Laminating machine multi-roll synchronization control device

A technology of synchronous control and synchronous controller, applied in the direction of program control, electrical program control, general control system, etc., can solve the problems of instability, easily damaged motor or heat roller, low synchronization rate, etc., and achieve stability and work efficiency Improve and ensure the synchronization of hot rollers and improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

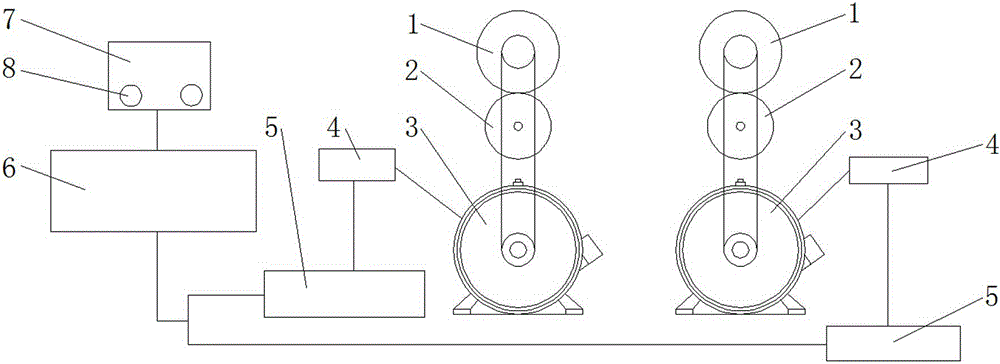

[0021] Such as figure 1 The multi-roller synchronous control device of the laminating machine shown includes two hot rollers 1 and a pressure roller 2 corresponding to the hot rollers 1. The hot rollers 1 are connected with servo motors, and the hot rollers 1 and the servo The motors are connected by chains, the servo motors are provided with encoders 4, and the encoders 4 are connected with servo controllers, and the servo controllers are connected with the PLC control system 6, and the PLC control system 6 is equipped with There is a control panel 7, and the control panel 7 is a touch screen, and the touch screen is provided with a fine-tuning device 8 that can adjust the servo motors respectively.

[0022] The servo motor is used to drive the heat roller 1 corresponding to it to rotate; the encoder 4 is used to read the rotation signal of the servo motor corresponding to it and feed it back to the servo controller, and then adjust it through the servo controller. The signa...

Embodiment 2

[0024] Such as figure 1 The multi-roller synchronous control device of the laminating machine shown includes two hot rollers 1 and a pressure roller 2 corresponding to the hot rollers. The hot rollers 1 are connected with ordinary motors, and the hot rollers 1 and ordinary motors Connected by a chain, the ordinary motor is provided with an encoder 4, and the encoder 4 is connected with a synchronous controller, and the synchronous controller is provided with a synchronous card and a frequency converter, and the synchronous controller is controlled with a PLC. The system 6 is connected, and the PLC control system 6 is provided with a control panel 7, and the control panel 7 is a touch screen, and the touch screen is provided with a fine-tuning device 8 that can adjust ordinary motors respectively.

[0025] The ordinary motor is used to drive the corresponding heat roller to rotate; the encoder 4 is used to read the rotation signal of the ordinary motor corresponding to it and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com