Wax producing device and wax producing process

A manufacturing process and candle technology, applied in the direction of candle preparation devices, etc., can solve the problems of low efficiency and high cost, and achieve the effects of reducing production costs, easy operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principle of the present invention will be described through embodiments. Other aspects, features and advantages of the present invention will become clear at a glance through the detailed description.

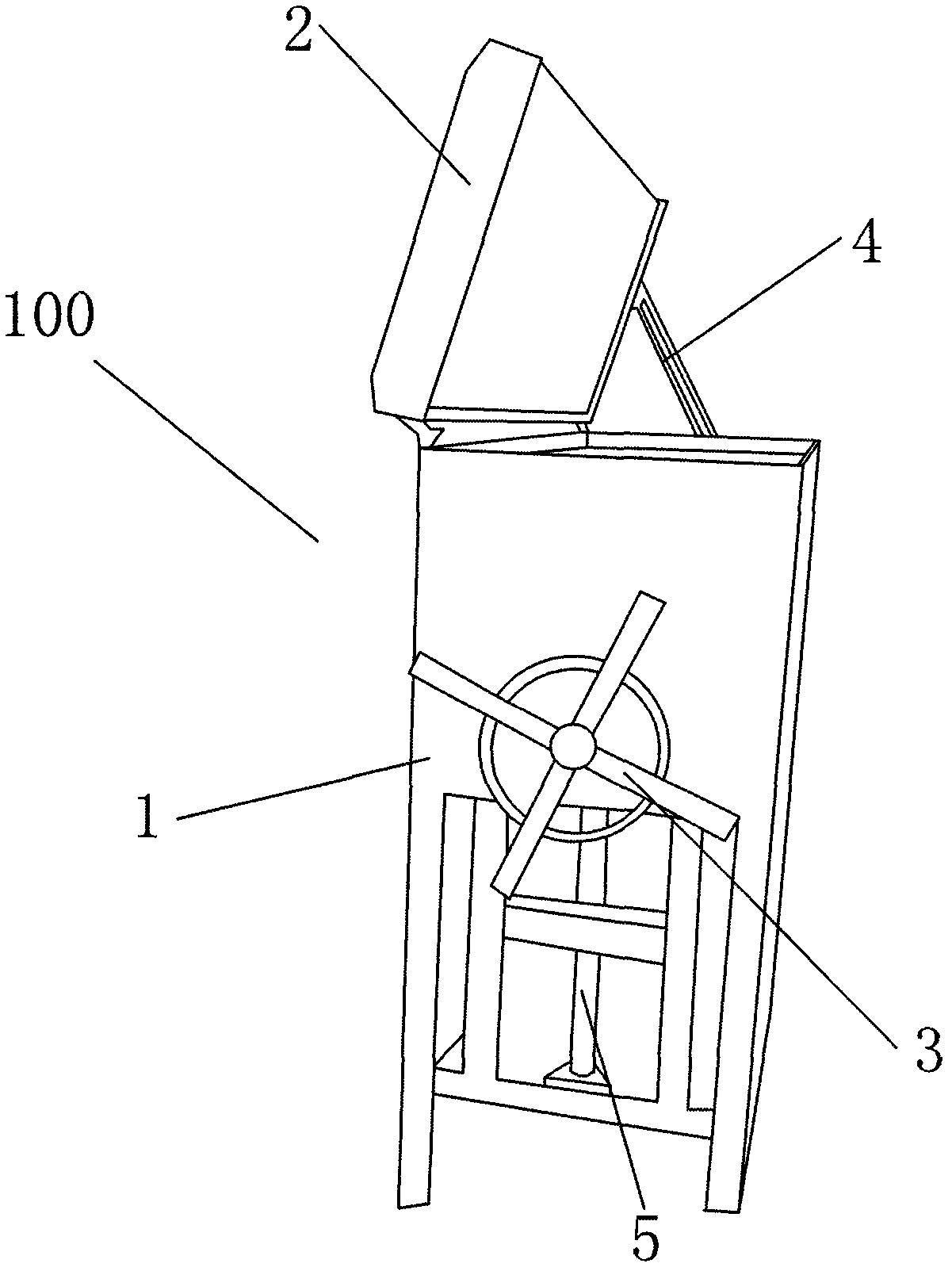

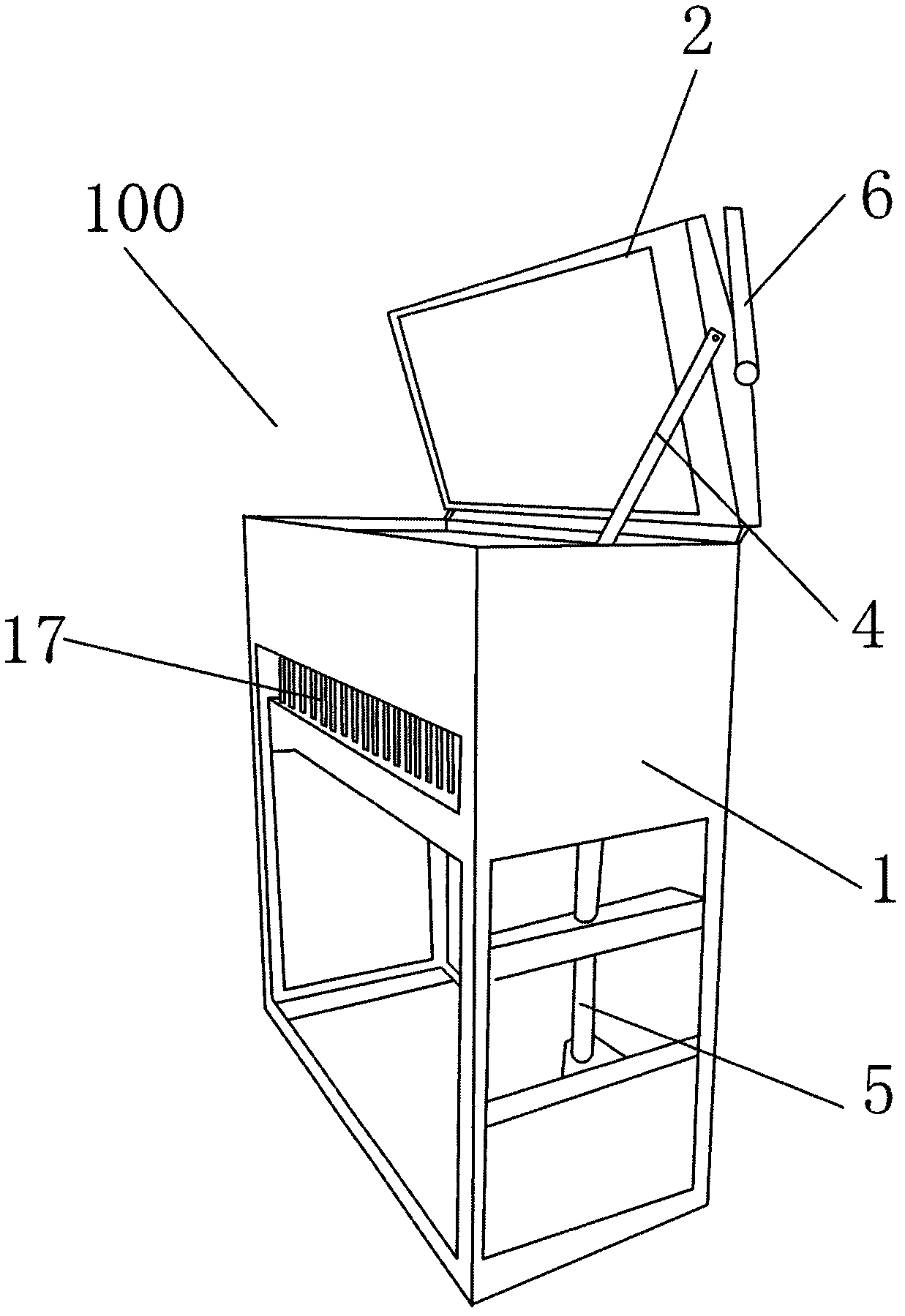

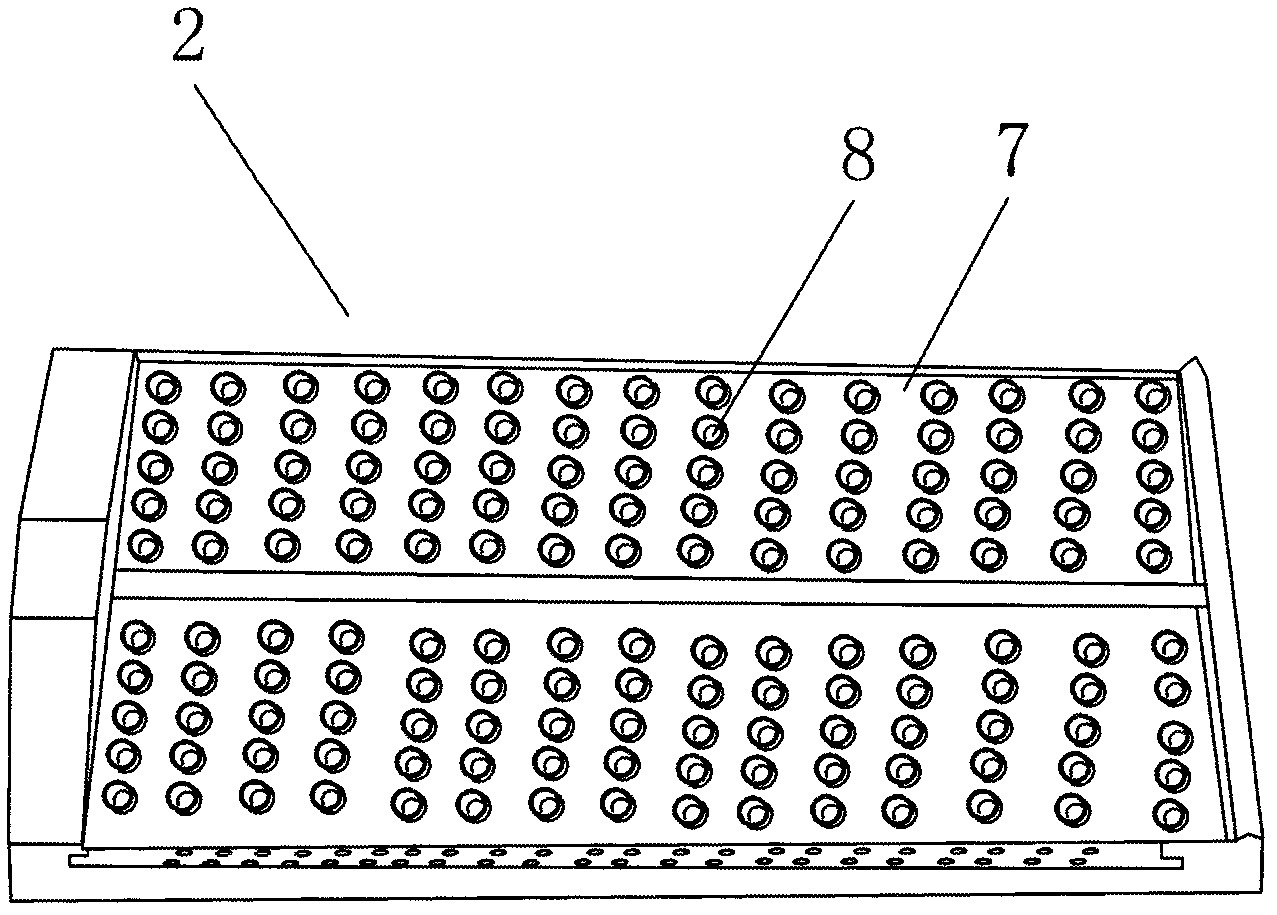

[0023] Such as Figure 1-8 As shown, the present invention provides a wax making device 100, which includes a body 1 and a wax tray 2 movably connected to the top of the body 1, wherein the body 1 is provided with a plurality of wax holding holes 12 ( Figure 5-6 shown), a plurality of said wax-holding holes 12 are provided with wax topping discs 13 for top waxing, one side of said body 1 is provided with a turntable 3, and said turntable 3 and a plurality of wax topping discs 13 are passed through silk The rod devices are connected together, the top of the body 1 is provided with a positioning wax plate 9, and the wax plate 2 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com