Board polishing device for furniture production

A polishing device and wood board technology, which is applied in the direction of grinding/polishing equipment, manufacturing tools, grinding machines, etc., can solve the problems of small contact area between the polishing belt and the wood board, the wood board cannot move forward, and the polishing efficiency is reduced, so as to improve the polishing effect , Fit tightly, reduce installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

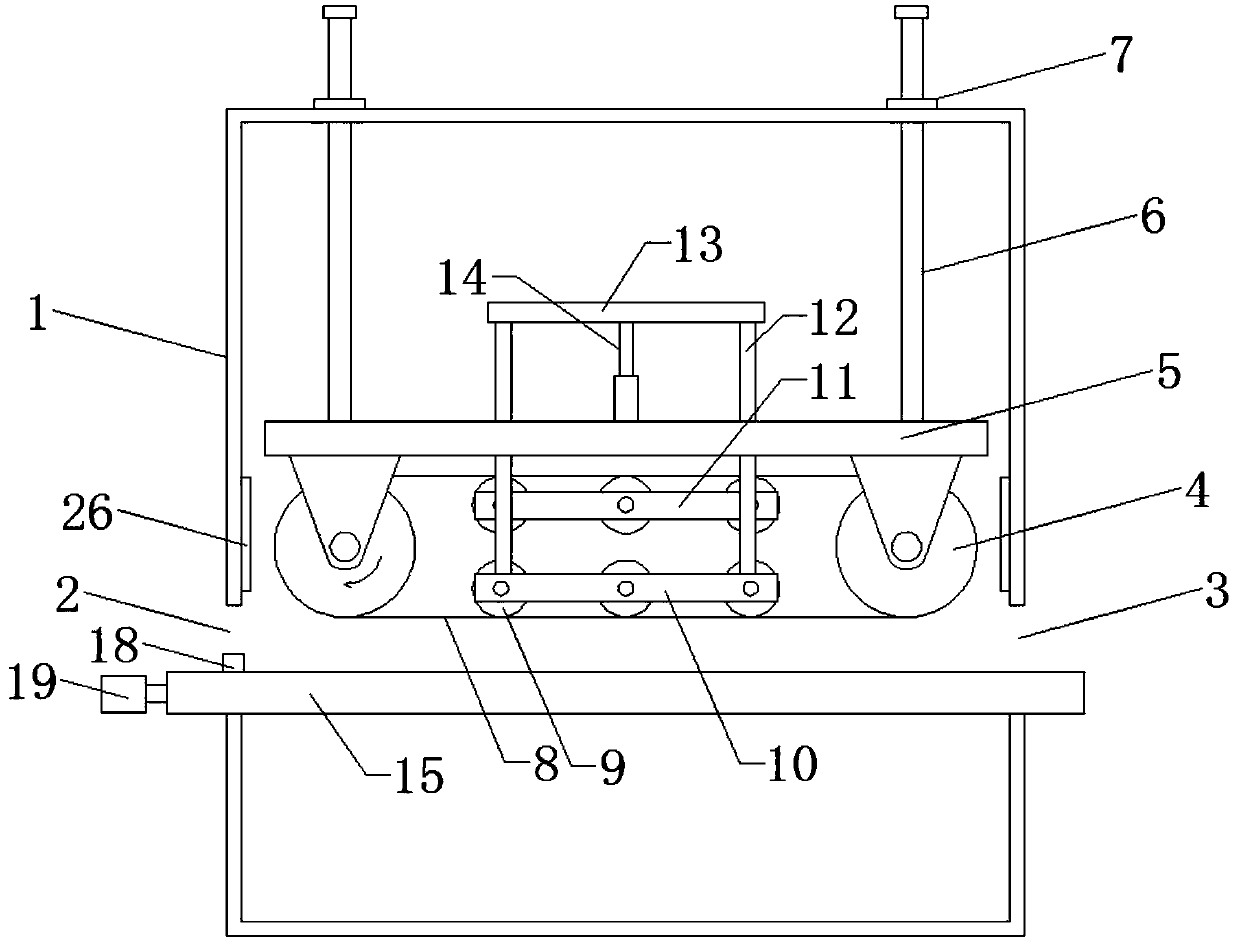

[0020] Please refer to the figure, in the embodiment of the present invention, a wood board polishing device for furniture production includes a casing 1, a feeding port 2, a discharging port 3, a polishing drive wheel 4 and a polishing belt 8; the feeding port 2 is opened. On the left side wall of the casing 1, the discharge port 3 is opened on the right side wall of the casing 1, and the feed port 2 and the discharge port 3 are at the same height; two polishing drive wheels 4 are arranged horizontally and in parallel, The polishing belt 8 is wound around the two polishing driving wheels 4, and the polishing driving wheel 4 rotates counterclockwise, so that the polishing belt 8 polishes and polishes the wooden board in the horizontal direction; the two polishing driving wheels 4 are installed on the bracket 5, and the polishing driving The rotating shaft of the wheel 4 is fixedly connected to the drive motor, the upper end of the bracket 5 is fixed with an adjusting rod 6 that...

