Patents

Literature

119results about How to "Stay tight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

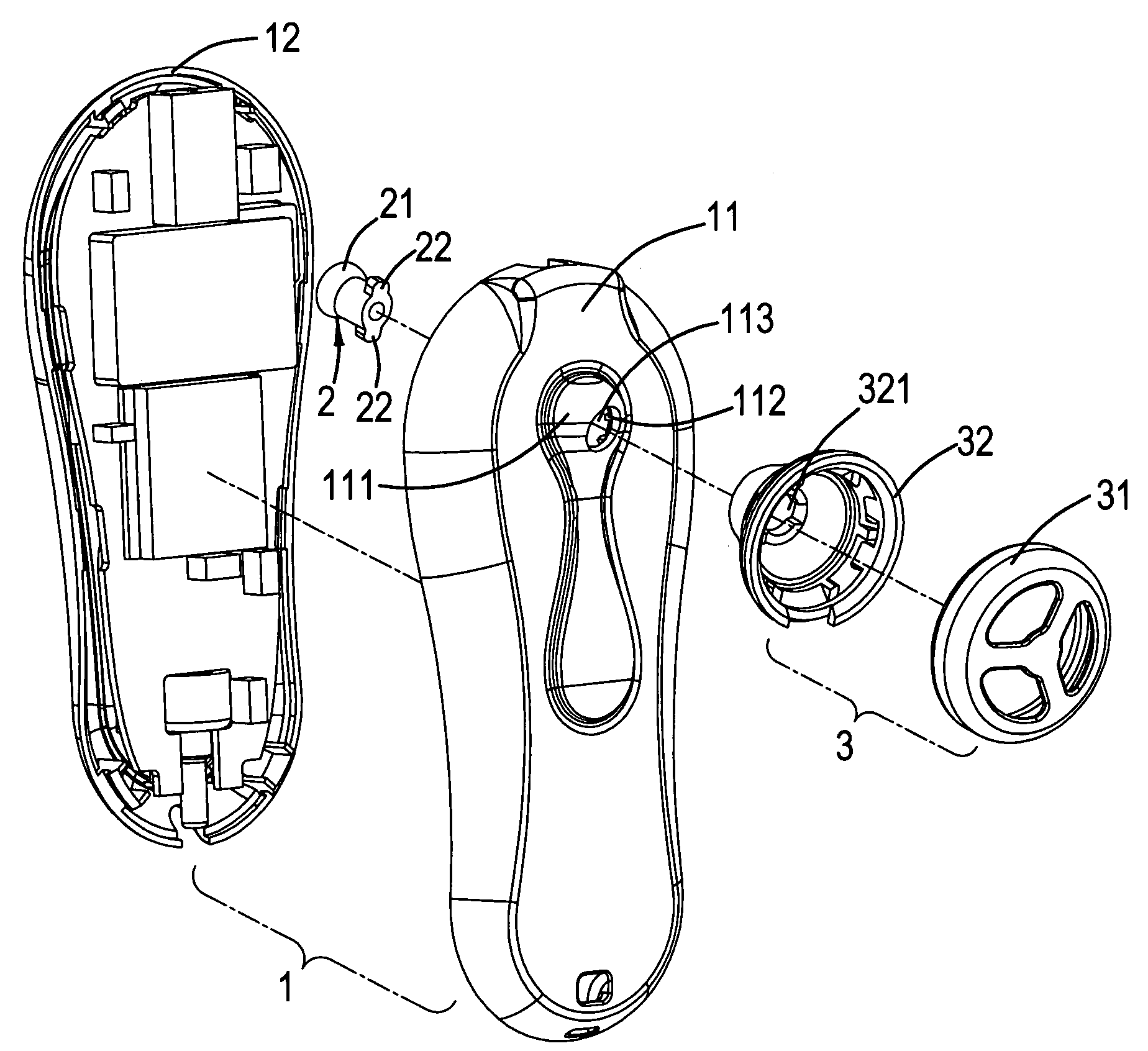

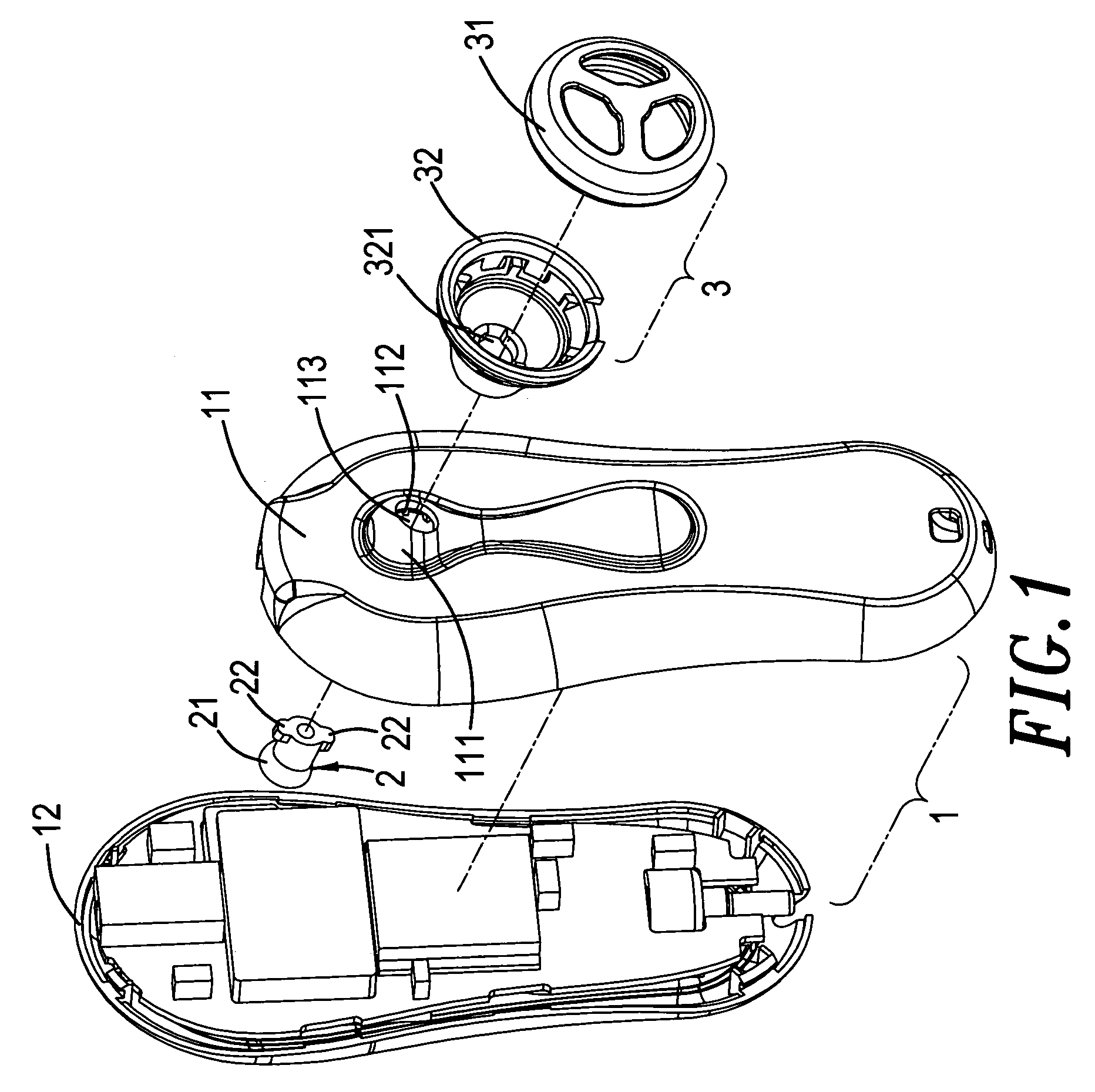

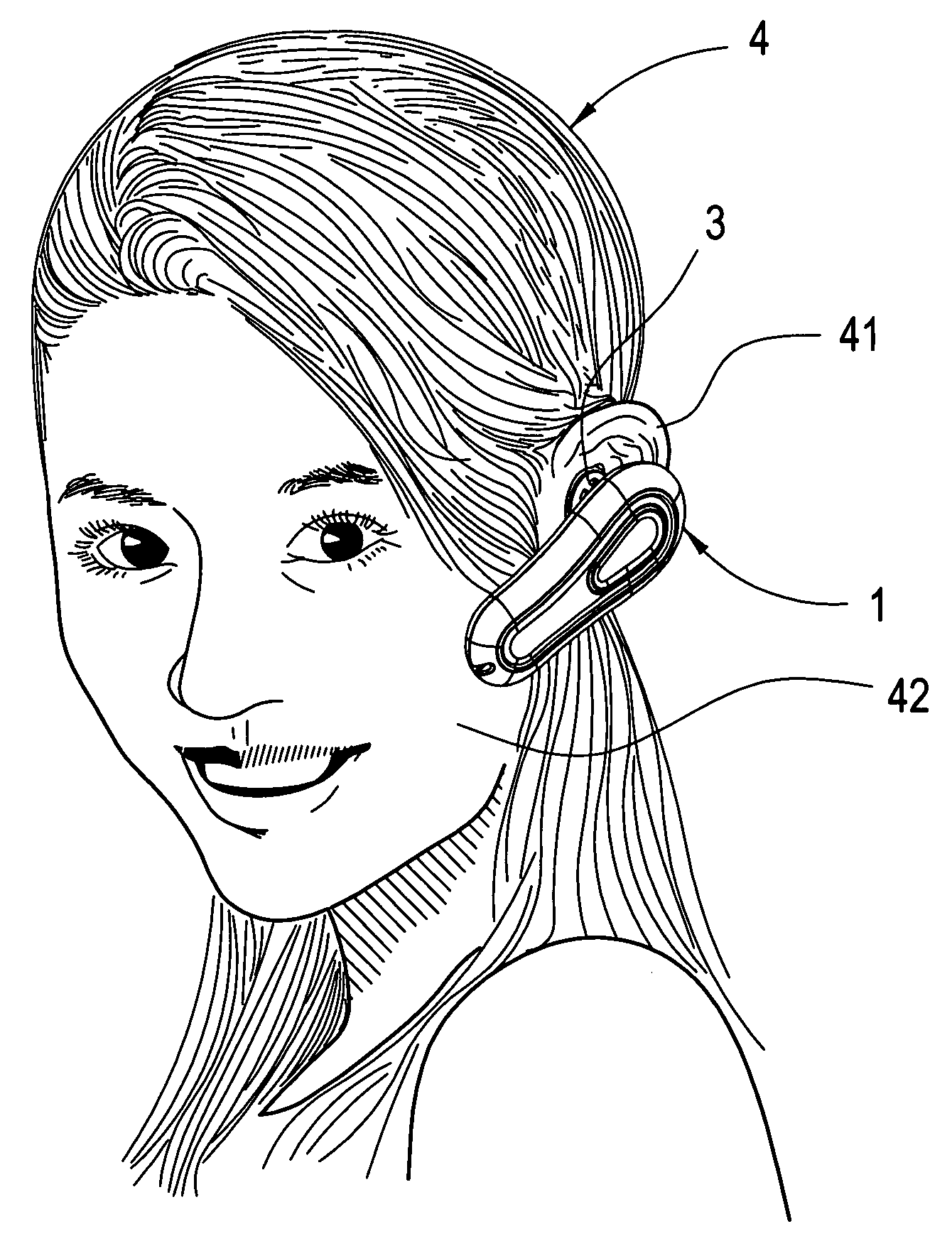

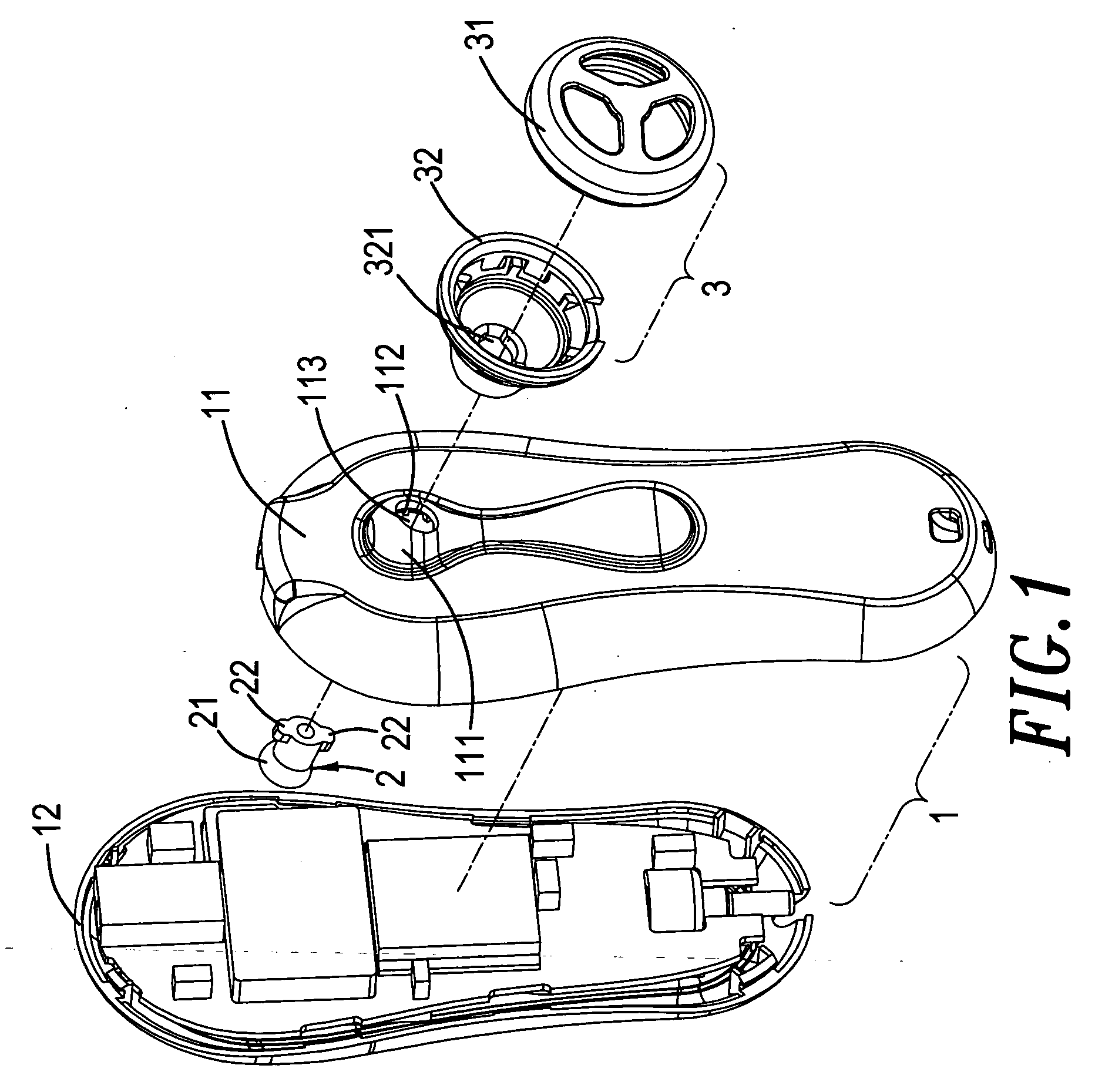

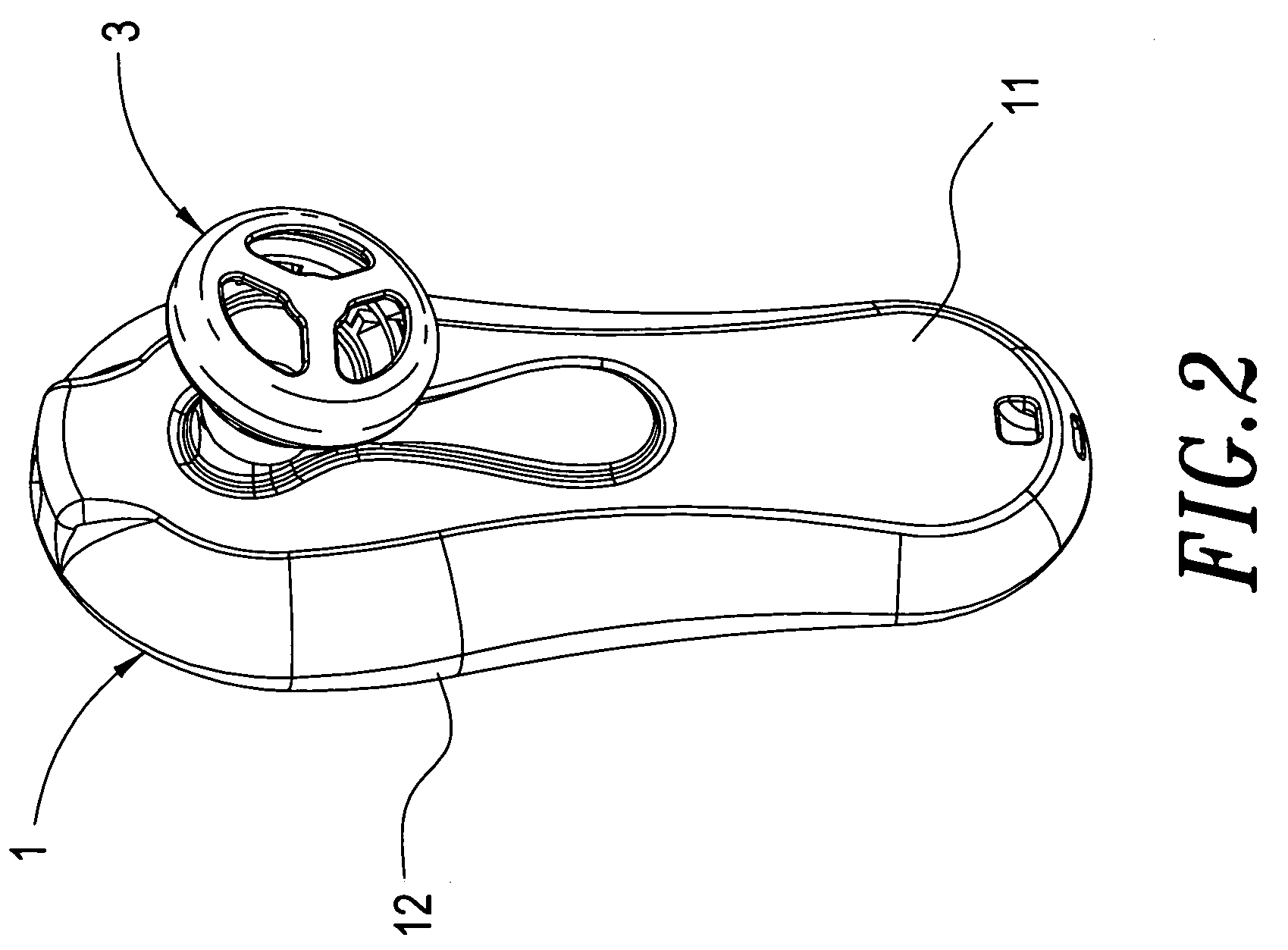

Adjustable bluetooth wireless earphone

InactiveUS7289640B2Not easy to dropPlug tightMicrophonesInterconnection arrangementsEngineeringHeadphones

An adjustable Bluetooth wireless earphone primarily comprises an earphone body pin-connecting with a link-part at the front upper portion thereof so that the earphone can be rotated in all direction using the link-part as an axis and the link-part connects with a plug-set. The plug-set can co-move with the link-part. When the plug-set plugged the ear of the user, using the feature that the earphone body can be rotated in all direction, so the earphone body can be pressed close to the cheek portion of the user to form an angle between the earphone body and the plug-set, such that the plugged plug-set may stay more tightly on the ear of the user and not drop off easily.

Owner:GLOBAL TARGET ENTERPRISE

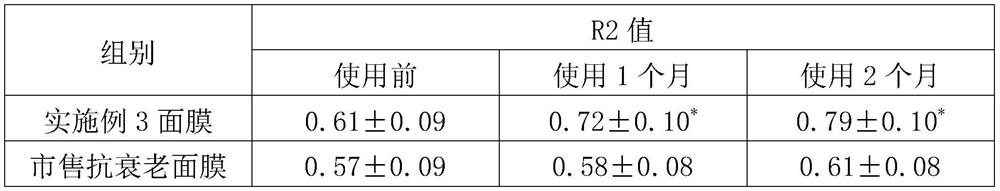

Moisturizing mask and preparation method thereof

InactiveCN106924073AImprove water retentionKeep shinyCosmetic preparationsToilet preparationsAdjuvantTremella

The invention discloses a moisturizing mask. The mask comprises the following ingredients (by weight): 0.01-3% of hyaluronic acid, 0.01-2% of tremella polysaccharide, 0.01-3% of bio-saccharide gum, 0.01-2% of oligopeptides, 2-15% of plant extracts, 2.96-20% of cosmetic adjuvants, and 55-95% of deionized water. The invention has the following beneficial effects: stoste is rich in various plant extract components and can nourish the skin and make the skin to be radiant; and hyaluronic acid, tremella polysaccharide, bio-saccharide gum and oligopeptides deeply moisturize the skin and make the skin to be rich in moisture, the moisture retention effect is more excellent, and the skin can be maintained to be moisturized and tightened.

Owner:南通千竹电子科技有限公司

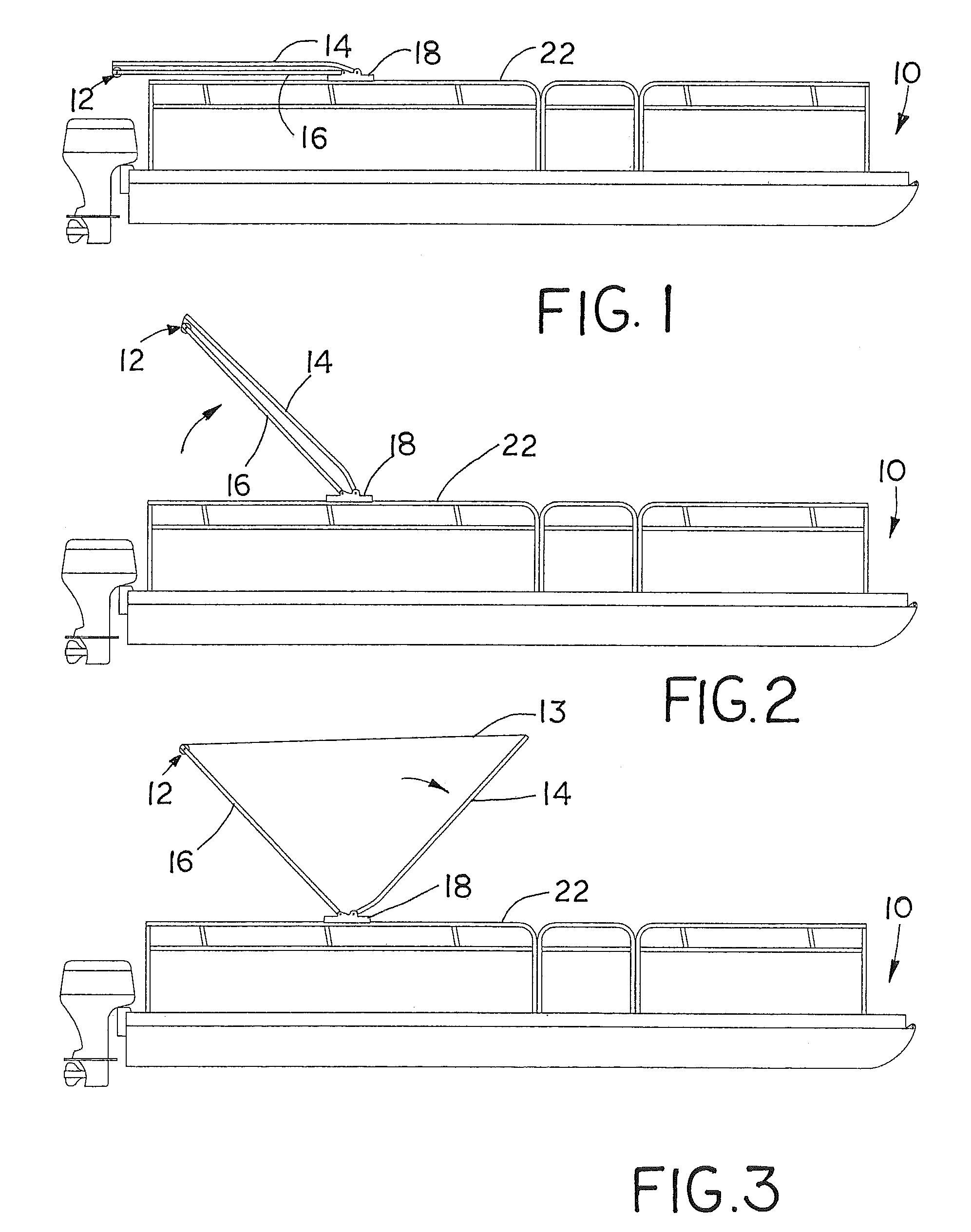

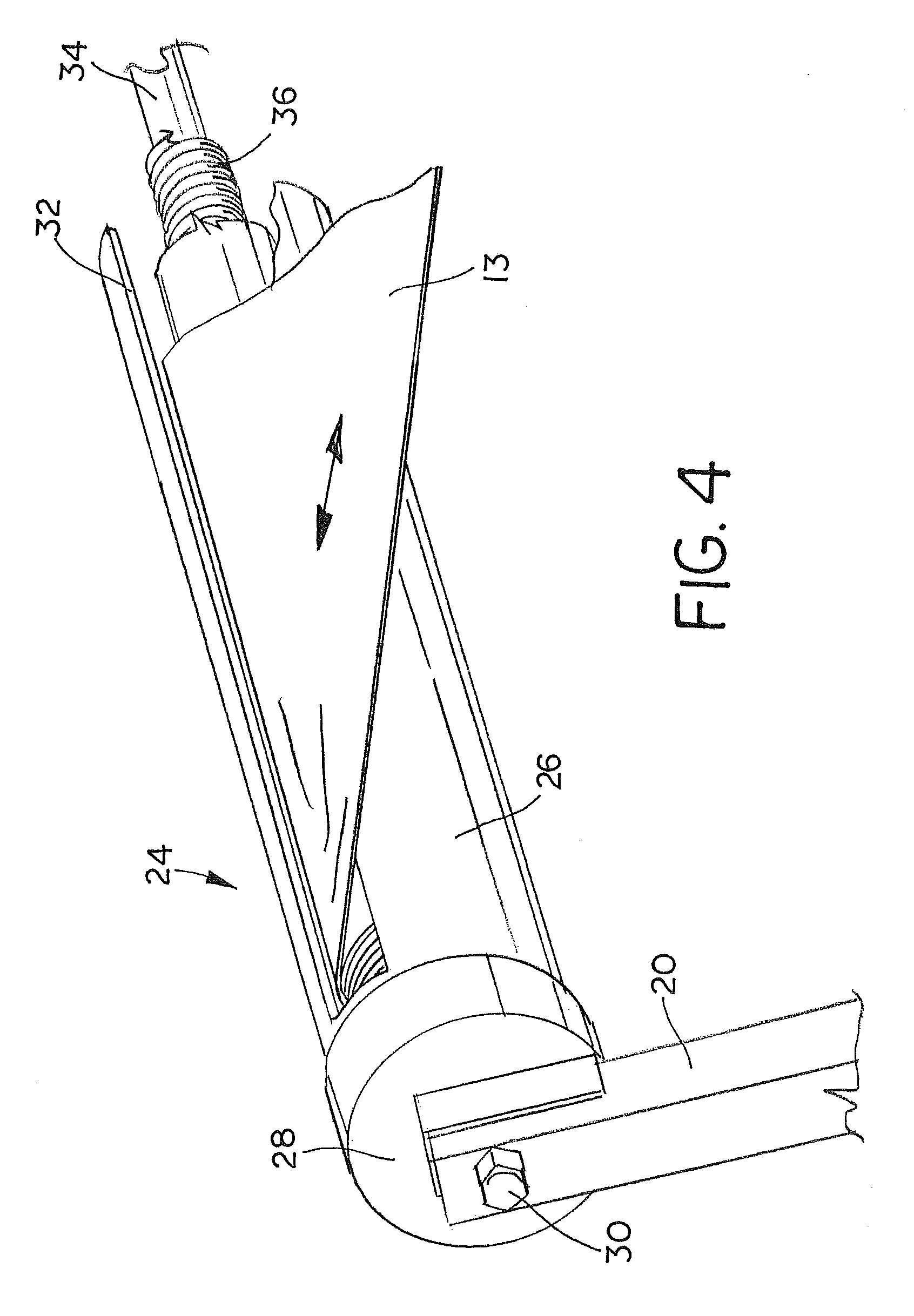

Retractable folding top assembly

A retractable top assembly for a vehicle, commonly referred to as a bimini top, includes a covering mounted on a pair of struts which are movable relative to one another to move the covering between a deployed position covering at least a portion of the vehicle and a retracted position. In the retracted position, the covering is wound upon a spindle rotatably mounted within a housing mounted on one of the struts. The housing has a slot through which the covering extends, so that the covering is attached to the other strut. A torsion spring within the housing biases the spindle in a direction winding the covering onto the spindle and thereby maintaining tautness of the covering as it unwinds from the spindle and is moved into the deployed position.

