A vacuum attachment apparatus for contact lithography of a flexible thin film substrate

A flexible film, contact technology, applied in the field of vacuum attachment devices, can solve the problems of incompatibility, unstable surface undulation, low rigidity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

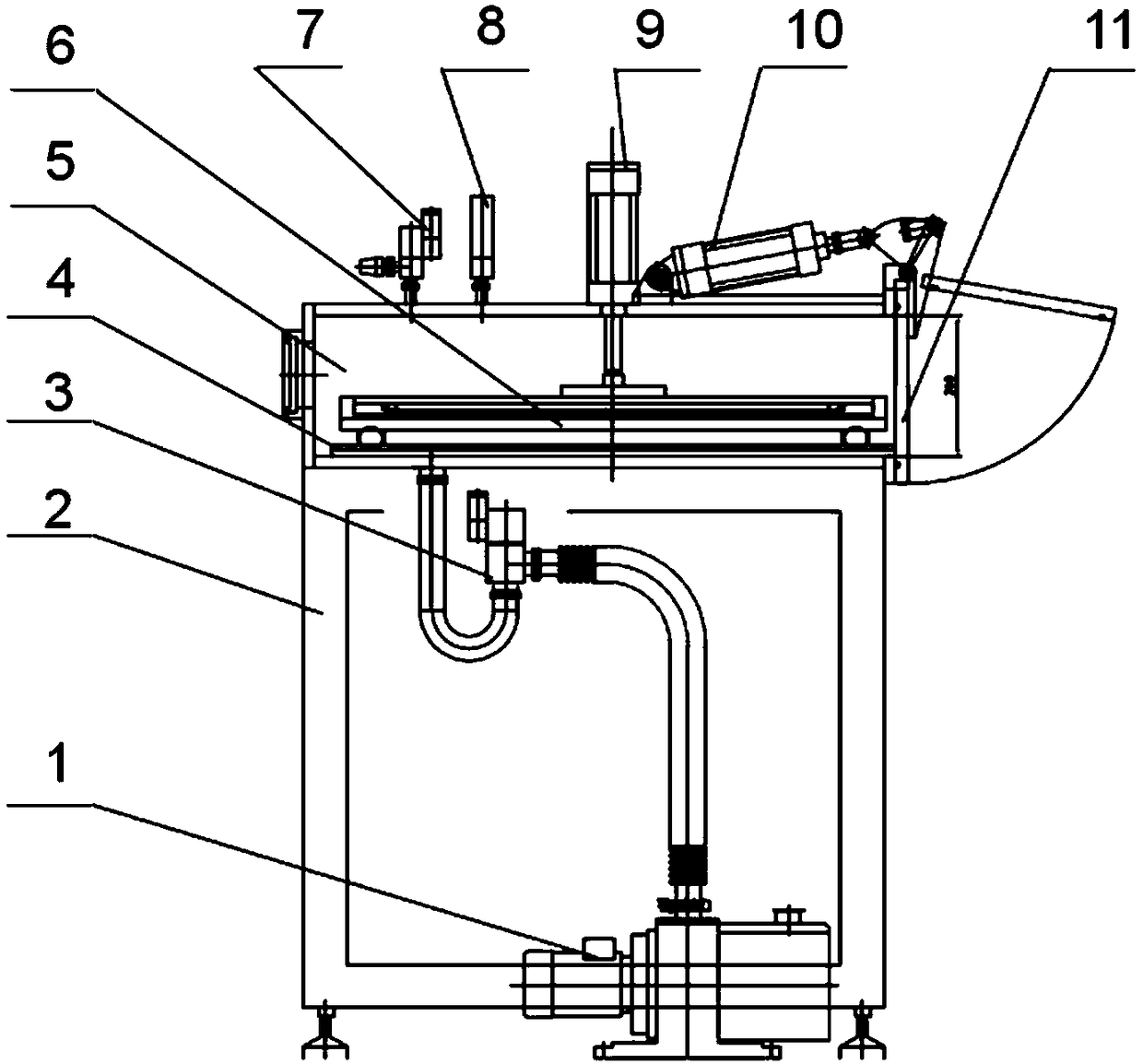

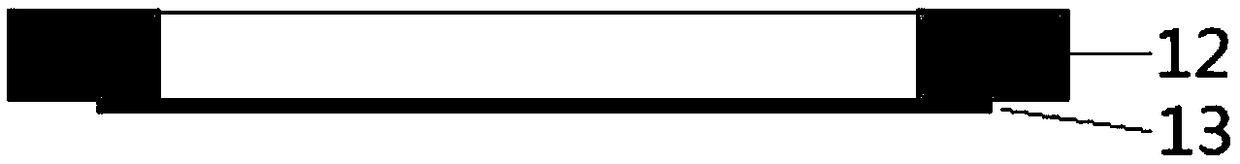

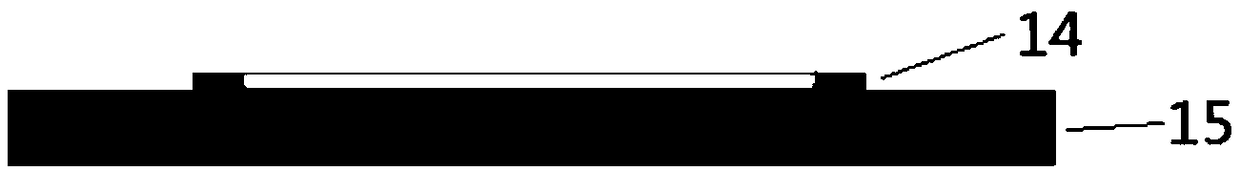

[0025] The present invention is a vacuum attachment device for contact photolithography of flexible film substrates, the device includes a vacuum pump 1, a frame 2, a baffle valve 3, a support table limiter 4, a vacuum cavity 5, a mask Membrane support table 6, deflation valve 7, vacuum gauge 8, top pressure mechanism 9, sealing door opening and closing mechanism 10, sealing door 11, membrane support 12, flexible membrane 13, sealing gasket 14, photolithography mask plate 15; The connection relationship is that the frame 2 is located below the vacuum chamber 5 to play a supporting role, the vacuum pump 1, the vacuum gauge 8, the baffle valve 3, the air release valve 7, and the top pressure mechanism 9 are connected with the vacuum chamber 5, and the sealed door 11 is connected to the airtight door opening and closing mechanism 10, and the airtight door opening and closing mechanism 10 controls the opening and closing of the airtight door 11. The mask support table 6 can move in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com