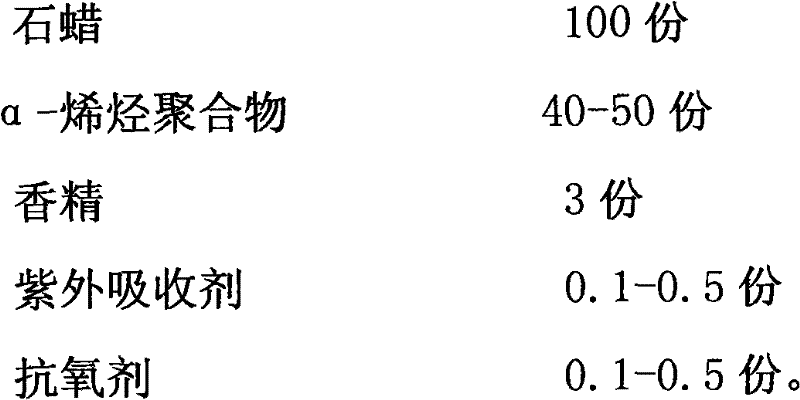

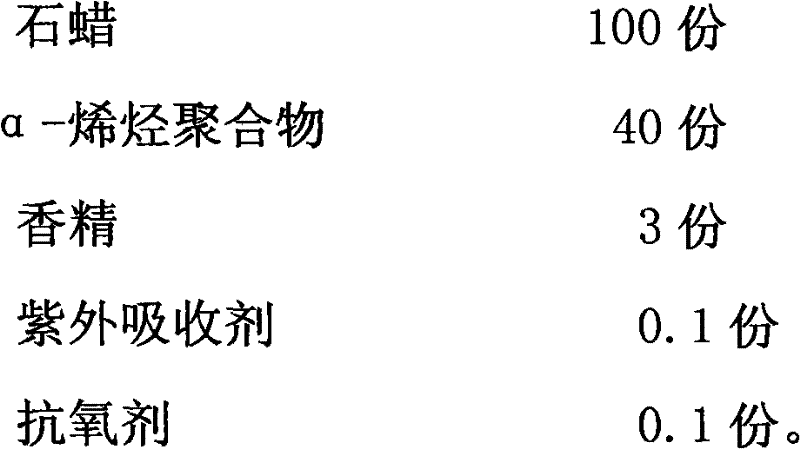

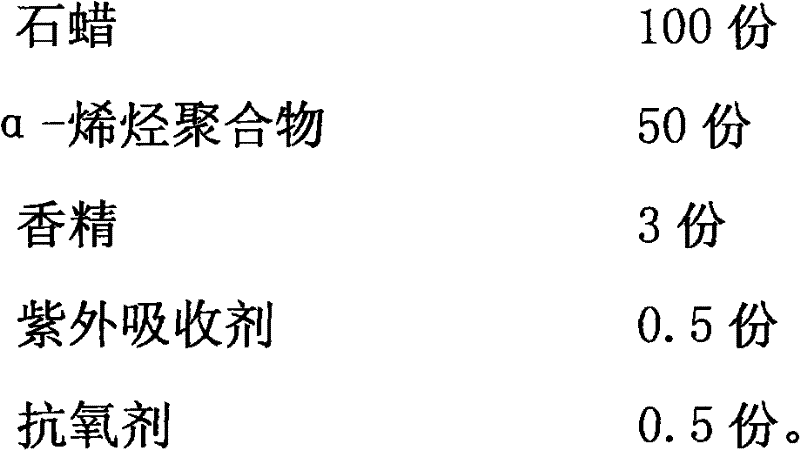

Snowflake candle with alpha-olefin polymer and preparation method thereof

ActiveCN102517158ARealistic effectOil seepage controlCandle preparation apparatusAntioxidantParaffin oils

The invention provides a snowflake candle with an alpha-olefin polymer. The snowflake candle is prepared from the following materials in parts by weight: 100 parts of paraffin, 40-50 parts of alpha-olefin polymer, 3 parts of essence, 0.1-0.5 part of ultraviolet absorbent and 0.1-0.5 part of antioxidant. The invention also provides a preparation method of the snowflake candle. The snowflake candle has the advantages of large, fewer and sparse snowflakes and low oil-leakage amount.

