Medium expiration and inspiration device

A medium and thin sheet medium technology, applied in transportation and packaging, coiling strips, thin material processing, etc., can solve the problems of conveyor belt slack and conveyor belt inability to tension, etc., and achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

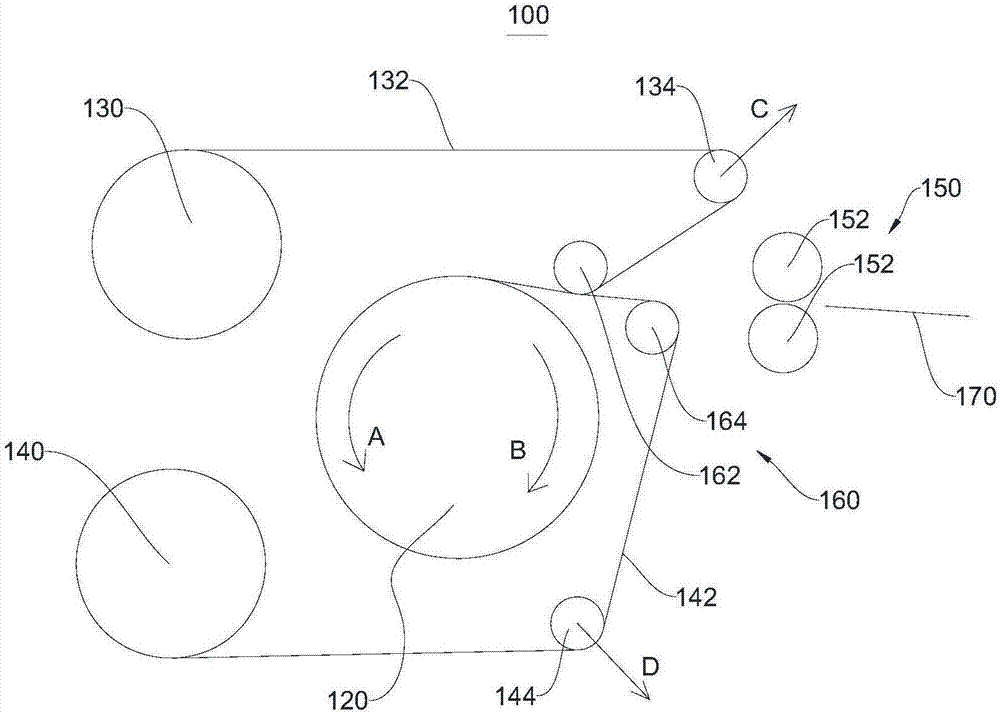

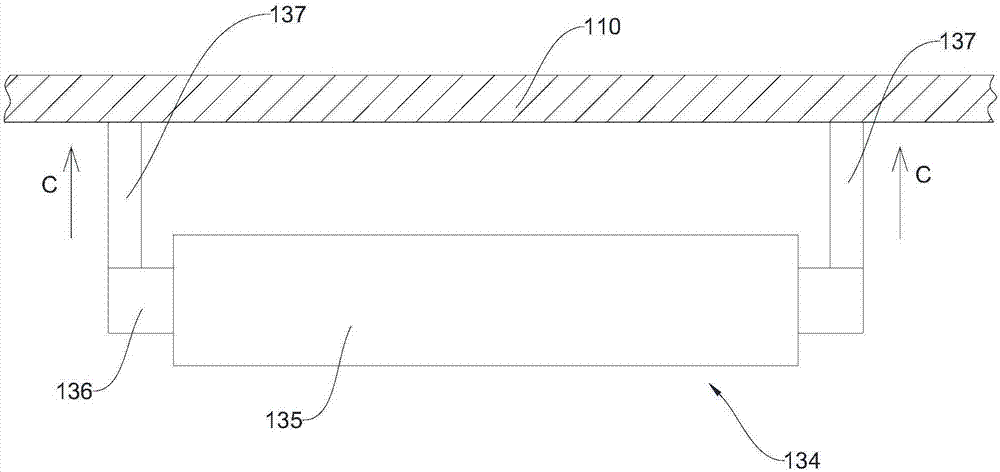

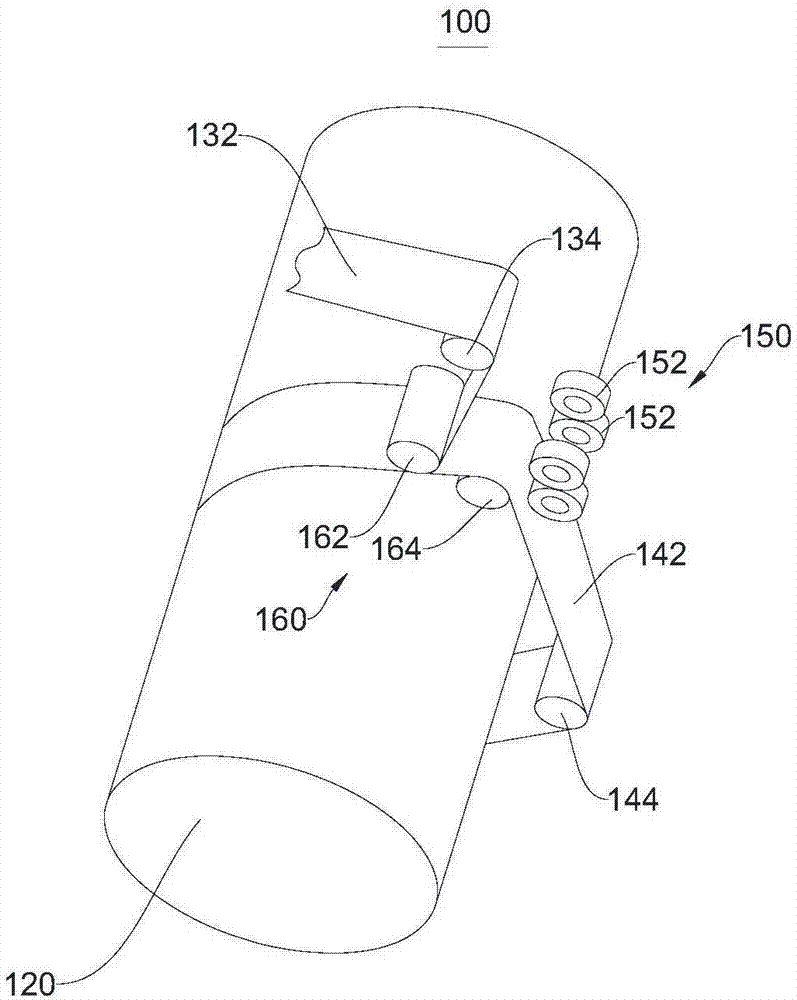

[0042] figure 1 It is a schematic diagram of the structure of the medium breathing device 100 in the embodiment of the present invention; figure 2 It is a schematic structural diagram of the first tension guide roller 134 of the medium discharge device 100 in the embodiment of the present invention; image 3 It is an axonometric view of the main components of the medium breathing device 100 in the embodiment of the present invention; Figure 4 It is a schematic diagram of the medium spitting device 100 when storing the medium 170 in the embodiment of the present invention. Please refer to Figure 1 to Figure 4 , the present embodiment provides a medium breathing device 100, which includes a housing 110, and a drum 120, a first conveyor belt 132, a second conveyor belt 142, a first reel 130, a second reel 140, a first The tensioning guide roller 134, the second tensioning guide roller 144 and the gathering mechanism 160, the medium feeding device 100 also includes a conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com