Owner:LIPPERT COMPONENTS MFG INC

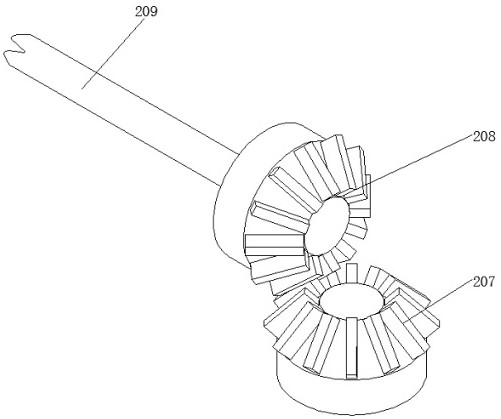

Adjustable bluetooth wireless earphone

InactiveUS20050208980A1Plug tightSimple structureMicrophonesInterconnection arrangementsEngineeringHeadphones

An adjustable Bluetooth wireless earphone primarily comprises an earphone body pin-connecting with a link-part at the front upper portion thereof so that the earphone can be rotated in all direction using the link-part as an axis and the link-part connects with a plug-set. The plug-set can co-move with the link-part. When the plug-set plugged the ear of the user, using the feature that the earphone body can be rotated in all direction, so the earphone body can be pressed close to the cheek portion of the user to form an angle between the earphone body and the plug-set, such that the plugged plug-set may stay more tightly on the ear of the user and not drop off easily.

Owner:GLOBAL TARGET ENTERPRISE

Anti-wrinkle eye cream and preparation method thereof

InactiveCN107693391AImprove microcirculationIncrease elasticityCosmetic preparationsToilet preparationsWrinkle skinOcular muscle

The invention provides an anti-wrinkle eye cream, wherein natural marine conotoxin is rich in various amino acids, the combined action of the natural marine conotoxin and dipeptide diaminobutyroyl benzylamide diacetate can improve ocular microcirculation and alleviate dark eye circles, and inhibit contraction of ocular muscles, thereby achieving the effect of reducing wrinkles; by jointing using hydrolyzed wheat protein, hydrolyzed collagen and hydrolyzed soybean protein, and utilizing compounding of the collagen, a moisturizing protective film is formed on a skin surface, so as to enhance theadherence of matrix outside epithelial cells, maintain a compact state of epithelial lipid monolayer molecular film, increase the level of cellular protein, and promote the synthesis of the collagen,thereby synergistically enhancing the anti-wrinkle effect; and ceramide, tocopherol acetate and saccharomyces lysate promote the skin metabolism, prevent pigment deposition, improve skin elasticity,lock moisture in the skin, repair skin barriers, and moisten the skin.

Owner:SHANGHAI LOFTY BRAND MANAGEMENT CO LTD

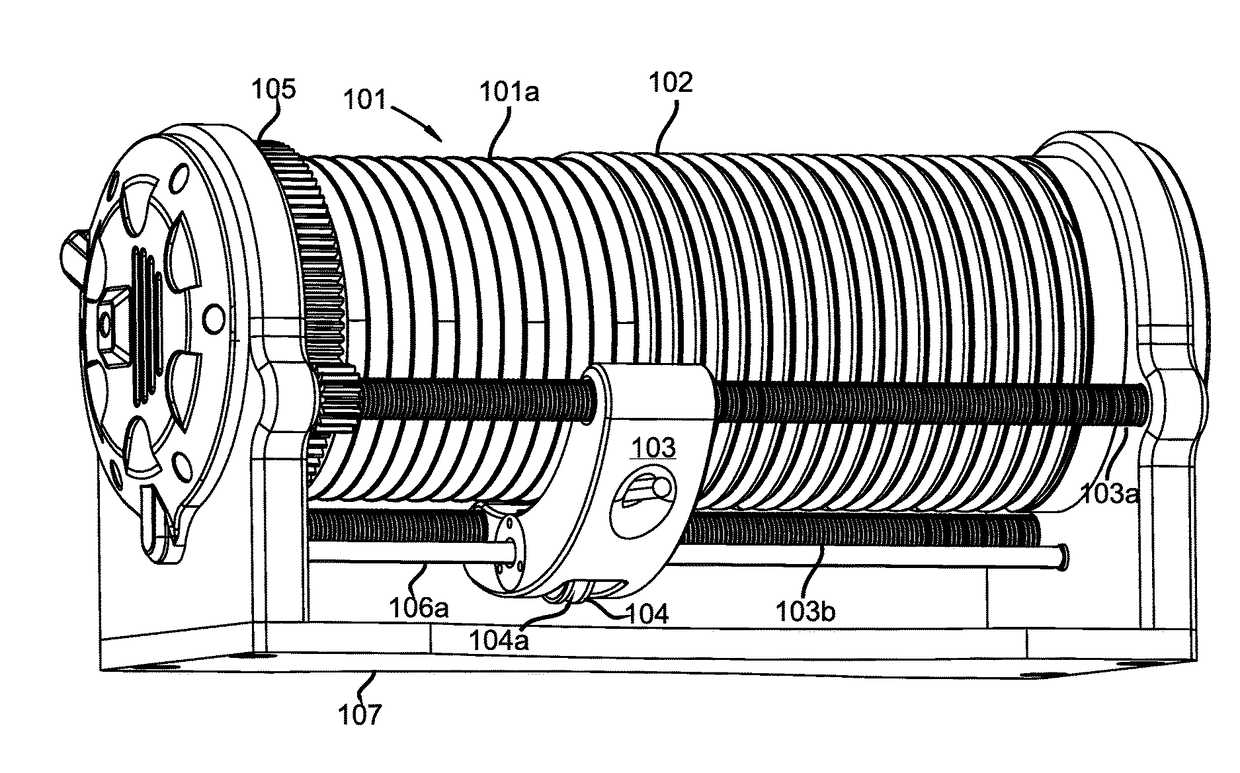

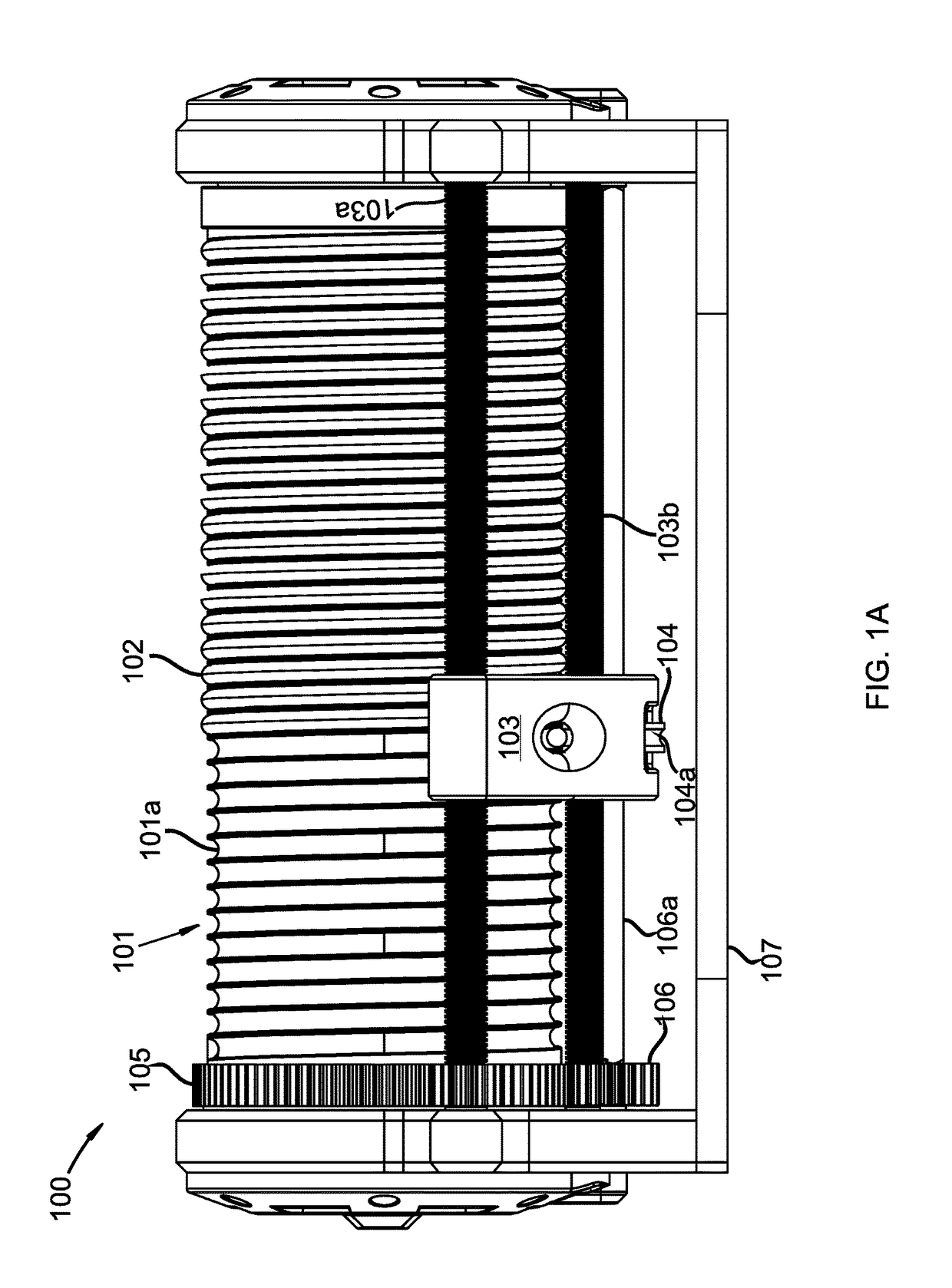

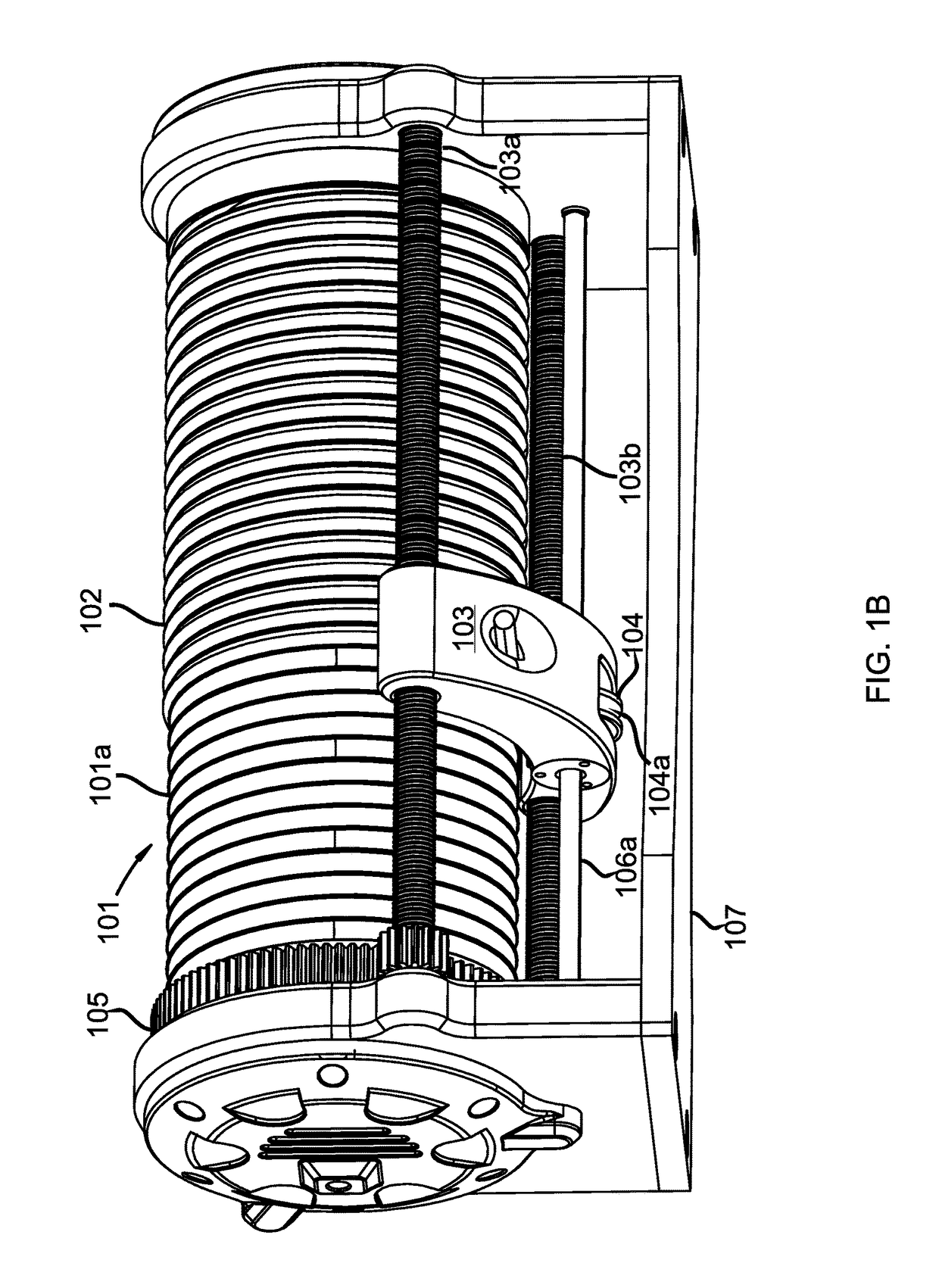

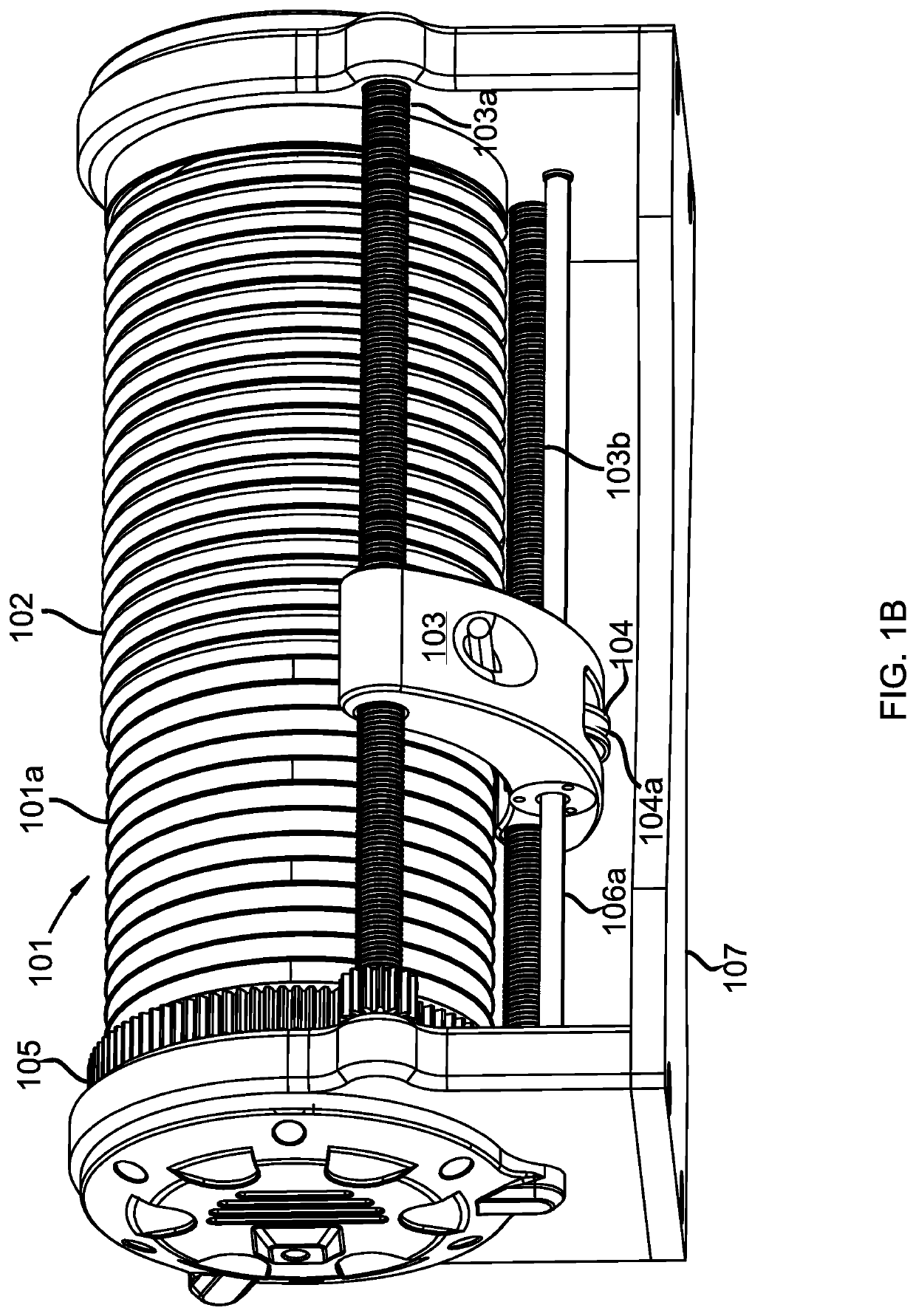

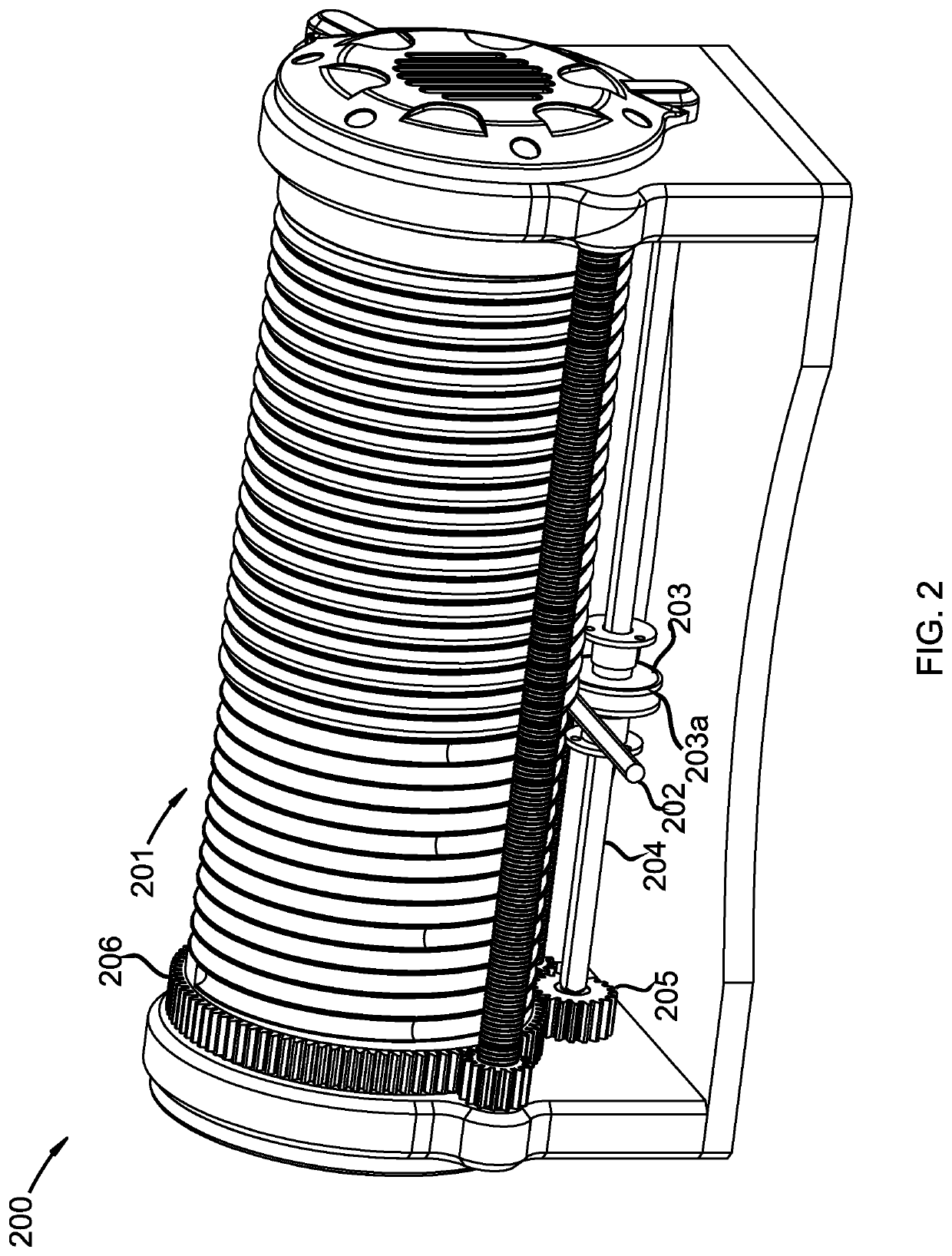

Winch With One-Way Reverse Tensioner

A winch is described that includes a drum, a motor and transmission, and a tensioner. The motor and transmission apply torque to the drum, thereby enabling the drum to draw in and let out a line. The tensioner is positioned adjacent to the drum, such that when the line passes between the tensioner and drum, the line is in frictional contact with the tensioner and drum. The tensioner rotates with a linear speed exceeding a linear speed of the drum as the line is let out from the drum, and rotates freely as the line is drawn onto the drum. Methods for making and using the winch are also described.

Owner:HALL LABS LLC

Methods for breeding and artificially fertilizing game chickens

The invention relates to methods for breeding and artificially fertilizing game chickens. The method for breeding the game chickens comprises the following steps: breeding hens: feeding a feed which is mainly prepared from beans, dried fruits, cereals and other materials to the hens at fixed time everyday between one week before egg laying and the end of egg laying, and feeding a feed which is prepared from cereals or cereals and other materials to the hens at fixed time everyday less frequently between the end of egg laying and one week before egg laying next time; and feeding cocks: feeding a feed which is mainly prepared from meat, eggs and other materials to the cocks at fixed time everyday. The method for artificially fertilizing the game chickens comprises the following steps: collecting sperms: collecting the sperms of the cocks by sperm collecting cups; diluting the sperm: adding a certain amount of normal saline into the sperm collecting cups: and injecting the sperms: sucking the sperms from the sperm collecting cups by a sperm injector, inserting the sperm injector into the fallopian tube channel of the hen at a depth of 1-1.5cm, and pressing the piston of the sperm injector so that the sperm are absorbed into the body of the hen by the vagina.

