Processing device of plastic wax-core holder

A processing device and wax core technology, which is applied in the field of plastic wax core holder processing devices, can solve problems such as unstable operation, high processing cost of wax core holders, and high scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

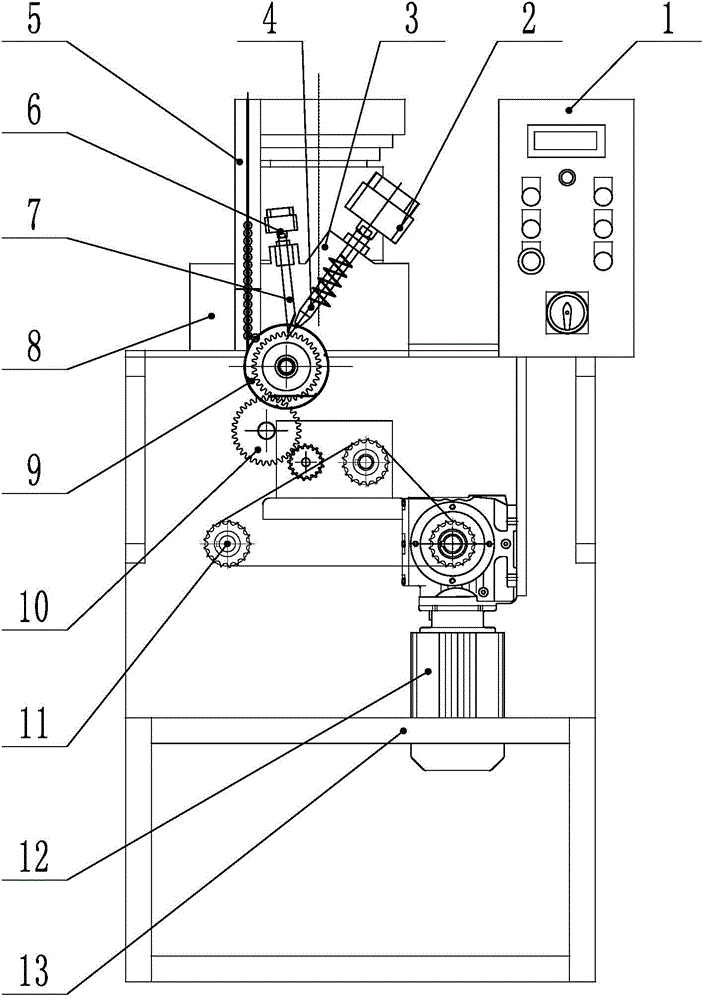

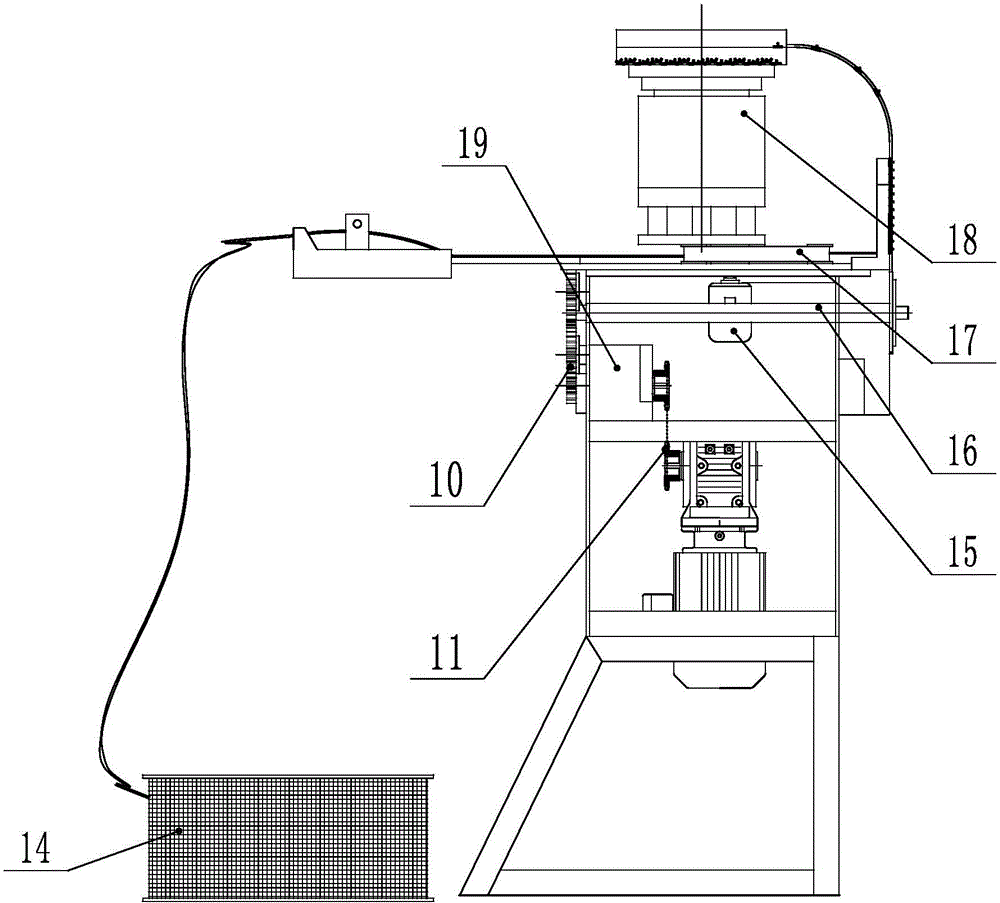

[0040] Such as figure 1 and figure 2 A plastic wax core holder processing device shown in the figure includes: wax nail feeding device, wax nail intermittent feeding device, wax core feeding mechanism, wax nail stamping mechanism and an electric control cabinet for controlling the above-mentioned mechanisms and devices. 20 (internal programmable logic controller (PLC));

[0041] Wax nail intermittent feeding device includes: support frame 13, motor 12 fixed on support frame 13, precision cam divider 19 and intermittent nail feeding disc 9 fixed on support frame 13;

[0042] The power is transmitted between the input shaft of the precision cam divider 19 and the motor 12 through the sprocket mechanism 11, and the power is transmitted between the output shaft of the precision cam divider 19 and the intermittent nail feeding disc 9 through the gear mechanism 10;

[0043]There are station grooves for embedding and positioning of wax nails evenly distributed on the outer edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com