Owner:NINGBO KWUNGS HOME INTERIOR & GIFT

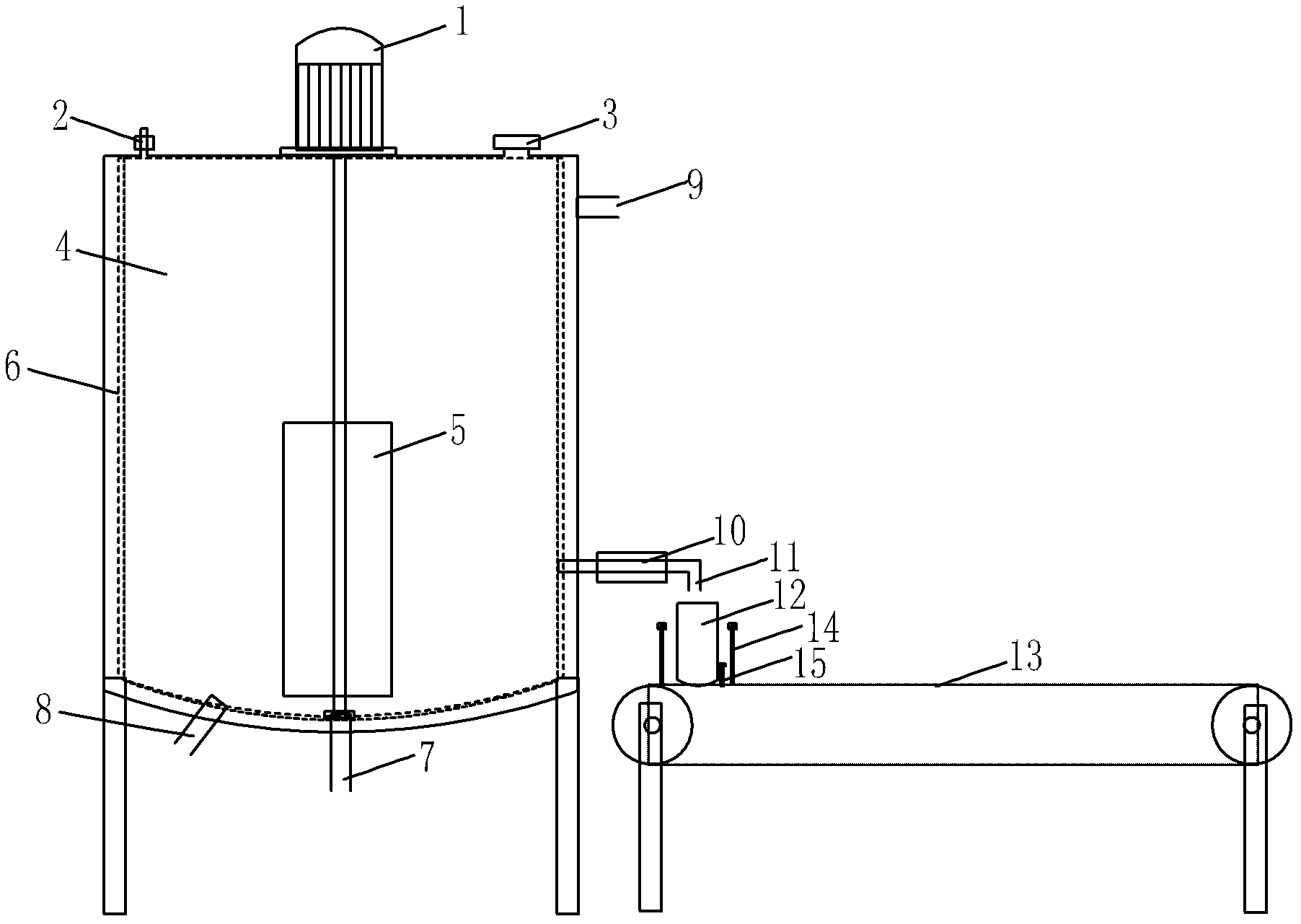

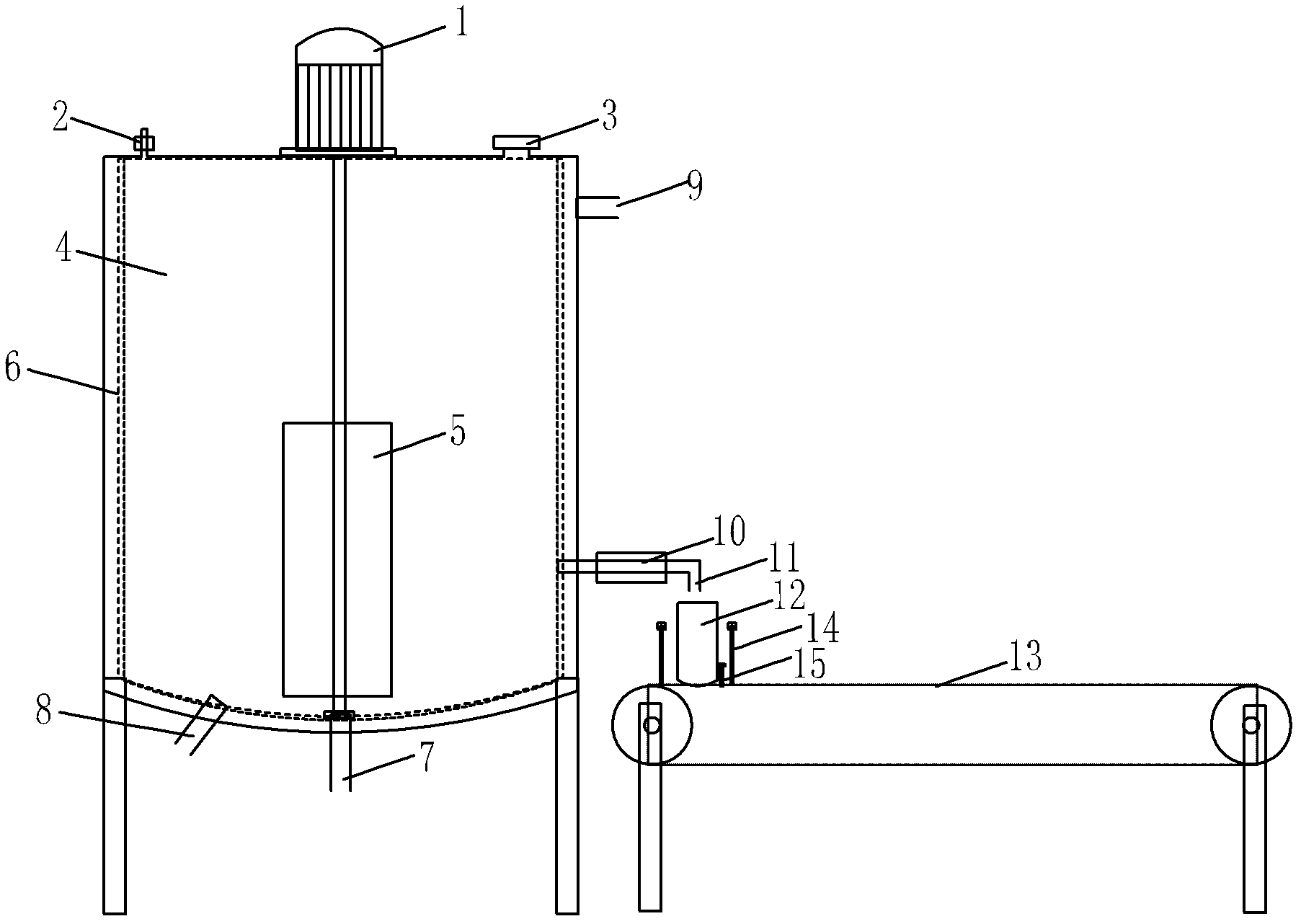

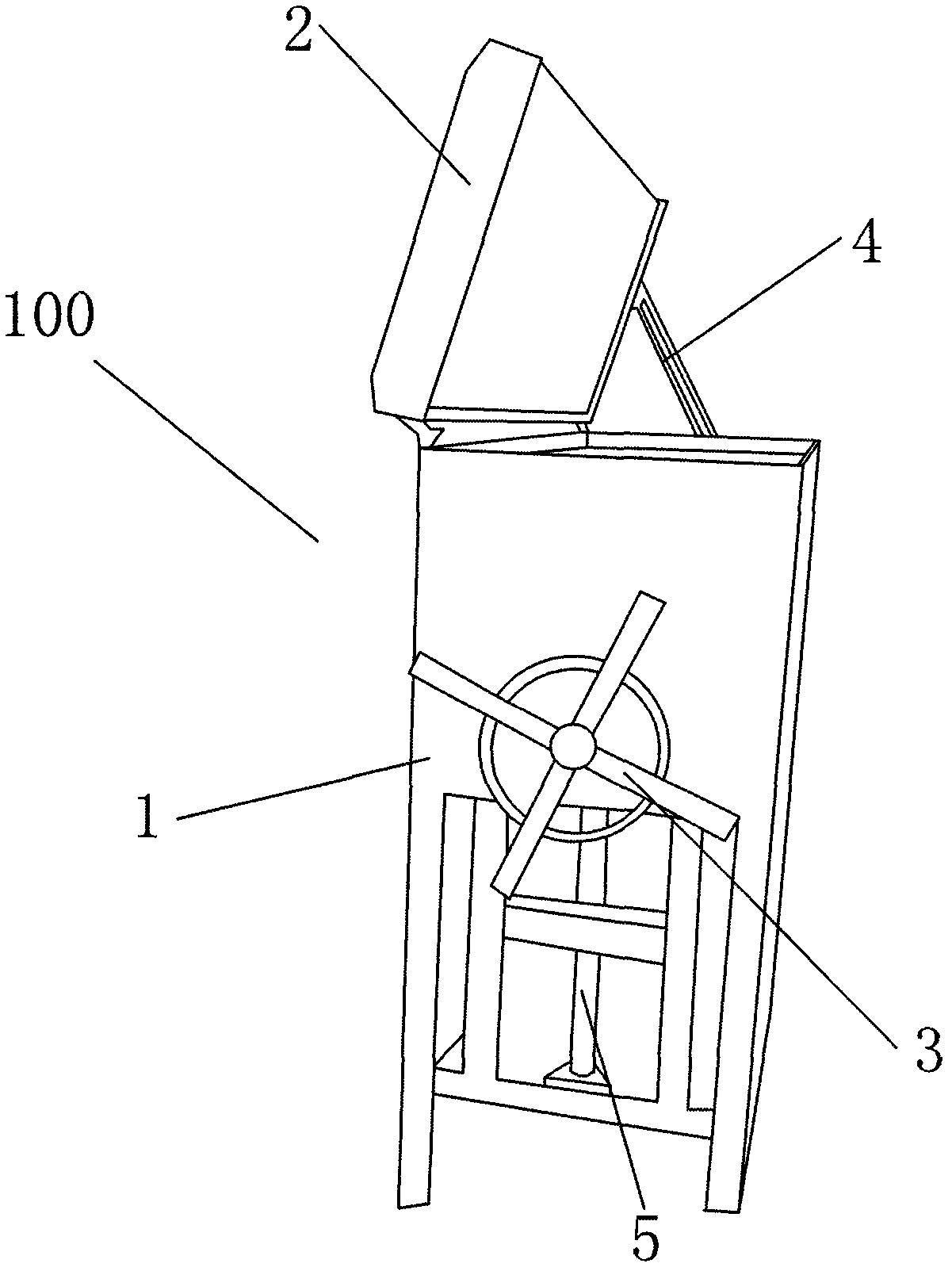

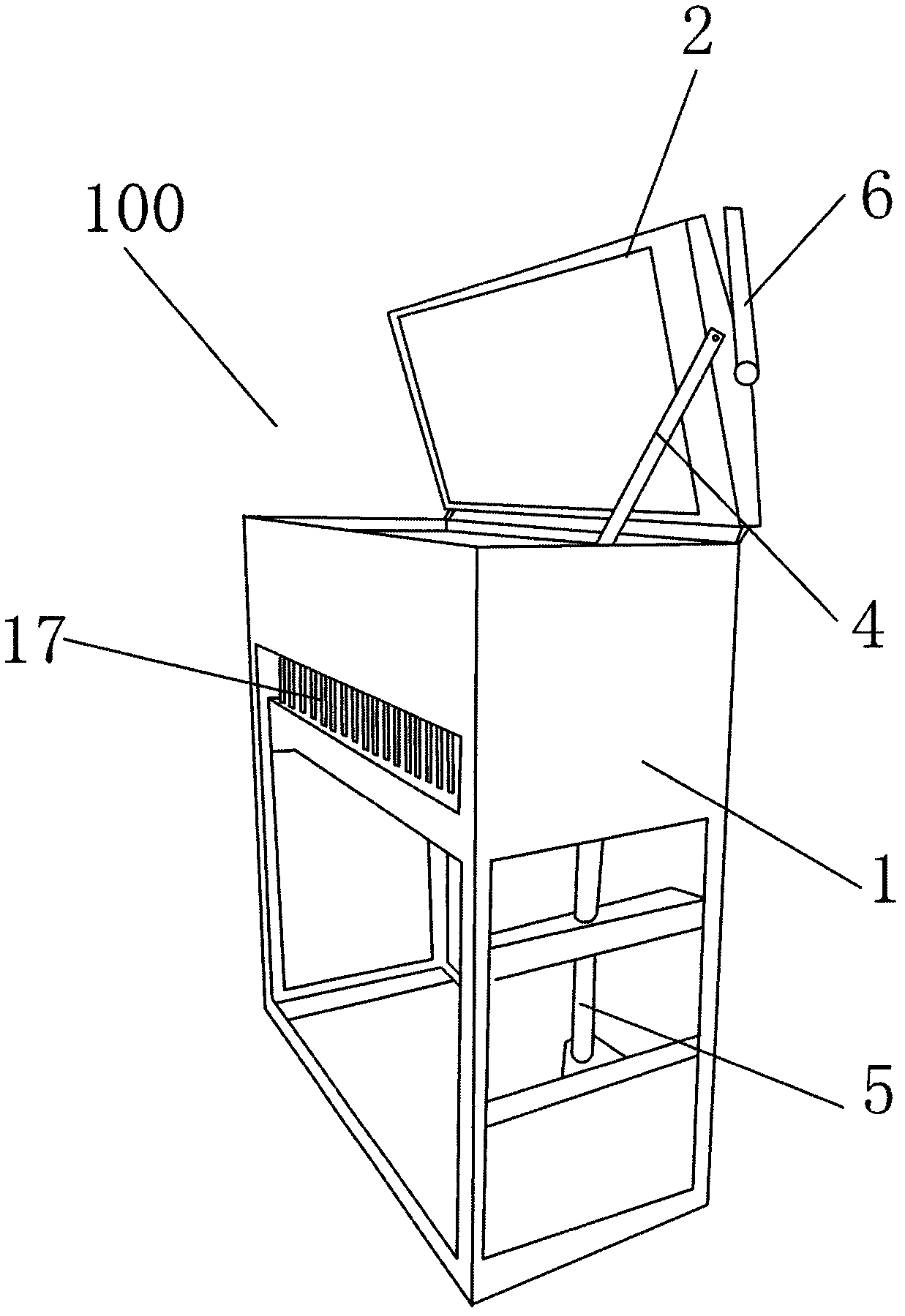

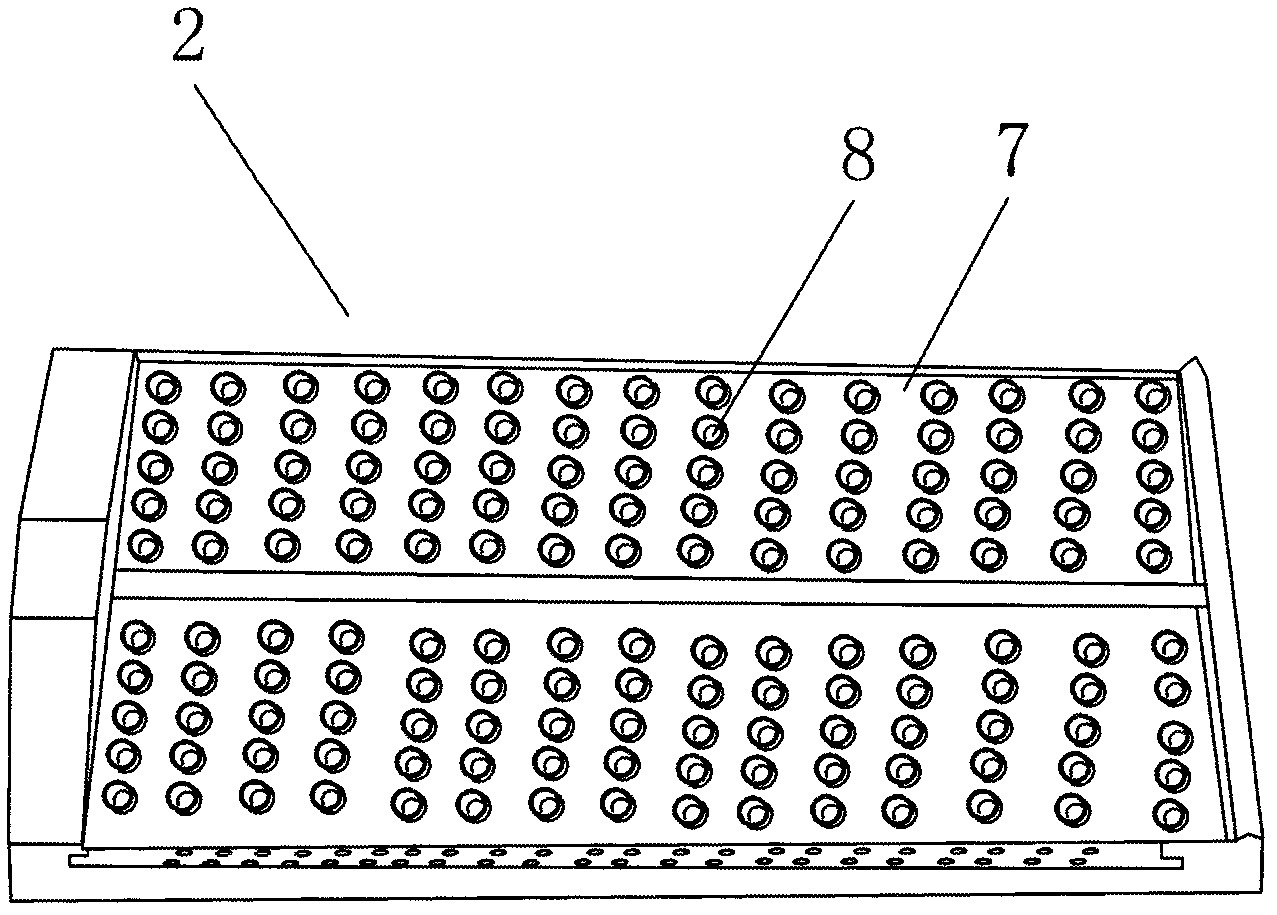

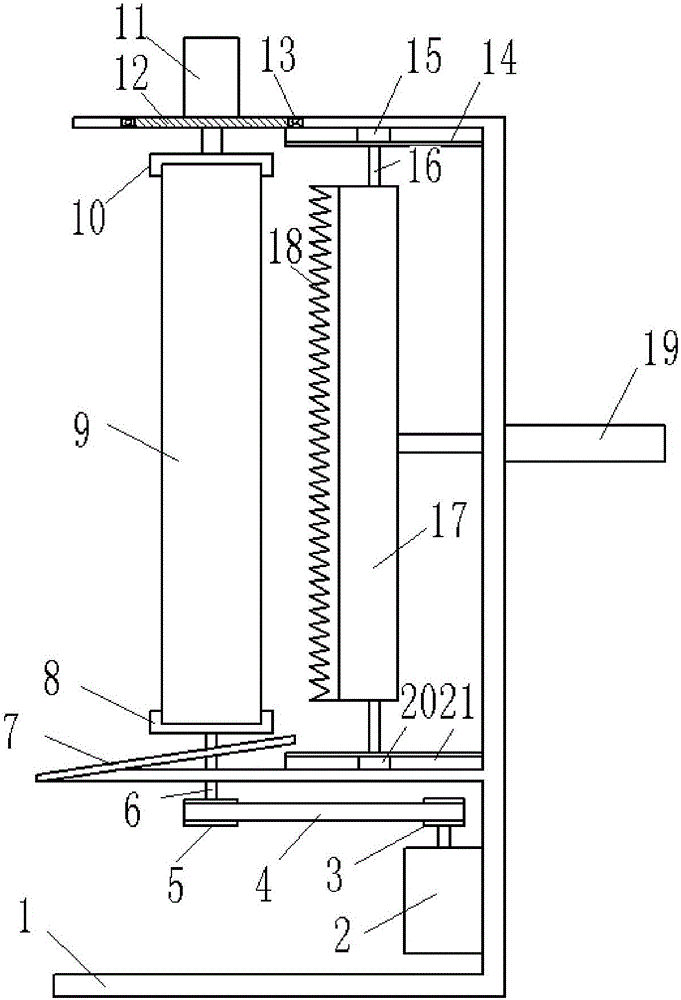

Full-automatic foaming candle filling device

InactiveCN102358869AReduce labor intensityRealize automated productionCandle preparation apparatusWaxEngineering

The present invention relates to a full-automatic foaming candle filling device. The device comprises a foaming cylinder. A foaming motor is arranged on the upper end of the foaming cylinder. An output shaft of the foaming motor is connected with a stirring rod inserting into the foaming cylinder. The lower end of the stirring rod is provided with a foaming blade. The device is characterized in that: a filling port is arranged on a side wall of the foaming cylinder; a conveying belt for conveying a candle container is arranged below the filling port; the position of the filling port is provided with a pneumatic ball valve; an infrared probe is arranged on the conveying belt arranged below the filling port; a layer of cooling water housing is covered on a housing of the foaming cylinder; acooling water inlet is arranged on a lower part of the cooling water housing; a cooling water outlet is arranged on an upper part of the cooling water housing; the upper end of the foaming cylinder is provided with a gas inlet and a wax injecting port; the lower end of the foaming cylinder is provided with a wax placing port. With the full-automatic foaming candle filling device of the present invention, the automatic production is realized, the labor intensity is reduced, and the production efficiency is improved.

