Adjustable vibrating mechanism of iron alloy granule-casting machine

A granulator and adjustable technology, applied in the field of adjustable rapping mechanism, can solve the problems of large rapping amplitude, inability to accurately calculate the working force, and high bearing failure rate, and achieve the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

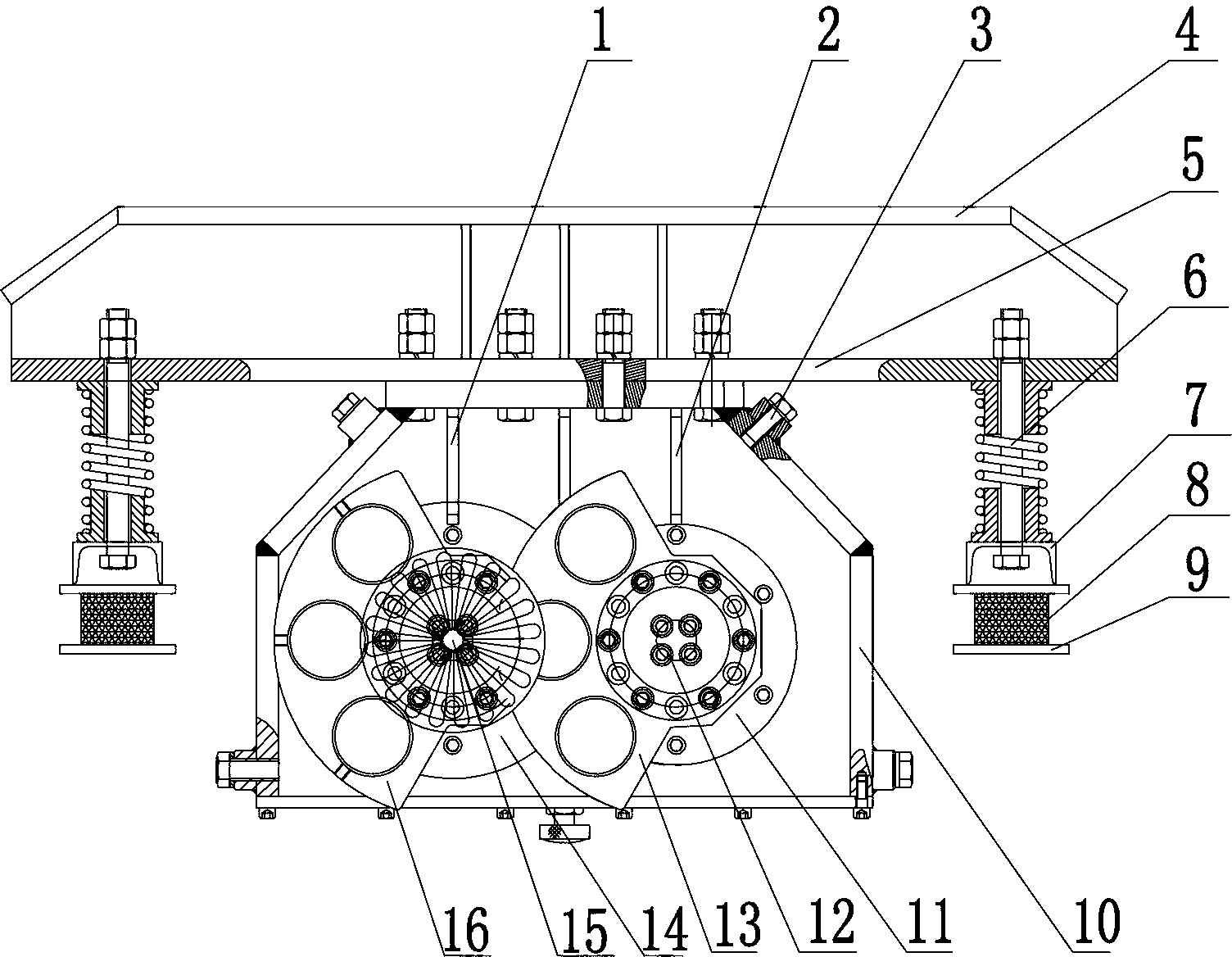

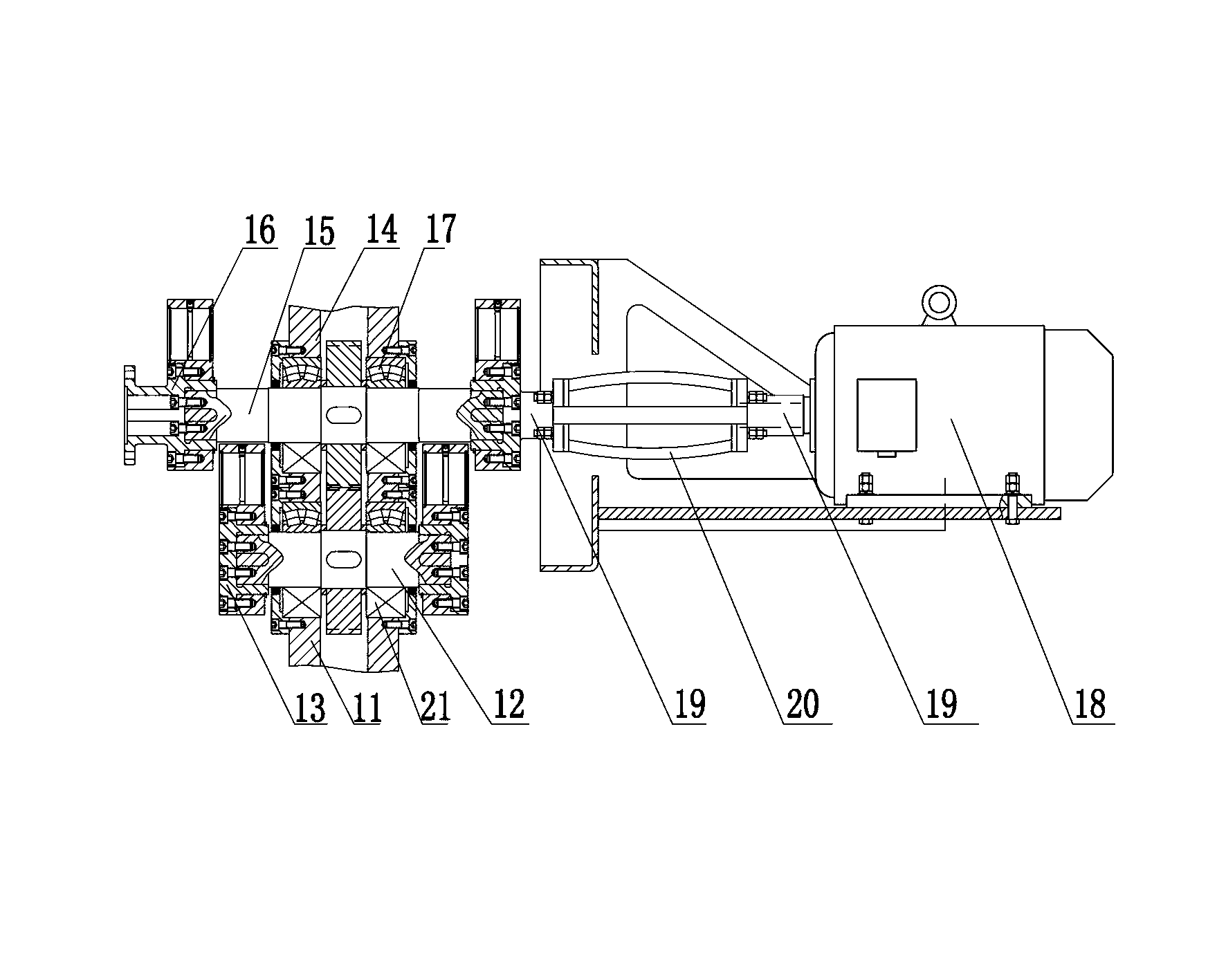