Embodiment 2

[0024] The same upper support frame 11 is arranged directly above the lower support frame 10 , the upper support frame 11 is located under the polishing belt 8 on the upper side, and is fixedly connected to the support rod 12 , and is also installed on the upper support frame 11 There are a plurality of pressure rollers 9 in a row, and the distance between the top end of the upper pressure roller 9 on the upper support frame 11 and the bottom end of the upper pressure roller 9 on the lower support frame 10 is equal to the diameter of the polishing drive wheel 4, so that regardless of the beam 13 Up or down can ensure that the polishing belt 8 is tensioned, which is convenient for polishing.

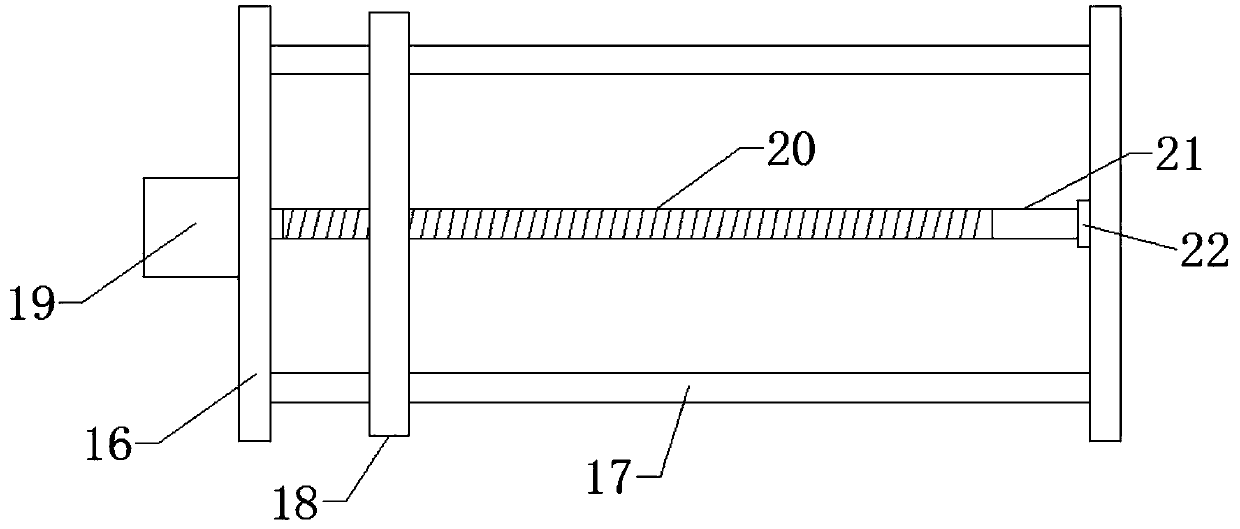

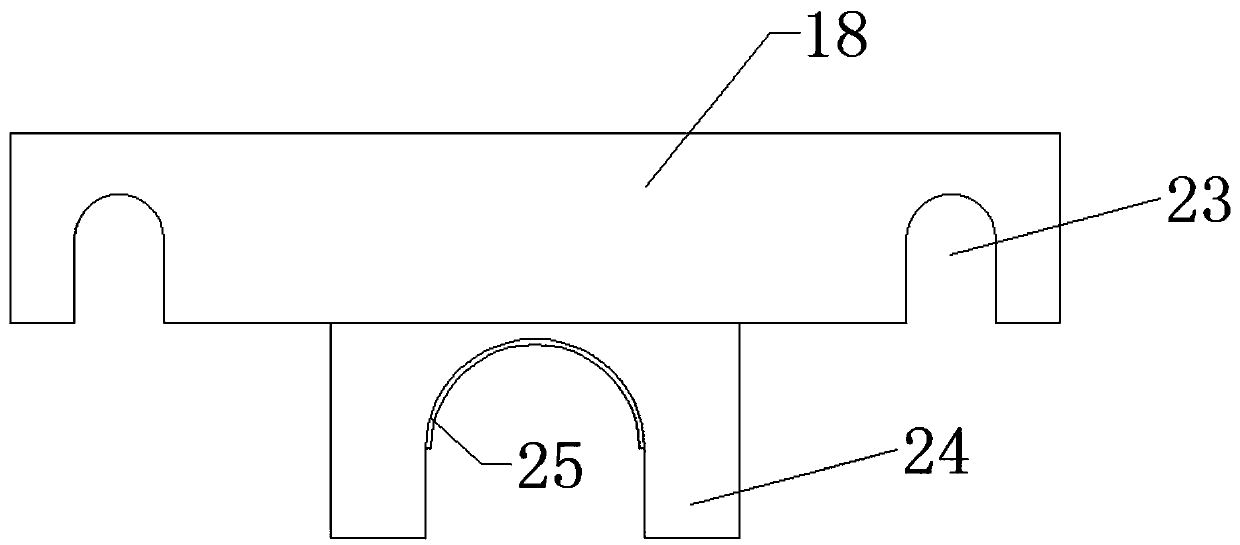

[0025] Put plank on the delivery rod 17 of the horizontal delivery mechanism 15, then put the push plate 18 on the horizontal delivery mechanism 15, start the power supply, make the delivery motor 19 rotate, and the screw mandrel 20 rotates the internal thread 25 that is threadedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com