Owner:无锡市灵山香烛工艺制品有限公司

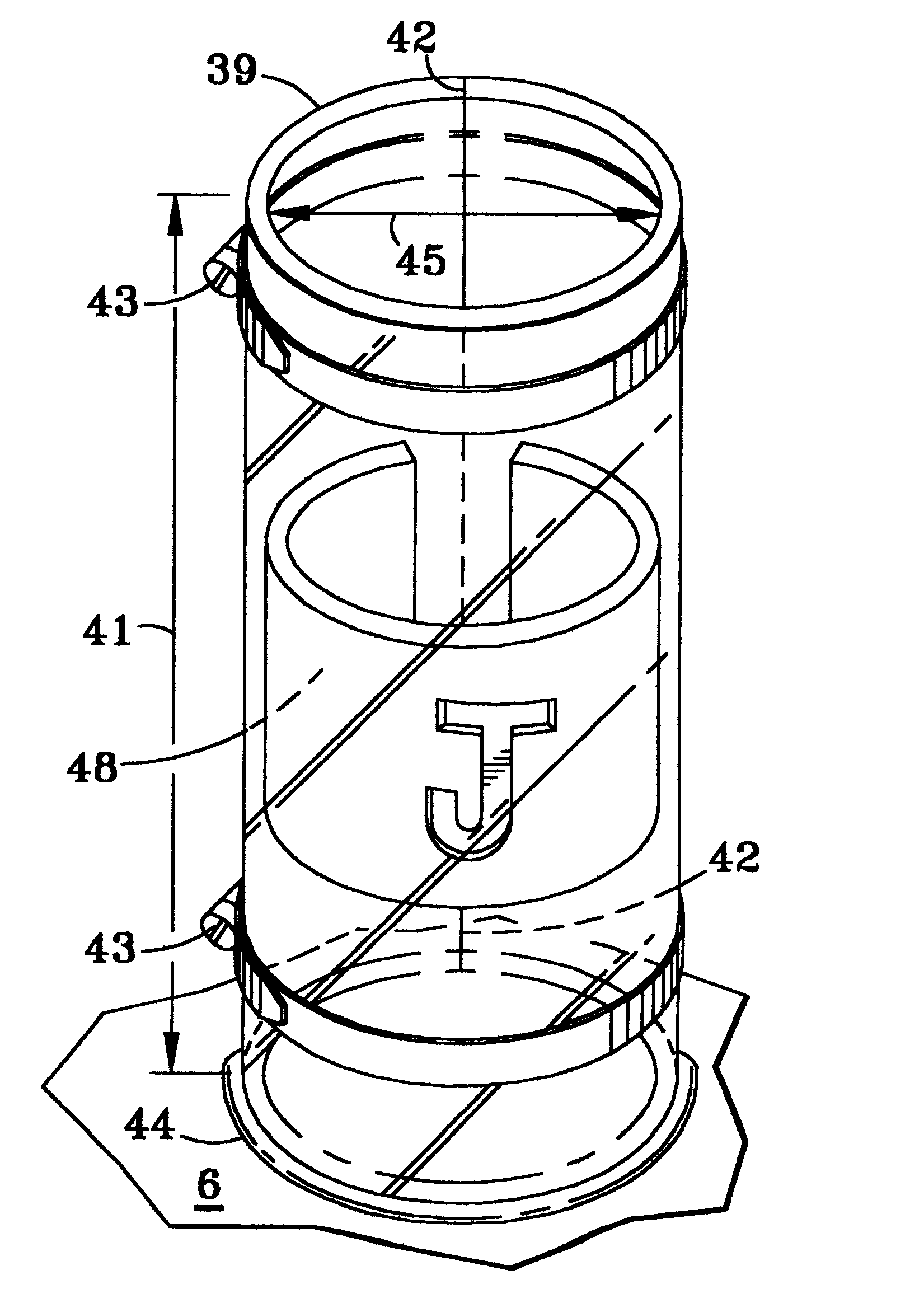

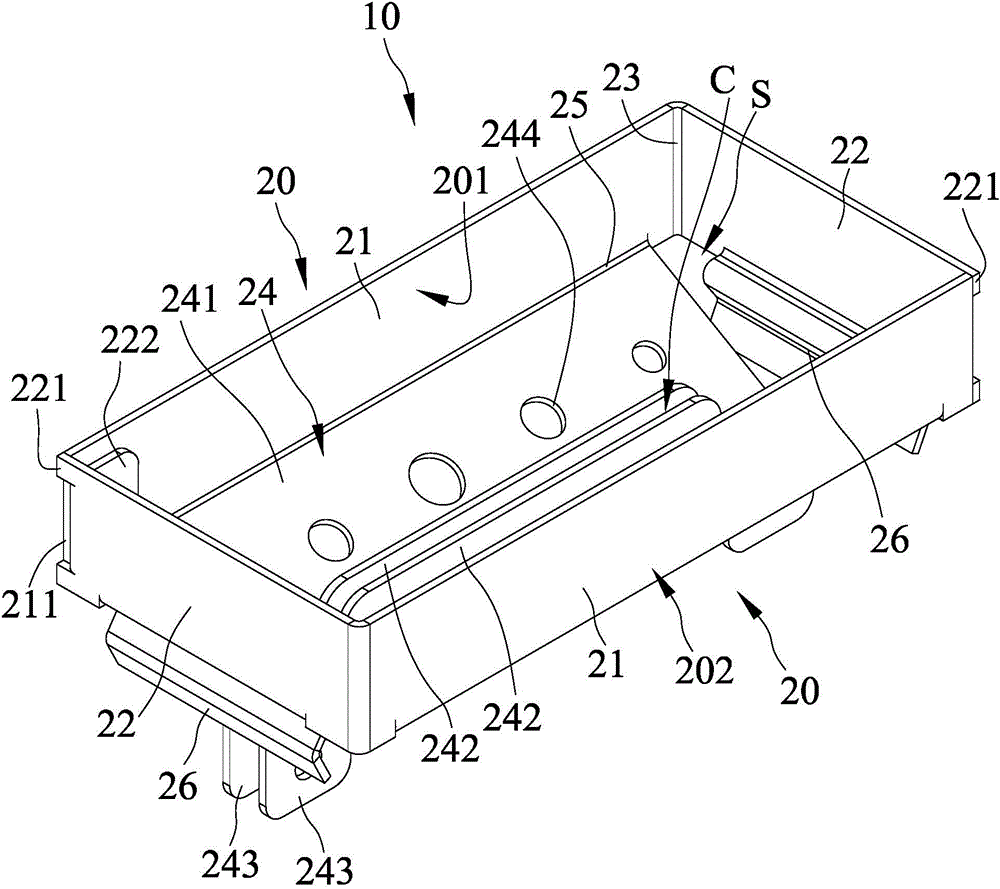

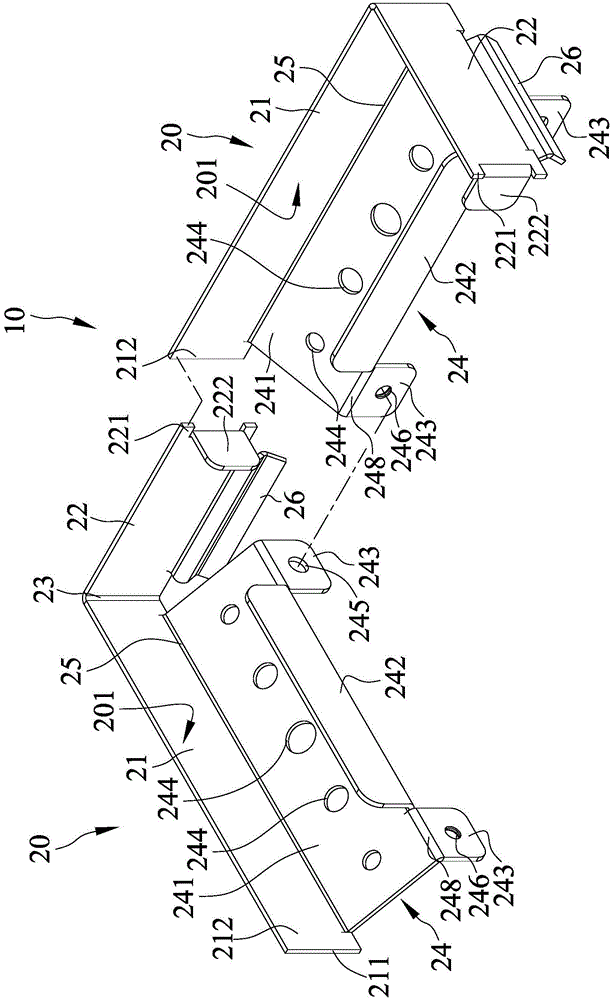

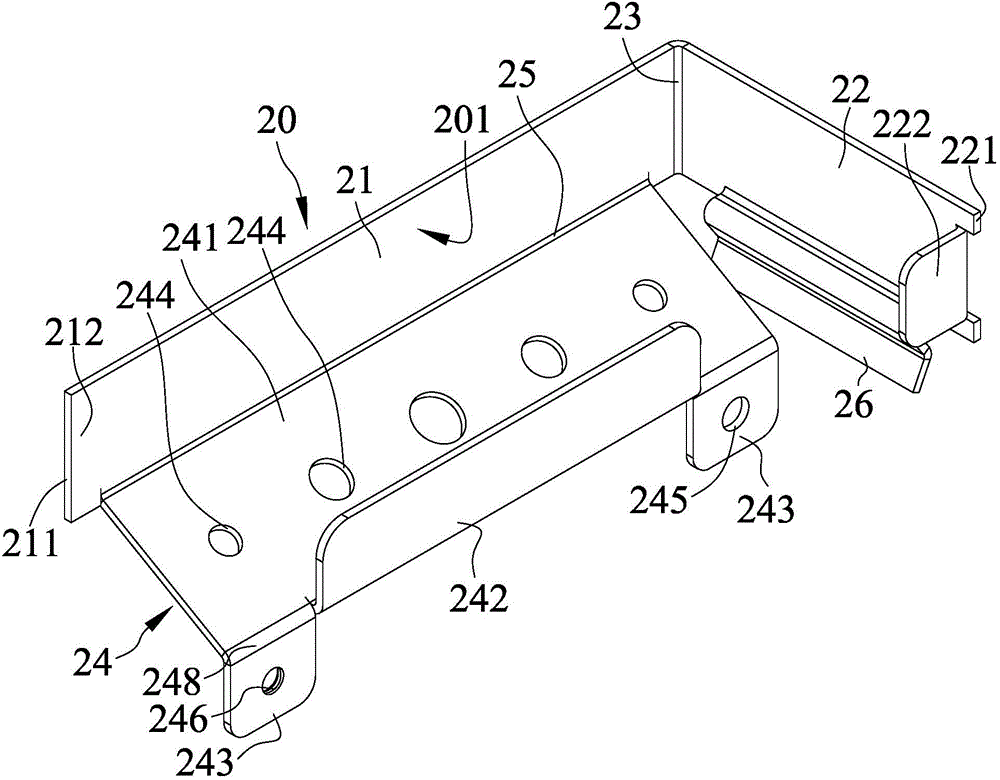

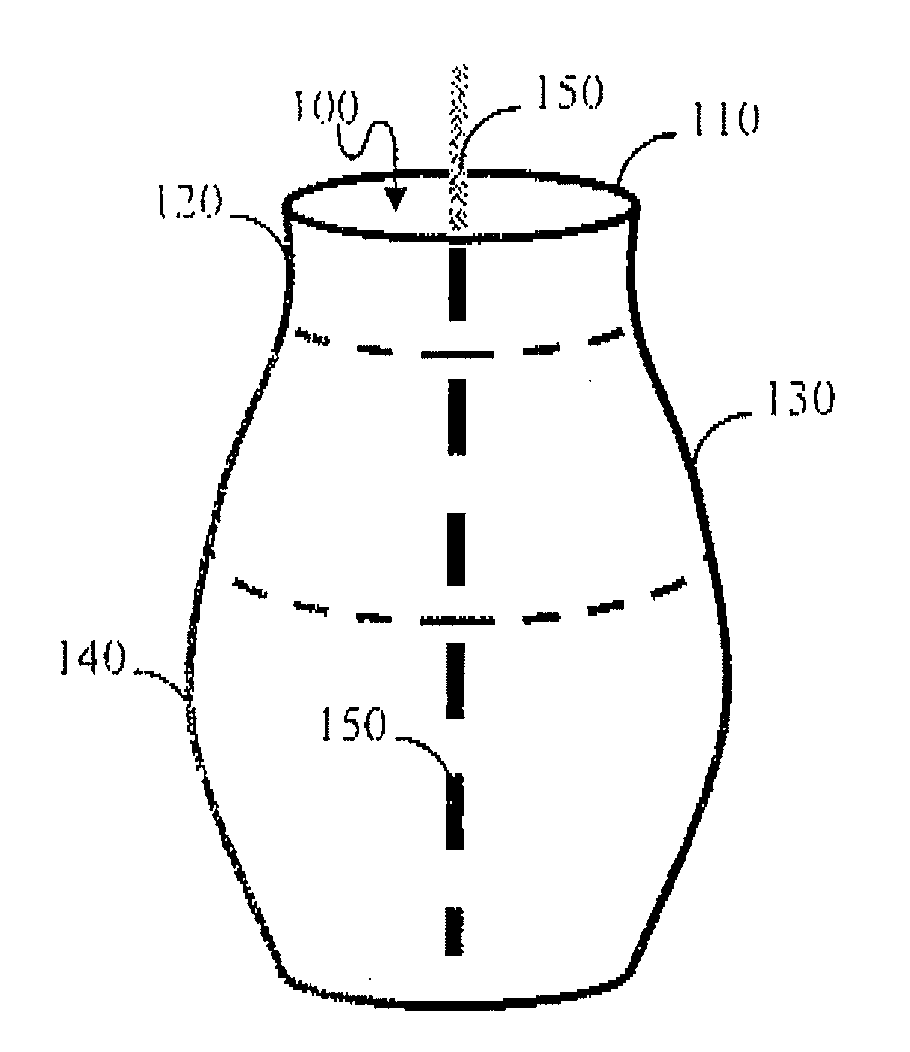

Modular wick holder and holder assemblies thereof

A modular wick holder comprises two holder assemblies and at least one adjusting member. Each holder assembly comprises a first side plate and a second side plate, one end, far from the second side plate, of the first side plate is provided with a first connecting portion, and one end, far from the first side plate, of the second side plate is provided with a second connecting portion. The second connecting portion of one holder assembly is connected to the first connecting portion of the other