Owner:凭祥市斗鸡协会

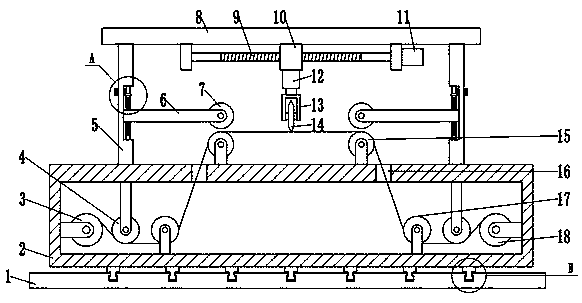

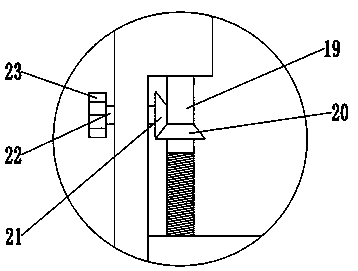

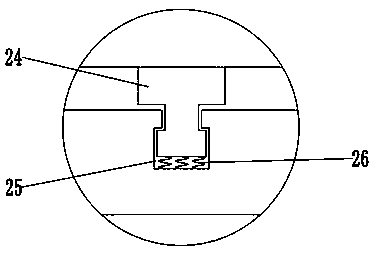

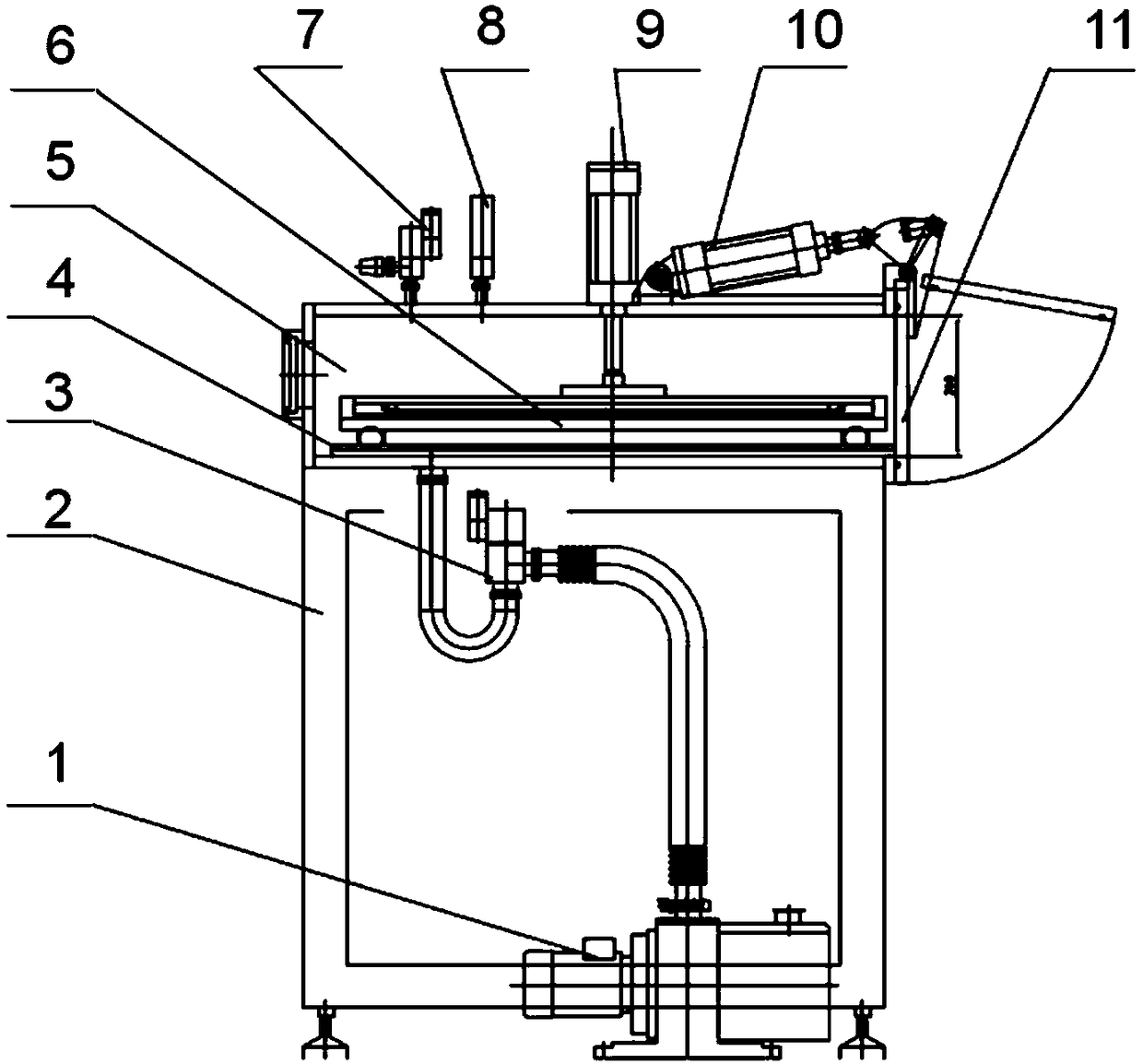

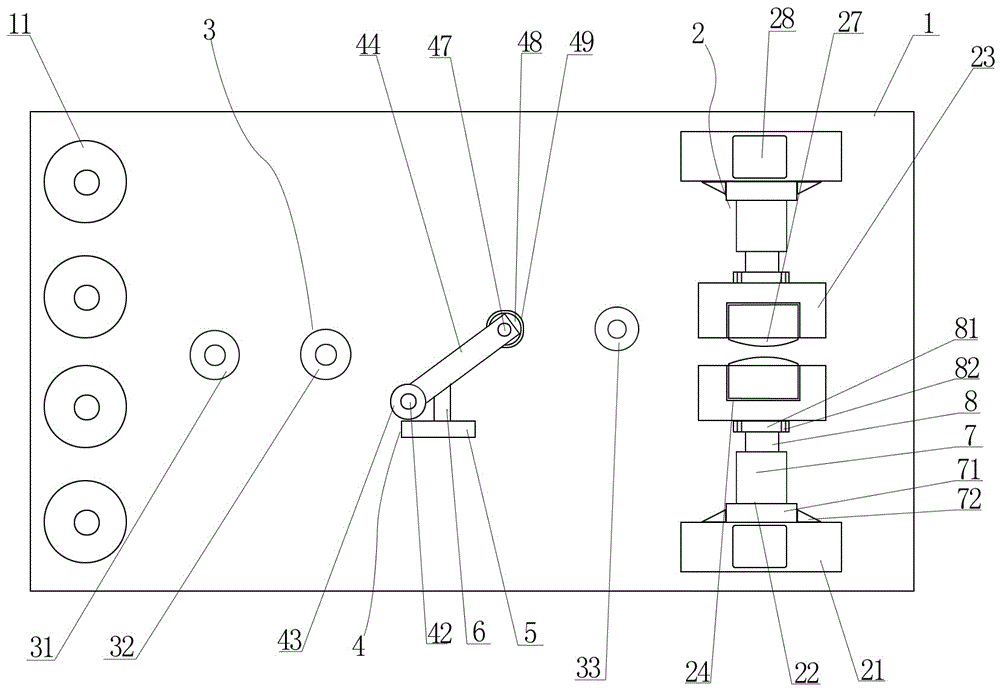

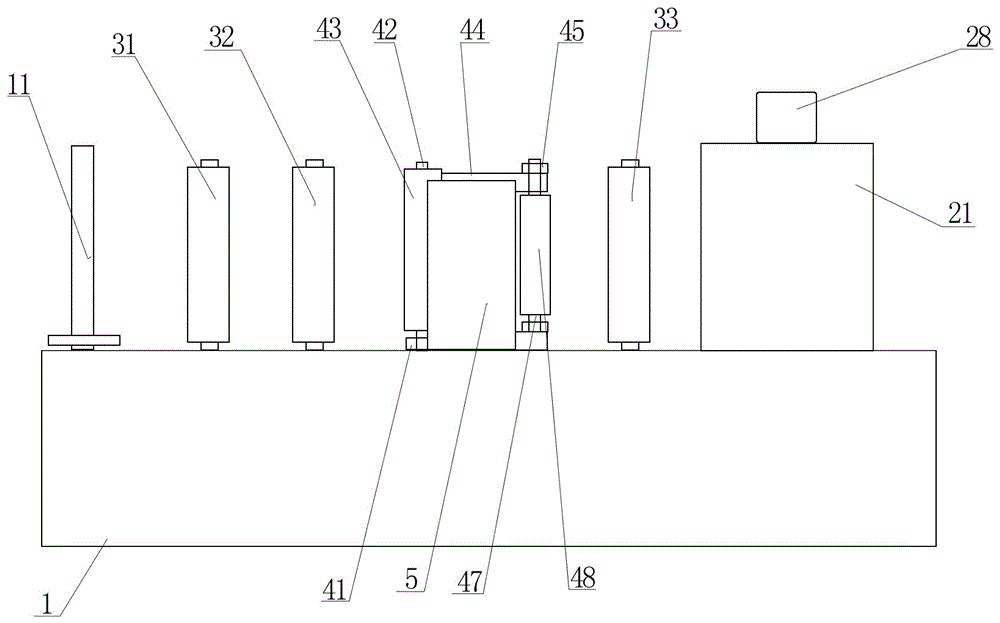

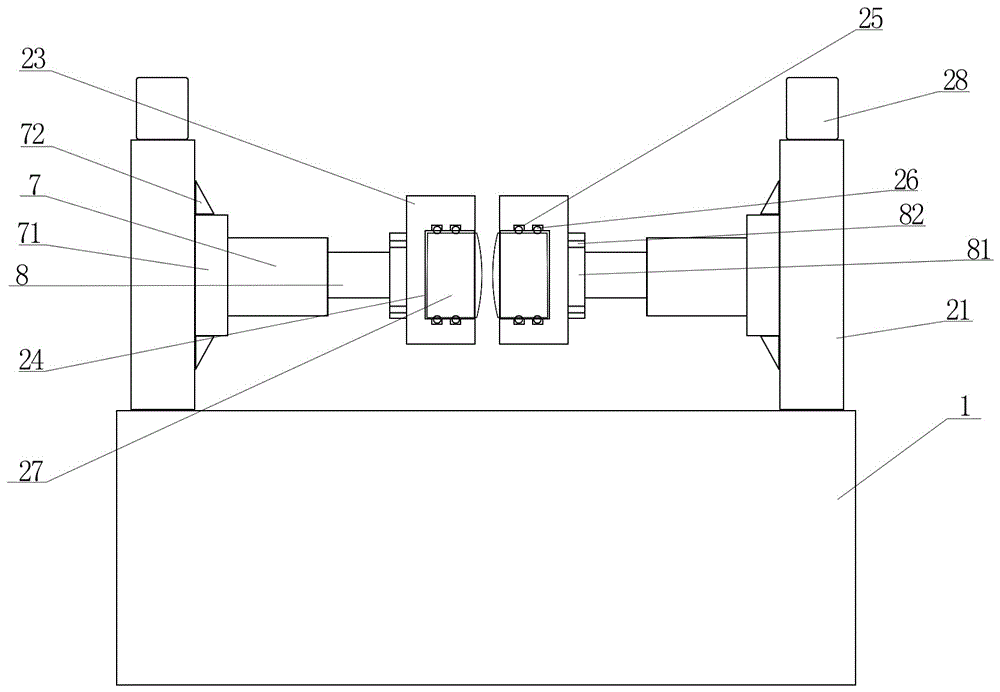

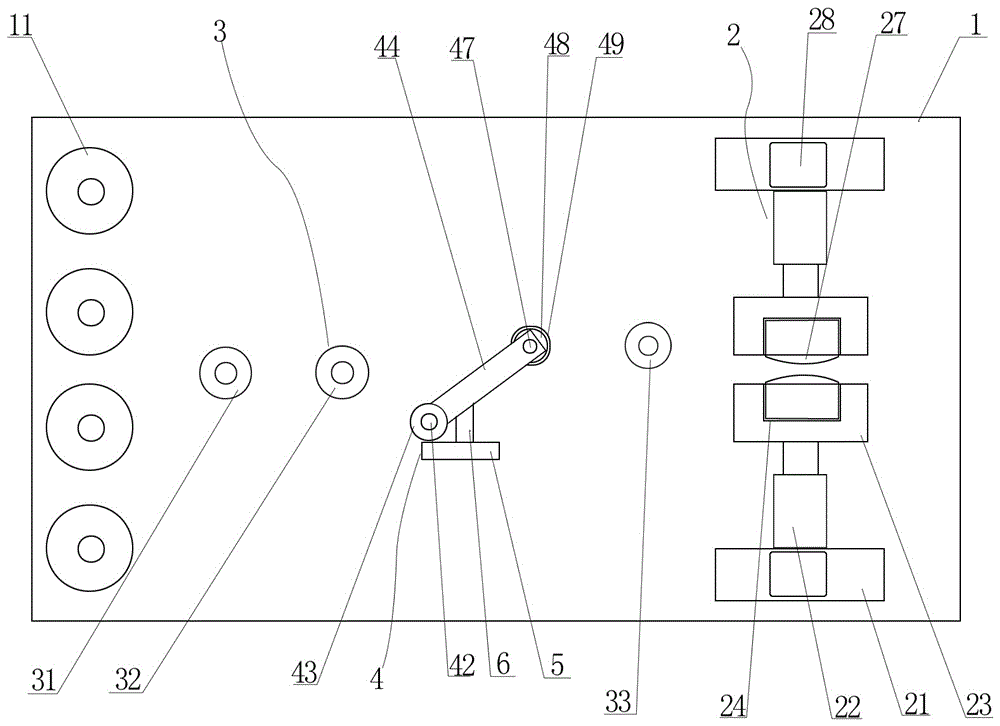

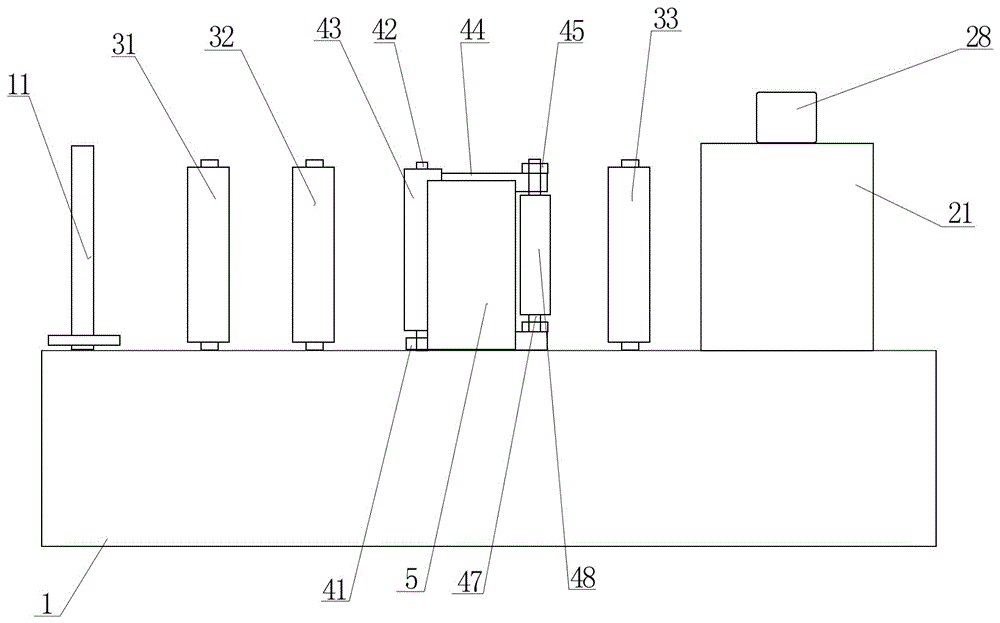

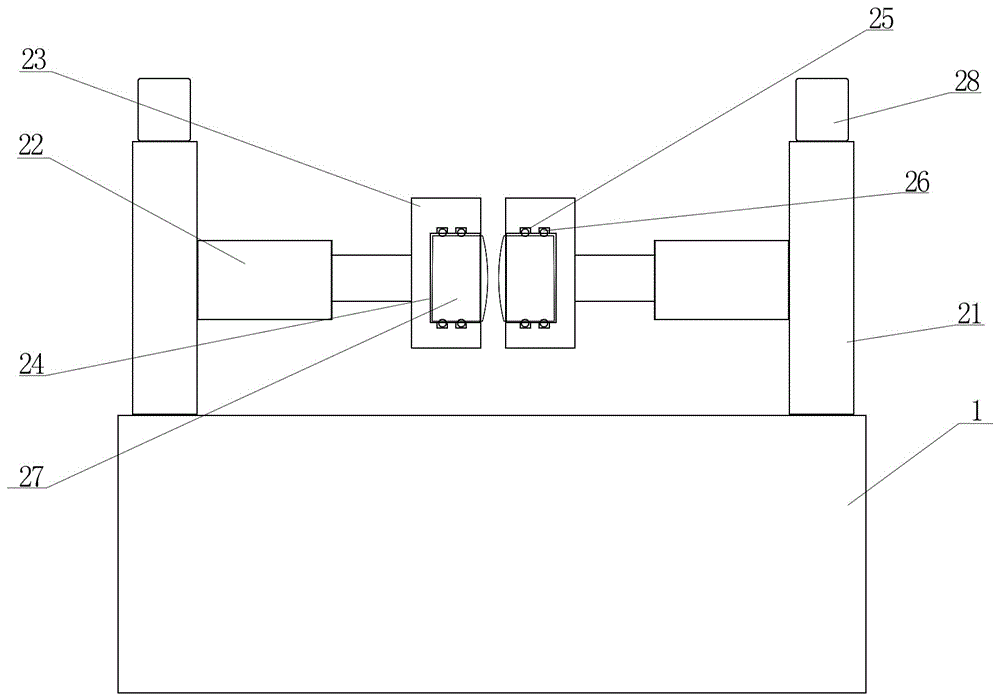

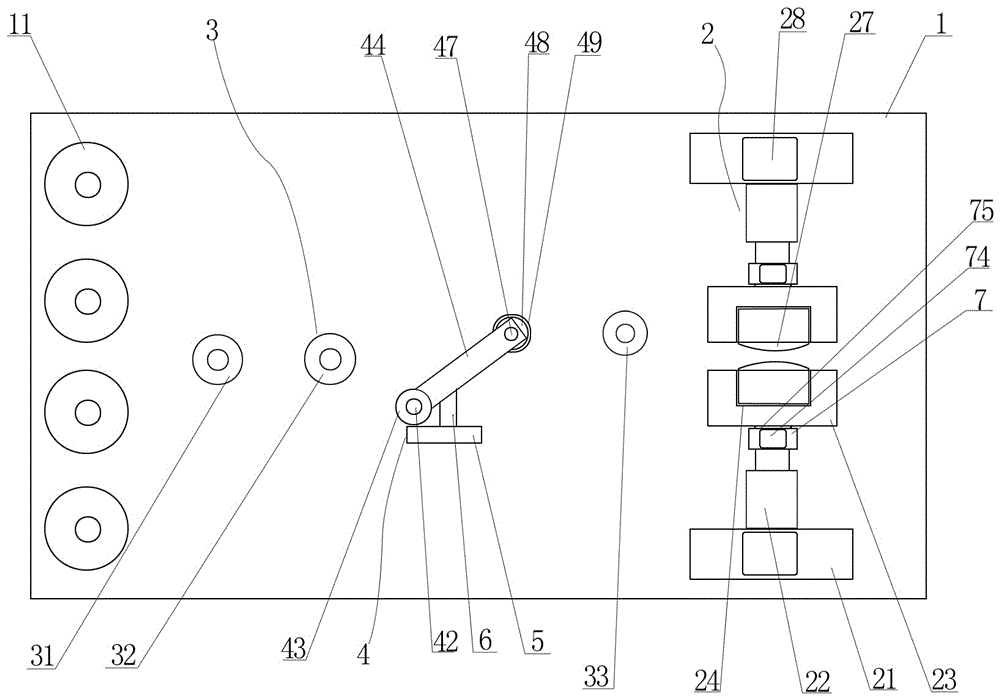

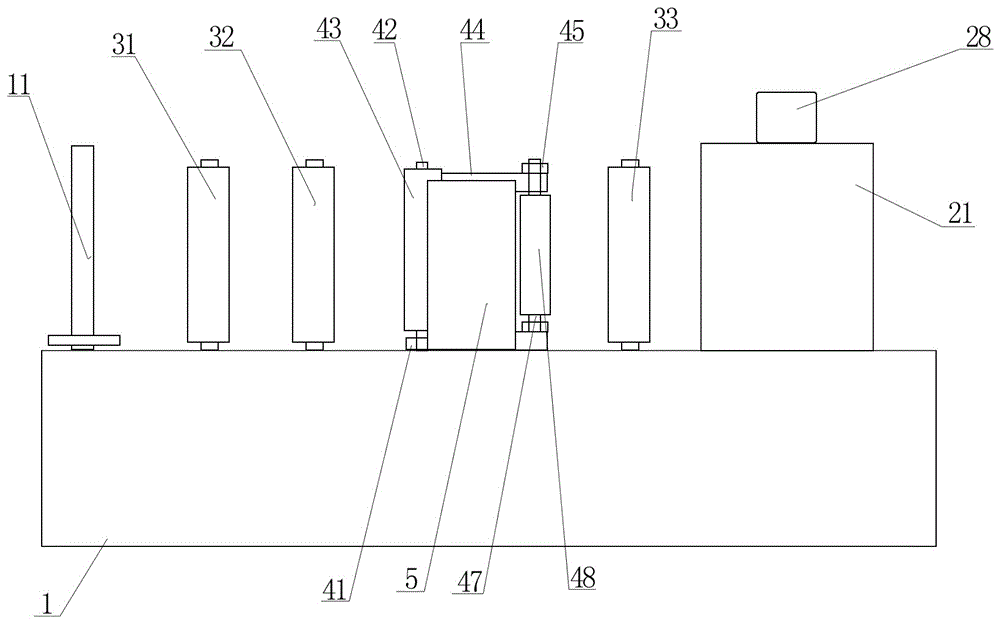

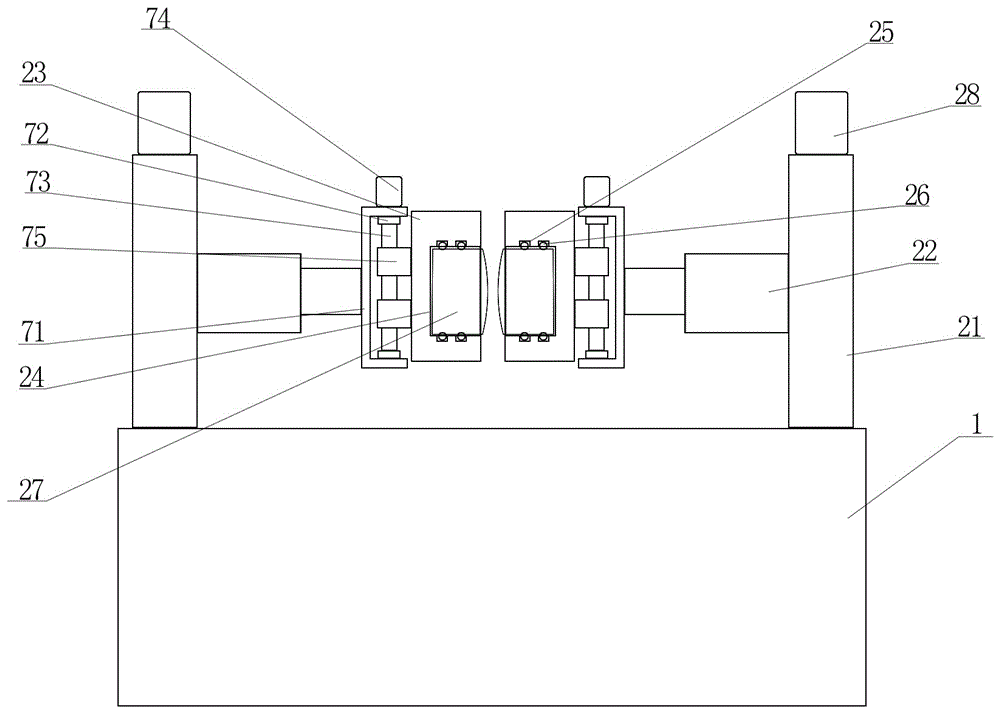

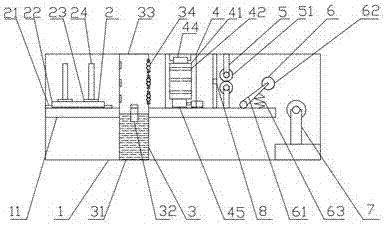

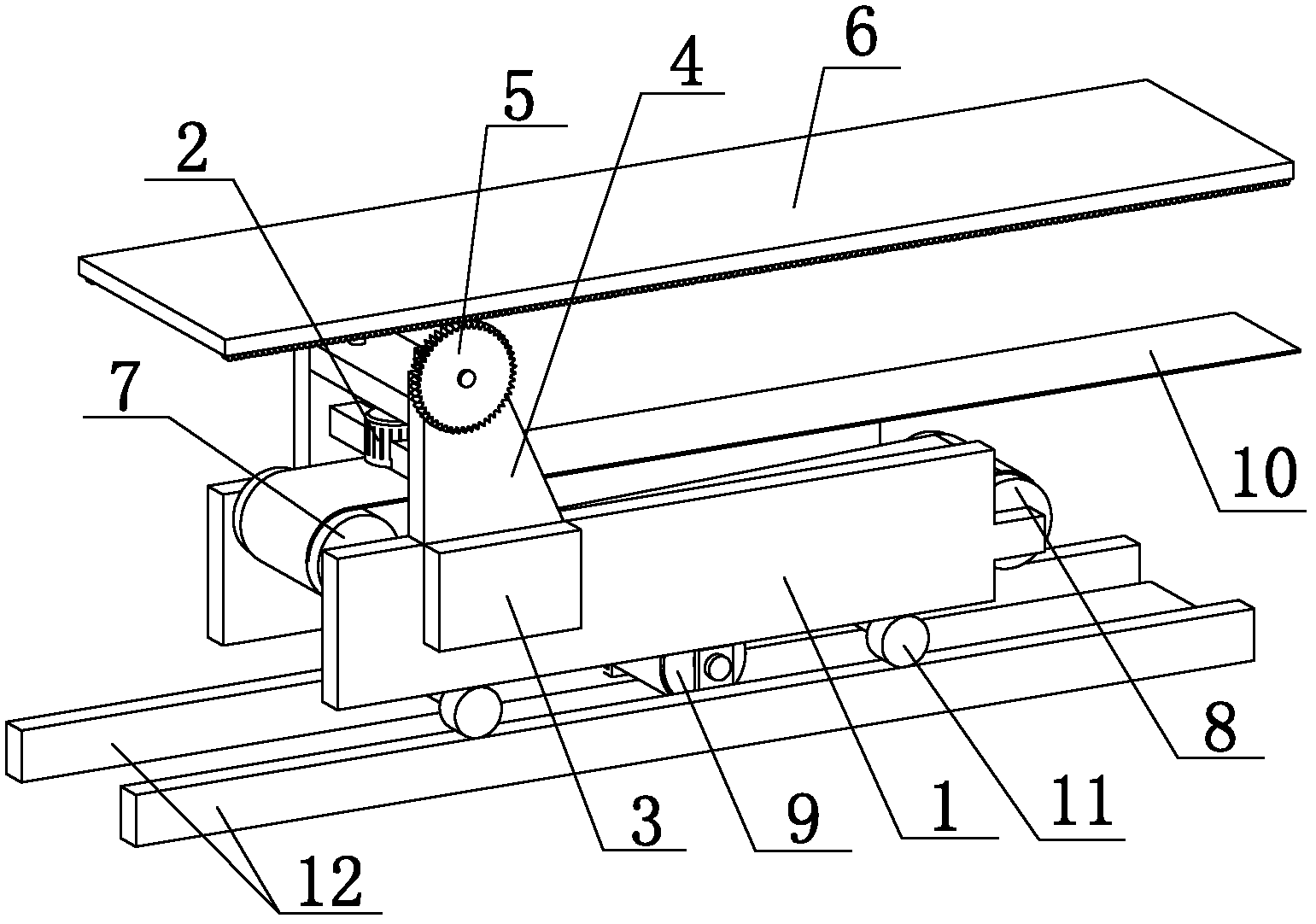

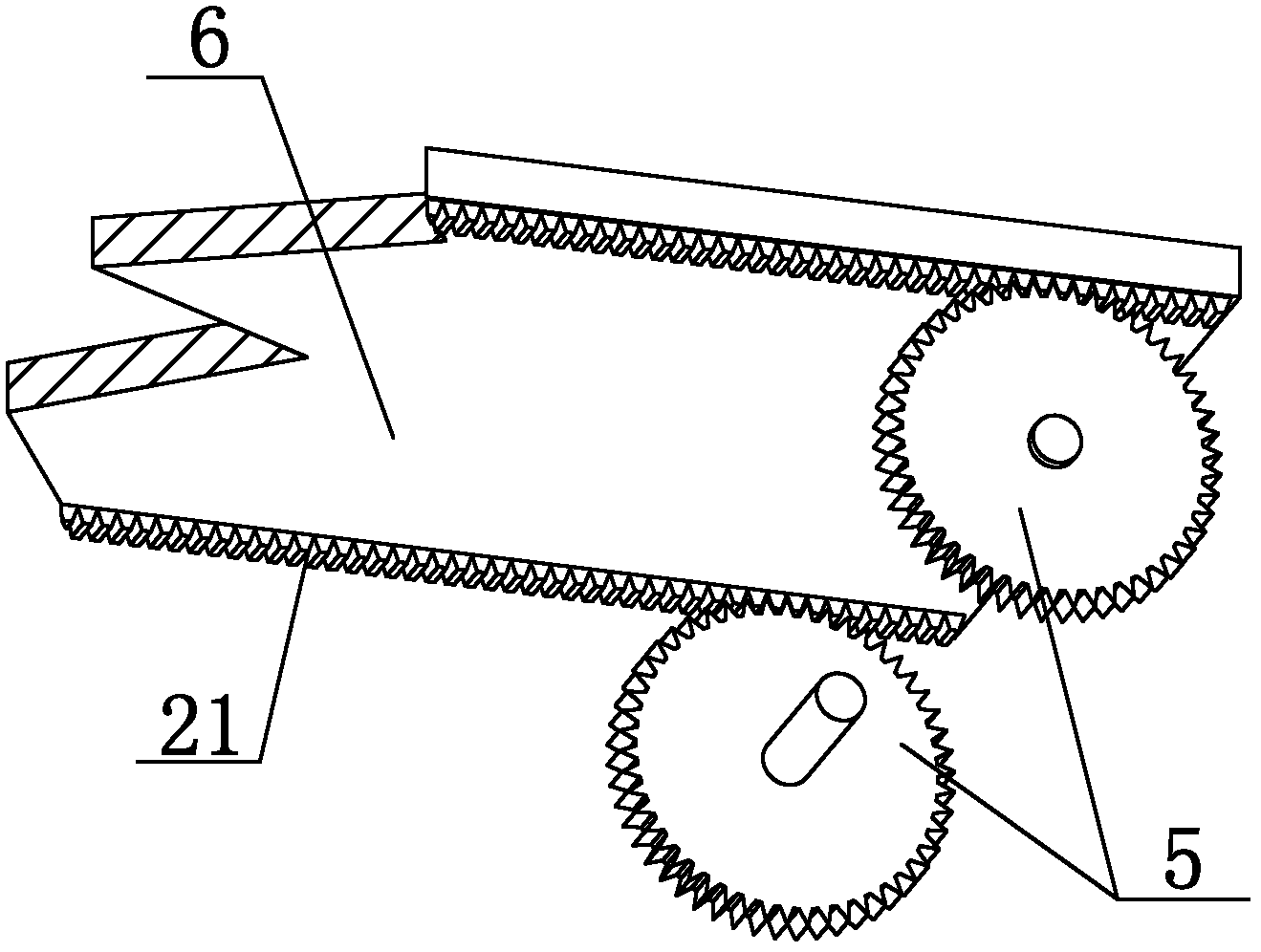

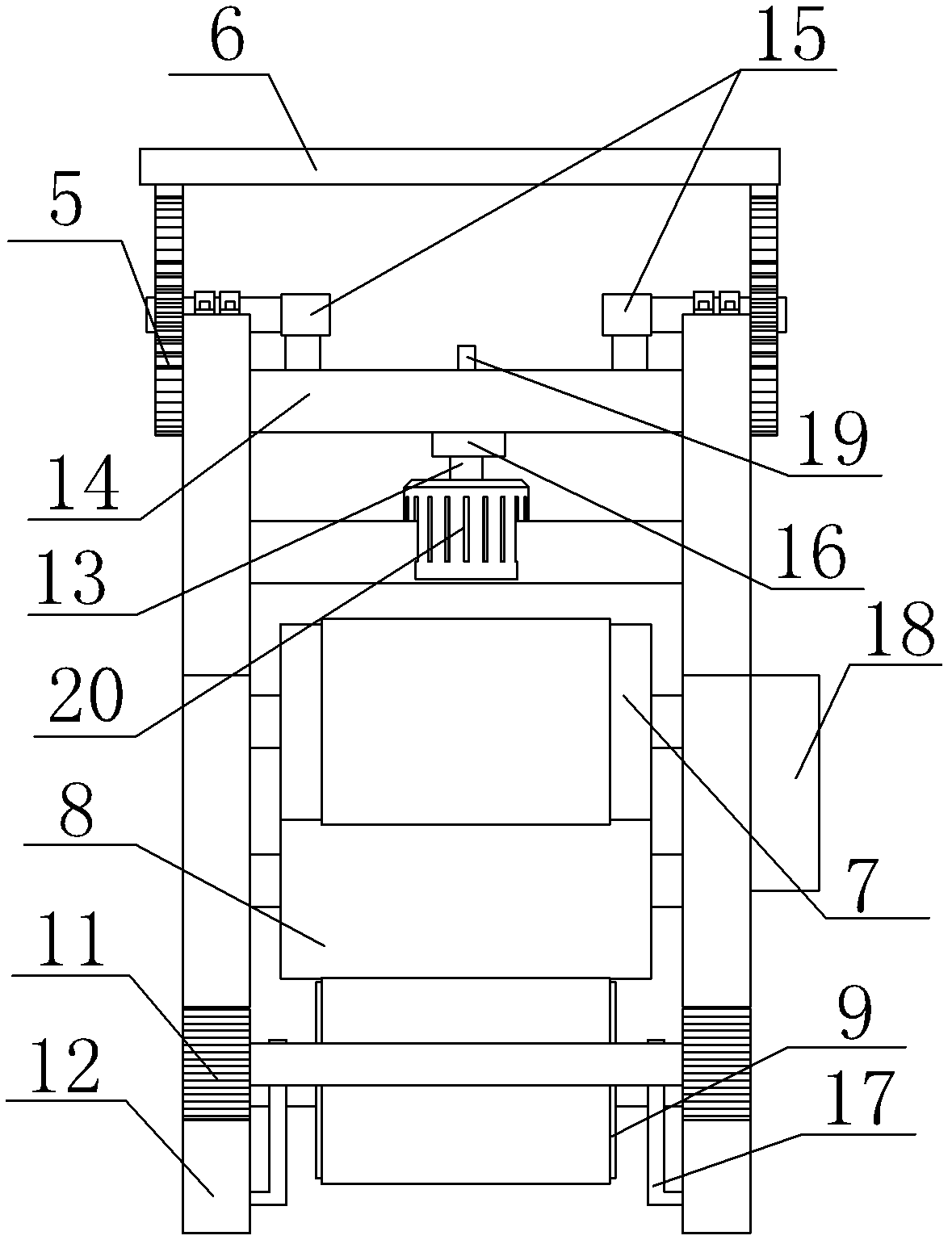

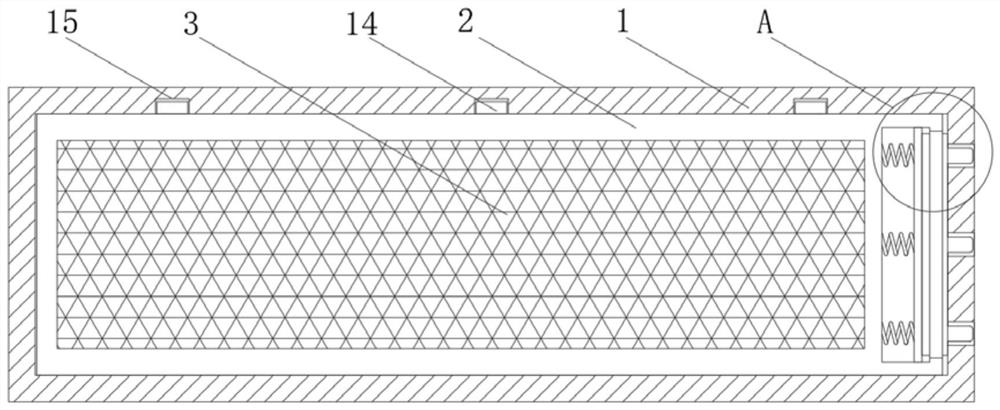

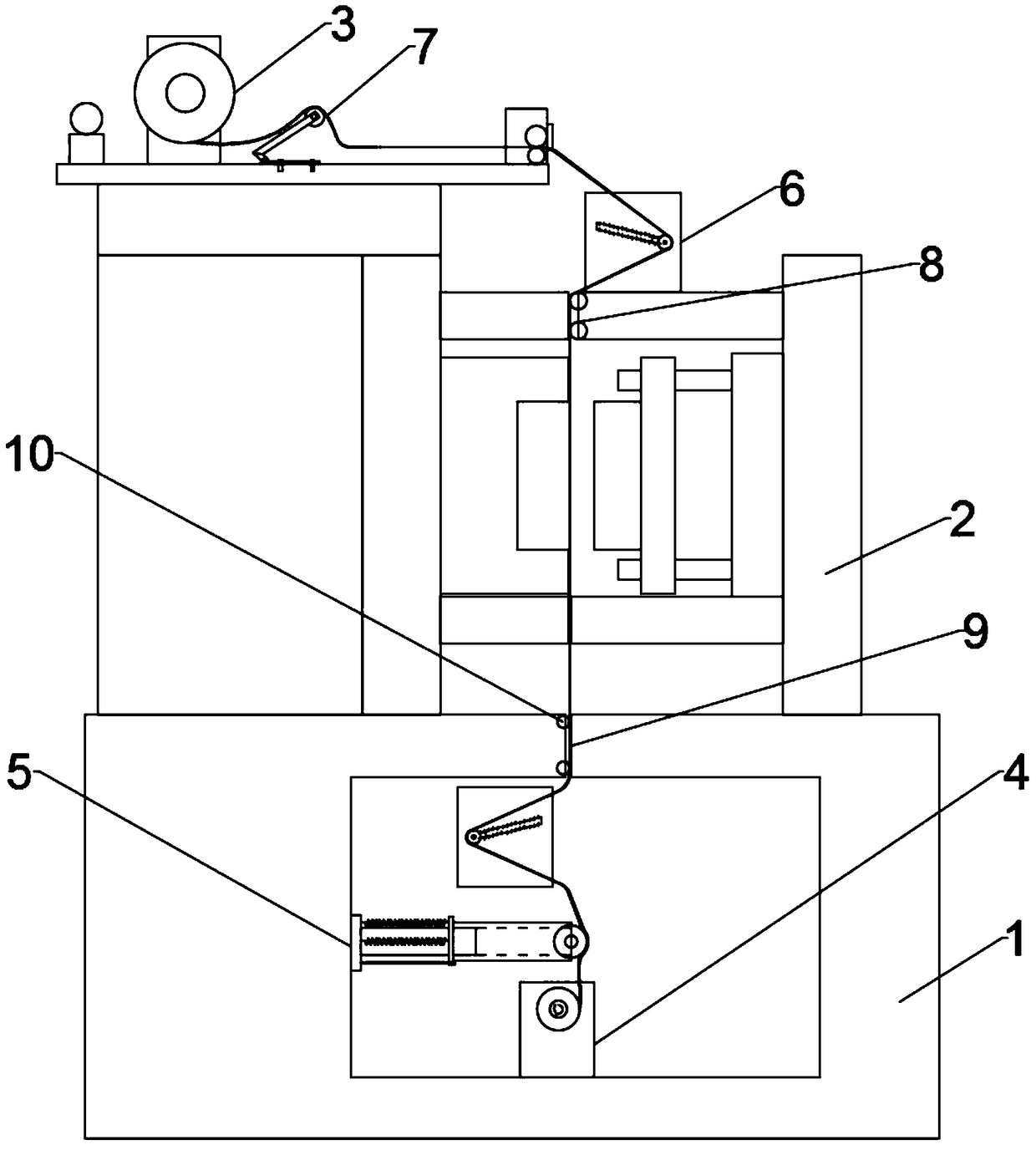

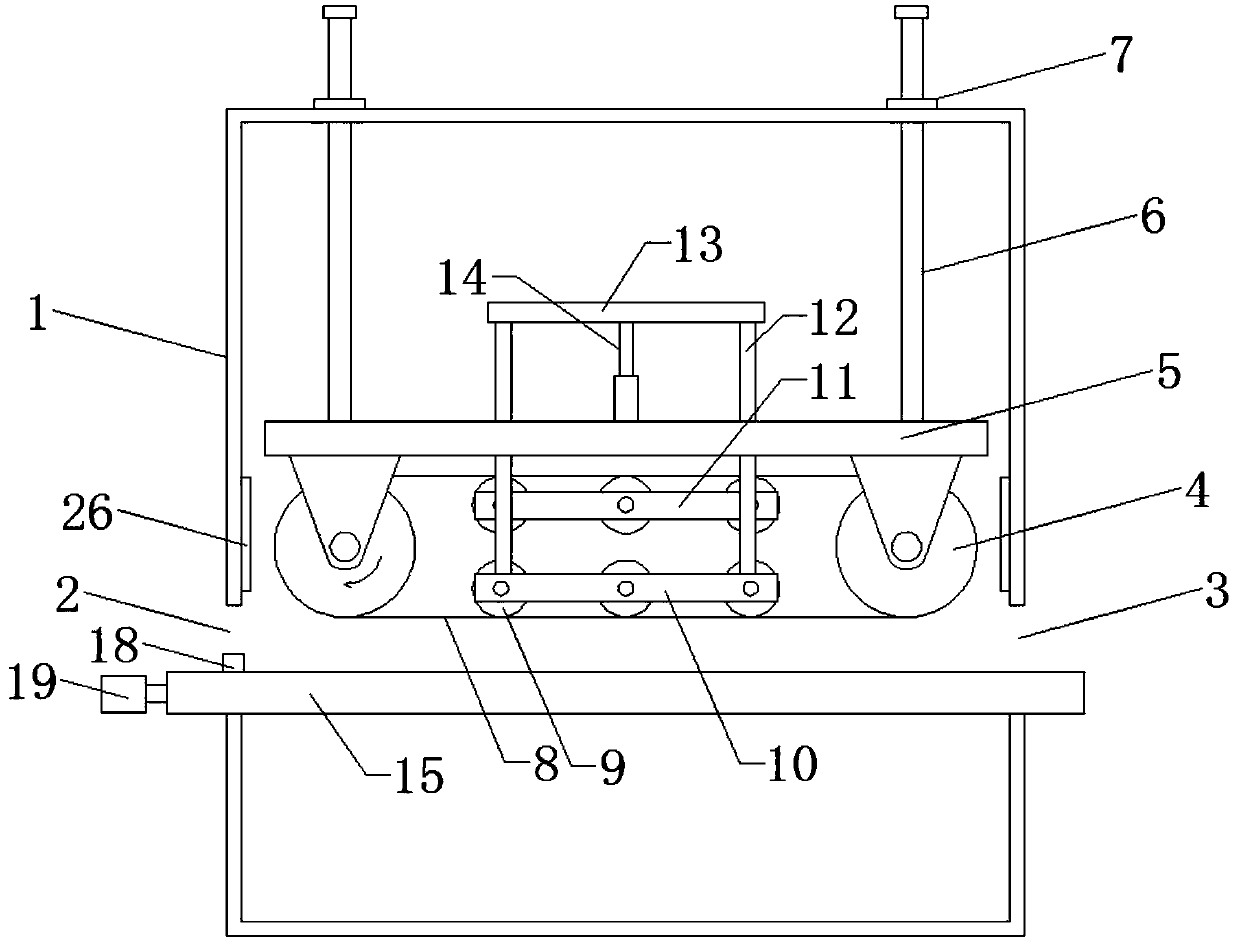

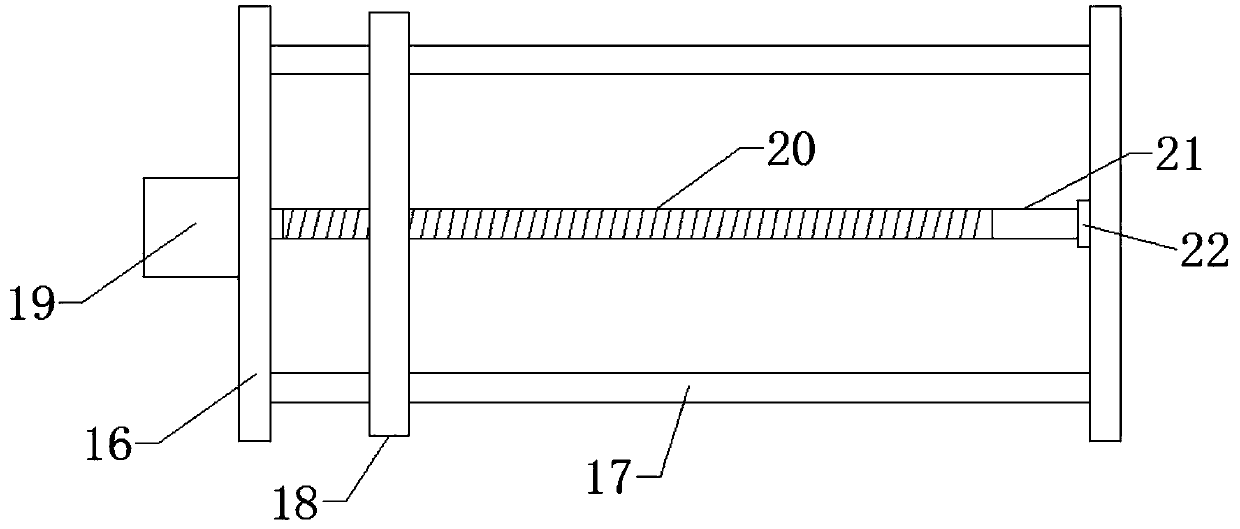

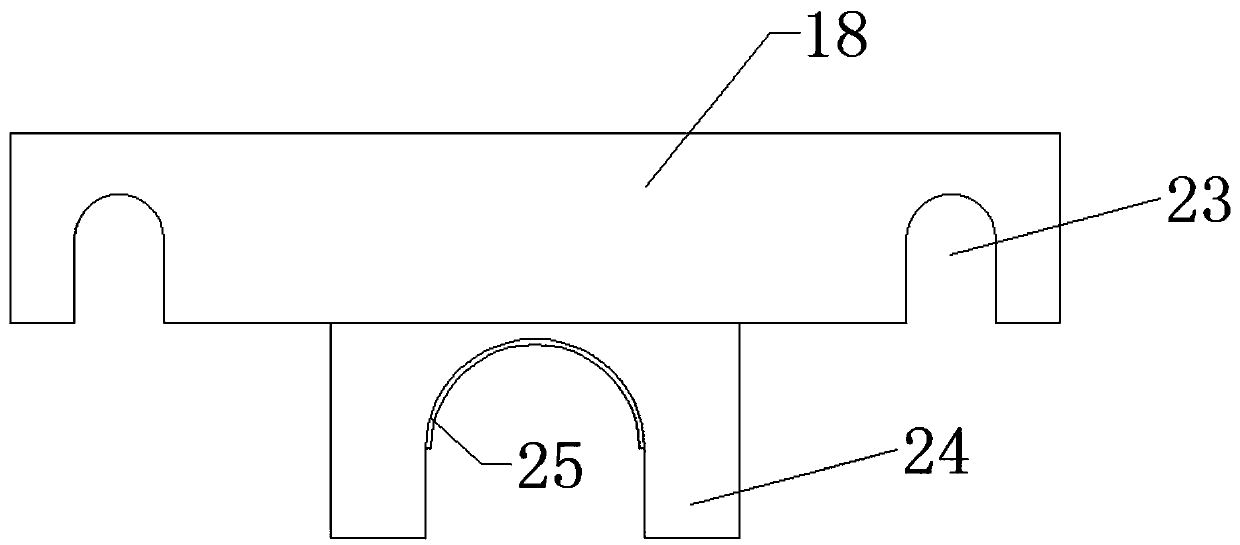

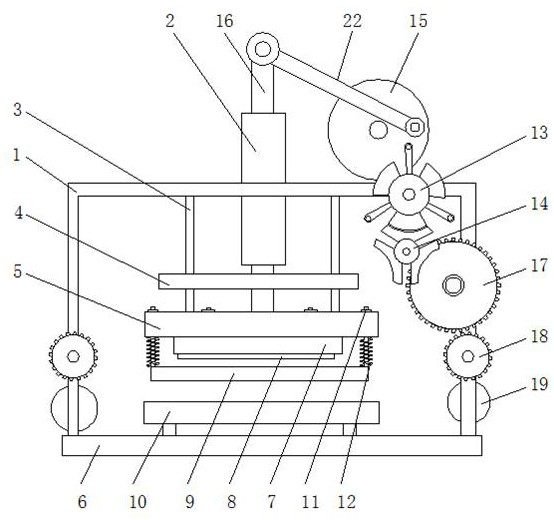

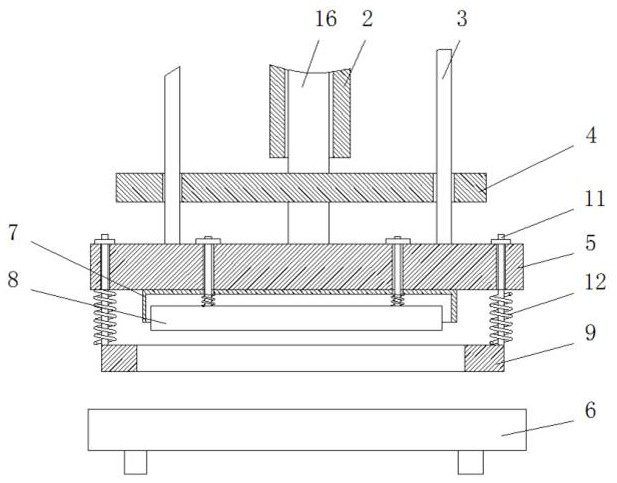

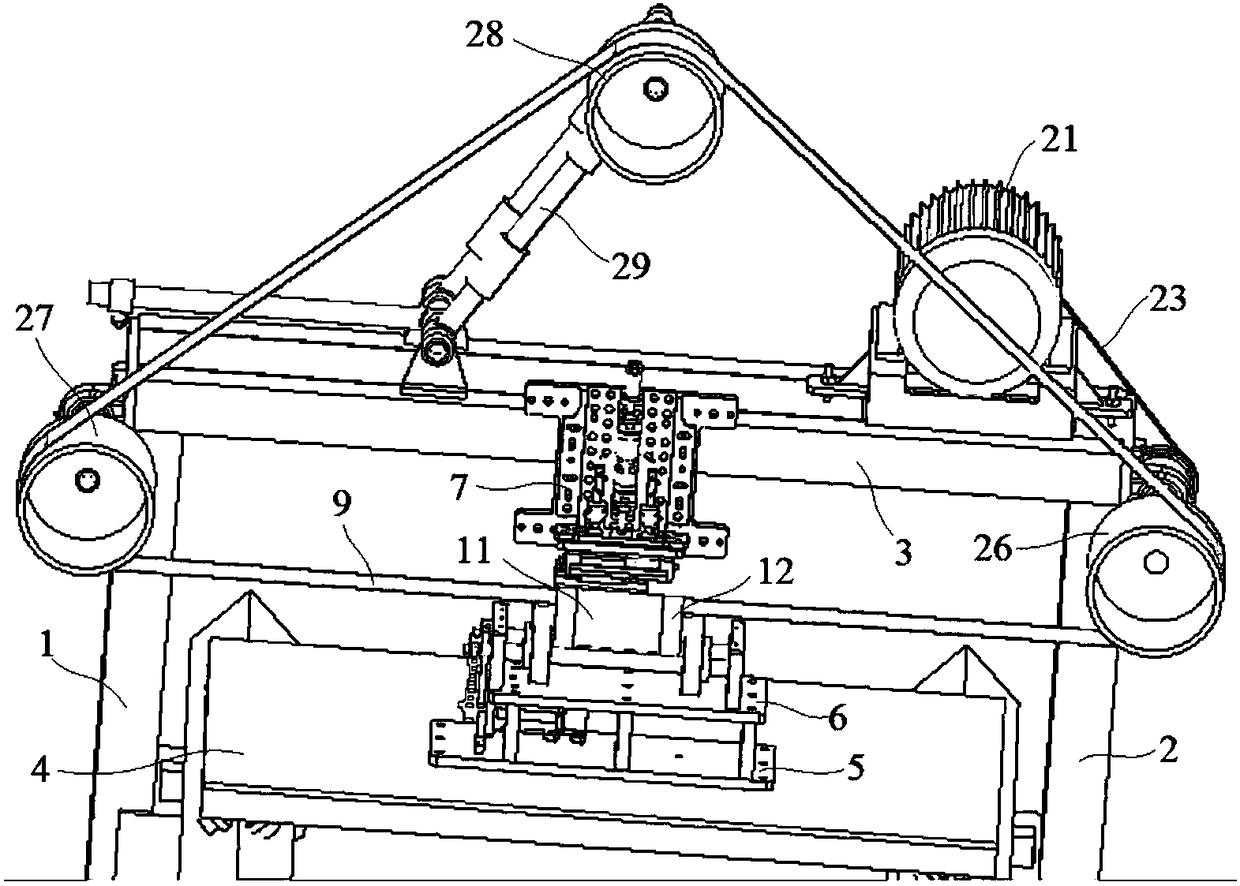

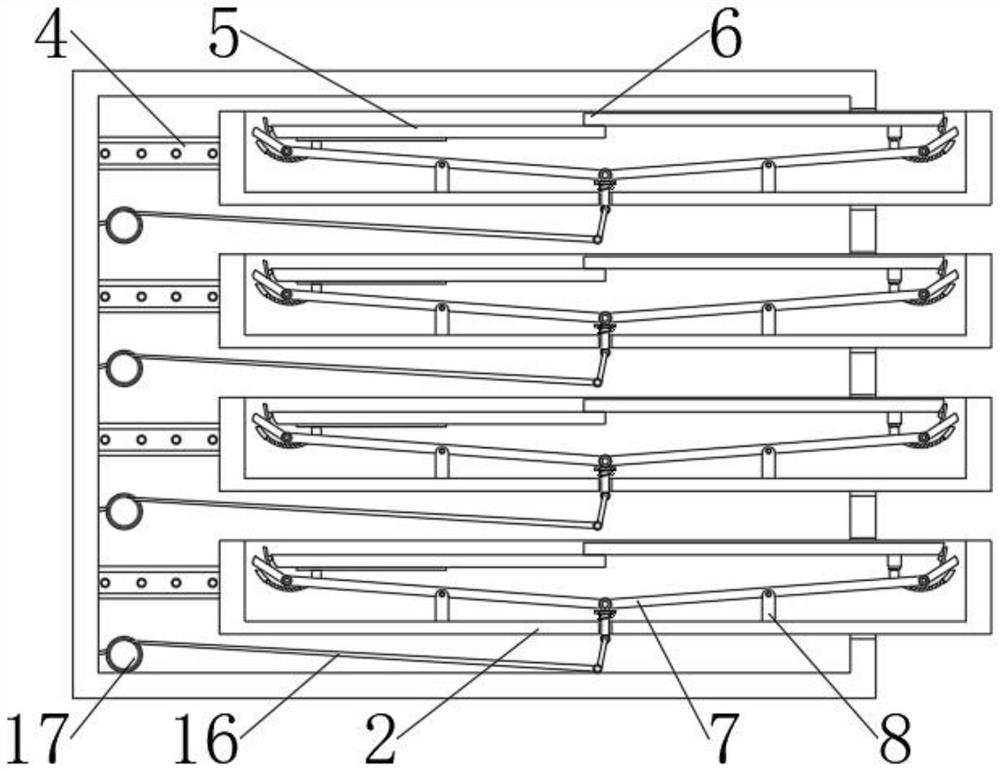

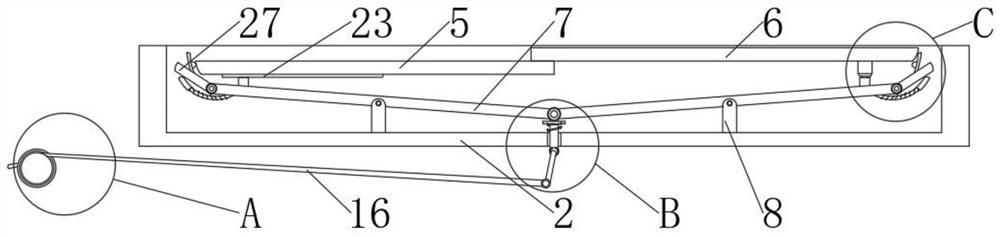

High-precision slitting and rewinding device for high-barrier thermal shrinkage film production

InactiveCN109592455AStay tightImprove cutting effectArticle deliveryWebs handlingEngineeringMechanical engineering

