Non-stop variable speed gear box for coiler with big reel or large tension

A technology of variable speed gearboxes and coilers, which is applied in the direction of gear transmissions, belts/chains/gears, mechanical equipment, etc., which can solve the problems that the variable speed gearboxes cannot achieve non-stop gear shifting, and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

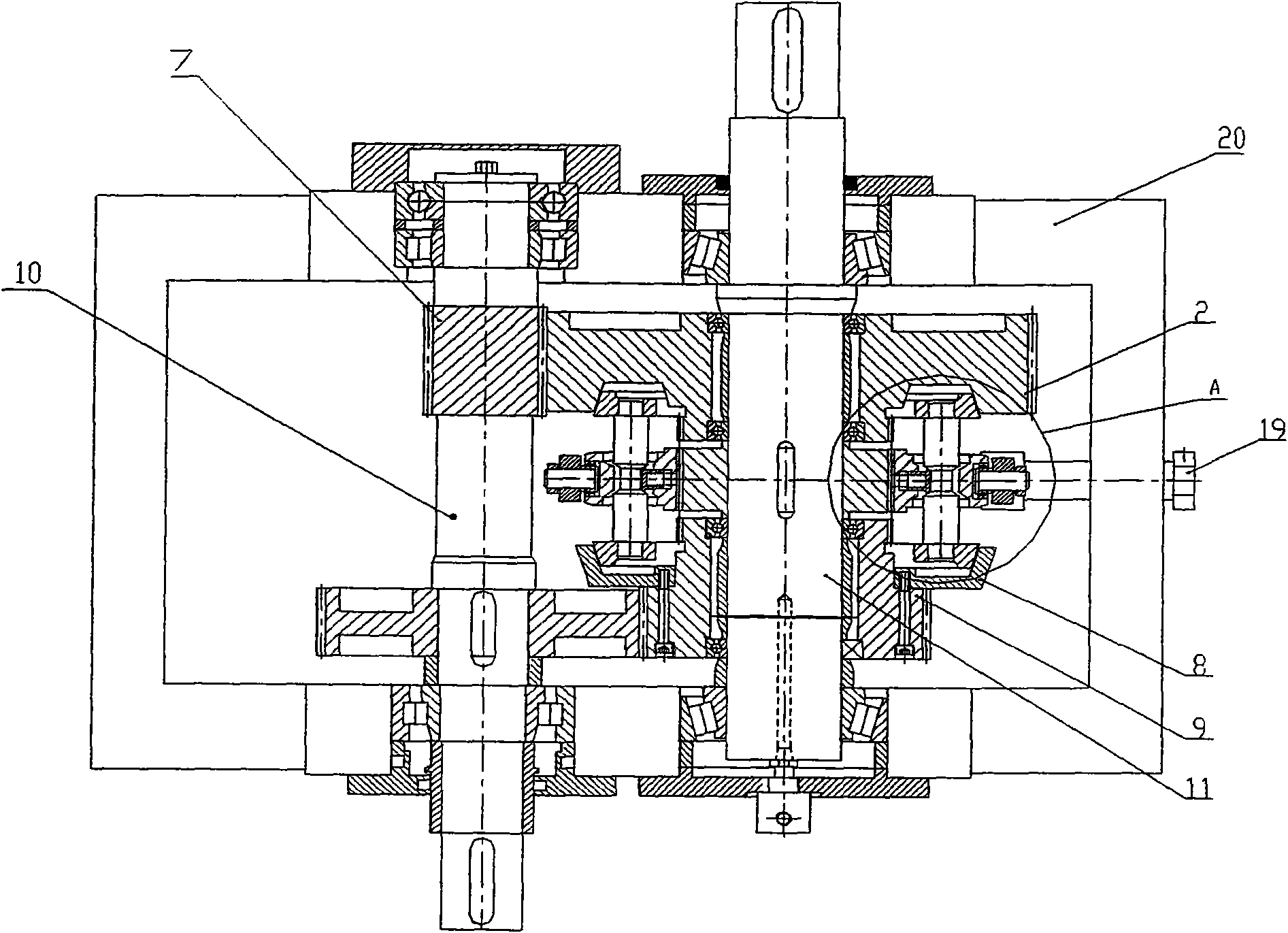

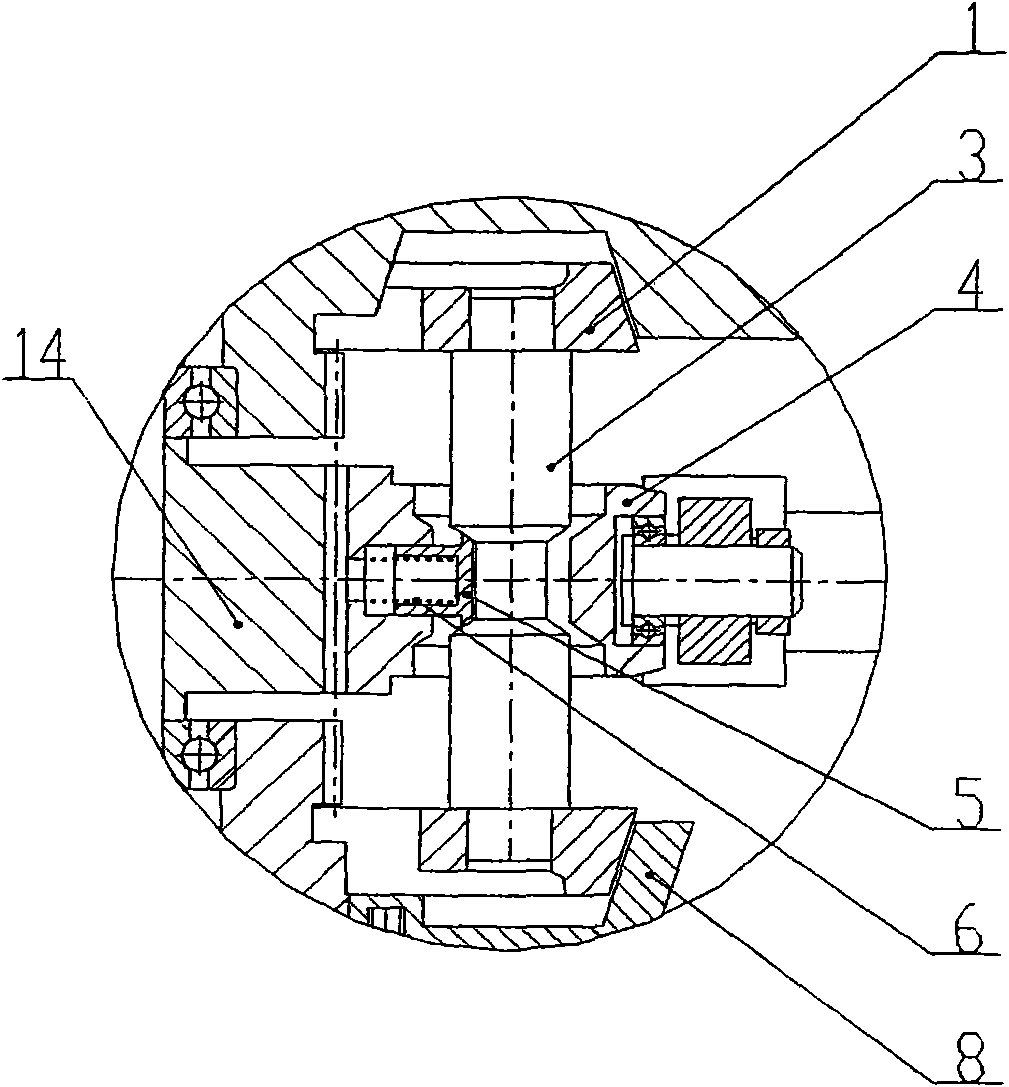

[0025] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

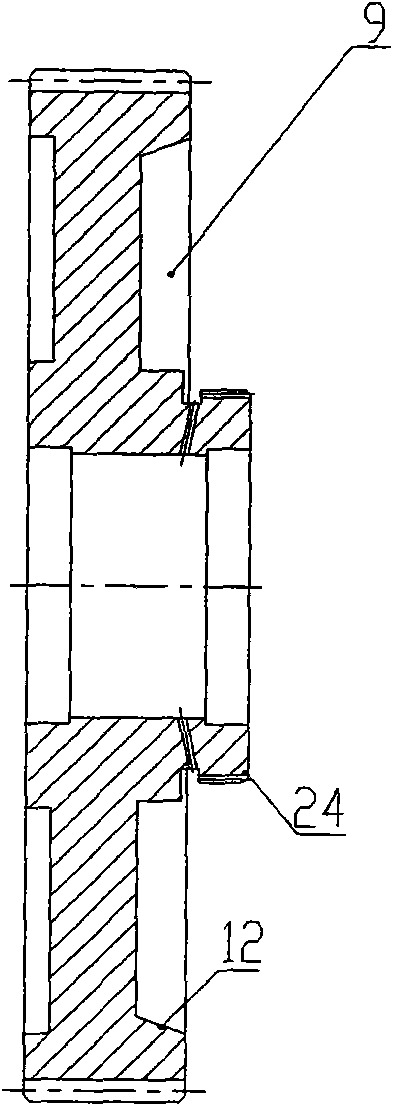

[0026] Depend on image 3 It can be seen that the distance from the edge of the annular outer friction ring groove 9 on the gear 2 to the axis center is greater than the distance from the bottom of the annular outer friction ring groove 9 to the axis center, and the groove wall from the edge of the annular outer friction ring groove 9 to the groove bottom is friction Surface 12.

[0027] Depend on Figure 4 Figure 5 It can be seen that the inner spline sleeve 4 is a disc structure, the center of the disc is an inner spline 21, the outer edge of the disc is a shift fork groove 22, and the concentric circle of the disc is provided with evenly distributed synchronous pin holes 16, synchronous A synchronizing pin is arranged in the pin hole 16....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com