holder assembly. Each holder assembly also comprises a clamping plate, the clamping includes a clamping portion, a clamping space is formed between the two clamping portions, and the adjusting member is positioned between the two clamping plates. The speed of wick absorbing fuel is controlled by adjusting the size of the clamping space by means of the adjusting member, further flame burning scale is controlled, and excess temperature of a fuel groove is prevented. The holder assemblies are modularly produced, thereby effectively reducing cost.

Owner:PRO IRODA INDS

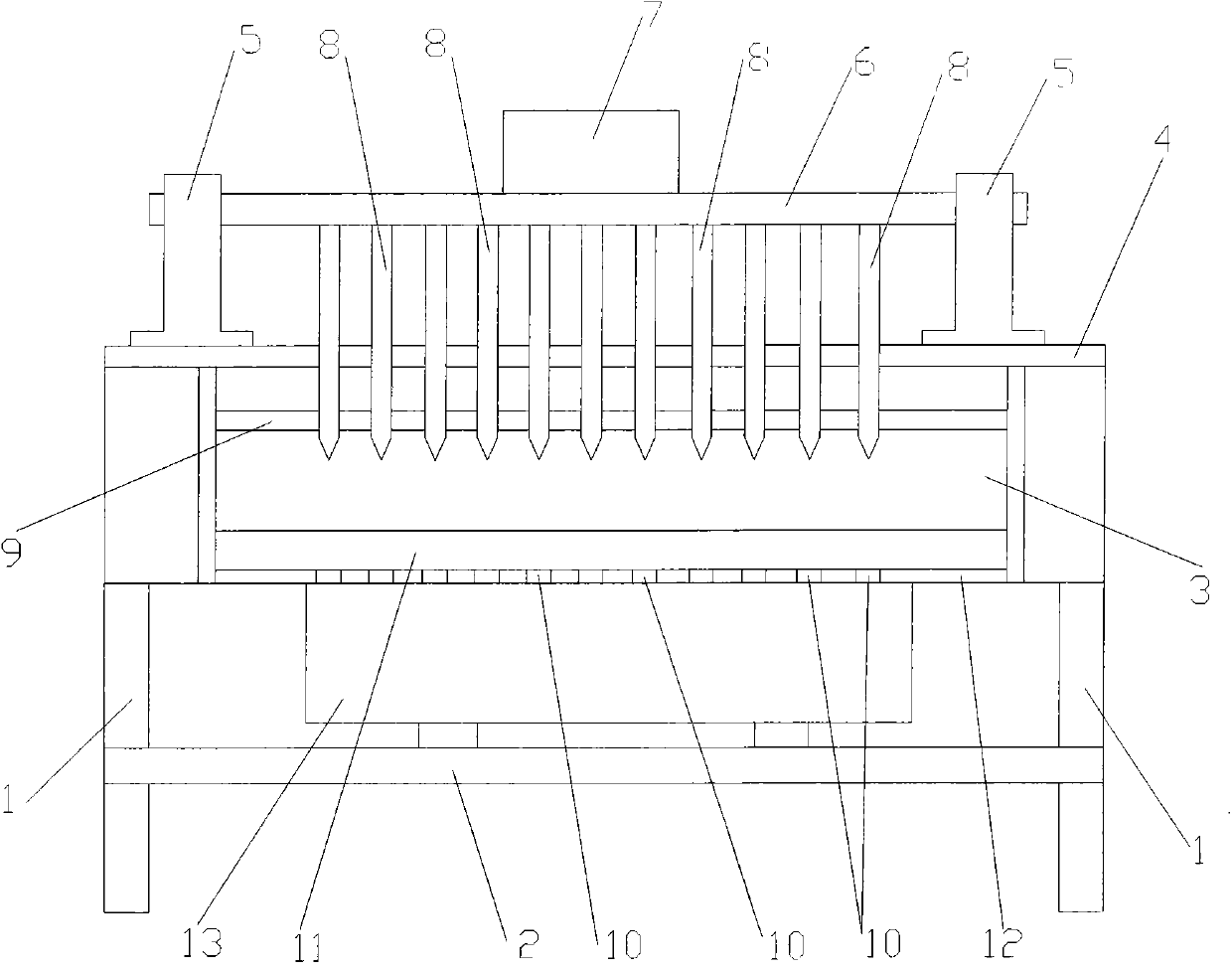

Automatic candle separating device

ActiveCN104191447AReduce manufacturing costIncrease productivityCandle preparation apparatusMetal working apparatusCandleEngineering