The invention discloses a high-precision slitting rewinding device for high-barrier thermal shrinkage film production. The high-precision slitting rewinding device comprises a base and a box body, wherein an unwinding roller and a winding roller are symmetrically and rotationally arranged on the left side and the right side of the interior of the box body, two first guide rollers are rotationallyinstalled at the part, on the right side of the unwinding roller, inside the box body, two second guide rollers are rotationally arranged at the parts, on the left side of the winding roller, inside the box body, two through holes are symmetrically formed in a top plate of the box body, and two parallel rollers are symmetrically and rotationally arranged at the parts, on the inner sides of the twothrough holes, of the upper side of the top plate of the box body. According to the high-precision slitting rewinding device, the first guide rollers, the parallel rollers and the second guide rollerare arranged in a staggered mode, so that a shrinkage film in the moving process is tightened, the shrinkage film is kept in a tight state in the cutting process, then the cutting effect is improved,and then the cutting precision is improved; and the height of lifting frames is adjusted by rotating second screw rods, so that pressing rollers are tightly attached to the shrinking film on the parallel rollers, and it is ensured that the shrinking film is kept tight during cutting.

Owner:SHANDONG ZHONGSU TAIFU TECH

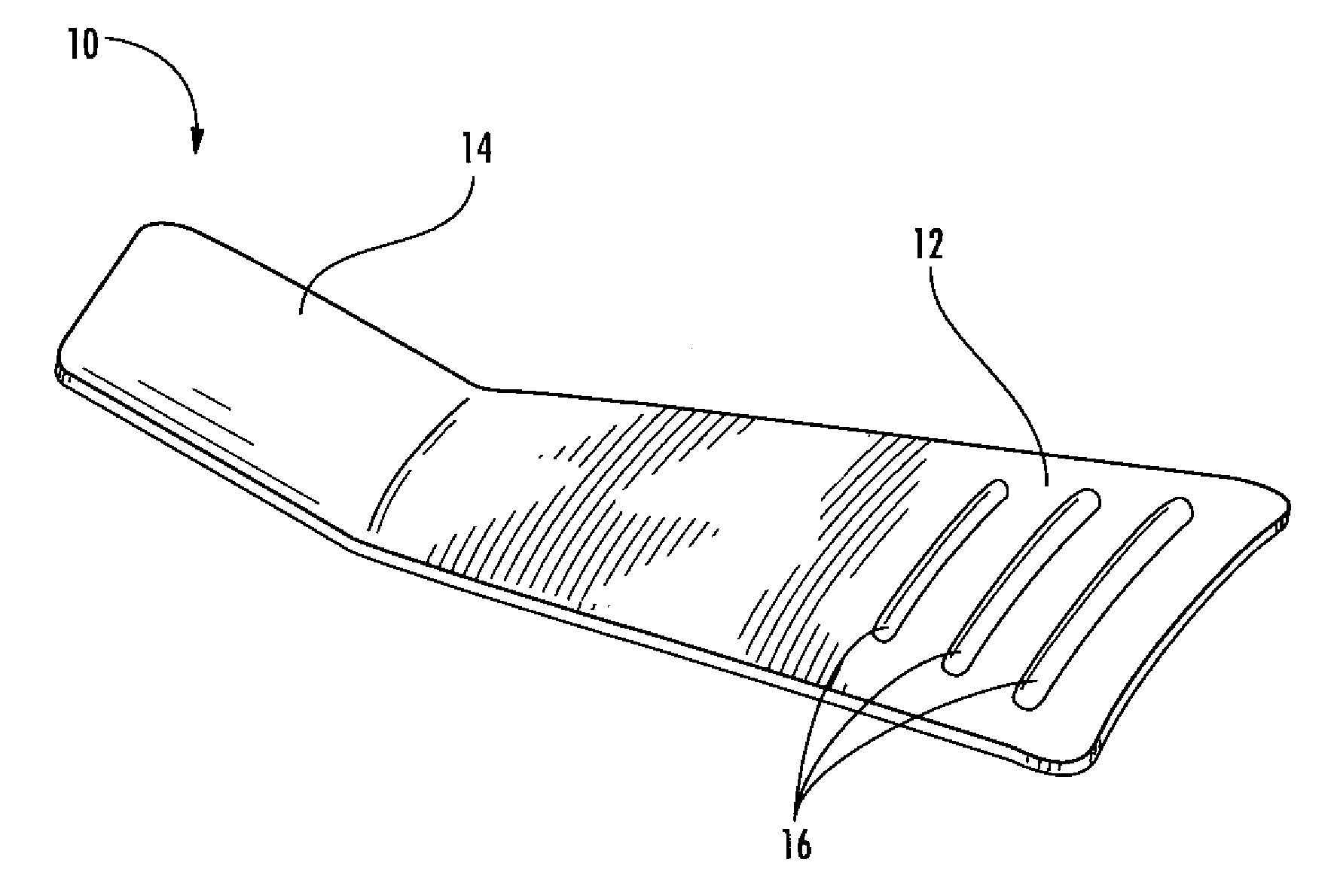

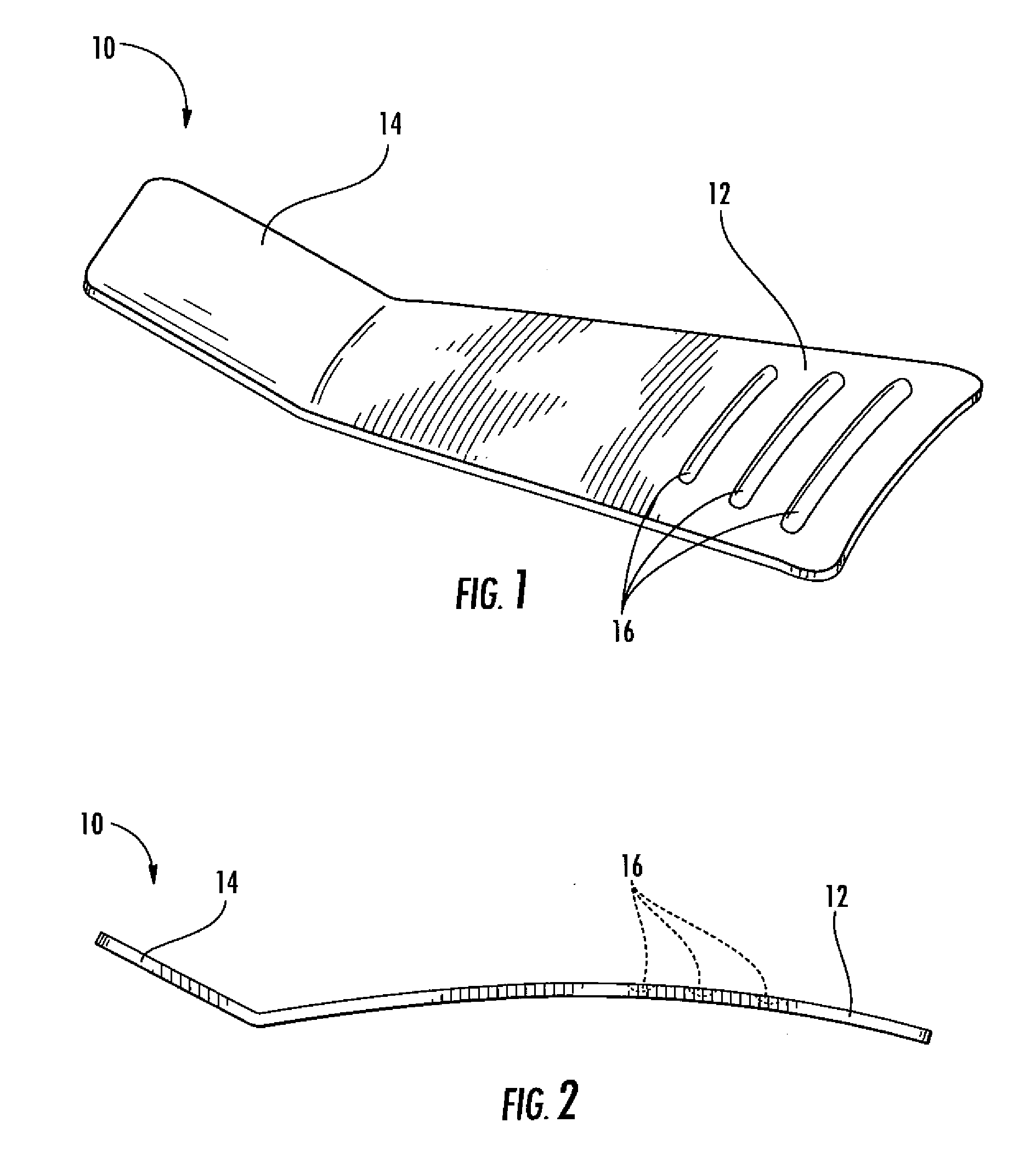

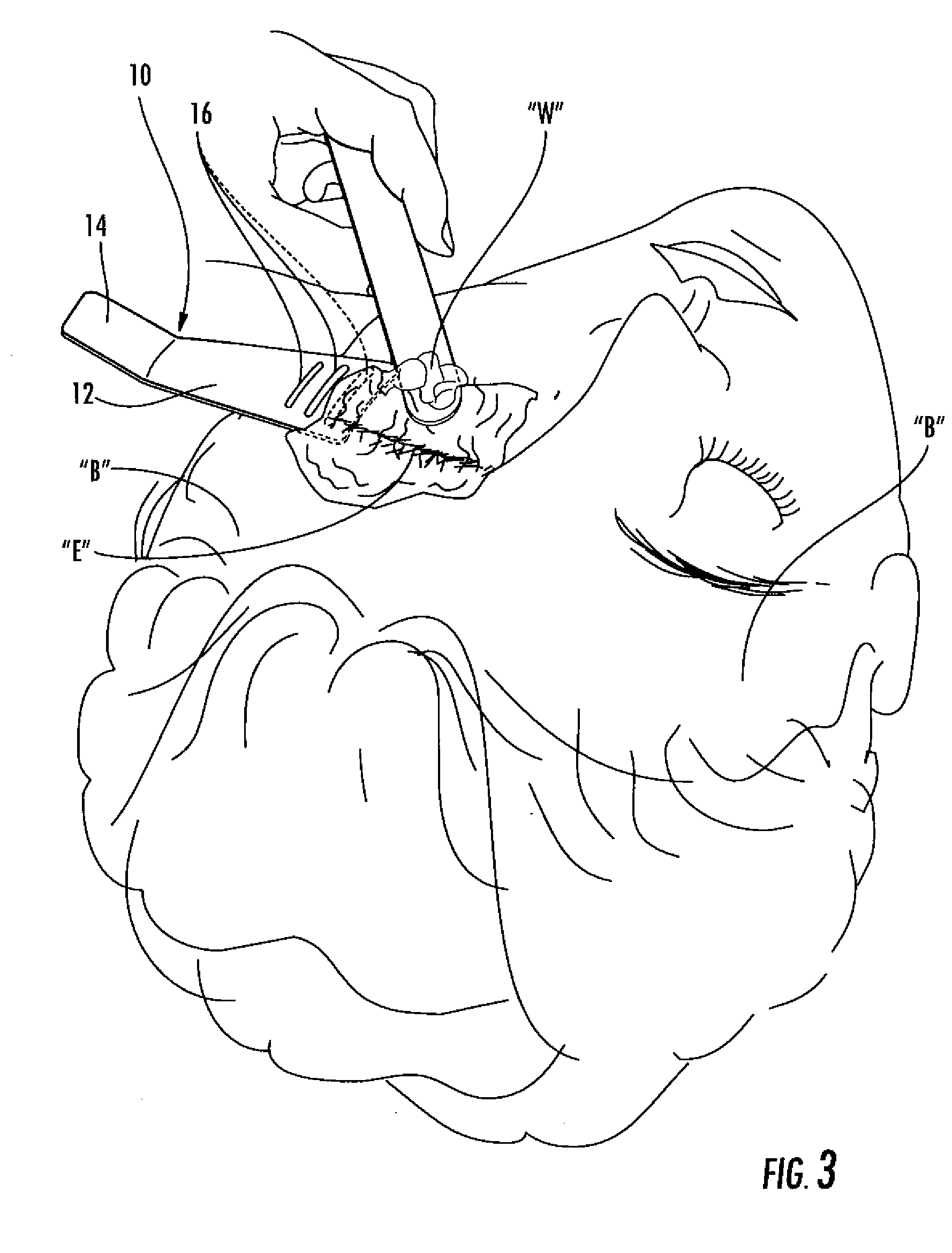

Hair removal appliance and method of using same

An appliance for aiding in the removal of a hardened wax from a person's body includes a curved member defining a handle for being grasped by a user and a substantially flat spatula for positioning on a person's skin. Cavities are formed in the spatula for receiving a wax in an initially liquid state and allowing the wax to harden within the cavity so that the wax becomes attached to the appliance. The cavities can be linear grooves formed in the spatula, or holes that penetrate all the way through the spatula.

Owner:MCMILLAN ANNA +1

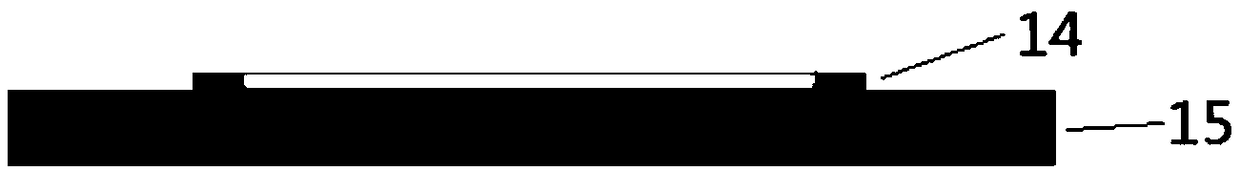

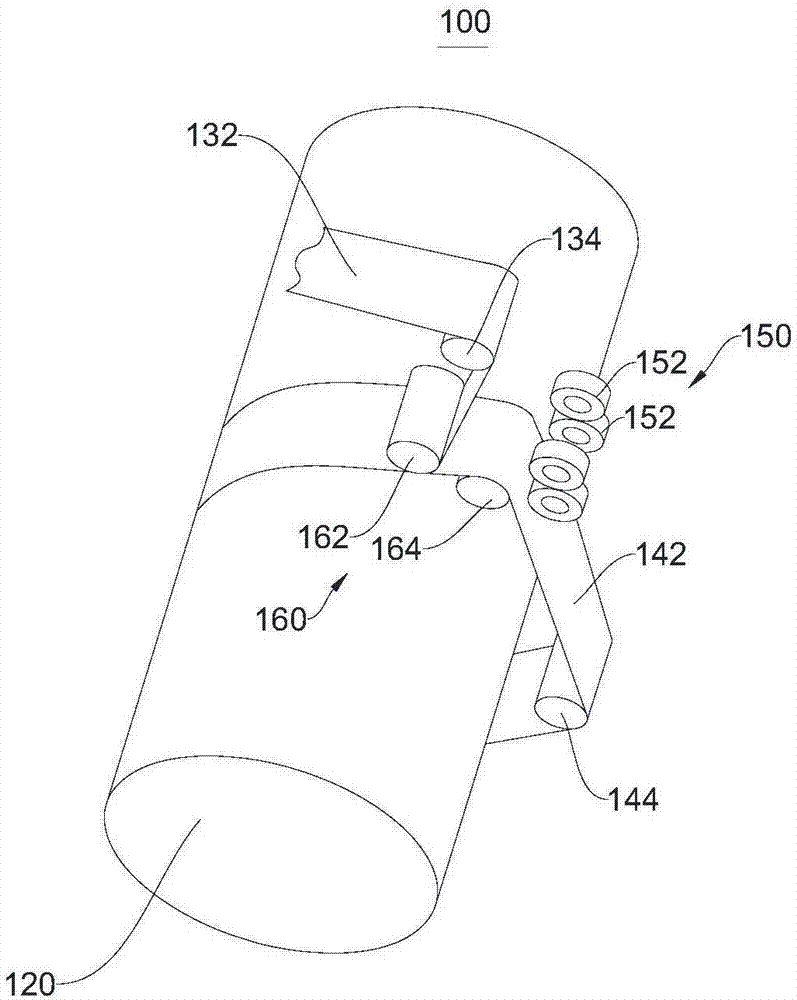

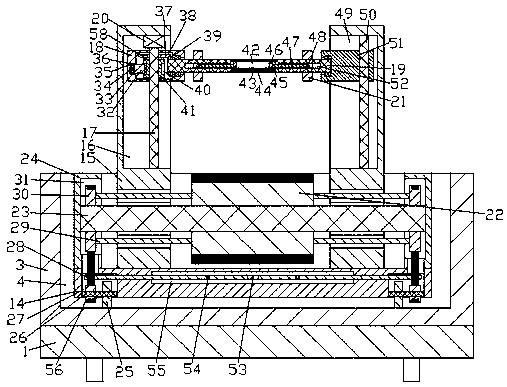

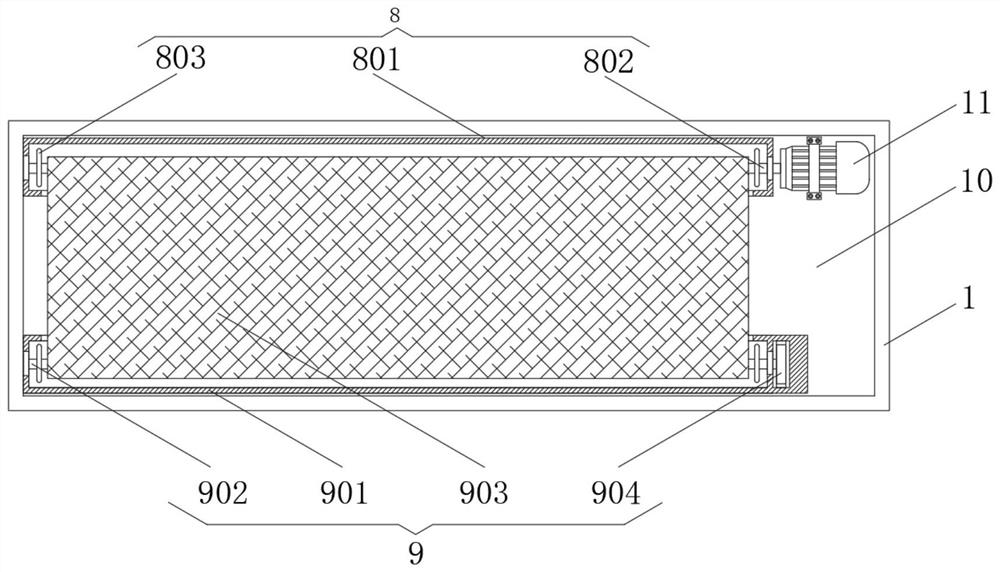

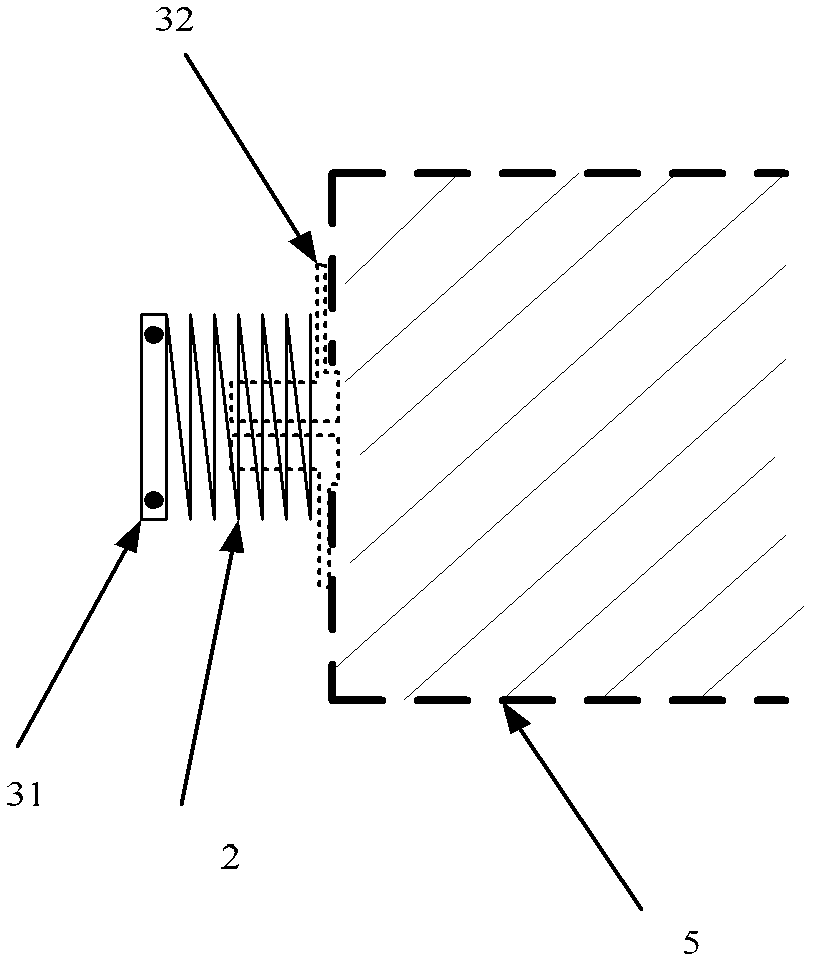

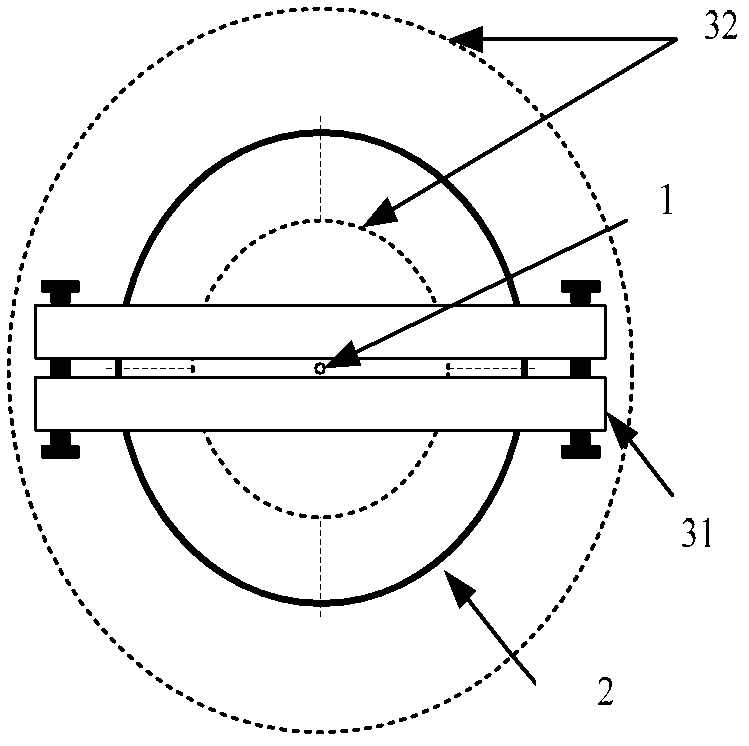

A vacuum attachment apparatus for contact lithography of a flexible thin film substrate

