Integrated wax preparing and injecting machine

An all-in-one machine and wax injection technology, applied in casting molding equipment, candle preparation equipment, etc., can solve the problems of wax paste becoming solid, large waste, troublesome operation, etc., and achieve the effect of stable and reliable product quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described now in conjunction with accompanying drawing:

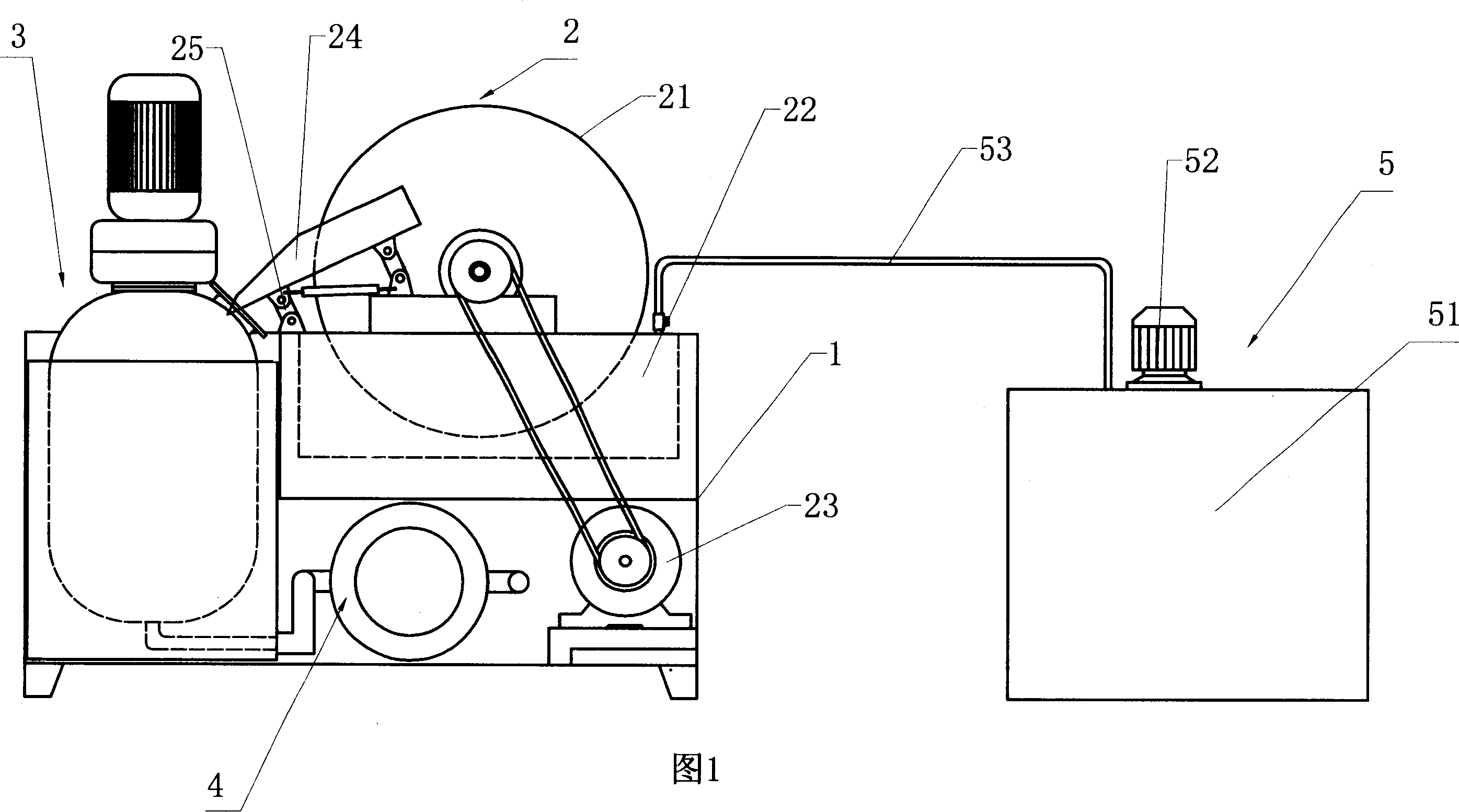

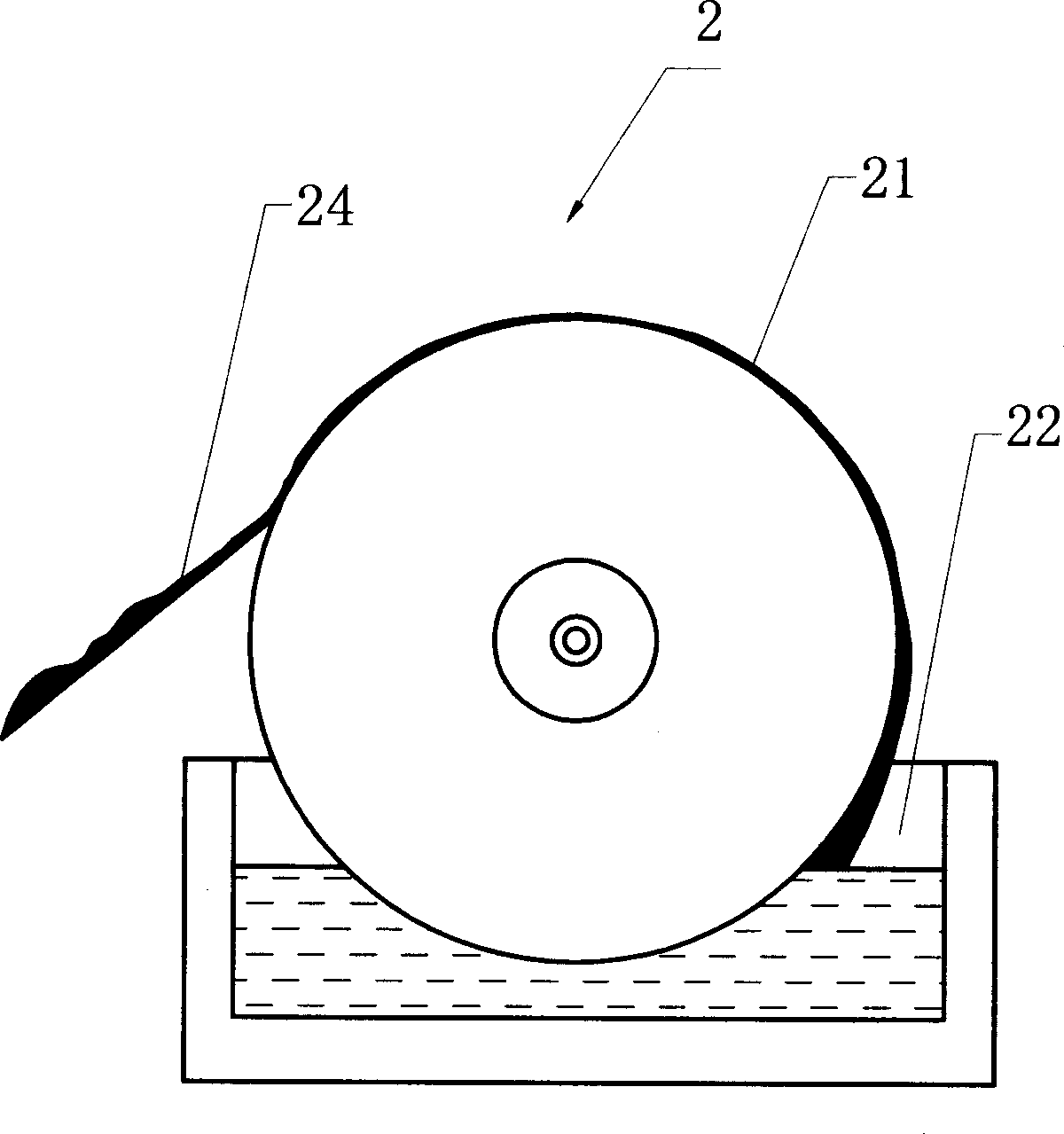