The invention relates to an automatic candle separating device which comprises a support, a candle groove and an automatic candle separator. The candle groove is formed in the support, a formed candle is placed in the candle groove, the upper end of the candle groove is provided with a first supporting plate, the automatic candle separator comprises guide columns, a supporting frame, a motor and a cutting device, the guide columns are arranged at the two ends of the first supporting plate respectively, the supporting frame is arranged on the guide columns in a sleeved mode, the motor is arranged on the supporting frame, the supporting plate moves up and down along the guide columns under the drive of the motor, the cutting device is arranged on the lower surface of the supporting plate, the cutting device penetrates through the first supporting plate to extend downwards, the upper portion of the candle groove is provided with a positioning plate, the positioning plate is uniformly provided with a plurality of positioning holes, the bottom of the candle groove is provided with a second supporting plate, the second supporting plate is uniformly provided with a plurality of through holes, and a waste collecting box is arranged below the second supporting plate. The automatic candle separating device has the advantages of being safe, reliable, high in automation degree and capable of recycling waste.

Owner:扬州好多树智能科技有限公司

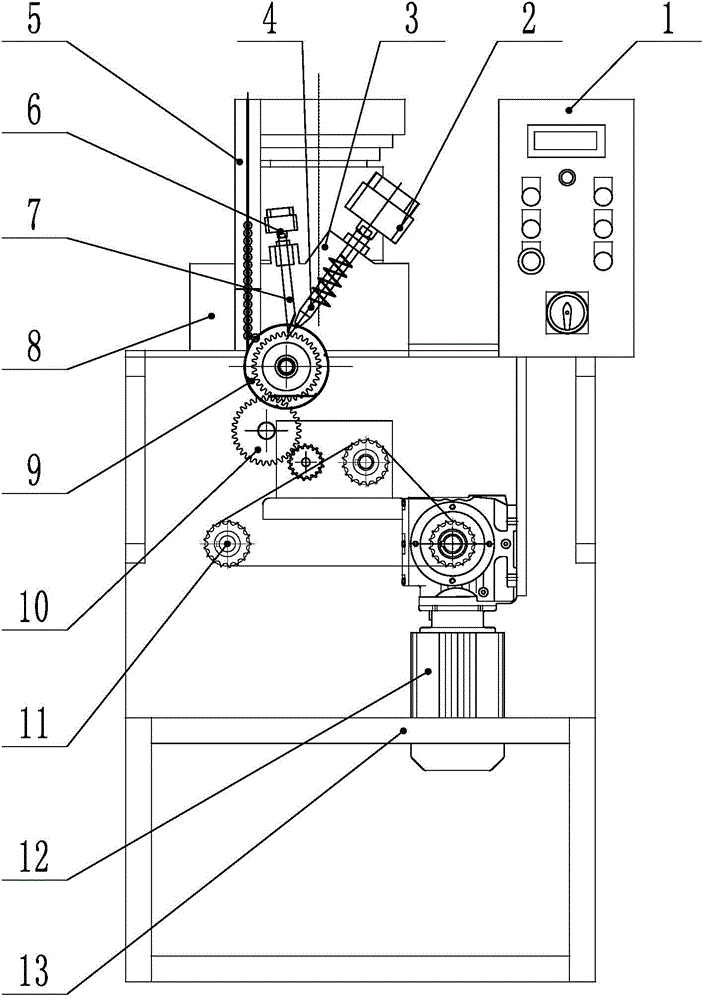

Processing device of plastic wax-core holder

The invention discloses a processing device of a plastic wax-core holder. The processing device comprises a wax-nail feeding device, a wax-nail intermittent feeding device, a wax-core feeding mechanism, a wax-nail punching mechanism, and an electronic control cabinet for controlling the devices and mechanisms mentioned above. The wax-nail intermittent feeding device utilizes a precise cam cutter to achieve intermittent feeding. The intermittent transmission characteristic of the precise cam cutter can determine the intermittent positions of the wax-nail intermittent feeding device. Then the wax-core feeding mechanism, the wax-nail punching mechanism, and a wax-core cutting mechanism are controlled to achieve wax-nail plastic deformation to fix the wax cores in a wax-nail central round pipe so as to form a finished wax-core holder. The whole device (wax-core intermittent feeding device, wax-core feeding mechanism, and wax-nail punching mechanism) can achieve the integral processing of wax-core holder, can process iron wax-core holder and plastic wax-core holder, and has a high efficiency and multiple functions. Furthermore, the device can be matched and co-used with a container candle production line to achieve automatic production.

