Tension constant resistor capable of calculating difference of alternating current and direct current

A technology of AC-DC difference and tension, applied in the direction of resistor installation/support, helical coil/screw disk resistance element, etc., can solve the problems of poor stability of AC-DC difference resistance, affect the accurate calculation of parasitic inductance, etc., and achieve the goal of improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

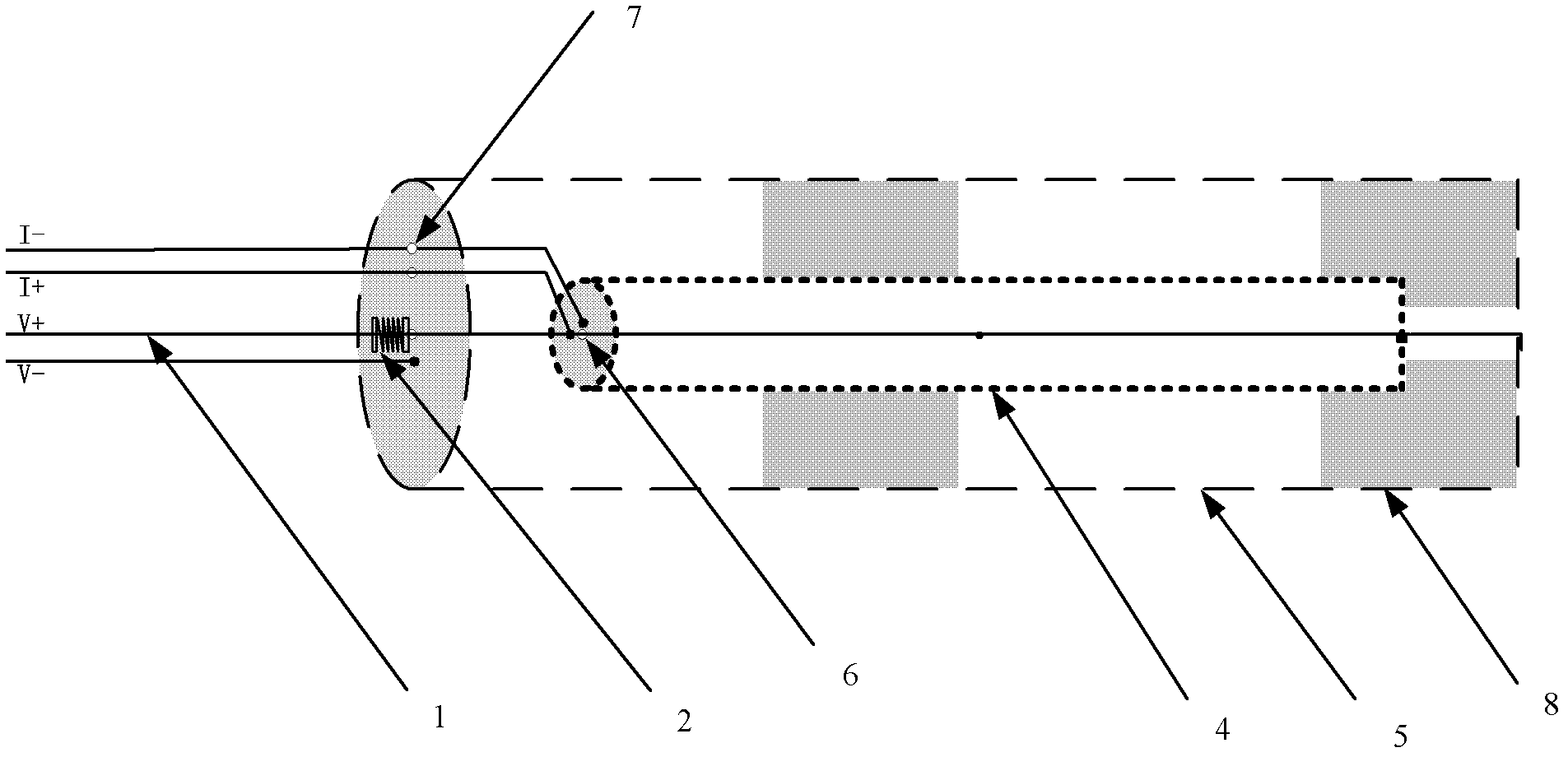

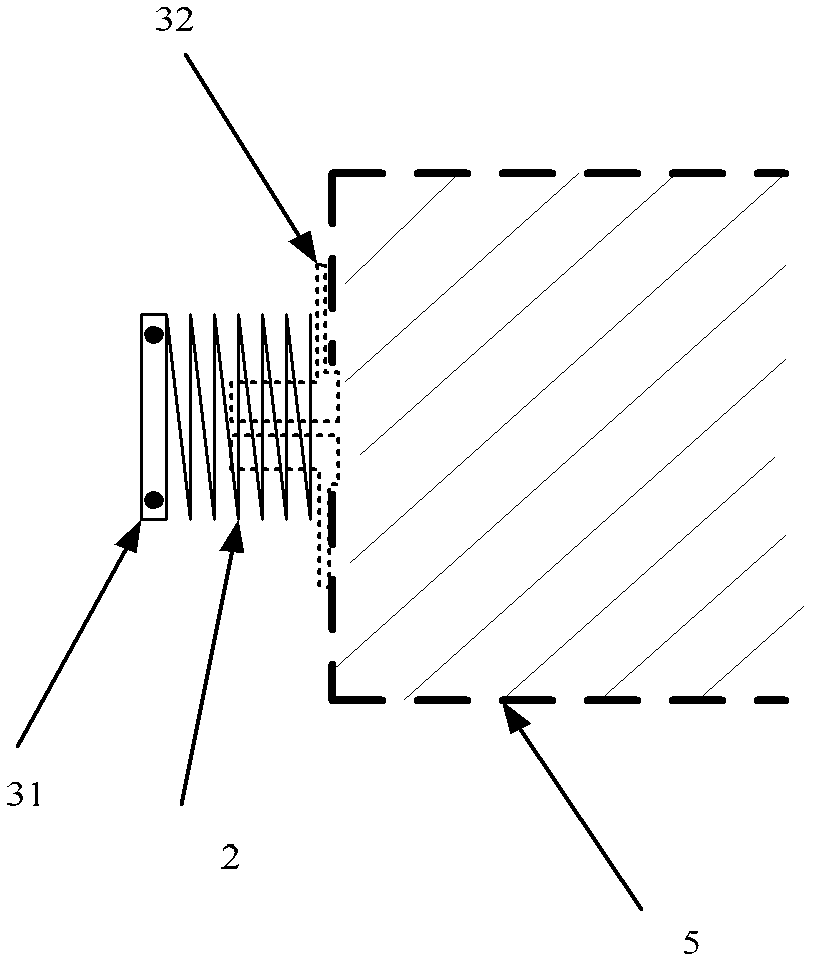

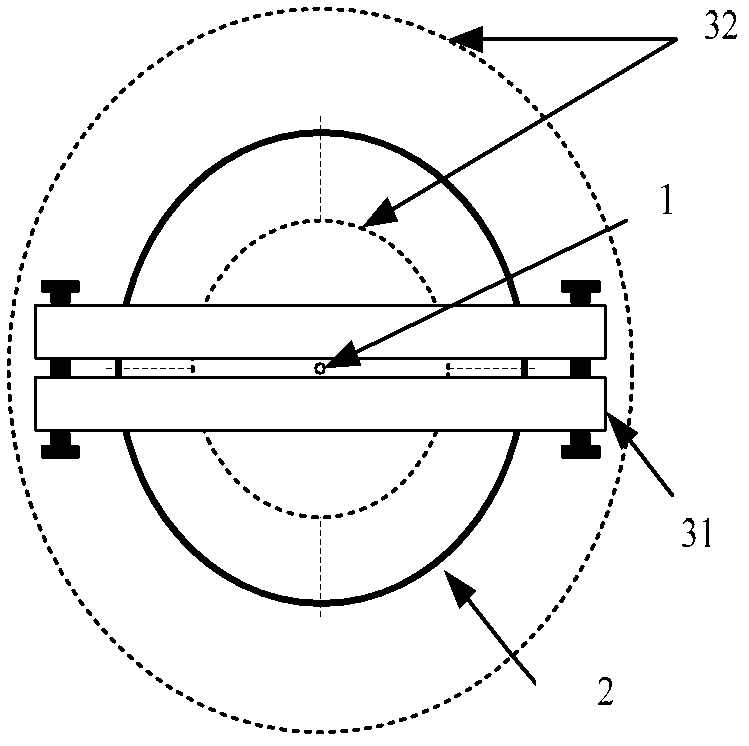

[0024] Such as figure 1 As shown, a constant tension AC-DC difference resistance can be calculated, including a coaxial inner metal sleeve 4 and an outer metal sleeve 5, the resistance wire 1 is located on the central axis of the inner metal sleeve 4, from the resistance wire 1 Lead out the current positive terminal lead-out line I+ and the voltage positive terminal lead-out line V+, draw the current negative terminal lead-out line I- from the front end face of the inner metal sleeve 4, and draw the voltage negative end lead-out line from the front end face of the outer metal sleeve 5 V-; the center of the front end of the inner metal sleeve 4 and the outer metal sleeve 5 respectively has a front center hole 6, and the resistance wire 1 passes through the center hole of the front end of the inner metal sleeve and the center of the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com