Connecting structure of sliding-rail synchronous gears

A technology of connecting structure and synchronizing wheel, which is applied to lighting and heating equipment, supports, household appliances, etc., can solve the problem that the synchronous wheel and the connecting shaft cannot be guaranteed to rotate synchronously.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

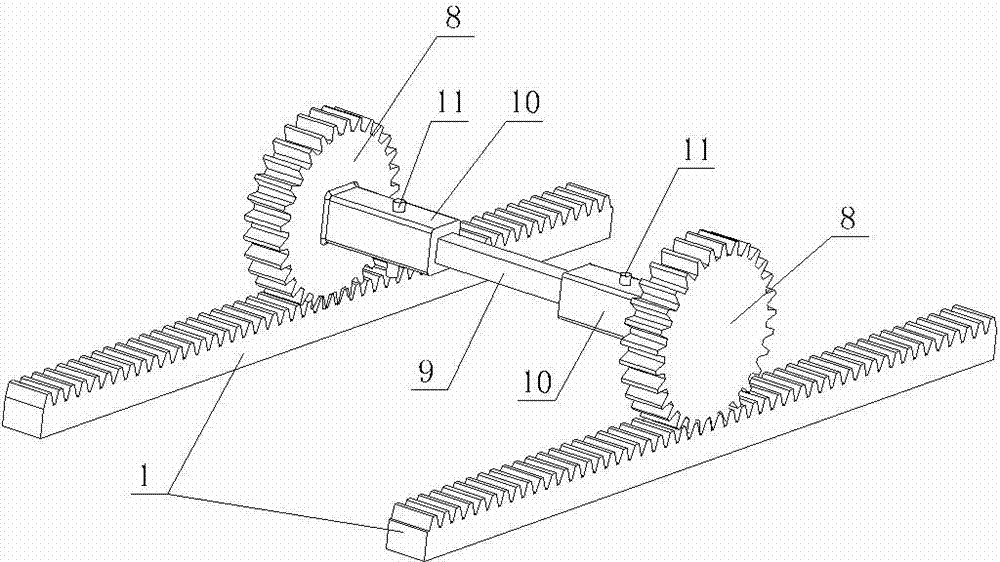

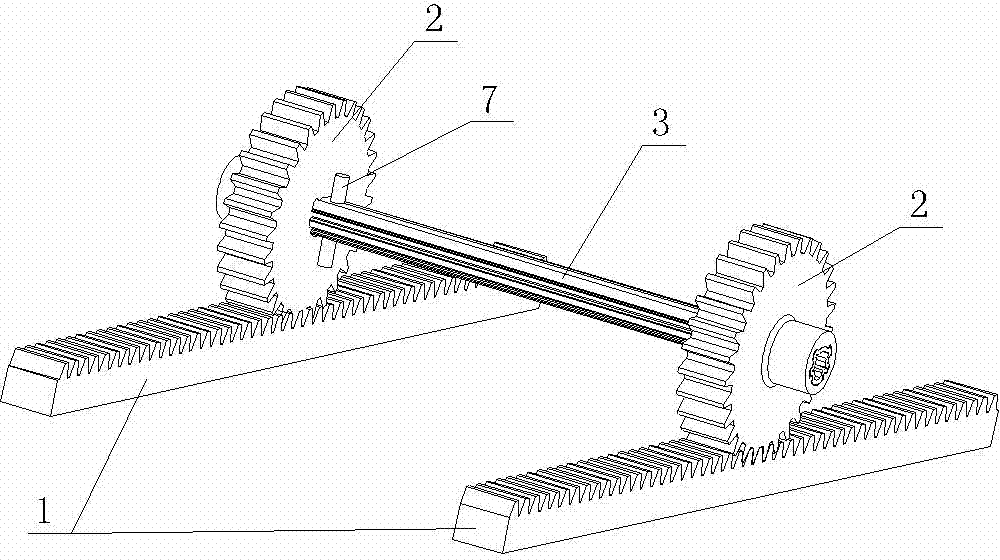

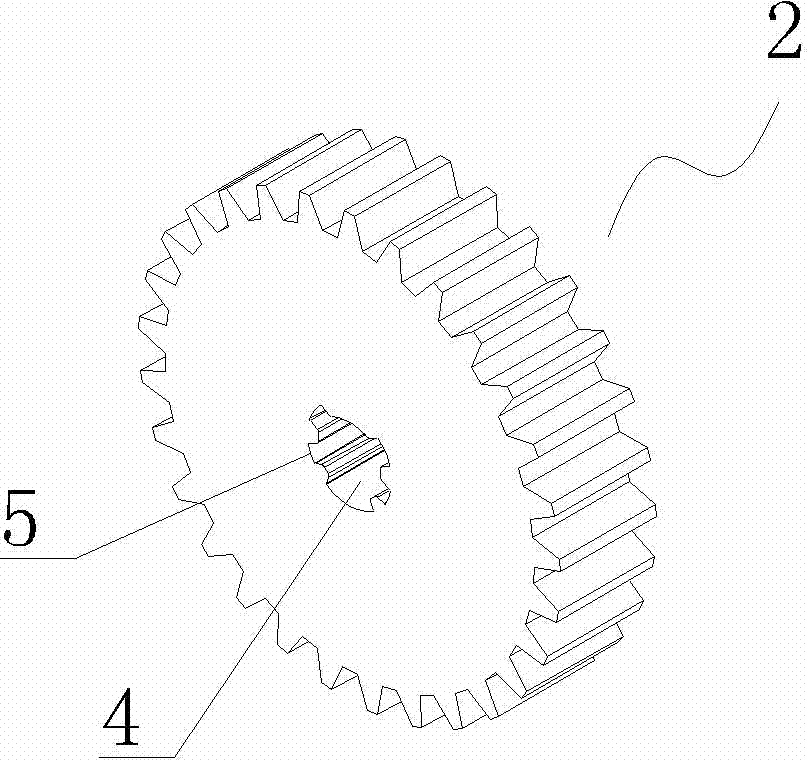

[0011] See figure 2 , image 3 and Figure 4 , the present invention includes two rack slide rails 1 installed in parallel, two synchronous gears 2 and a connecting shaft 3, and the two synchronous gears 2 are respectively installed on the two rack slide rails 1 and connected with the two rack slide rails 1 Toothed meshing connection, two synchronous gears 2 are connected by a connecting shaft 3, both synchronous gears 2 have a connecting shaft hole 4, the circumference of the connecting shaft hole 4 is provided with a toothed groove 5, and the connecting shaft 3 The outer peripheral surface is provided with positioning teeth 6 that match the toothed grooves 5 of the connecting shaft hole 4 , and the positioning teeth 6 of the connecting shaft 3 and the toothed grooves 5 of the connecting shaft hole 4 are directly gap-fitted. The two ends of the connecting shaft 3 are provided with radial through holes close to the mounting end of the synchronous gear 2, and a positioning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com