Owner:DALIAN TALENT GIFT CO LTD

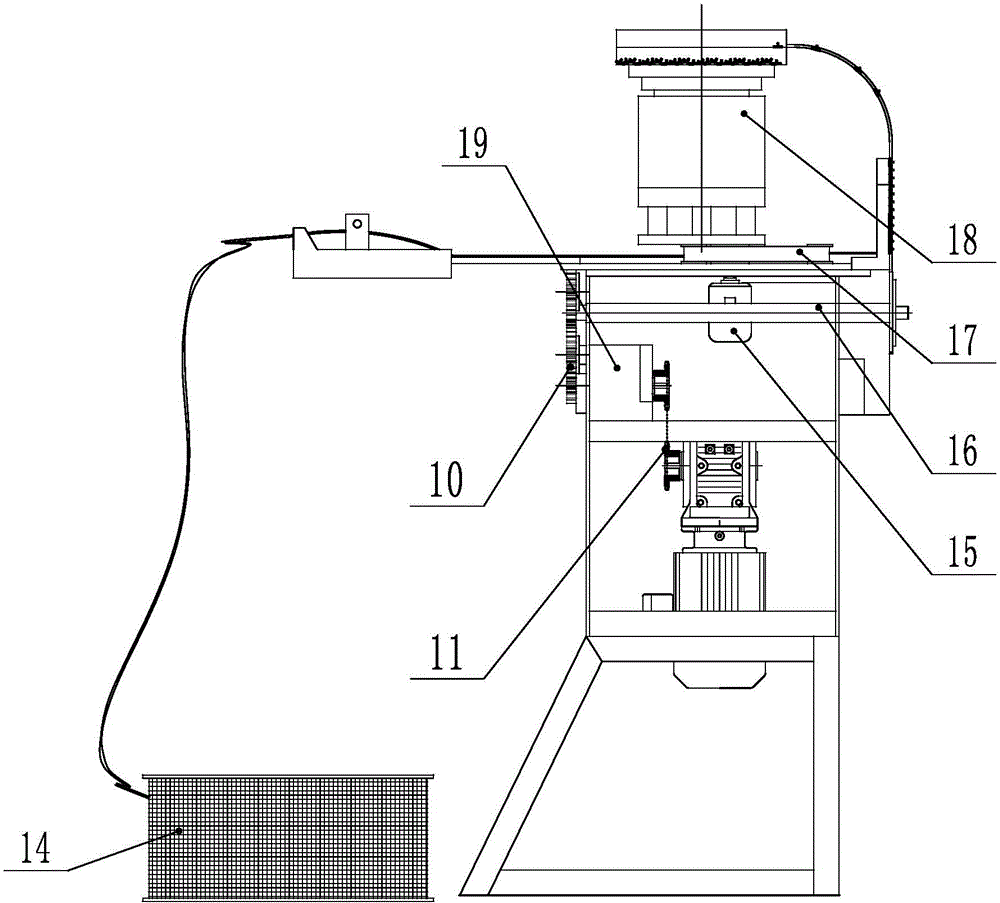

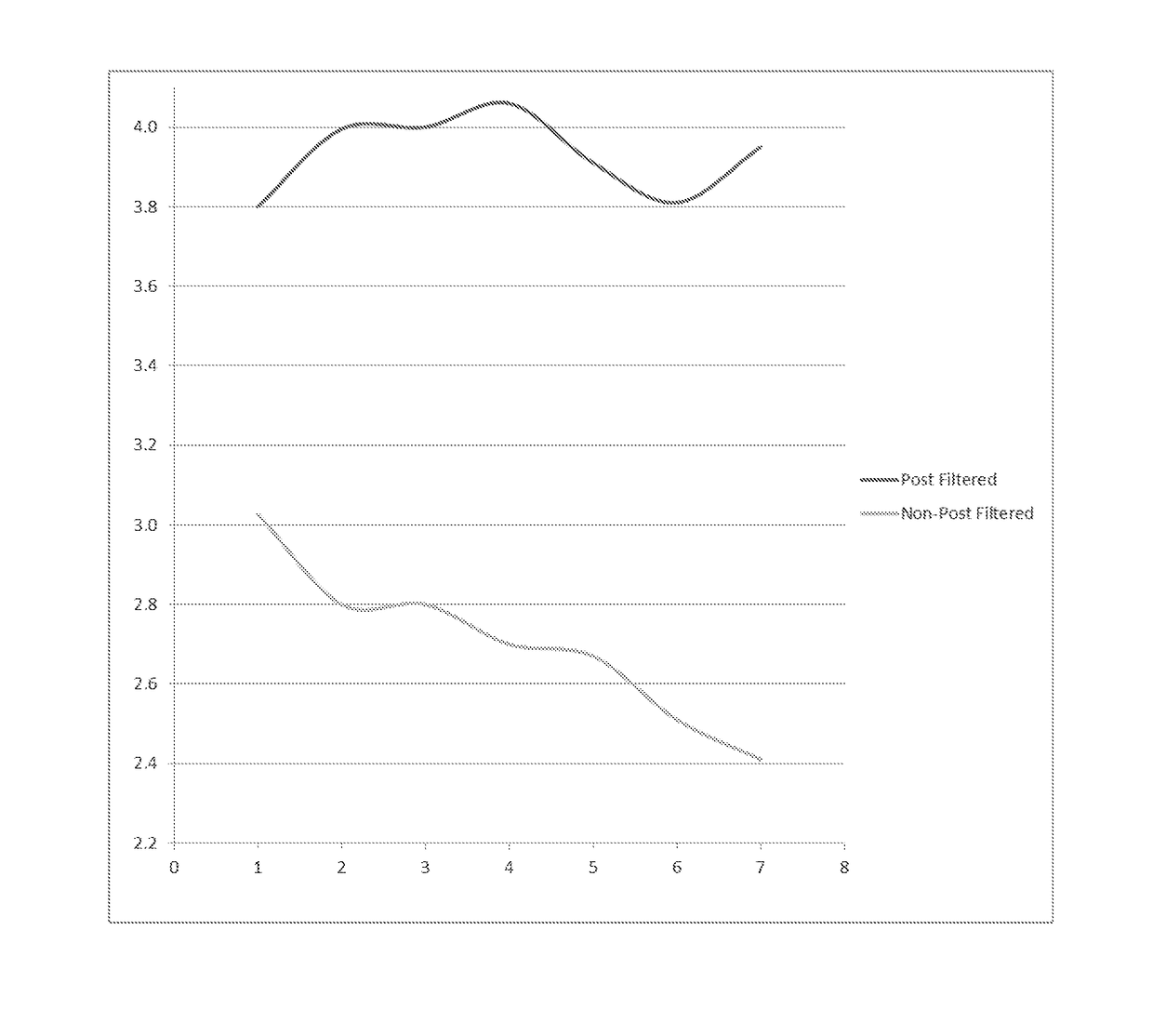

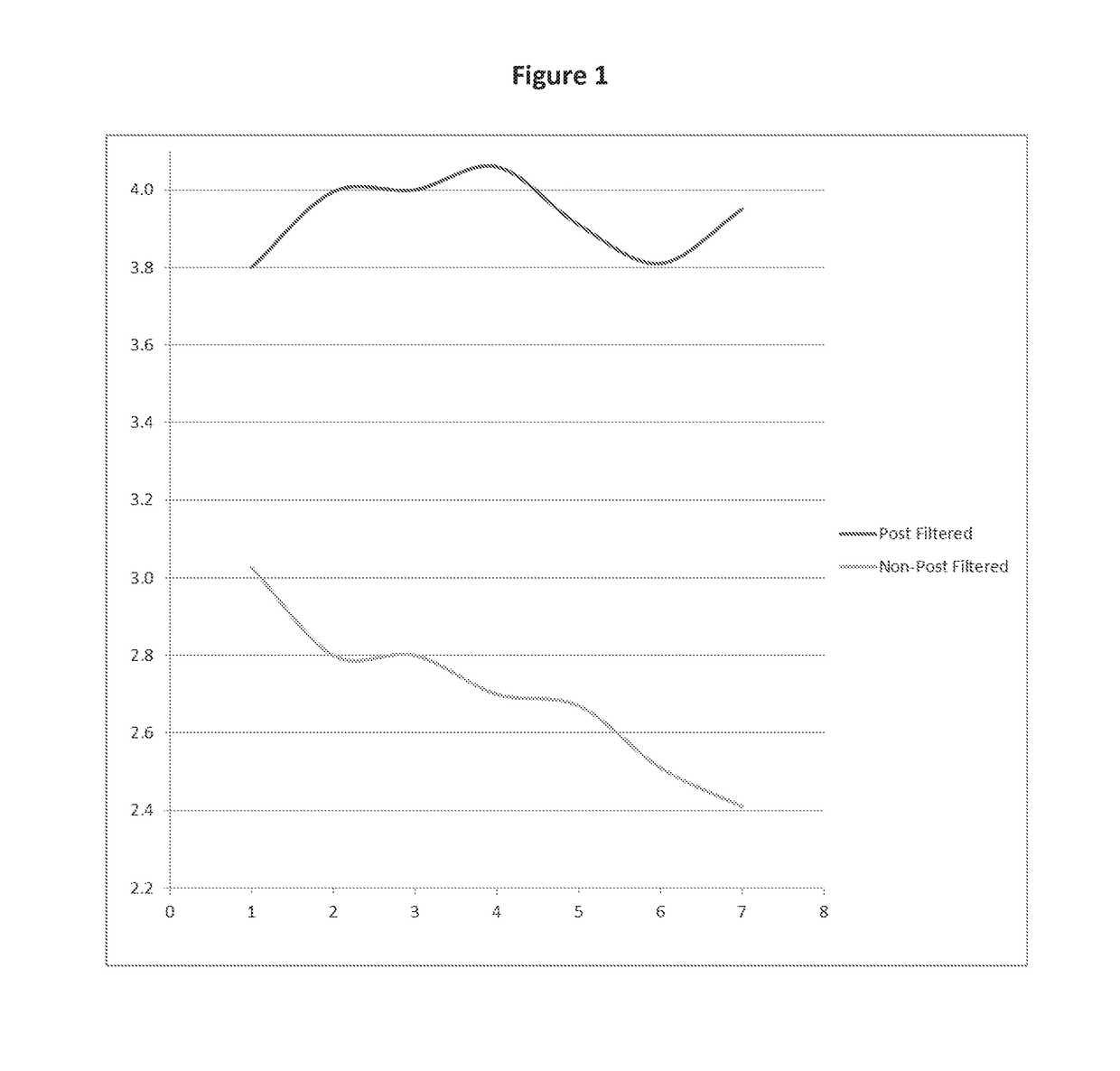

Wax compositions and the effect of metals on burn rates

A wax composition is disclosed, comprising a hydrogenate natural oil with (i) at least about 50 wt % of a triacylglycerol component having a fatty acid composition from about 14 to about 25 wt % C16:0 fatty acid, about 45 to about 60 wt % C18:1 fatty acid and about 20 to about 30 wt % C18:0 fatty acid, (ii) a nickel content of less than 1 ppm, and (iii) a melt point of about 49° C. to about 57° C. The hydrogenated natural oil is filtered and / or bleached to obtain a nickel content of less than 0.5 ppm. A candle is also disclosed, comprising a wick and the above described wax.

Owner:CARGILL INC

Production method of foamed candle

The invention relates to a production method of a foamed candle. The method is characterized by comprising the technological steps of: (1) melting paraffin so as to obtain a paraffin liquid at a temperature of 75-85DEG C, and filling the paraffin liquid into a foaming machine; (2) initiating a cooling water pump and the foaming machine which is maintained at a low speed running state, thus obtaining a paraffin liquid at a temperature of 65-75DEG C; (3) cooling the paraffin liquid to a temperature of 57-59DEG C; and initiating the foaming machine to run at a high speed, thus obtaining a foamed paraffin liquid; (4) injecting the foamed paraffin liquid obtained in step (3) into a die or container, the center of which is inserted with a cotton wick, cooling the foamed paraffin liquid for 12-15min so as to obtain a solid candle; covering the solid candle with a layer of paraffin liquid at a temperature of 75-85DEG C and with thickness of 1-2mm, and flattening the surface of the paraffin liquid; continuing to conducting cooling for 12-15min, then carrying out demoulding, thus obtaining the foamed candle. The method of the invention adopts mechanical foaming which is easy to operate and has no need for other substances as boosting agents.

