Snowflake candle with alpha-olefin polymer and preparation method thereof

An olefin polymer and snowflake technology, which is applied in candle preparation equipment, candles, fatty acid production, etc., can solve the problems of serious oil leakage, affecting the appearance and use effect of wax-based materials, and small candle snowflakes, so as to control oil leakage and cost The effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

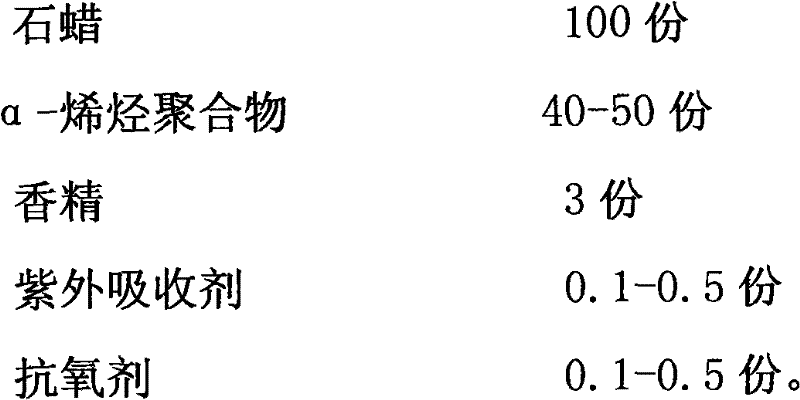

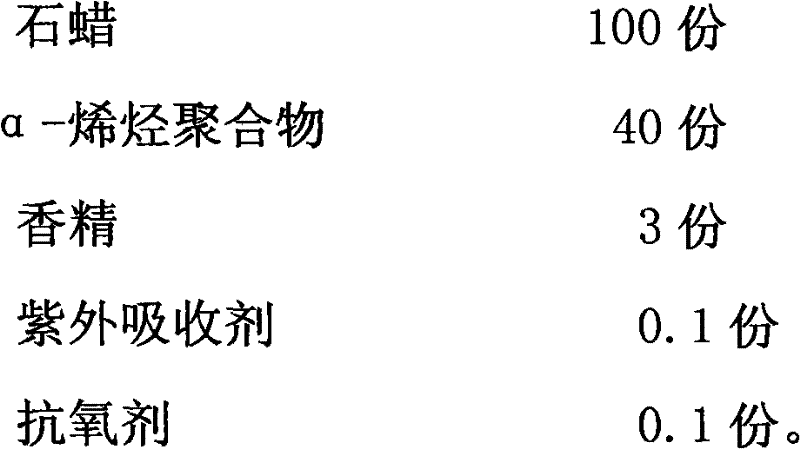

[0017]

[0018] The α-olefin polymer is α-polyethylene, and its number average molecular weight is 4000-5000; the essence is vanilla essence and lavender essence, and the weight ratio of the two is 5:5; the ultraviolet absorber is ultraviolet Absorber UV2908, the antioxidant is antioxidant VYBAR103.

[0019] Mix the above-mentioned paraffin wax, α-olefin polymer, essence, ultraviolet absorber and antioxidant evenly, and then melt at 90°C; then cool the melt at 10°C to form snowflake candle A1.

Embodiment 2

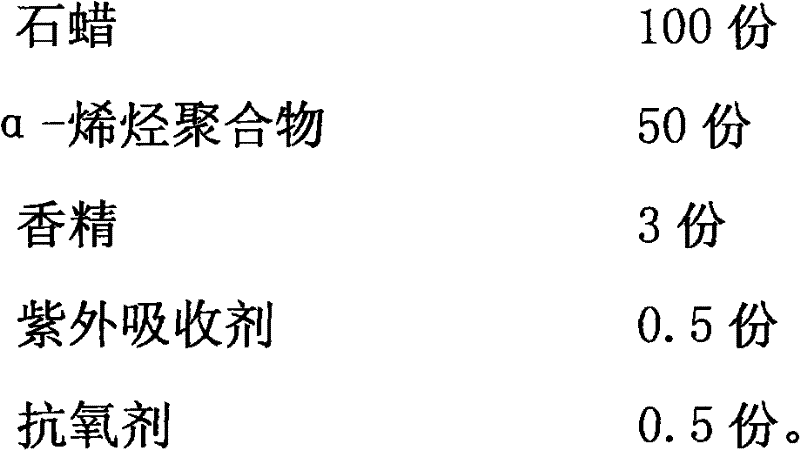

[0021]

[0022] The α-olefin polymer is α-polyethylene, and its number average molecular weight is 5000-6000; the essence is rose essence, and the ultraviolet absorber is ultraviolet absorber UV594 and ultraviolet absorber UV55199, both weight The ratio is 5:5; the antioxidant is antioxidant VYBAR260.

[0023] Mix the above-mentioned paraffin wax, α-olefin polymer, essence, ultraviolet absorber and antioxidant evenly, and then melt at 95°C; then cool the melt at 15°C to form snowflake candle A2.

Embodiment 3

[0025]

[0026]

[0027] The α-olefin polymer is α-polyethylene, and its number average molecular weight is 4000-5000; the essence is strawberry essence, the ultraviolet absorber is ultraviolet absorber CEC376, and the antioxidant is antioxidant Oxygen agent VYBAR343.

[0028] Mix the above-mentioned paraffin wax, α-olefin polymer, essence, ultraviolet absorber and antioxidant evenly, and then melt at 100°C; then cool the melt at 10°C to form snowflake candle A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com