ActiveCN109143791AIncrease pressureImprove uniformitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusContact formationLithographic artist

The invention provides a vacuum attachment device for contact lithography of a flexible film substrate, comprising a vacuum pump, a frame, a flapper valve, a support table limiter, a vacuum chamber, amask support table, a bleed valve, a vacuum gauge, a top pressure mechanism, a sealing door opening / closing mechanism, a sealing door, a film holder, a flexible film, a sealing pad, and a photolithography mask. Wherein the mask support table can carry the photolithography mask and the film to be attached to move into and out of the vacuum chamber, the lithography mask is separated from that flexible film and spaced apart with the sealing pad, the support table limiter realizes positioning of the mask support table, the sealing door is closed, the vacuum pump and vacuum gauge control the degree of vacuum, As that action of the top pressure mechanism lowers the film support, the flexible film is in close contact with the sealing pad on the surface of the mask plate to form an airtight space, the pressure difference introduce by the vacuum is broken outside the airtight space by the bleed valve, the airtight space is compressed, the flexible film is closely adhered to the surface of themask plate, the mask support table is taken out and the mask plate and the flexible film are treated as a whole to be exposed.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

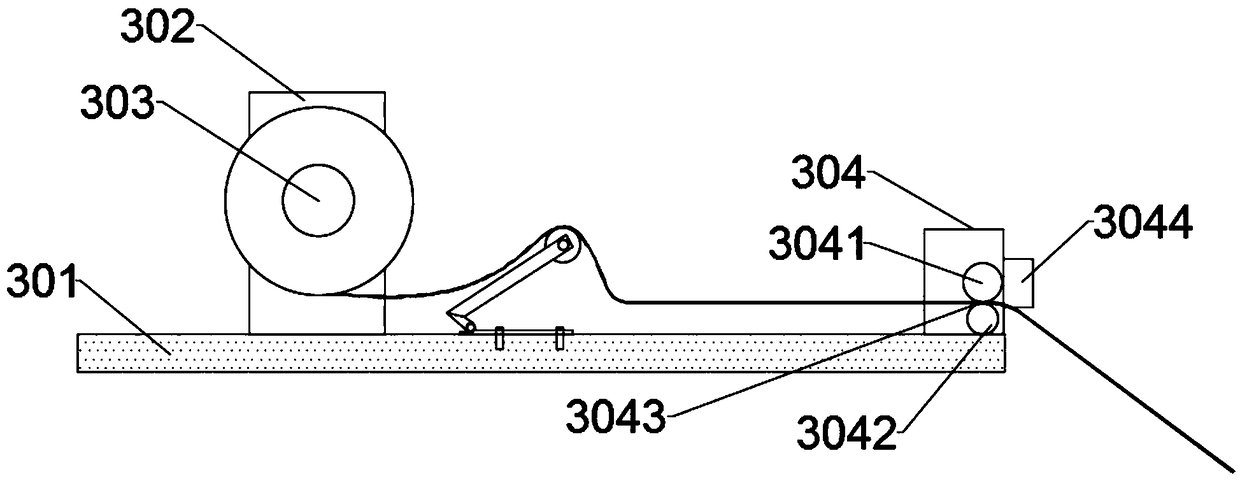

Fastening-type yarn waxing mechanism for spinning

The invention discloses a fastening-type yarn waxing mechanism for spinning. The mechanism comprises a rack, wherein a waxing assembly and a yarn transmission assembly are disposed on the rack; the waxing assembly comprises vertical plates disposed on two sides of the rack; each of the adjacent sides of the vertical plates is correspondingly connected to an expansion rod; the expansion rods are disposed horizontally; each expansion rod comprises a fixed rod and a movable rod; the fixed rod is connected to the vertical plate; a fixation ring sleeves the fixed rod; four notches are formed at equal intervals on the fixation ring; the fixation ring is connected to a triangular plate by the notches; the triangular plates are connected to the vertical plates; one end of each of the two movable rods is correspondingly equipped with a fixation box; a fixation disk sleeves each movable rod; multiple installation holes are formed in the fixation disk; the fixation disk is firmly connected to the fixation box by the installation holes; a groove is formed correspondingly on each of the adjacent sides of the two fixation boxes; a wax block used for yarn waxing is disposed in each groove; multiple round grooves are formed in the upper side and the lower side of the groove; hoodles are disposed in the round grooves; gas pumps are disposed on both of the vertical plates; and each gas pump is connected to the expansion rod on the corresponding side.

Owner:SUZHOU KANGJIAN TEXTILE

Yarn waxing mechanism applied to spinning

The invention discloses a yarn waxing mechanism applied to spinning. The mechanism comprises a rack, wherein a waxing assembly and a yarn transmission assembly are disposed on the rack; the waxing assembly comprises vertical plates disposed on two sides of the rack; each of the adjacent sides of the vertical plates is correspondingly connected to an expansion rod; the expansion rods are disposed horizontally; one end of each expansion rod is correspondingly equipped with a fixation box; each of the adjacent sides of the two fixation boxes is correspondingly equipped with a groove; wax blocks used for yarn waxing are disposed inside the grooves; multiple round grooves are formed in the upper side and the lower side of each groove; hoodles are disposed in the round grooves; gas pumps are disposed on the vertical plates; and the gas pumps are connected to the expansion rods on the corresponding sides. The mechanism disclosed by the invention has the advantages of a simple structure, convenient use and fewer yarn losses, etc.

Owner:SUZHOU KANGJIAN TEXTILE

Uniform yarn waxing mechanism for spinning

The invention discloses a uniform yarn waxing mechanism for spinning. The mechanism comprises a rack, wherein a waxing assembly and a yarn transmission assembly are disposed on the rack; the waxing assembly comprises vertical plates disposed on two sides of the rack; each of the adjacent sides of the vertically plates is correspondingly connected to an expansion rod; the expansion rods are disposed horizontally; one end of each of the two expansion rods is correspondingly equipped with a spiral vertical rod; the spiral vertical rod comprises a U-shaped plate; the U-shaped plate is connected to the expansion rod; one rotary bearing is disposed correspondingly on the upper end and the lower end of the U-shaped plate; a screw rod is disposed between the rotary bearings; a stepping motor connected to the screw rod is disposed on the top of the U-shaped plate; a connecting part is disposed on the screw rod; the connecting part is connected to a fixation box; a groove is formed correspondingly in each of the adjacent sides of the two fixation boxes; a wax block used for yarn waxing is disposed in the groove; multiple round grooves are formed in the upper side and the lower side of the groove; hoodles are disposed in the round grooves; gas pumps are disposed on the vertical plates; and each gas pump is connected to the expansion rod on the corresponding side. The mechanism disclosed by the invention has the advantages of a simple structure, convenient use and fewer yarn losses, etc.

Owner:SUZHOU KANGJIAN TEXTILE

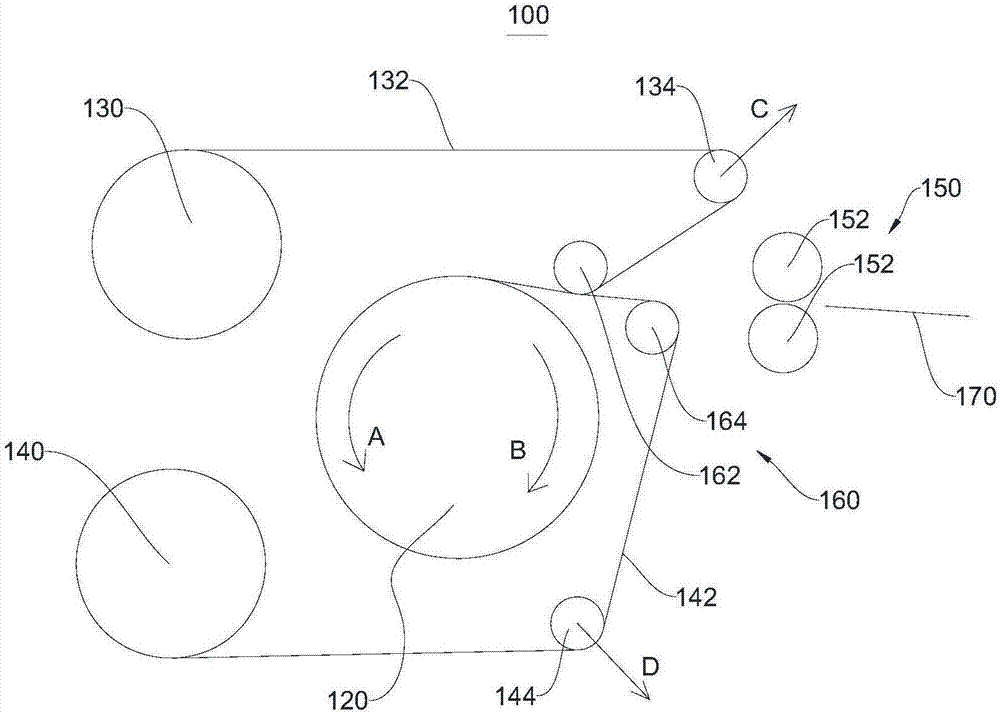

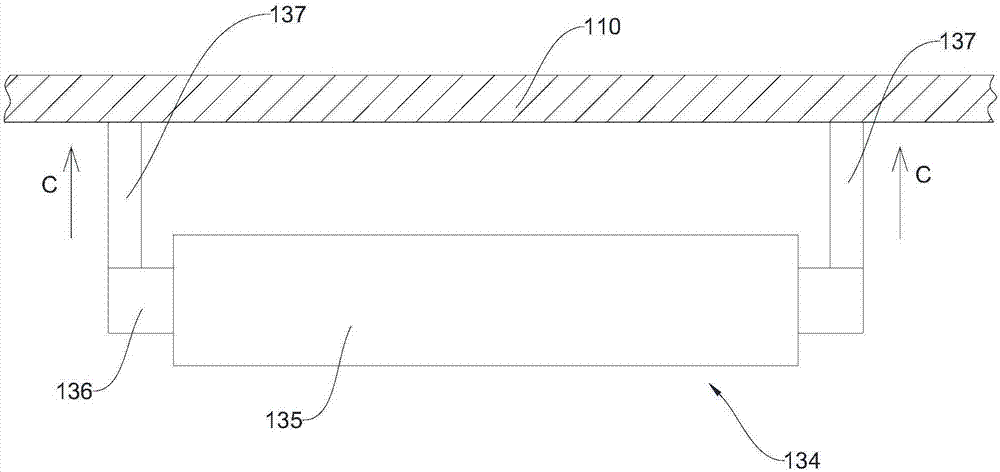

Medium expiration and inspiration device

The invention relates to the field of storage devices, and discloses a medium expiration and inspiration device. The medium expiration and inspiration device comprises a roller, a first winding shaft, a second winding shaft, a first conveying belt, a second conveying belt and a first tension guide roller. The first conveying belt and the second conveying belt are both wound on the roller, and can commonly clamp a medium; and the roller is rotated to wind the two conveying belts thereon and to store the sheet medium on the peripheral side thereof. The other ends of the first conveying belt and the second conveying belt are wound on the first winding shaft and the second winding shaft; and the first winding shaft and the second winding shaft are rotated to unwind the first conveying belt and the second conveying belt on the roller to split out the medium. The first tension guide roller with a displacement tendency is arranged between the first winding shaft and the roller for keeping the first conveying belt tight to achieve more stable operation.

Owner:SHENZHEN YIHUA COMP +2

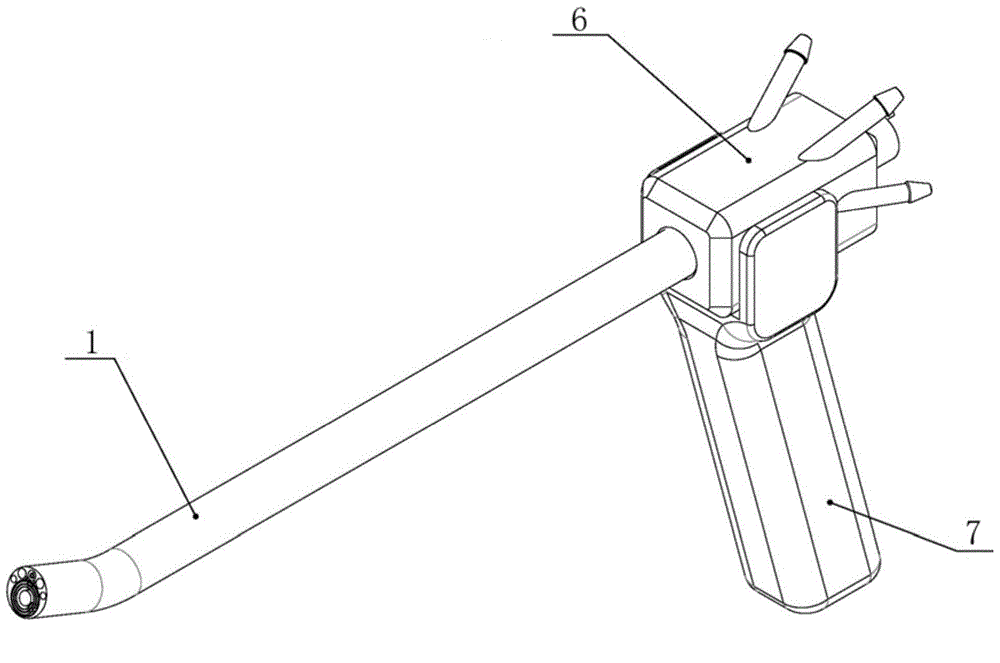

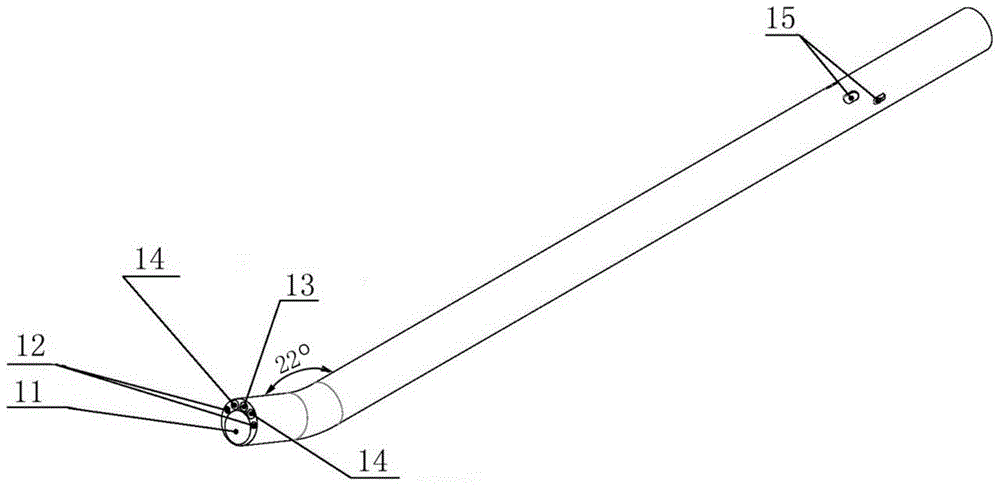

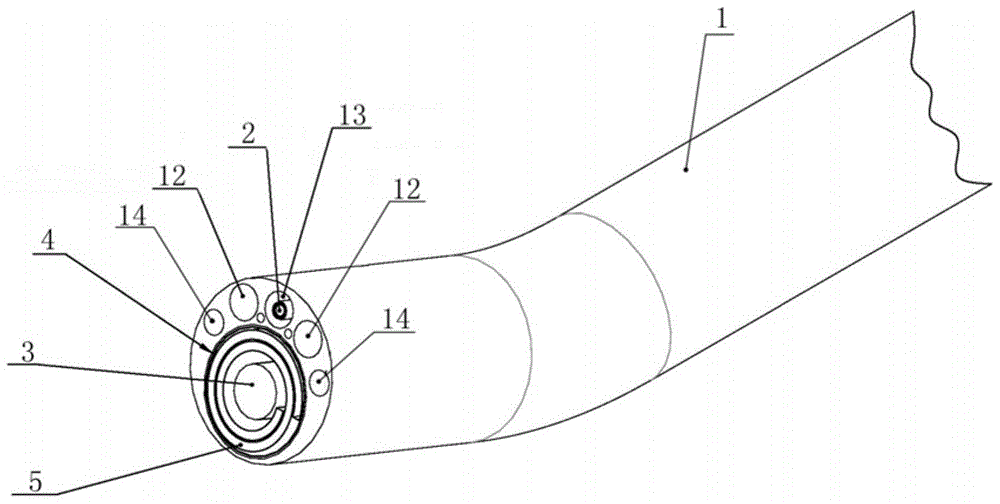

Endoscopic surgery system aiming at endometrial repair and applications of endoscopic surgery system

ActiveCN105769304AAvoid operabilityAvoid painSuture equipmentsInternal osteosythesisEndoscopic sinus surgeryEndoscopic surgery

The invention discloses an endoscopic surgery system aiming at endometrial repair and applications of the endoscopic surgery system, belonging to the technical field of medical apparatus and instruments. The system comprises a multi-cavity sleeve with a plurality of processing channels, a visible imaging system, a sacculus placement apparatus, a flexible apparatus and the like, wherein the multi-cavity sleeve is provided with a large processing channel, a visible endoscope channel, flexible apparatus channels and water outlet channels; the visible imaging system is used for providing a visible environment in the endometrial repair process, and is placed in the visible endoscope channel; the sacculus placement apparatus is used for conveying a collagen membrane into the uterus, spreading the collagen membrane, keeping the attaching state of the collagen membrane and the uterus wall, and conveying the collagen membrane into the uterus through the large processing channel of the multi-cavity sleeve; the flexible apparatus is used for enabling the collagen membrane to reach the preset repair position and flat spreading the collagen membrane after the collagen membrane is placed into the uterus. With the endoscopic surgery system, the examination for the uterus wall, the placement and spreading of the collagen membrane, the tight attaching of the collagen membrane to the uterus wall and other operations can be realized under the visible condition, and therefore, the surgery success rate and efficiency are greatly improved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

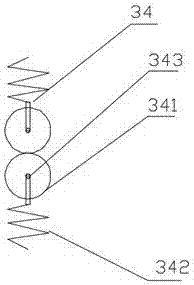

Doubling machine

The invention discloses a doubling machine comprising a machine box. The machine box is internally provided with a horizontal separation plate, a yarn releasing device, a plying device, a second yarn winding hole and a yarn winding device. The doubling machine further comprises a humidifying device arranged between the yarn releasing device and the plying device. A water tank is arranged at the bottom of the humidifying device and is internally provided with an ultrasonic nebulizer. A nebulization box is fixed to the top end of the water tank and is a hollow box. The side, close to the yarn releasing device, of the nebulization box is provided with a yarn inlet. The side, opposite to the yarn inlet, of the nebulization box is provided with yarn pressing roller sets of the same number. Each yarn pressing roller set comprises two rollers. The axes of the rollers are parallel in the longitudinal plane. The rollers make contact with one another. Each yarn pressing roller set further comprises a roller frame. The two ends of rotary shafts of the rollers are fixed to the roller frames. Springs are fixed to the unoccupied ends of the roller frames and are located on the upper sides and the lower sides of the yarn pressing roller sets. The unoccupied ends of two springs are fixed to the nebulization box. Yarn enters the nebulization box through the yarn inlet and penetrates out between two rollers of the yarn pressing roller sets. Through the doubling machine, the doubling quality can be improved effectively.

Owner:TAIHE COUNTY TAIQING TEXTILE RAW MATERIAL CO LTD

Modern logistic consignment device

Owner:诸暨市拉美奇物联网科技有限公司

Method and device for receiving material by plurality of material receiving devices through unloading equipment

The invention discloses a method and a device for receiving a material by a plurality of material receiving devices through unloading equipment. The device comprises a car body, a walking driving device and an electric control device, wherein a driving bracket is arranged on the top of the car body and the walking driving device is placed on the driving bracket; two sides of the driving bracket are respectively provided with driving wheels; the driving wheels are connected with the walking driving device and a transmission plate is arranged above the driving wheels; the driving wheels are connected with the transmission plate in a rolling manner; the other end of the car body is provided with an unloading rotary barrel and the other end of the car body is provided with a redirection rotary barrel; a fixed redirection rotary barrel is arranged below the car body and a rubber belt sequentially winds around the unloading rotary barrel, the redirection rotary barrel and the fixed redirection rotary barrel; wheels are arranged at the bottom of the car body and the wheels are arranged on a walking rail; and the side face of the car body is provided with an electric control device and the electric control device is connected with the walking driving device through a cable. The device disclosed by the invention has the advantages of capability of overcoming defects of traditional material transportation, strong carrying capability, complete protection measure, firm structure, long service life and the like.