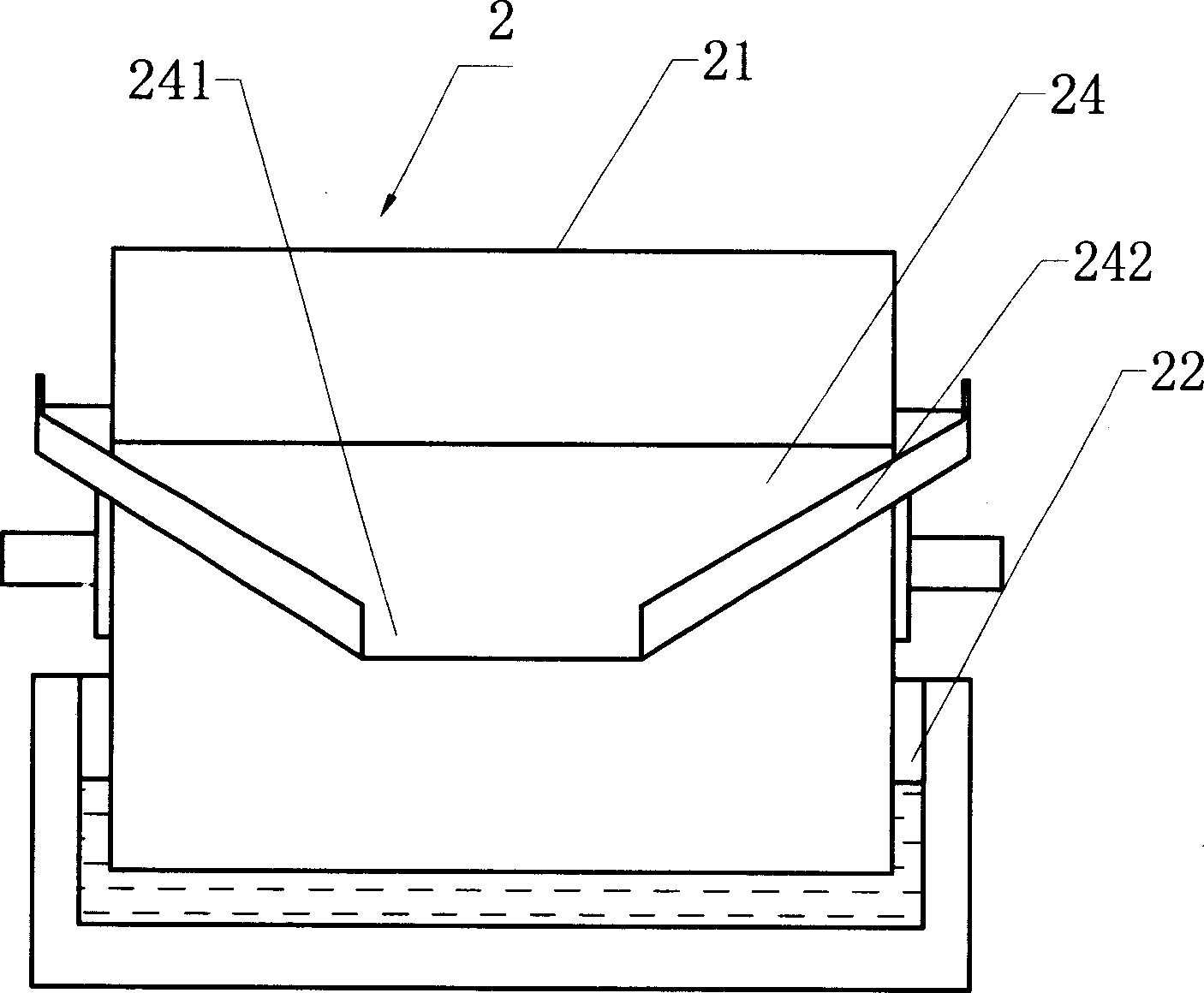

[0024] From Fig. 1 to Fig. 6, it can be known that the present invention is an integrated wax preparation and injection machine, which includes a frame 1, a wax water condensation scraping device 2 and a wax stirring device that are arranged on the frame 1 and connected in sequence. 3 and extruding wax paste device 4, usually also include wax water conveying device 5 (of course also can adopt the method for manually pouring wax water), described wax water conveying device 5 includes wax water pool 51 and pump 52, wax water pool 51 communicates with the wax storage tank 22 of the wax water condensation and scraping device 2 through the pipeline 53, and the wax water is transported to the next process through the pump 52, that is, the wax water condensation and scraping device 2. Obviously, the wax water can also be sent in other ways such as sending Into the wax water condensa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com