Wax column forming equipment

A molding equipment and wax column technology, applied in the field of wax column molding equipment, can solve the problems of high labor intensity, low processing efficiency, troublesome operation, etc., and achieve the effect of low labor intensity, high processing efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

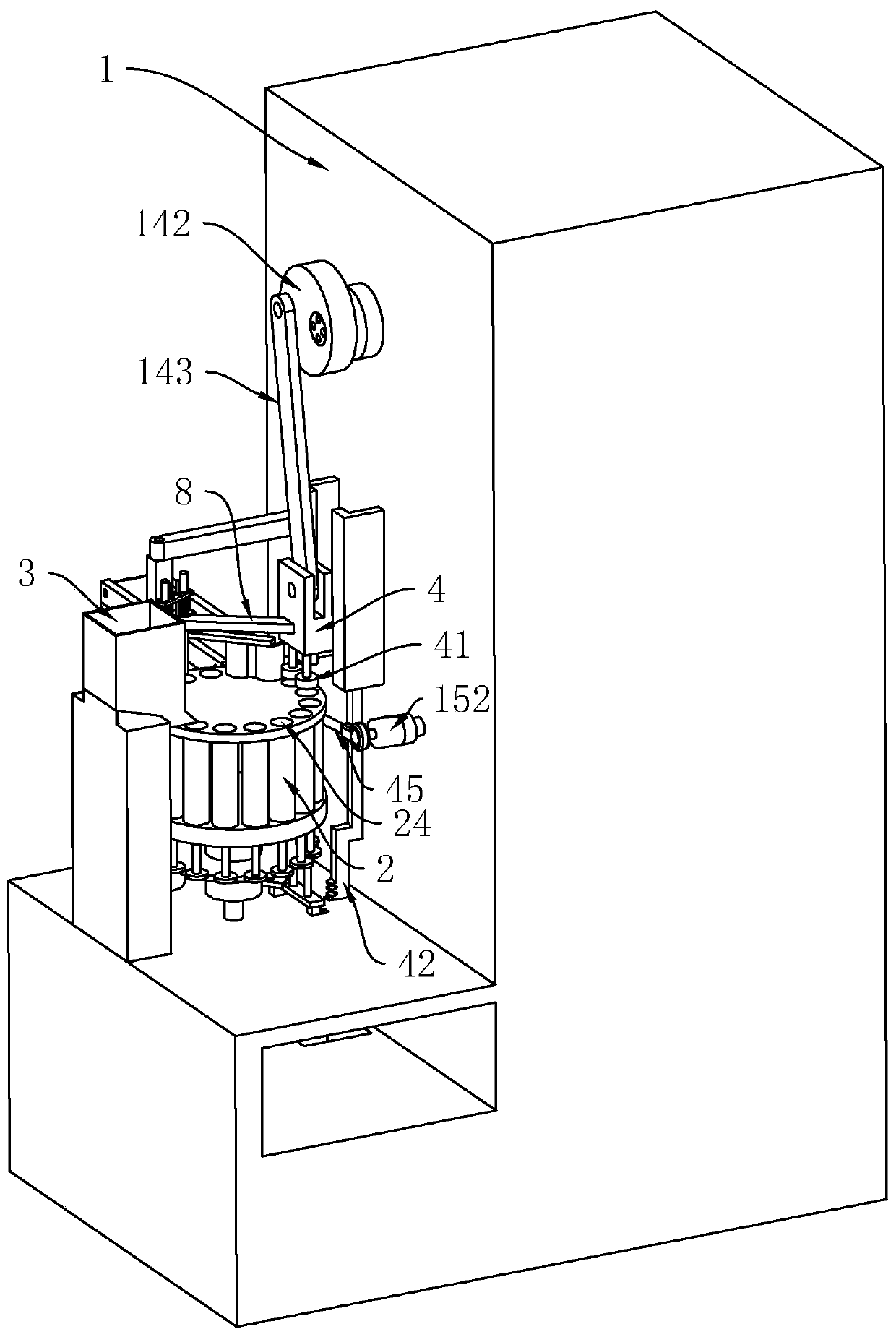

[0043] Embodiment one: refer to figure 1 , is a kind of wax column molding equipment disclosed by the present invention, which includes a frame 1, and the middle part of the frame 1 is provided with a rotating body 2 whose axis is vertically arranged.