Owner:HUADIAN HEAVY IND CO LTD

Assembly type kitchen and bathroom air conditioner dust prevention structure

PendingCN112066537AEasy to useReduce replacement frequencyHeating and ventilation casings/coversElectric machineryEngineering

The invention relates to the technical field of air conditioner dust prevention, and discloses an assembly type kitchen and bathroom air conditioner dust prevention structure. The assembly type kitchen and bathroom air conditioner dust prevention structure comprises a dust prevention outer frame, a dust prevention cover is clamped to the bottom of the inner side wall of the dust prevention outer frame, a first dust prevention net is arranged in the middle of the inner side wall of the dust prevention cover, a sliding groove is formed in one side of the dust prevention cover, and a sliding plate is movably connected to the inner side wall of the sliding groove; and reset springs are arranged on one side of the sliding plate, a buckle device is arranged on the other side of the sliding plate, a mounting plate is arranged on one side in the dust prevention outer frame, a motor is arranged on one side of the mounting plate, a winding mechanism is arranged on the side, close to the motor, of the upper surface of the mounting plate, and a storage mechanism is arranged on the other side of the upper surface of the mounting plate. According to the assembly type kitchen and bathroom air conditioner dust prevention structure, through the arrangement of the mounting plate, the motor, the winding mechanism and the storage mechanism, the motor works to drive winding rollers to rotate, the winding rollers rotate to enable a second dust prevention net with dust after use to be wound around the surfaces of the winding rollers, and then the second dust prevention net is replaced.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

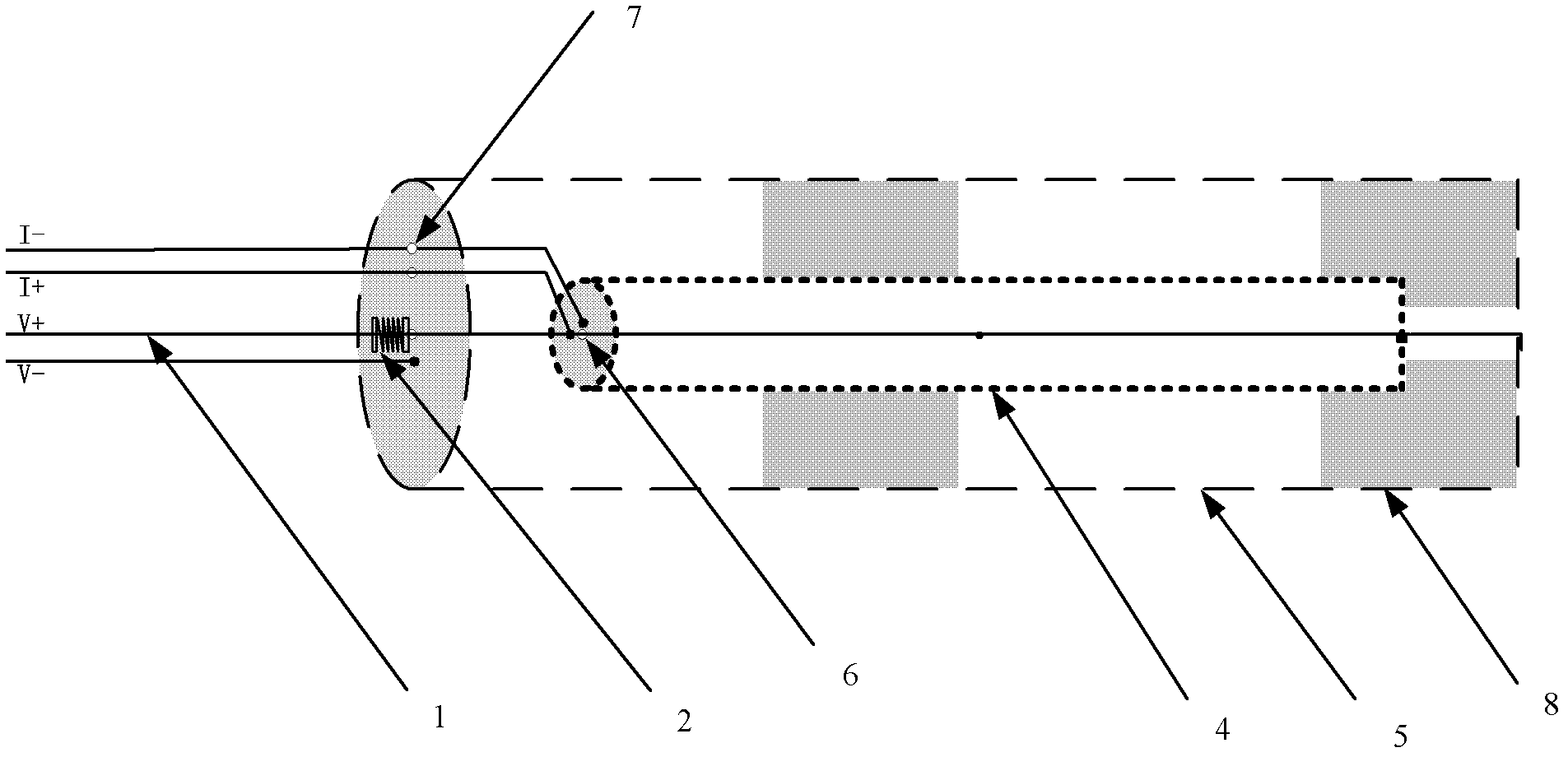

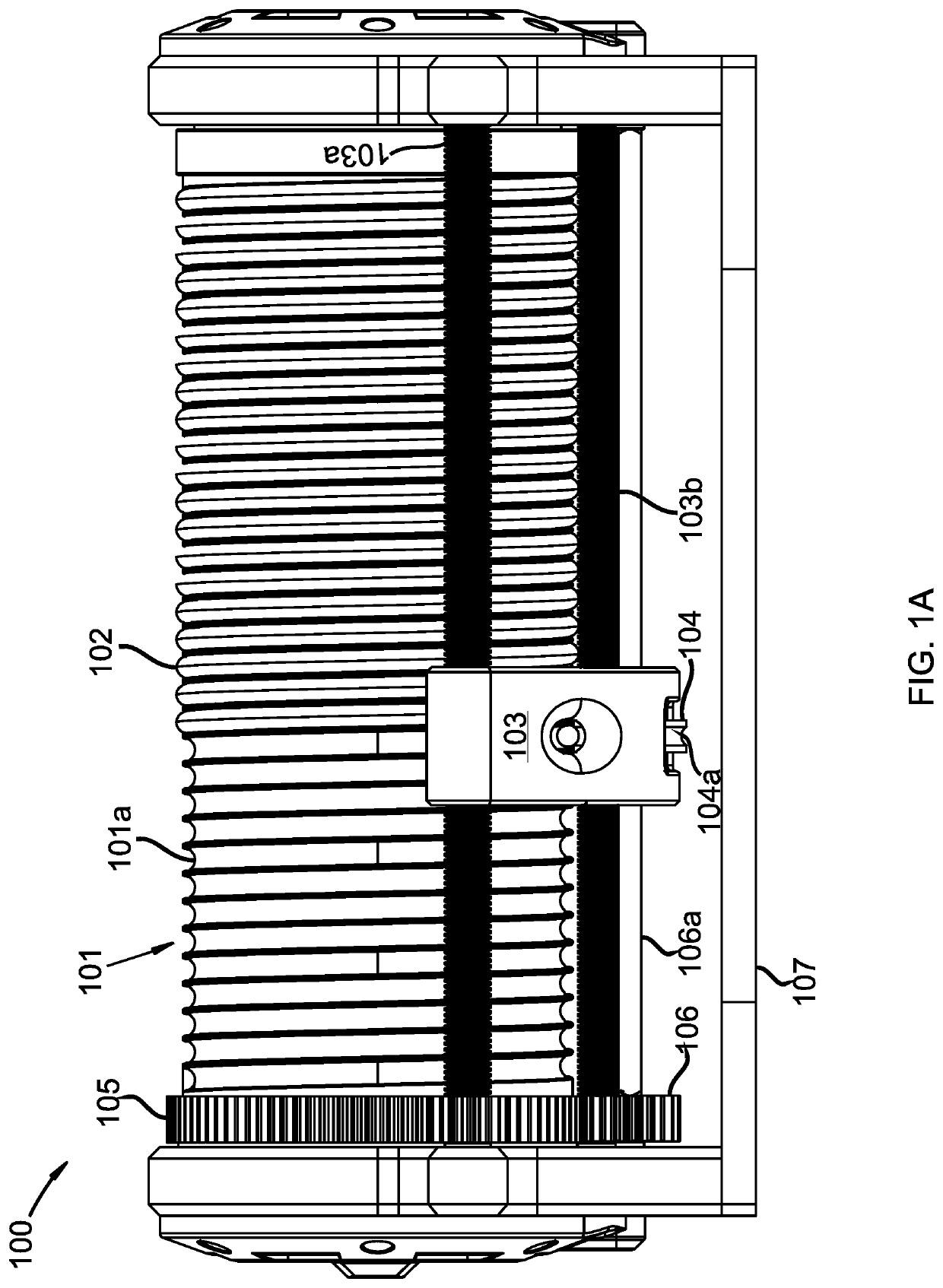

Tension constant resistor capable of calculating difference of alternating current and direct current

ActiveCN102568720AAvoid slackStay tightResistor mounting/supportingCoil/loop resistive elementsCoaxial lineEngineering

The invention provides a tension constant resistor capable of calculating difference of alternating current and direct current, which is applicable to a coaxial-line hang-spring structure and is provided with a tension device enabling a resistance wire to keep in a tight state all the time. The tension constant resistor improves the stability of a resistor structure capable of calculating the alternating current and the direct current. The tension constant resistor comprises an inner metal sleeve and an outer metal sleeve which are coaxial, a mono-wire linear resistance wire is located in the central axial of the inner metal sleeve, the resistance wire adopts a duel-hole return wire method to be connected with a back end face of the inner metal sleeve and then to be connected with the a back end face of the outer metal sleeve in a pressure welding mode. A front end face center hole is respectively arranged in the central positions of front end faces of the inner metal sleeve and the outer metal sleeve, the resistance wire sequentially penetrates through the front end face center holes of the inner metal sleeve and the front end face center hole of the outer metal sleeve, and the tension device enabling the resistance wire to keep in the tight state is arranged at the position where the resistance wire penetrates from the front end face center hole of the outer metal sleeve.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

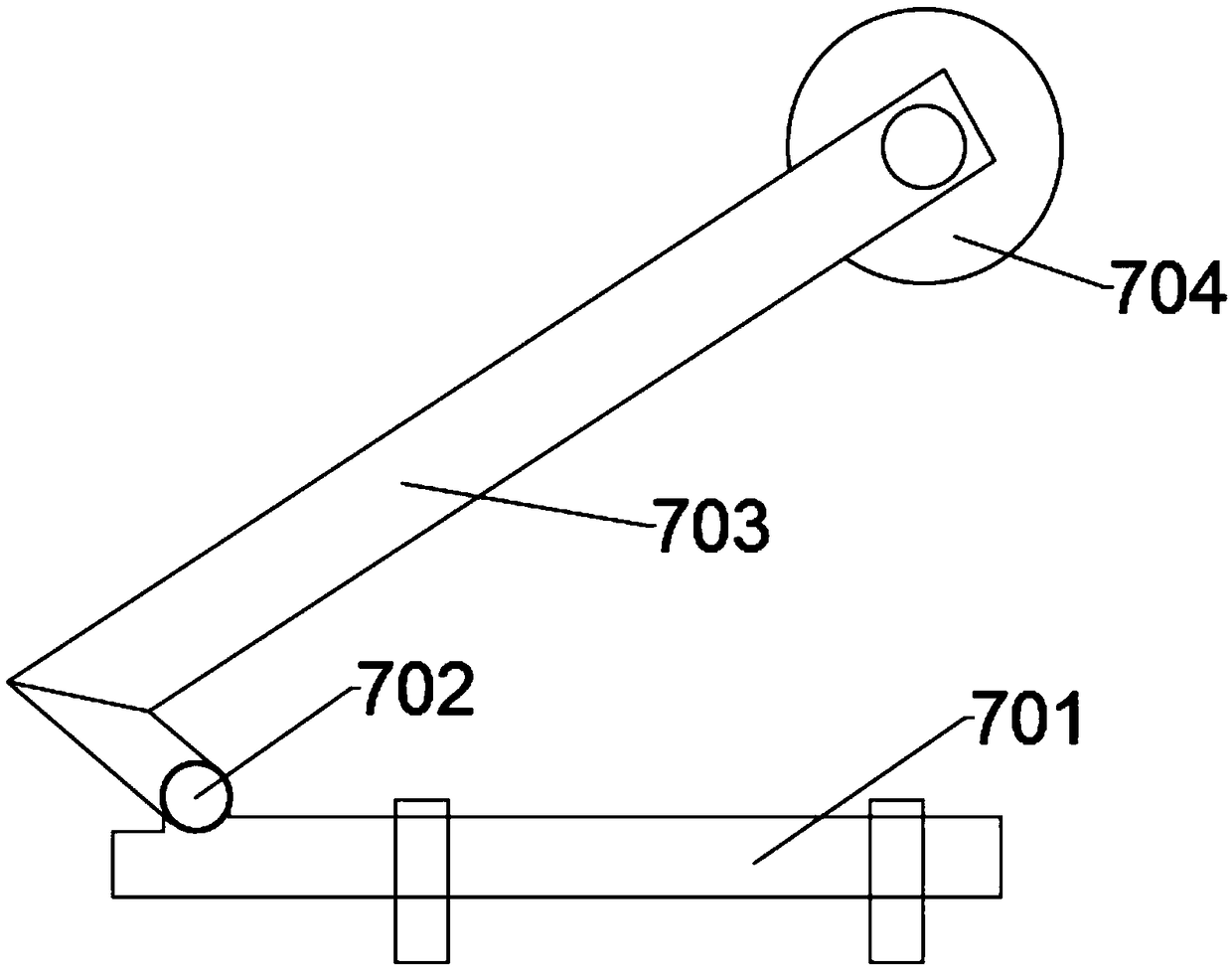

IMT in-mold transfer printing device and method

The invention discloses an IMT in-mold transfer printing device. A bearing base and an injection molding framework base arranged on the upper surface of the bearing base are included; a base materialfeeding mechanism is arranged at the upper end of the injection molding framework base; a waste film winding mechanism for reeling base material waste subjected to injection molding cutting is arranged in the bearing base, and a material receiving tensioning mechanism is further arranged above the waste film winding mechanism; and the upper surface and the lower surface of the injection molding framework base are each provided with an injection molding base material compensating mechanism for compensating for the mold closing extruding length of a base material. The invention further relates to a transfer printing method. A base material passes through the injection molding framework base in the vertical direction; the injection molding framework base performs mold closing, and the injection molding base material compensating mechanisms provide a pressed movement amount of the base material; the injection molding framework base performs mold opening, and the injection molding base material compensating mechanisms automatically return. Due to the scheme, the base material movement amount can be compensated for in the injection molding extruding process, the transfer printing qualityproblem caused by the fact that the surface tension of the base material at the injection molding position is too large is solved, the production quality of in-mold transfer printing is improved, using is convenient and fast, the control principle is simple, and the production quality is improved.

Owner:东莞华誉精密技术有限公司

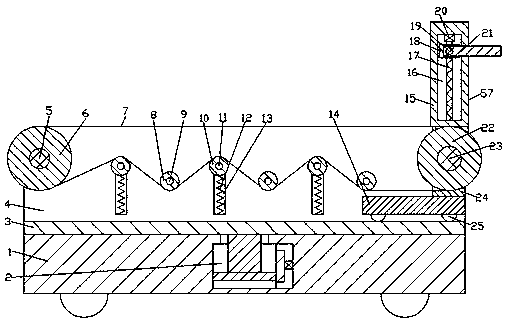

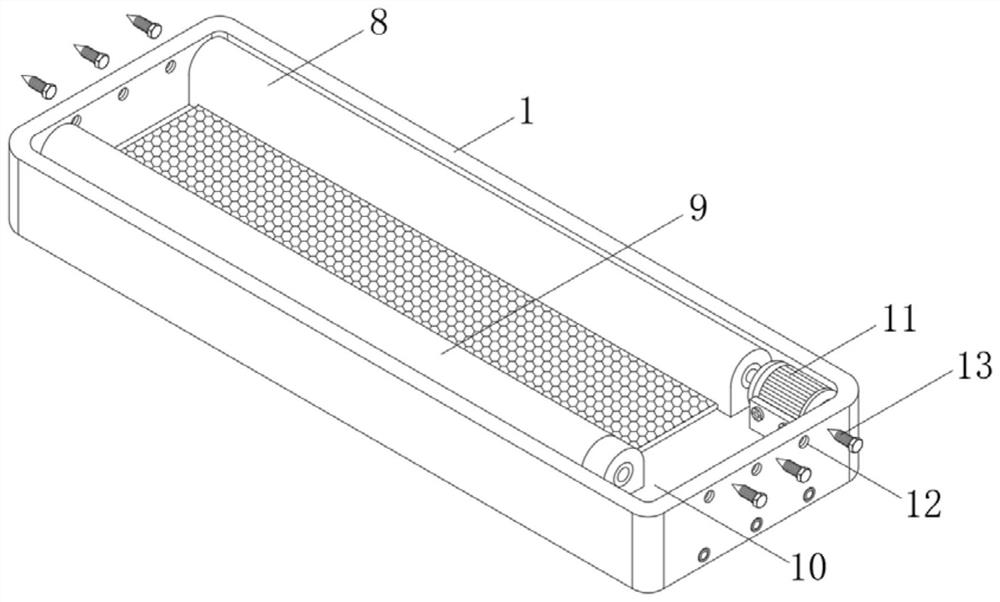

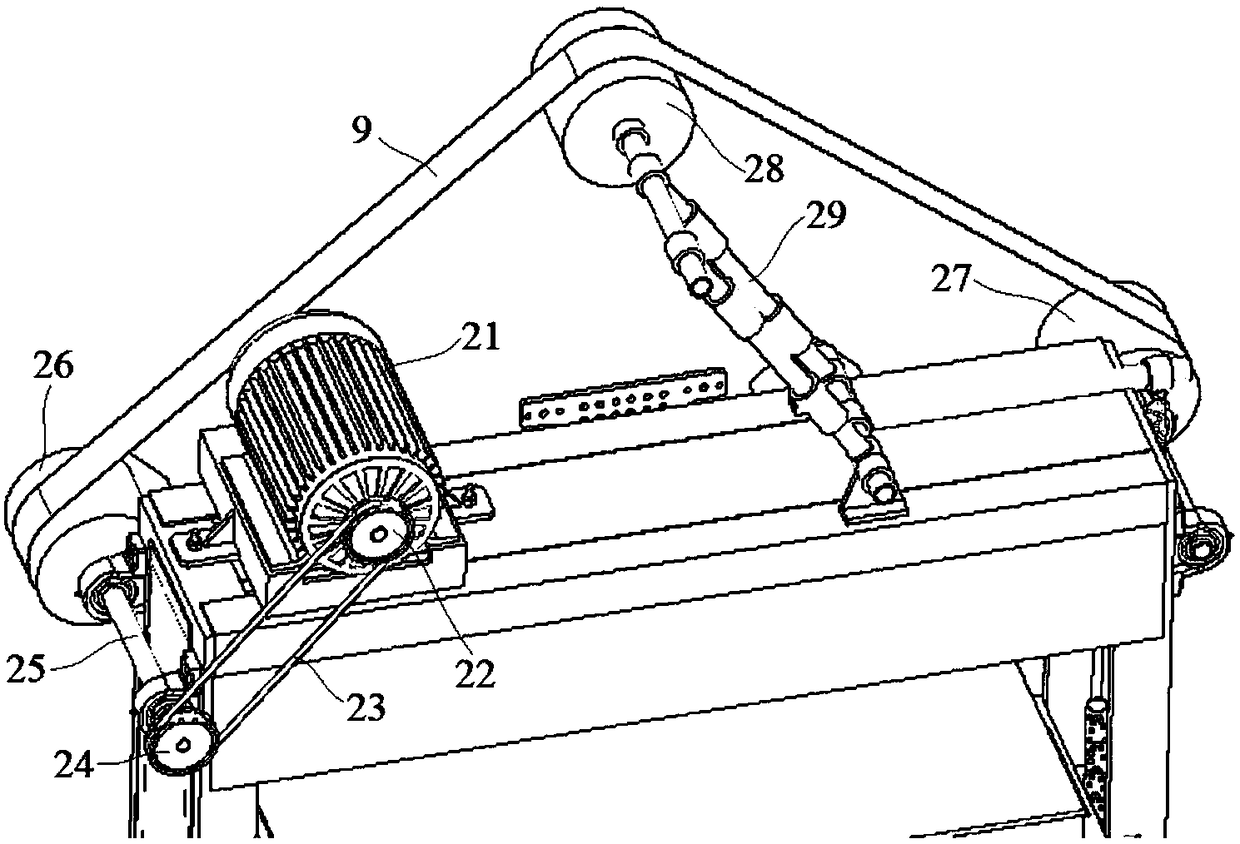

Board polishing device for furniture production

InactiveCN109590864AStay tightIncrease the polishing areaBelt grinding machinesEngineeringMechanical engineering

The invention relates to the field of furniture production, in particular to a board polishing device for furniture production. The board polishing device comprises a housing, a feeding opening, a discharging opening, polishing driving wheels and a polishing belt, wherein the polishing belt is arranged on the two polishing driving wheels in a surrounding manner; a row of pressing wheels which arehorizontally and uniformly arranged are arranged on the polishing belt on the lower side, and are mounted on a horizontal lower supporting frame through a rotating shaft; supporting rods which vertically penetrates upwards through a bracket are fixedly connected to two ends of the lower supporting frame; the upper ends of the supporting rods are fixedly connected with a horizontal crossbeam; a horizontal conveying mechanism is horizontally arranged in the feeding opening; and the boards are placed on the mechanism. According to the board polishing device disclosed by the invention, the pressing wheels are arranged, so that the polishing belt is pressed on the board, the polishing region is enlarged, and the polishing efficiency is improved; the boards are pushed on the horizontal conveyingmechanism, and through the block of a pushing plate, the phenomenon of slipping cannot be generated, and the polishing is guaranteed; and a baffle can be recycled, so that the mounting time is shortened, and the production efficiency is improved.

Owner:张玉真

Winch with one-way reverse tensioner

A winch is described that includes a drum, a motor and transmission, and a tensioner. The motor and transmission apply torque to the drum, thereby enabling the drum to draw in and let out a line. The tensioner is positioned adjacent to the drum, such that when the line passes between the tensioner and drum, the line is in frictional contact with the tensioner and drum. The tensioner rotates with a linear speed exceeding a linear speed of the drum as the line is let out from the drum, and rotates freely as the line is drawn onto the drum. Methods for making and using the winch are also described.

Owner:HALL LABS LLC

Cloth cutting machine capable of tidily cutting clothes for rapid production of clothes

InactiveCN112813668ANeatly croppedKeep StraighteningSevering textilesEngineeringMechanical engineering

The invention relates to the technical field of garment production, and discloses a cloth cutting machine capable of tidily cutting clothes for rapid production of clothes. The cloth cutting machine comprises a frame body, wherein a fixing sleeve is fixedly connected to the top of the frame body, a limiting rod is fixedly connected to the inner top wall of the frame body, a movable rod is connected to the interior of the fixing sleeve in a sliding mode, a rocker is movably connected to the top of the movable rod, a fixing plate is fixedly connected to the position, located under the fixing sleeve, of the outer side of the movable rod, and a mounting base is fixedly connected to the bottom of the movable rod. Through the matched use of an inner pressing plate, an upper template and an anti-falling body, when the machine is cutting cloth, the mounting base moves downwards, a transportation gear does not move, the upper template and the inner pressing plate compress the cloth, and the upper template and the anti-falling body on the inner pressing plate can keep compressing the cloth when the cutting device moves downwards, so that the cloth is kept in a tight state when being cut, and the cut edge is kept neat.

Owner:HUNAN UNIV OF TECH

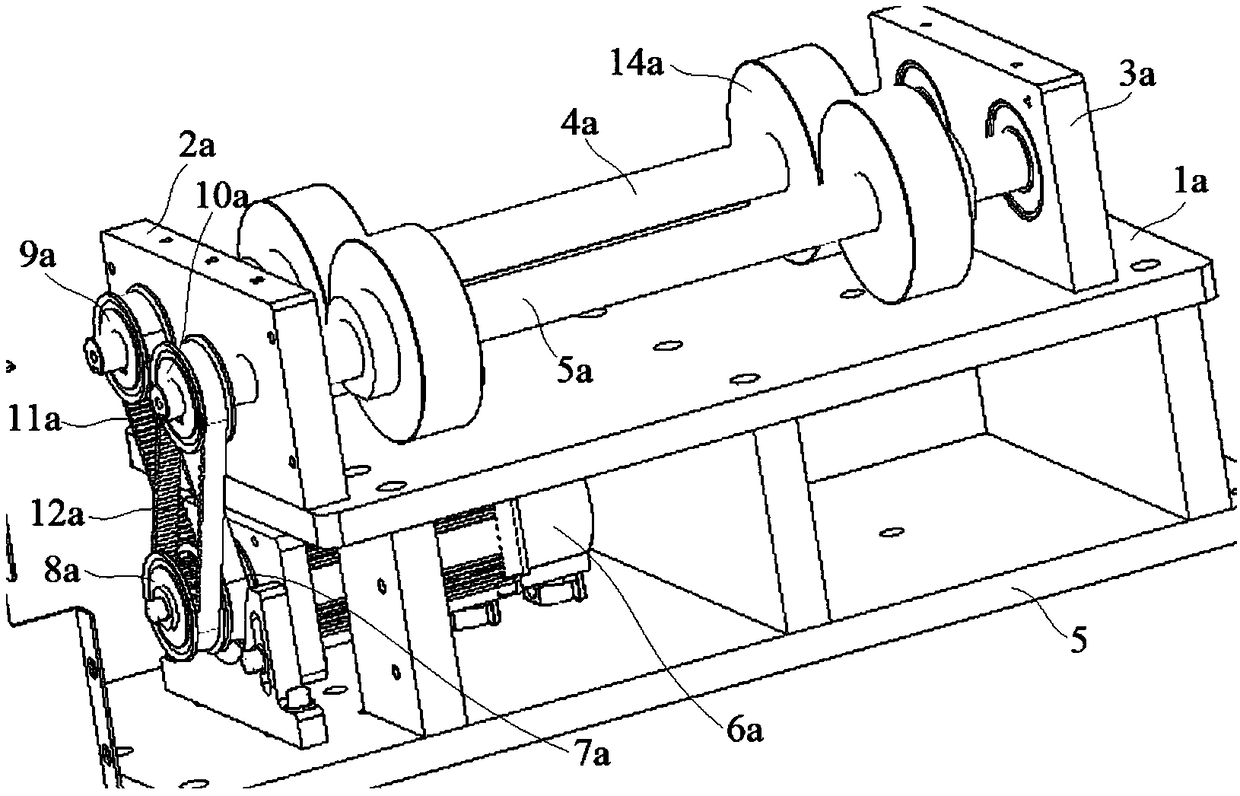

Automatic metal surface treatment device

ActiveCN108177061AAutomatic straight wire drawingGuaranteed drawing qualityGrinding drivesBelt grinding machinesDrive wheelPiston rod

The invention discloses an automatic metal surface treatment device which comprises a left vertical plate, a right vertical plate, a beam plate, a carrier plate, a base plate, a clamp base, a pressing-down mechanism and an abrasive belt. The left vertical plate and the right vertical plate are arranged in parallel. The beam plate is in bridging connection with the left vertical plate and the rightvertical plate. An output shaft of a motor is provided with a driving wheel, the driving wheel is in transmission connection with a driving auxiliary wheel through a belt, an air cylinder is vertically installed on the front surface of an installation plate, a piston rod of the air cylinder is fixedly connected with a pressing-down plate, a middle shaft is sleeved with a left fixing ring and a right fixing ring from the two ends of a supporting sleeve, the left fixing ring and the right fixing ring make close contact with the two end faces of the supporting sleeve correspondingly, and the supporting sleeve is sleeved with a circular pipe which is fixed through the left fixing ring and the right fixing ring. Straight wiredrawing operation of the metal surface can be automatically achieved,wiredrawing straightness, wire flow uniformity and wiredrawing efficiency are improved, the wiredrawing quality of the metal circular pipe is ensured, and the rate of finished products is improved.

