Doubling machine

A parallel machine and chassis technology, applied in the field of parallel machines, can solve the problems of poor quality and other benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

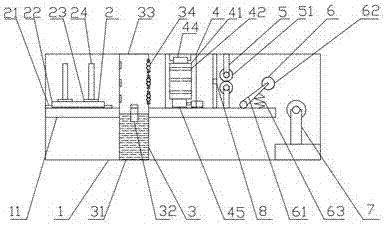

[0016] Such as figure 1 and 2 As shown, a doubling machine includes a case 1, a horizontal partition 11 is provided in the case 1, a wire releasing device 2 is provided in the case 1, a plying device 4, a second winding hole 8 and a winding The device 7 also includes a humidifying device 3, the humidifying device 3 is arranged between the wire-feeding device 2 and the plying device 4, the bottom of the humidifying device 3 is a water tank 31, and the water tank 31 is provided with an ultrasonic atomizer 32, and the top of the water tank 31 is fixed An atomization box 33, the atomization box 33 is a hollow box body, a wire inlet hole is provided on the side adjacent to the wire-feeding device 2, and the side opposite to the wire inlet hole is provided with the same number of crimping wheel sets 34;

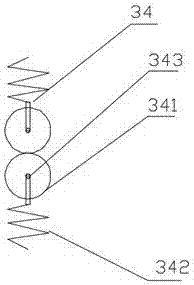

[0017] Crimp wheel group 34 comprises two rollers 341, and the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com