Owner:无锡市灵山香烛工艺制品有限公司

Massage oil wax and preparation method thereof

InactiveCN103816060APromote absorptionCan't play a roleCosmetic preparationsToilet preparationsAdditive ingredientSkin care

The invention discloses massage oil wax and a preparation method thereof. The massage oil wax is prepared from the following raw materials in parts by weight: 10-40 parts of soybean oil, 20-80 parts of coconut oil, 5-10 parts of vitamin E, 10-20 parts of sweet almond oil, 10-30 parts of shea butter, 10-30 parts of sunflower seed oil, 30-60 parts of grape seed oil and 5-10 parts of pheromone. The invention provides the massage oil wax and the preparation method thereof. The massage oil wax can be used for illumination and can be directly used on the surface of skin in a massage manner; the oil wax employs different material formulae to achieve the purpose of reinforcing absorption of a human body to beneficial ingredients in the wax, and achieves a skin care effect; since the pheromone is added, the attraction between opposites is increased; the life interest is raised.

Owner:青岛兰兰生物科技有限公司

Method for preparing candle

InactiveCN101768520AReduce energy consumptionIncrease productivityCandle preparation apparatusHydrocarbon mixturesCandle

The invention discloses a method for preparing a candle, which comprises the following steps: mixing a saturated hydrocarbon mixture, additives, pigment and essence according to the formula, and heating to 60-70 DEG C to soften the raw materials for 1.5 hours; pressing the softened raw materials into a mold of 25-35 DEG C by applying a pressure of 5 MPa, demolding after 0.5-1 hour, and cooling to form, thereby obtaining the product. The candle comprises the following components in percentage by mass: 2-3% of additive, 0.2-1% of pigment, 2-3% of essence and balance of saturated hydrocarbon mixture. The candle has the characteristics of low energy consumption, high production efficiency and wide adaptability.

Owner:QINGDAO KINGKING APPL CHEM CO LTD

Wax producing device and wax producing process

The invention discloses a wax producing device, which comprises a machine body and wax plates, wherein the machine body has a plurality of wax accommodating holes; wax ejecting plates are arranged in the wax accommodating holes; a turntable is arranged on one side of the machine body and are connected with the wax ejecting plates by screw devices; the top of the machine body is provided with a positioning wax plate; the wax plate comprises a movable wax plate which is positioned above the positioning wax plate, and a tool is arranged between the wax plate and the positioning wax plate; the positioning wax plate and the movable wax plate have a plurality of positioning wax plate holes and movable plate holes, which correspond to wax accommodating holes, respectively; plastic rubber rings are arranged in the positioning wax plate holes and the movable wax plate holes respectively; one end of the wax plate is provided with a rocker; and the rocker is connected with the movable wax plate by threads. The invention also discloses a candle manufacturing process, which improves wax production efficiency, saves labor force and reduces production cost.

Owner:周山

Candle forming mold

The invention relates to a candle forming mold, and belongs to a candle processing device. The candle forming mold provided by the invention is characterized in that a thermal conductive layer sleeves a candle forming groove; the forming groove sleeved by the thermal conductive layer is disposed in a water cooling chamber; the bottom of the candle forming groove is provided with a concave slot; the outer wall of the forming groove is higher than the thermal conductive layer; and the top side wall of the forming groove is fixedly provided with clamping arms. The mold is provided with a cooling layer, so that liquid wax can be cooled rapidly after being injected into the mold, thereby reducing work forming time and increasing yield.

Owner:DALIAN LONSIN NEW MATERIALS

Transparent, elastic and free-standing composition, such as for the manufacture of candles, and the free-standing candle obtained with the composition

A composition includes a mixture of a hydrocarbon oil in a relation of about 75 to 88 in weight percent and at least one copolymer selected from the group of triblock and diblock polymers in a proportion from about 12 to 25 in weight percent, the hydrocarbon oil having a viscosity of at least 180 SUS@ at 37° C. (100° F.) and, when the viscosity is in CST@, the viscosity being greater than 32 CST@ at 40° C. (104° F.), and the flash point being greater than 220° C. (425° F.). Also a free standing candle is made with the composition, the candle maintaining a free standing condition even when lit by means of a flame produced as a consequence of the combustion of a wick that crosses the body of the candle projecting toward outside one of its ends.

Owner:GUTBEZAHL GABRIEL SERGIO

Moulding process

ActiveUS20180085972A1Low costShorten the timeAdditive manufacturing apparatusFrozen sweetsEngineering3 dimensional printing

Owner:PIXSWEET BV

Polymerized wax candles

InactiveUS20060010766A1High fragrance loadingCost-effective materialCandle preparation apparatusSolid fuelsWaxPolymer science

A candle made with a wax base and a synthetic thermoplastic rubber copolymer. The wax base may be prepared from a plurality of two or more different fuel sources including petroleum sources, animal sources, vegetable sources, synthetic sources and blends thereof. The synthetic thermoplastic rubber copolymer may be a diblock, triblock, radial block, multiblock copolymers, and blends thereof. In addition to the wax base and the synthetic thermoplastic rubber copolymer, candles made according to the invention can also include stabilizers, fragrances, dyes as well as other standard candle additives. The addition of the synthetic thermoplastic rubber copolymer allows for the production of high quality candles with improved shipping stability, controllable burn rates, less dripping and higher fragrance loading capabilities. Additionally, disclosed candles decrease processing times and percent defects as part of an improved manufacturing process.

Owner:BLYTH INC

Polymerized wax candles

InactiveUS20030148239A1Reduce processing timeReduce percent defectCandle preparation apparatusCandle ingredientsWaxPolymer science

A candle made with a wax base and a synthetic thermoplastic rubber copolymer. The wax base may be prepared from a variety of sources including petroleum sources, animal sources, vegetable sources, synthetic sources, and blends thereof. The synthetic thermoplastic rubber copolymer may be a diblock, triblock, radial block, multiblock copolymers, and blends thereof. In addition to the wax base and the synthetic thermoplastic rubber copolymer, candles made according to the invention can also include stabilizers, fragrances, dyes as well as other standard candle additives. Moreover, candles produced according to the invention have several cost saving advantages. The addition of the synthetic thermoplastic rubber copolymer allows for the production of high quality candles while utilizing less expensive wax bases. Additionally, disclosed candles decrease processing times and percent defects.

Owner:SZCZERBA MARGARET +2

Therapeutic Skin Treatment Composition and Method

A method of using a novel candle apparatus at least includes: candle housing; candle fuel deposited in the candle housing, the candle fuel at least including non-toxic solidified therapeutic skin substance; and a candle fuel liquefier; wherein the candle fuel is adapted to, upon application of the fuel liquefier, liquefy into a therapeutic substance adapted for human skin. In one refinement, the therapeutic skin substance is massage oil. In another refinement, the therapeutic skin substance is a soap agent for cleansing skin, and the like. A therapeutic skin treatment method at least includes: a) providing a candle that at least includes, candle housing, candle fuel deposited in the candle housing, the candle fuel at least including non-toxic solidified therapeutic oil, and a candle fuel liquefier; b) liquefying the candle fuel into therapeutic oil for human skin; and c) applying to the skin, therapeutic oil produced in element b).

Owner:YINGST SHARON K

Automatic candle carving equipment

InactiveCN105904295AReduce labor intensityNovel structureRevolution surface grinding machinesCandle preparation apparatusAgricultural engineeringCandle

The invention discloses automatic candle carving equipment. The automatic candle carving equipment comprises a main frame; a lower end panel of the main frame is mounted on the ground; a motor is mounted on the inner side of a right panel of the main frame, and is connected with a small belt wheel through a key; the small belt wheel is connected with a belt; the left side of the belt is connected with a large belt wheel; the large belt wheel is connected with a rotating shaft through a key; the rotating shaft is slidingly connected with a middle panel of the main frame; a guide plate is mounted above the middle panel of the main frame; a lower clamping plate is mounted above the rotating shaft; a candle is connected to the upper portion of the lower clamping plate; an upper clamping plate is connected to the upper portion of the candle; and a clamping cylinder is mounted on the upper end surface of the upper clamping plate, and is mounted in the center of a center wheel. The automatic candle carving equipment is novel in structure, scientific in design, simple in structure, convenient for installation and low in cost, can replace cutter teeth, needs no manual polishing, reduces the labor intensity of users, improves the working efficiency, and is high in automation degree.

Owner:重庆市荣昌区鸿强工艺蜡烛厂

A kind of colored flame candle with various shapes and its preparation method

InactiveCN102268330AReduce manufacturing costSimple production processCandle preparation apparatusParaffin waxPolymer science

The invention discloses a colored flame candle with various shapes and a preparation method thereof. The colored flame candle is composed of a candle wick and a candle body. The candle wick is obtained by soaking a absorbent cotton thread in the candle wick soaking solution of the present invention and then dried naturally in the shade. The composite main combustion agent is obtained by Calculated by weight percentage, including 88-98% trimethyl citrate, 0.5-5% organic alcohol, 0.5-3% paraffin or beeswax, 1-5% stearic acid amide and 0.5-5% trioxygen Heterocycloethanes. The colored flame candle of the present invention has low cost of raw materials for the candle body and only one candle wick, so the production cost is low and the production process is simple and convenient. And the candle wick serves as both a burning agent and a coloring agent, and burns synchronously with the candle body whose shape and area change greatly, so that it can be made into a colored flame candle of arts and crafts with various shapes and large area change.

Owner:许国军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com