Owner:苏州丰川电子科技有限公司

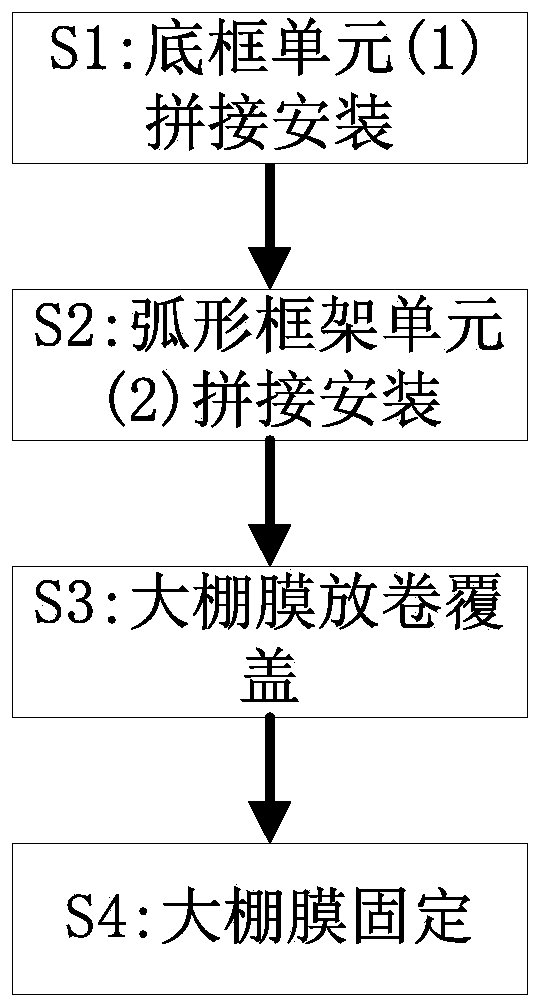

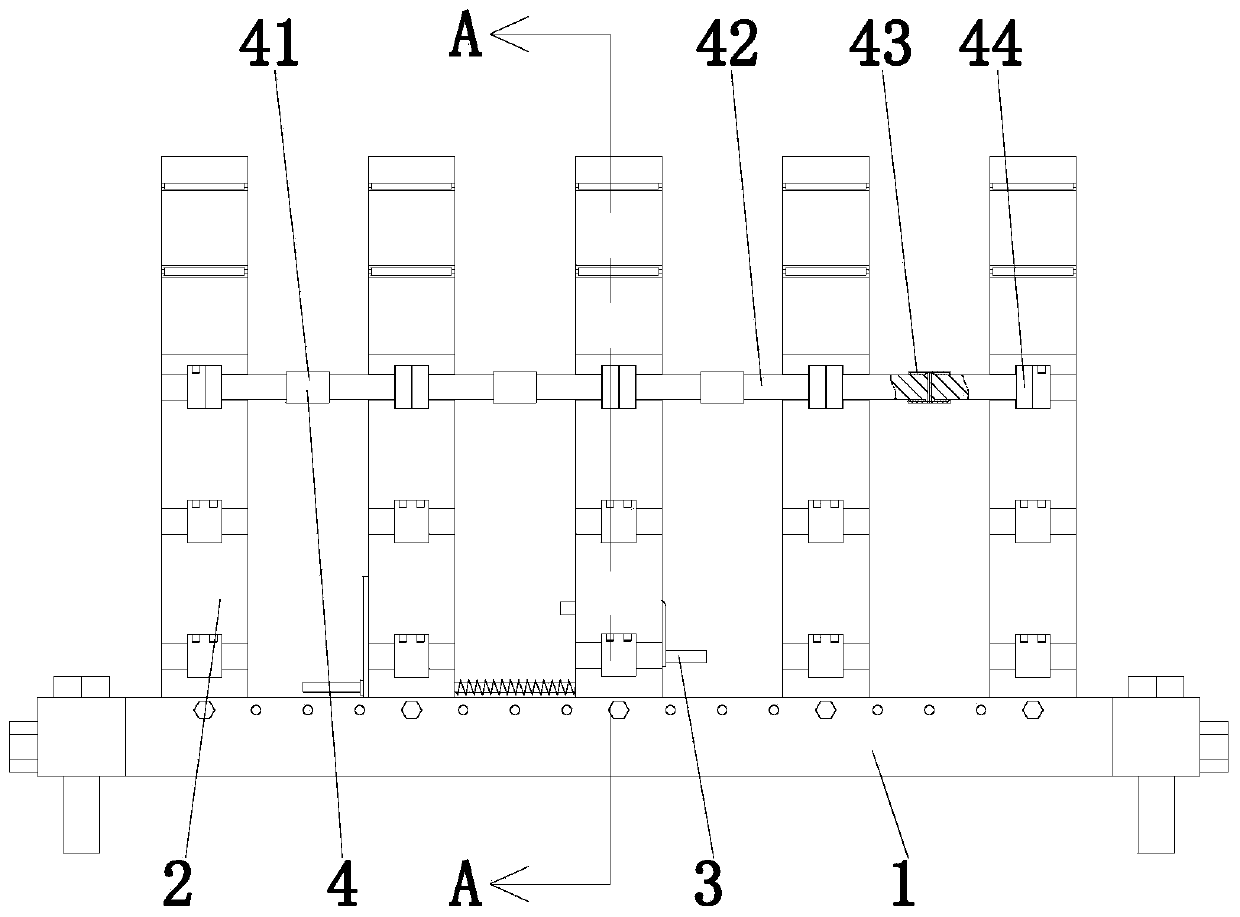

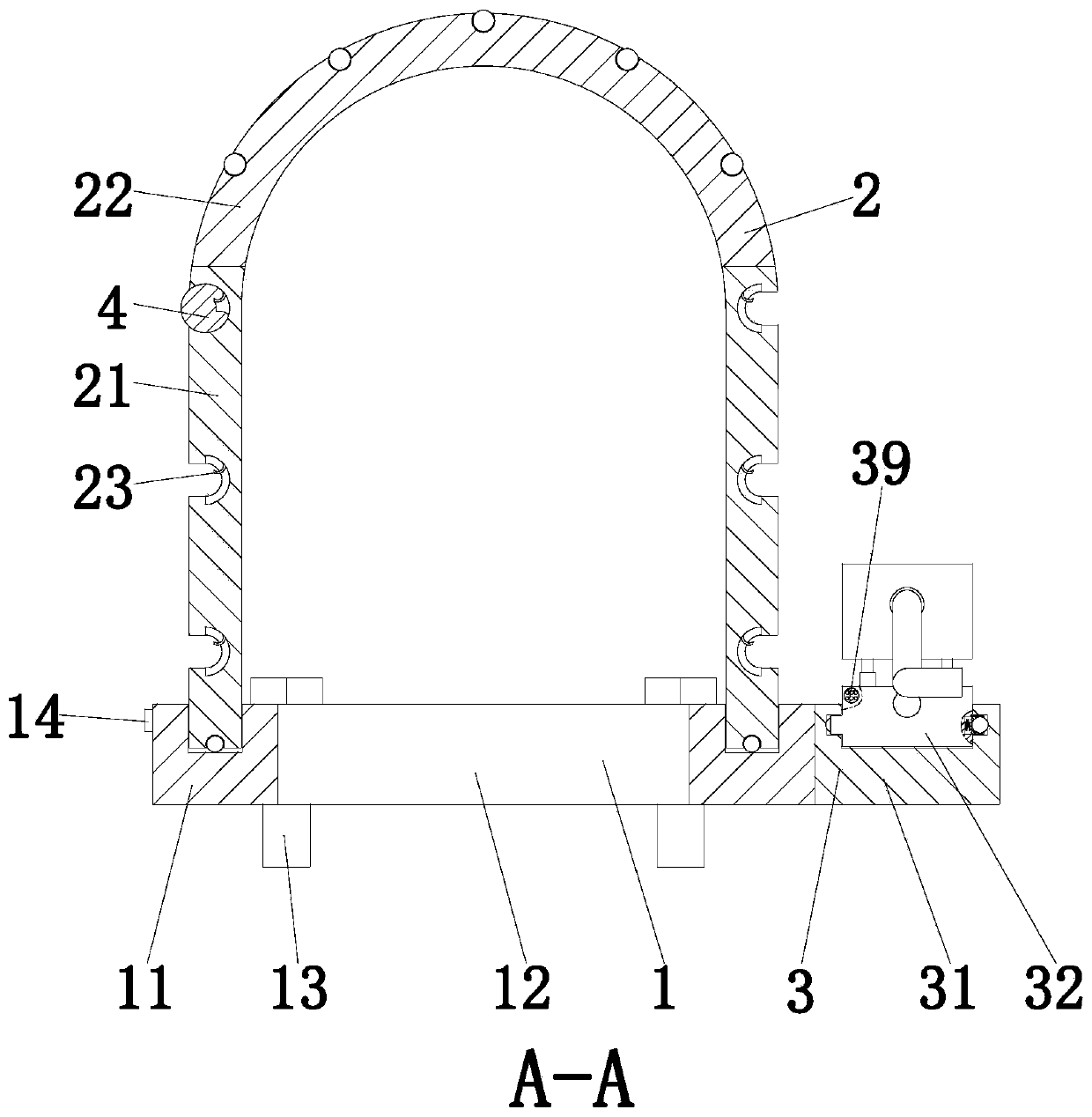

Building method of structural steel frame for agriculture ecologic greenhouse

ActiveCN111527943AGuaranteed compression effectGuaranteed installation qualityClimate change adaptationGreenhouse cultivationEnvironmental resource managementGreenhouse

The invention provides a building method of a structural steel frame for an agriculture ecologic greenhouse. Through cooperation of a bottom frame unit, a curved frame unit, a film placing unit and alimiting unit, building of the structural steel frame for an agriculture ecologic greenhouse can be completed. According to the building method, the difficult problems that at current, in the buildingand using process of a greenhouse framework, a plastic film is paved on the greenhouse framework, the plastic film easily causes friction with the framework to enable the plastic film to be broken, after the plastic film is used, the inner temperature of the greenhouse can be influenced, the plastic film and the greenhouse framework are fixed in a fixing manner of tying down with a rope, the manner of tying down with a rope is not firm, the greenhouse film and the greenhouse framework are loose, and the greenhouse film is easy to come off and break due to strong wind, are solved

Owner:新疆科创天达农业工程有限公司

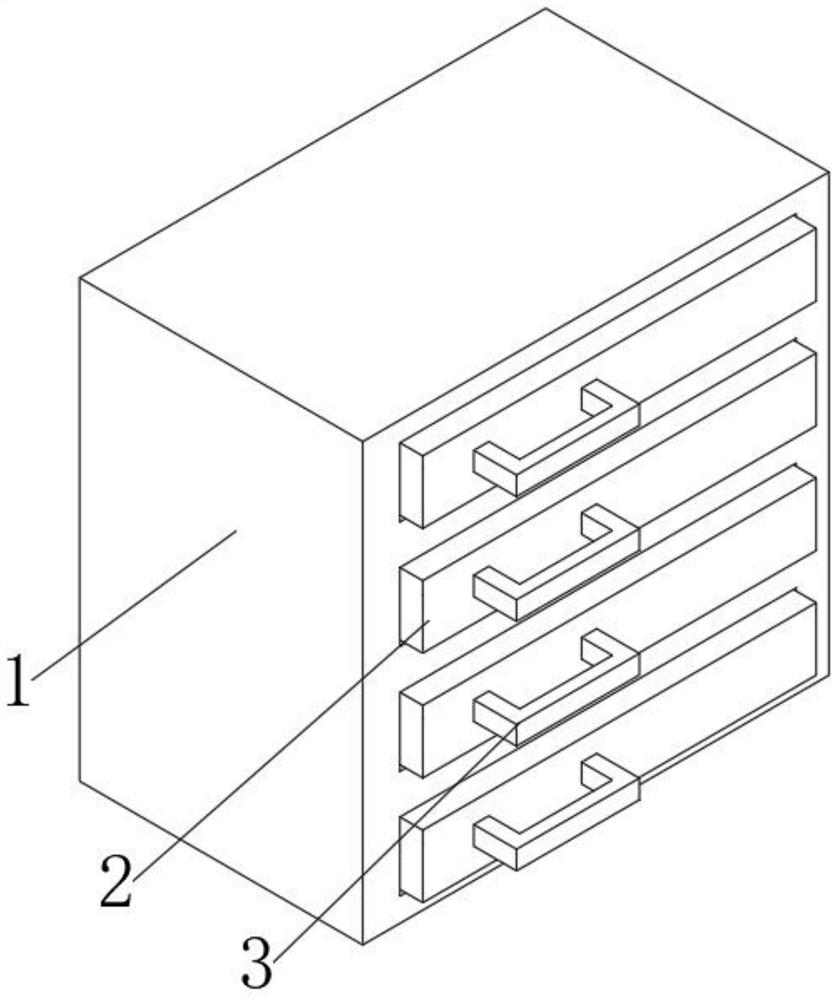

Lentivirus kit refrigerating box for clinical laboratory department

ActiveCN112815595AEasy to placeIncrease spacingLighting and heating apparatusDomestic refrigeratorsCold airLentivirus

The invention provides a lentivirus kit refrigerating box for a clinical laboratory department, and relates to the field of kits. The lentivirus kit refrigerating box for the clinical laboratory department comprises a box body, a plurality of drawing boxes which are randomly placed in cavities in a one-to-one correspondence manner; a plurality of left half box frames and right half box frames, supporting plates which are correspondingly arranged at the bottoms of the left half box frames and the bottoms of the right half box frames; a stretching mechanism and a binding mechanism which are used for achieving the traction effect on a pull rope; and a coating mechanism which is arranged at the end, far away from the hinge seat, of any supporting plate. According to the lentivirus kit refrigerating box for the clinical laboratory department, an operator can conveniently place reagent bottles on the placement plates, the distance between the left half box frame and the right half box frame and the pulling boxes at the top is increased, so that cold air in the box body can be rapidly diffused into each pulling box, the cold and heat transfer rate is increased, and the better heat preservation effect is achieved.

Owner:立凯生物技术(杭州)有限公司

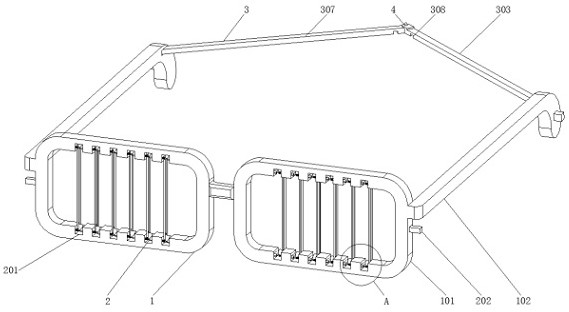

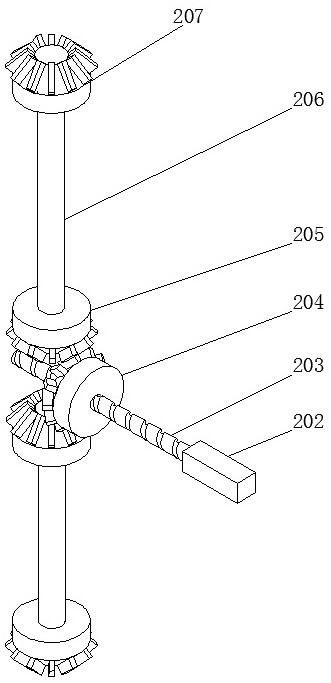

Glasses for protecting eyes during sports

ActiveCN112946927AStay tightQuick installationNon-optical adjunctsNon-optical partsProtecting eyeProtective glasses

The invention discloses glasses for protecting eyes during sports, and relates to the field of protective glasses. The glasses comprise a main body, a protective mechanism, a storage mechanism and a connecting mechanism, wherein the main body comprises a glasses frame, and two ends of the glasses frame are connected with glasses legs; the protection mechanism comprises a movable groove located in an inner wall of the glasses frame, and replacement blocks are connected to two ends of the glasses frame and located below the glasses legs. By arranging the protection mechanism, when protection coil is replaced, a replacement block is pushed, the replacement block moves to drive a rotating shaft to rotate, the rotating shaft rotates to drive connecting wheels to move, the connecting wheels move to be close to each other, a protection coil is placed on the outer walls of the connecting wheels, a replacement block is loosened, and the rotating shaft rotates under the action of the elastic force of a torsional spring; the rotating shaft rotates to drive the connecting wheel to displace, the connecting wheel displaces to tighten the protective coil, the protective coil can be conveniently and rapidly mounted and dismounted, and meanwhile tightness of the protective coil is kept.

Owner:深圳市方元千色科技开发有限公司

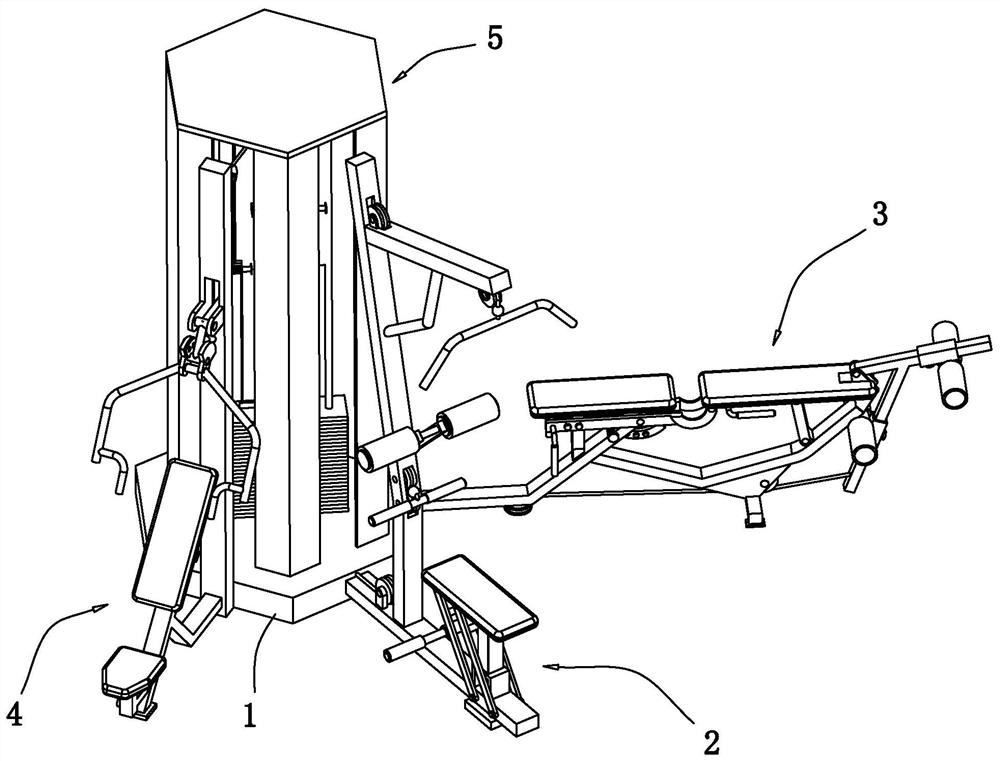

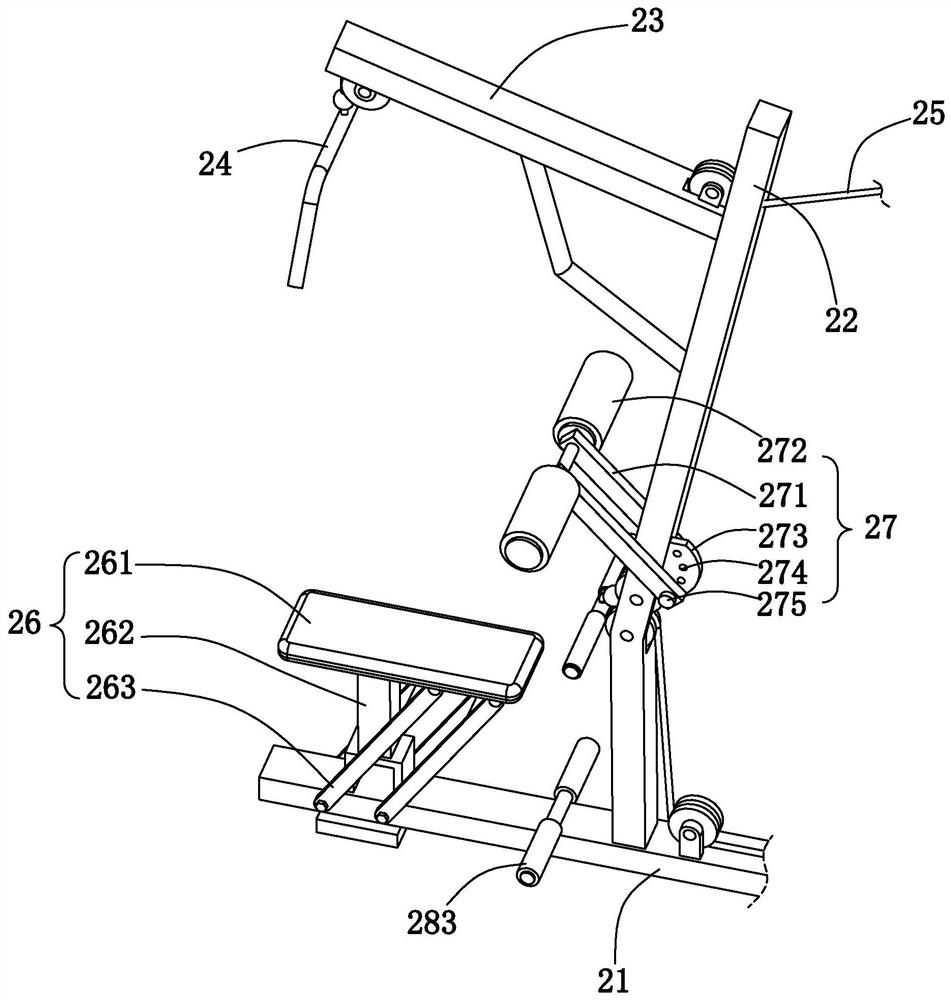

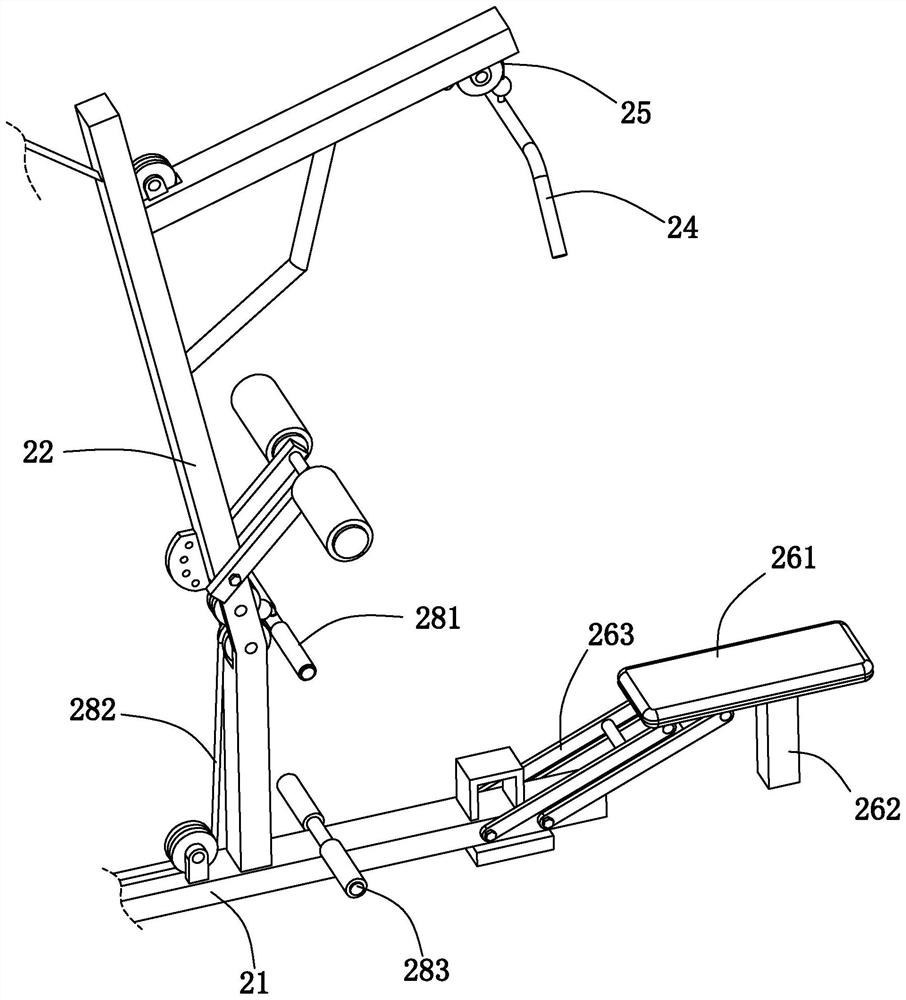

Multifunctional fitness equipment

PendingCN113262435AReduce weightReduce overall weightMuscle exercising devicesPhysical therapyMechanical engineering

Owner:北京冠之路科技集团有限公司

Glowing and anti-aging mask and preparation method thereof

PendingCN114081858AIncrease elasticityStay tightCosmetic preparationsToilet preparationsArginineGlycerol

The invention relates to a glowing and anti-aging mask and a preparation method thereof. The glowing and anti-aging mask is prepared from the following raw material components: water, glycerol, butanediol, trehalose, hydroxyethyl urea, xylitol-based glucoside, dehydrated xylitol, xylitol, aloe extract, radix gentianae extract, propylene glycol, butyrospermum parkii butter, lavender oil, hydrolyzed keratin, collagen, elastin, 1, 2-hexanediol, ammonium acryloyldimethyl taurate / VP copolymer, arginine, carbomer and disodium EDTA. The glowing and anti-aging mask disclosed by the invention can effectively replenish water, preserve moisture, improve skin elasticity, keep skin compact and prevent skin darkness, thereby playing a role in rejuvenating the skin.

Owner:上海本正清源干细胞科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com