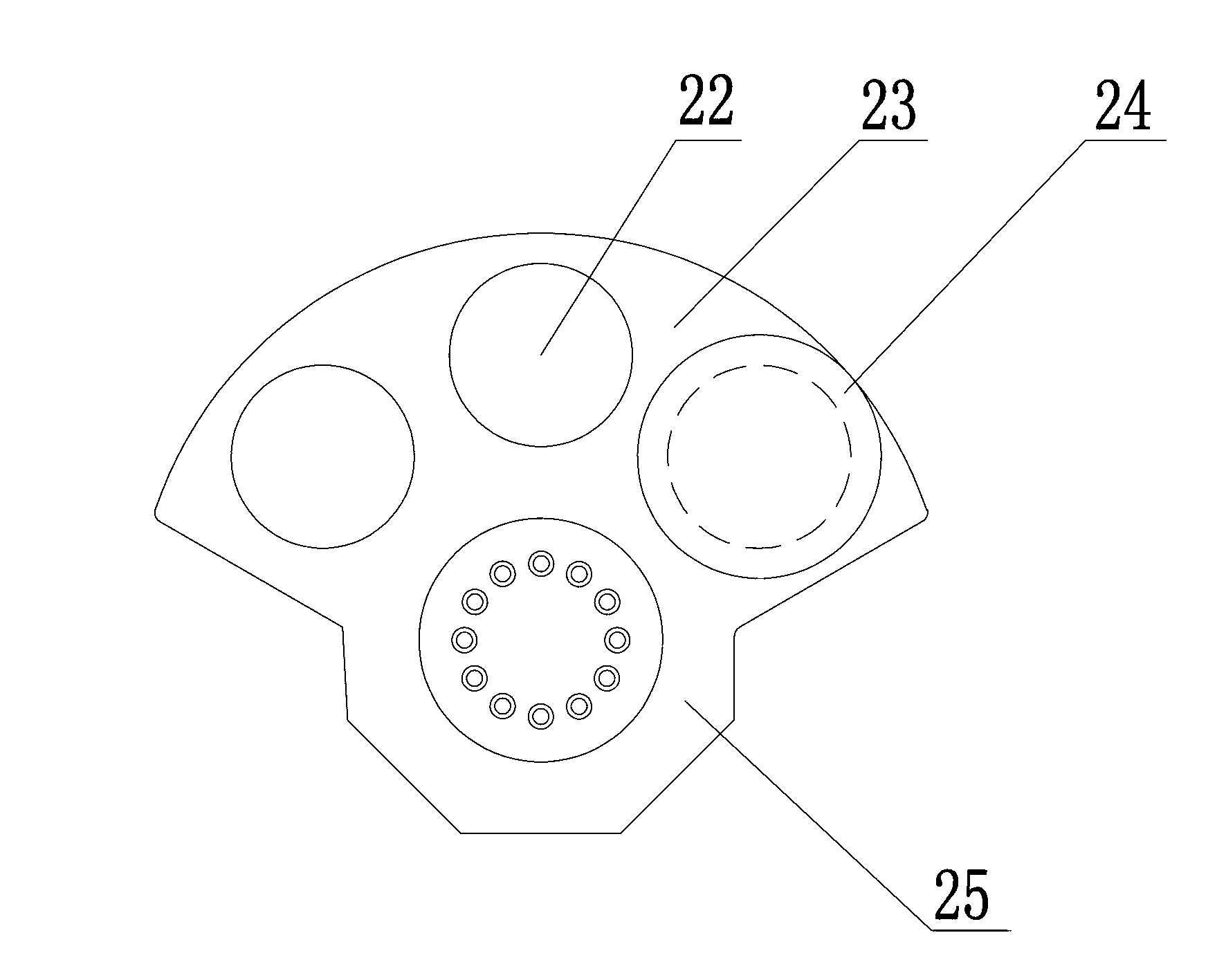

[0020] Such as figure 1 , 2 As shown, the adjustable rapping mechanism of a ferroalloy casting machine of the present invention includes a rapping drive device, a spring bed assembly connected to the rapping drive device and a rapping plate 4 connected to the spring bed assembly , it is characterized in that the described rapping driving device is composed of a driving motor 18 and a rapping device connected with the driving motor 18 through elastic connecting parts, and the described rapping device includes a vibrating box with an oil filling hole 3 10. The bearing assembly I17 and bearing assembly II21 provided in the vibration box 10, the drive gear shaft 15 which is rotatably connected with the bearing assembly I17, and the drive gear 14 provided on the drive gear shaft 15 are provided on the The bias weight I16 at both ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com