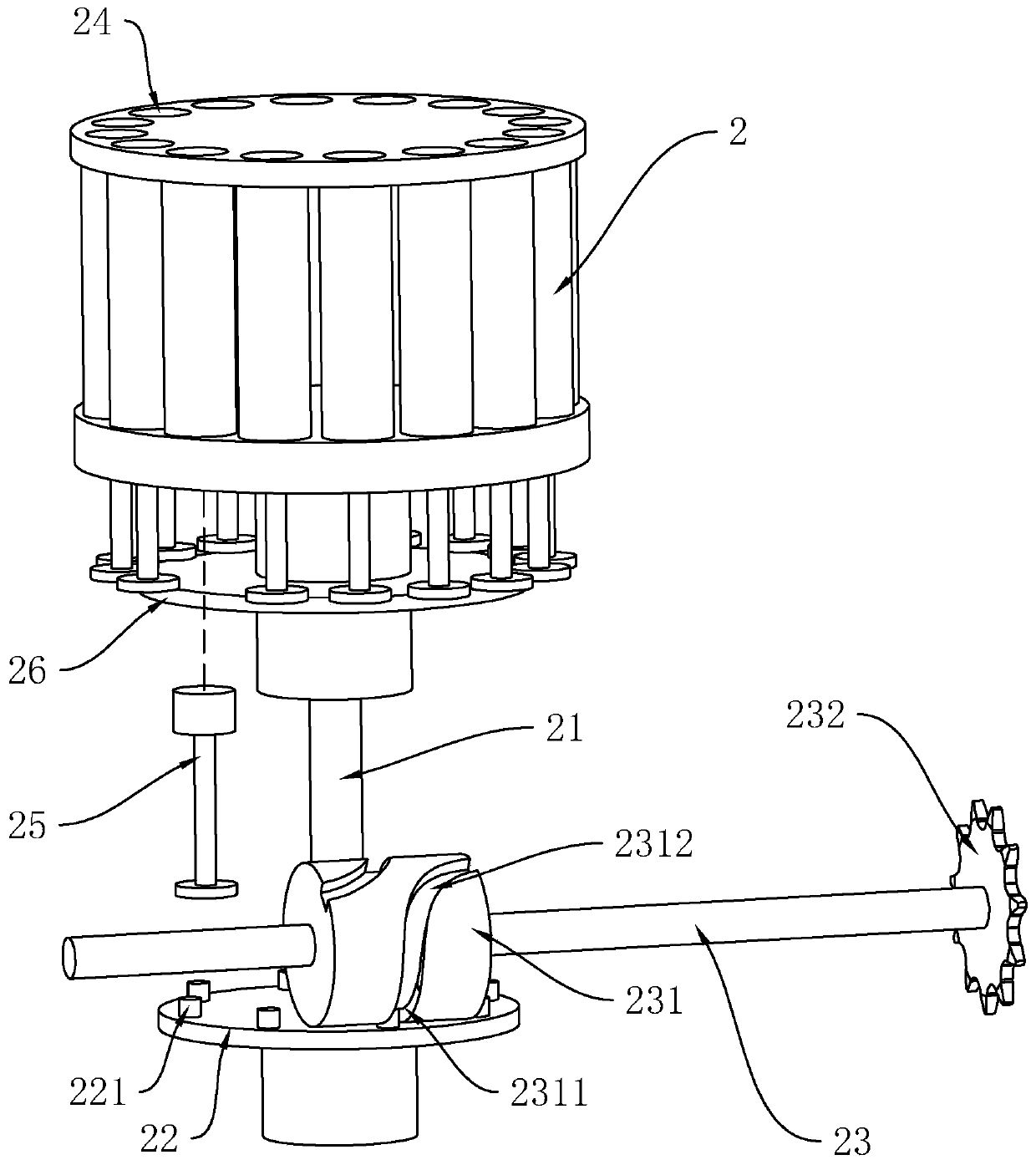

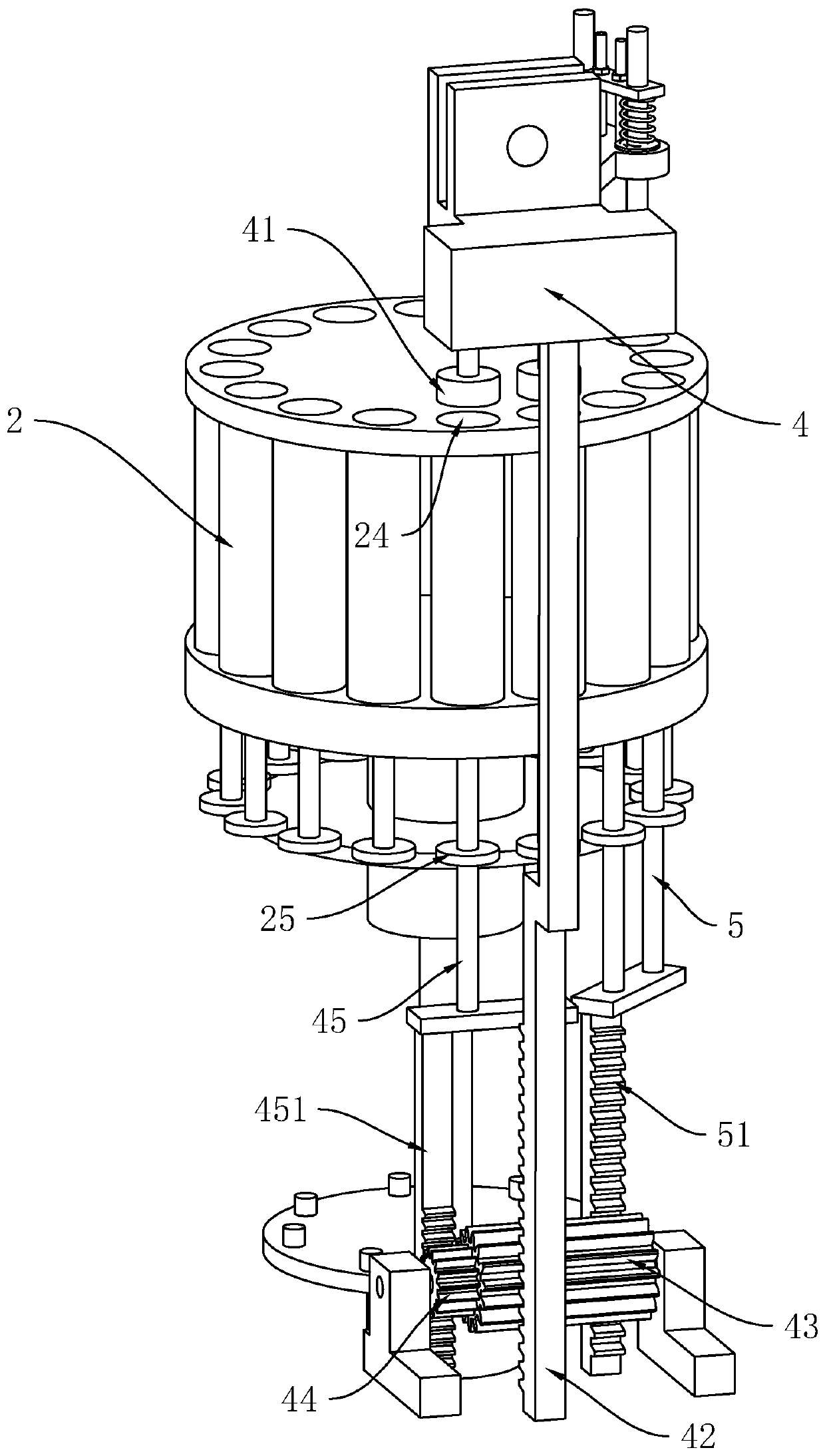

[0044] refer to figure 2 A rotating shaft 21 is fixedly connected to the axial position of the rotating body 2, and the rotating shaft 21 is rotatably connected to the frame 1 (not shown in the figure). The lower end of the rotating shaft 21 is fixedly connected with a turntable 22 coaxial with the rotating shaft 21 , and the upper side of the turntable 22 is centered on the center of the turntable 22 with a number of indexing columns 221 rotatably connected to the turntable 22 , and the frame 1 corresponds to the turntable 22 The position on the upper side is rotatably connected with the transmission shaft four 23 arranged horizontally on the axis, and the middle part of the transmission shaft four 23 is fixedly connected wi...

Embodiment 2

[0058] Embodiment two: refer to Figure 6 , a kind of wax column forming equipment, compared with the first embodiment, the difference is that the transmission shaft two 14 includes a first half shaft 146 and a second half shaft 147 that are respectively rotatably connected to the frame 1 and are coaxial, and the sprocket four 141 is affixed to the first semi-shaft 146, sprocket five 144 and eccentric wheel one 142 are affixed to the second semi-shaft 147, and one end of the second semi-shaft 147 and the first semi-shaft 146 close to each other is provided with a device that can be connected to the second half-shaft under normal conditions. Friction clutch 148 between half shaft 146 and second half shaft 147 .

[0059] Compared with Embodiment 1, the advantage is that: under normal conditions, the friction clutch 148 is used to complete the connection between the first half shaft 146 and the second half shaft 147, thereby ensuring the synchronous rotation of the first half sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com